Aircraft turbine blade laser shock method and device

A technology of aircraft turbine blades and laser shock, which is applied in the direction of heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of easy deformation, poor strengthening effect, difficult laser shock on the curved surface of aircraft turbine blades, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

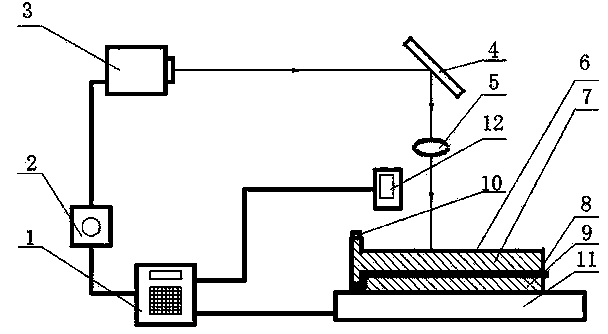

[0026] The device for laser impacting aircraft turbine blades of the present invention includes: high-power pulse laser 3, flexible film 6, aircraft turbine blades 7, gasket 8, die 9, three-axis numerical control workbench 11, computer control system 1, thickness measuring device 12. The laser system consists of a laser power supply 2, a high-power pulse laser 3, a 45° total reflection mirror 4, and a transmission mirror 5. The clamping seat 10 is used for clamping the tenon of the aircraft turbine blade 7 to ensure that the aircraft turbine blade 7 and the die 9 fit closely. The clamping device 10 is fixed on the three-axis numerical control workbench 11, and the flexible film 6 is the constraining layer and the absorbing layer. The computer control device 1 controls the three-axis numerically controlled workbench 11, the high-power pulse laser 3 and the thickness measuring device 12, and impacts by area until the target surface of the entire aircraft turbine blade 7 is proc...

Embodiment 2

[0028] The specific steps of implementing a method for laser shock strengthening aircraft turbine blades are:

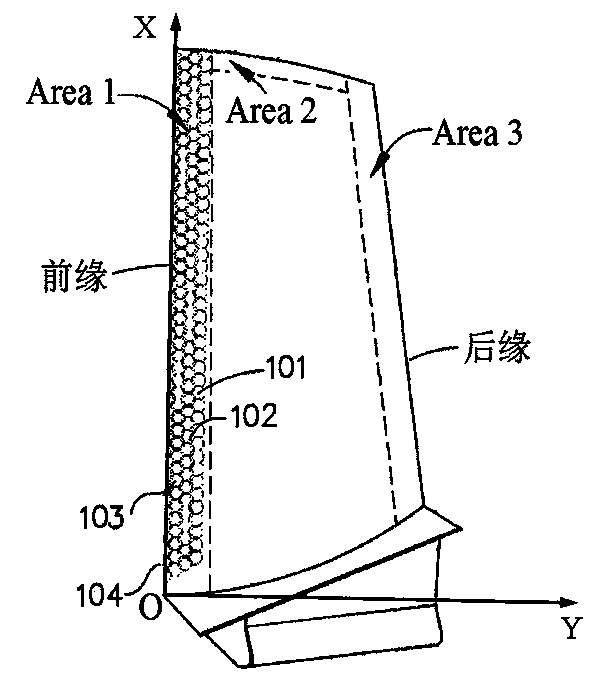

[0029] (1) Use UG, PRO / E and other three-dimensional software to carry out the solid modeling of the aircraft turbine blade 7. The aircraft turbine blade is made of IN853 nickel-based superalloy, and the maximum thickness of the aircraft turbine blade 7 is 2 mm. The thinnest area between the leading edge and the trailing edge 0.25mm, the die 9 is processed, and the die 9 is polished and deburred;

[0030] (2) The die 9 is placed on the three-axis numerical control workbench 11, and then a 0.5mm flexible gasket 8 is placed on the die, and then the aircraft turbine blade 7 is placed on the top of the flexible gasket 8 to ensure that the aircraft turbine blade 7. The flexible gasket 8 and the die 9 are tightly fitted, and finally the tenon of the aircraft turbine blade 7 is fixed by the clamping device 10;

[0031] (4) the 0.1mm thick flexible film 6 is adhered to the ...

Embodiment 3

[0038] Change the parameters of the high-power pulsed laser 3 in Example 2 to laser energy and power density as shown in Table 3 below, the spot radius is 1.5mm and the laser pulse width is 12ns, the flexible spacer is 0.8mm, and other methods and steps remain unchanged .

[0039] Table 2 Corresponding value of blade impact point thickness and laser energy and power density

[0040] Thickness (mm) Energy (J) Power density (GW / cm 2 ) 0.27 2.48 2.93 0.40 3.67 4.33 0.48 4.41 5.20 0.56 5.14 6.06

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com