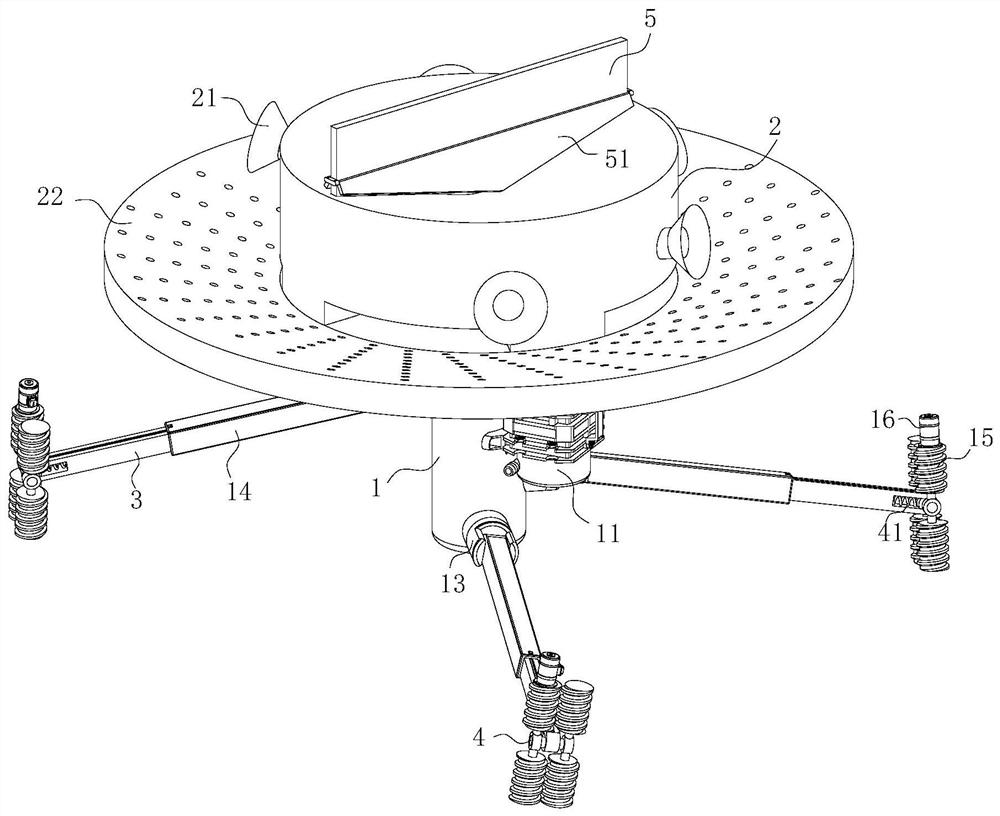

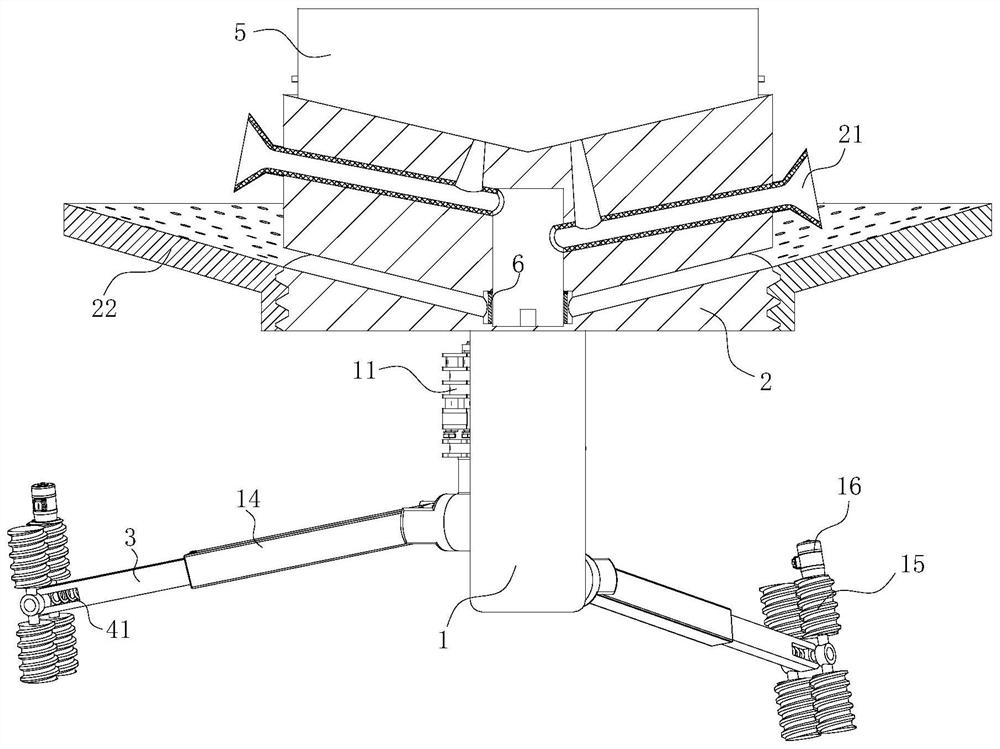

Shot blasting polisher

A polishing machine and shot peening technology, which is applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of troublesome pipeline cleaning process, large labor cost, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

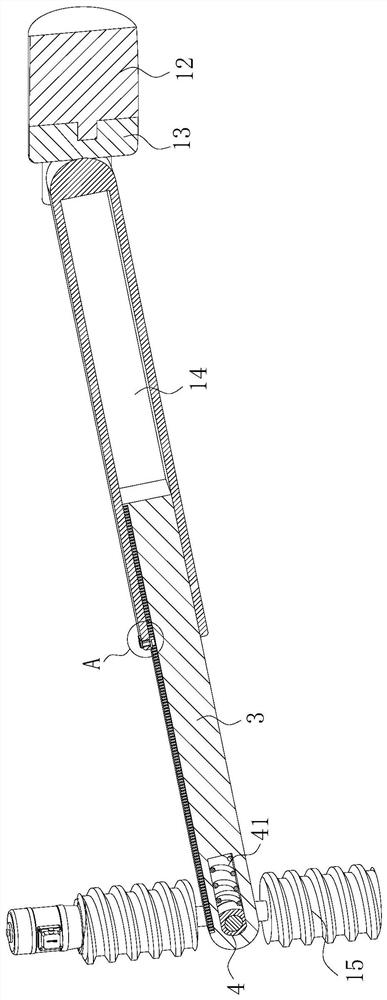

[0025] As an embodiment of the present invention, the rotating base 13 is provided with a first groove at the end away from the connecting base 12; the support rod 14 is connected in rotation in the first groove through a rotating shaft; the support rod 14 is away from the frame body 1 One end is provided with a sliding groove; the extension rod 3 is fixedly connected in the sliding groove; the upper surface of the extension rod 3 is provided with a limit groove; the inner wall of the limit groove is designed in a rack shape; the upper surface of the support rod 14 is provided with There is a first through slot; the limit block 31 is elastically connected by a spring in the first through slot; the limit block 31 is designed in a "ten" shape and the limit block 31 extends to the upper surface of the support rod 14; The bit block 31 is located at the upper surface of the support rod 14 and is connected with a rotating ring 32 for rotation; during work, due to the difference in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com