Method for producing Q890 high-strength steel intermediate-thickness plate through online quenching

A production method and high-strength steel technology, which is applied in the field of production of high-strength steel Q890 medium-thick plates with a thickness of 16-50mm by on-line quenching, which can solve the problems of large surplus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

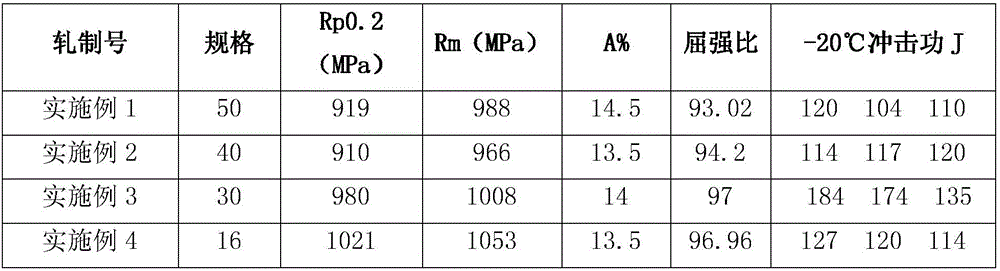

Embodiment 1--4

[0015] The chemical composition that present embodiment mentions is as shown in table 1 below:

[0016] Table 1: Chemical Composition (%) of Examples

[0017]

Embodiment 1

[0021] Rolling: Heating furnace heating temperature 1150°C, total heating time 1.0 hour; adopt two-stage rolling, rough rolling descaling 2 passes, finish rolling descaling 2 passes, rough rolling start rolling temperature 1050°C, intermediate billet thickness ≥ 80mm, the second-stage rolling temperature is 860°C, and the final rolling temperature is 830°C;

[0022] Cooling: Water-cooled on-line quenching is adopted, the water inlet temperature is 770°C, the redness temperature is 250°C, the cooling speed is 15°C / s, and the cooling strength is enhanced by 2-3 swings during the water cooling process;

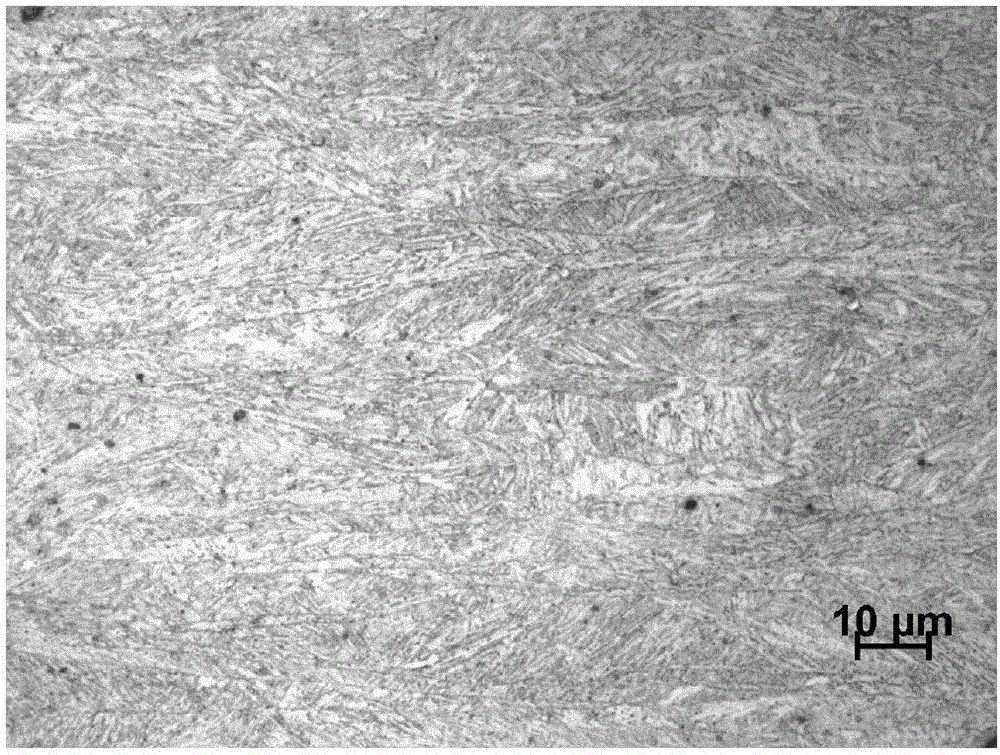

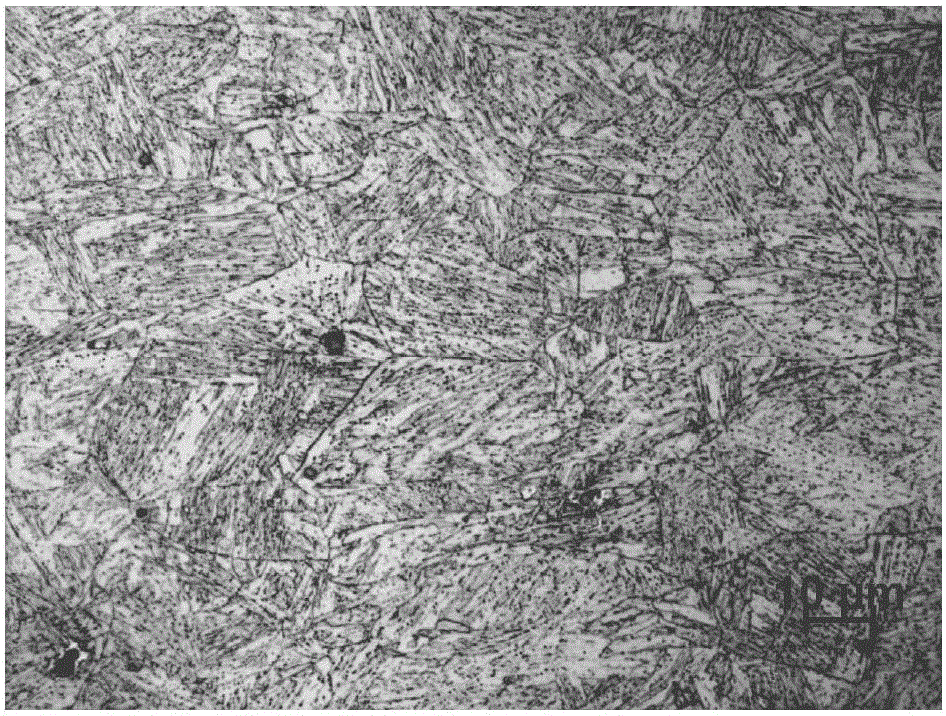

[0023] Heat treatment: Tempering temperature is 490°C, heating rate is 1.8min / mm, holding time is 20min, and then air-cooled to room temperature to obtain a dual-phase structure of lath martensite plus lath bainite.

Embodiment 2

[0025] Rolling: The heating temperature of the heating furnace is 1180°C, and the total heating time is 1.1 hours; Two-stage rolling is adopted, with 2 passes of rough rolling and descaling, 2 passes of finishing rolling and descaling, the starting temperature of rough rolling is 1100°C, and the thickness of the intermediate billet is ≥ 80mm, the second-stage rolling temperature is 850°C, and the final rolling temperature is 800°C;

[0026] Cooling: Water-cooled on-line quenching is adopted, the water inlet temperature is 780°C, the red return temperature is 240°C, the cooling speed is 20°C / s, and the cooling strength is enhanced by 2-3 swings during the water-cooling process;

[0027] Heat treatment: Tempering temperature is 500°C, heating rate is 1.6min / mm, holding time is 25min, and then air-cooled to room temperature to obtain a duplex structure of lath martensite plus lath bainite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com