Pattern marking machine for decoration surface treatment

A technology for surface treatment and decoration, which is applied to the field of decoration machines for decoration surface treatment, can solve the problems of decorations that are difficult to handle small hardware, unfavorable to the development of the processing industry, and high processing costs, achieves a significant decoration effect, and is conducive to workshop layout. and operation, good effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

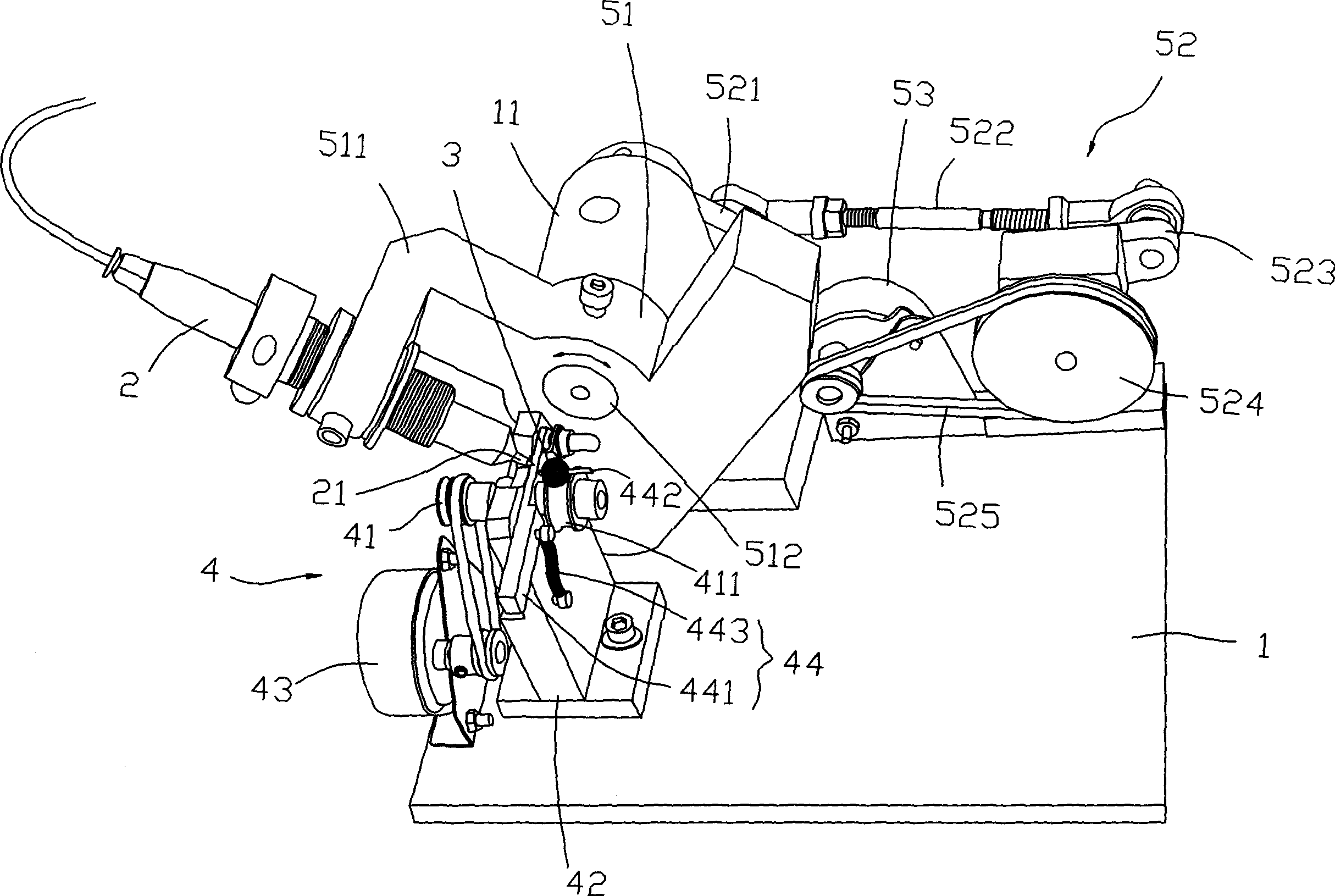

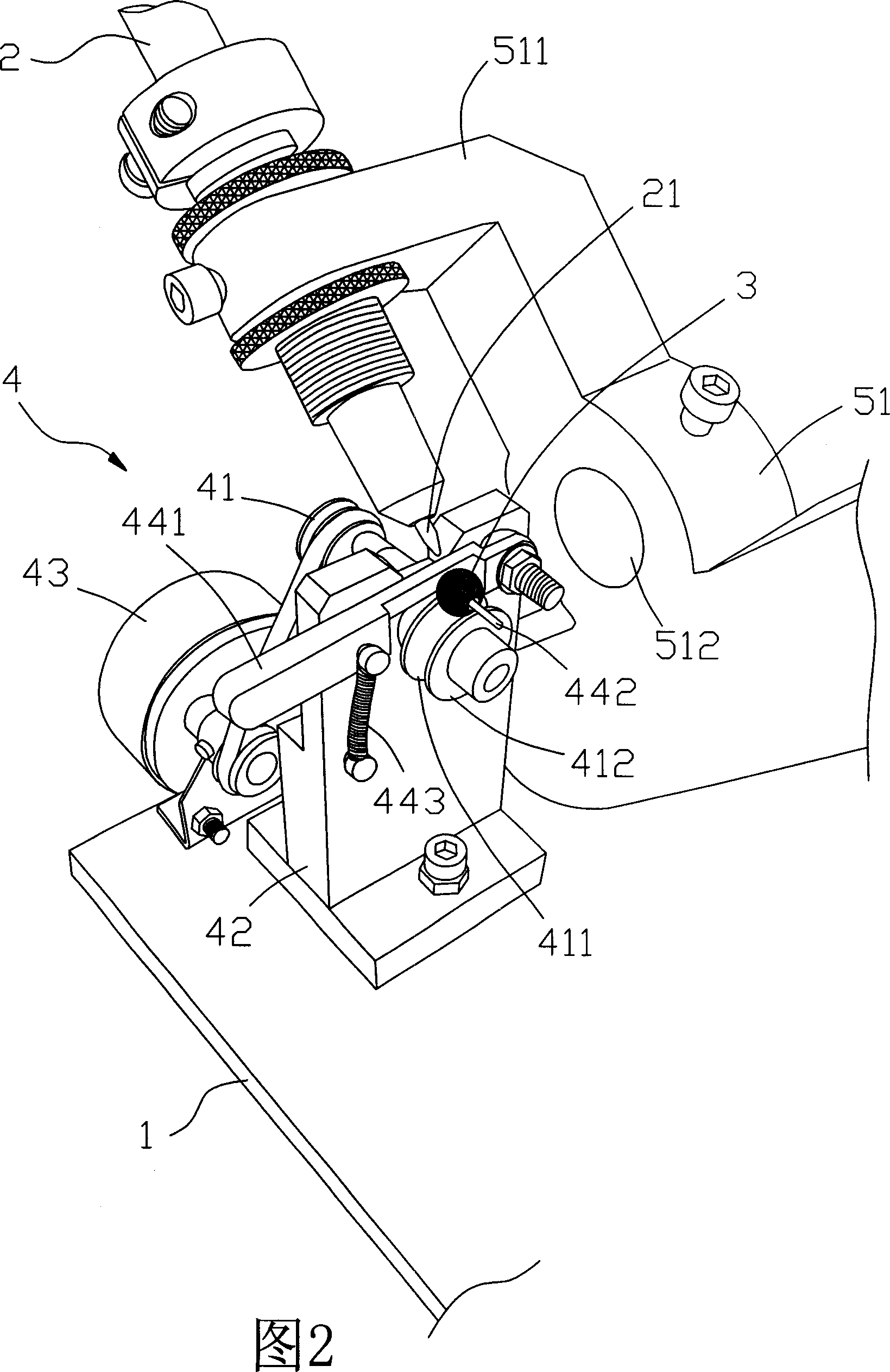

[0017] See attached figure 1 , shown in 2, the present invention comprises support 1, is installed with the percussion drill 2 that pattern is used on support 1, and the drill bit 21 of percussion drill 2 has along percussion drill 2 axial telescopic dynamics and follows percussion drill 2 around workpiece 3 revolutions of rotation. The workpiece 3 is installed on a workpiece rotation device 4 that can rotate the workpiece 3. The workpiece rotation device 4 is installed on the support 1. The rotation direction of the workpiece 3 and the revolution direction of the drill bit 21 intersect each other.

[0018] The percussion drill 2 of the present invention is a pneumatic type. The inner end of the drill bit 21 forms a piston structure and is assembled in the cylinder of the percussion drill 2. The drill bit 21 is axially stretched and impacted by the action of air pressure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com