Special automotive frame correcting device

A correction device and a technology of automobile girders, which are applied in the field of special-purpose automobile manufacturing, can solve problems such as scrapping, differences in the length and width of girders, and affecting the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

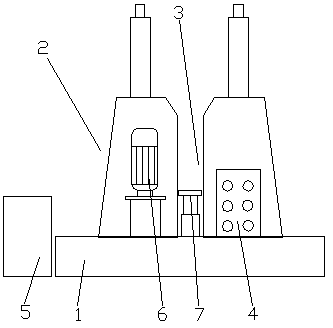

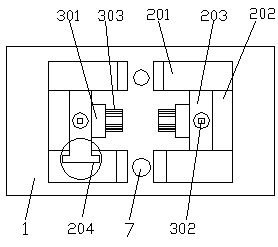

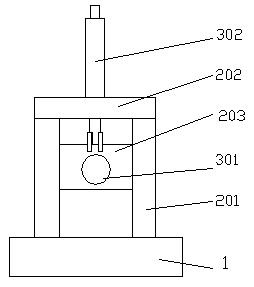

[0023] As shown in the figure, a special automobile girder correction device includes a base 1, a frame 2, a pair of correction mechanisms 3, a hydraulic mechanism 4 and an electrical box 5, and the electric box 5 controls the correction mechanism 3 to correct the girder through the hydraulic mechanism 4. ; The frame 2 includes two sets of left-right symmetrical support assemblies, and there is a reserved channel for placing the girder between the two sets of support assemblies; each set of support assemblies includes a concave-shaped structure composed of two beams 201 and a longitudinal beam 202 , the correcting mechanism 3 is fixedly installed on the inner side of two facing longitudinal beams 202; the lower part of the longitudinal beam 202 is provided with a lifting plate 203; the correcting mechanism 3 includes a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com