Plastic alloy as well as preparation method and application thereof

A technology of plastic alloy and active kaolin, applied in the field of plastics, can solve problems such as poor compatibility and mechanical properties, and achieve the effects of low cost, excellent tensile strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

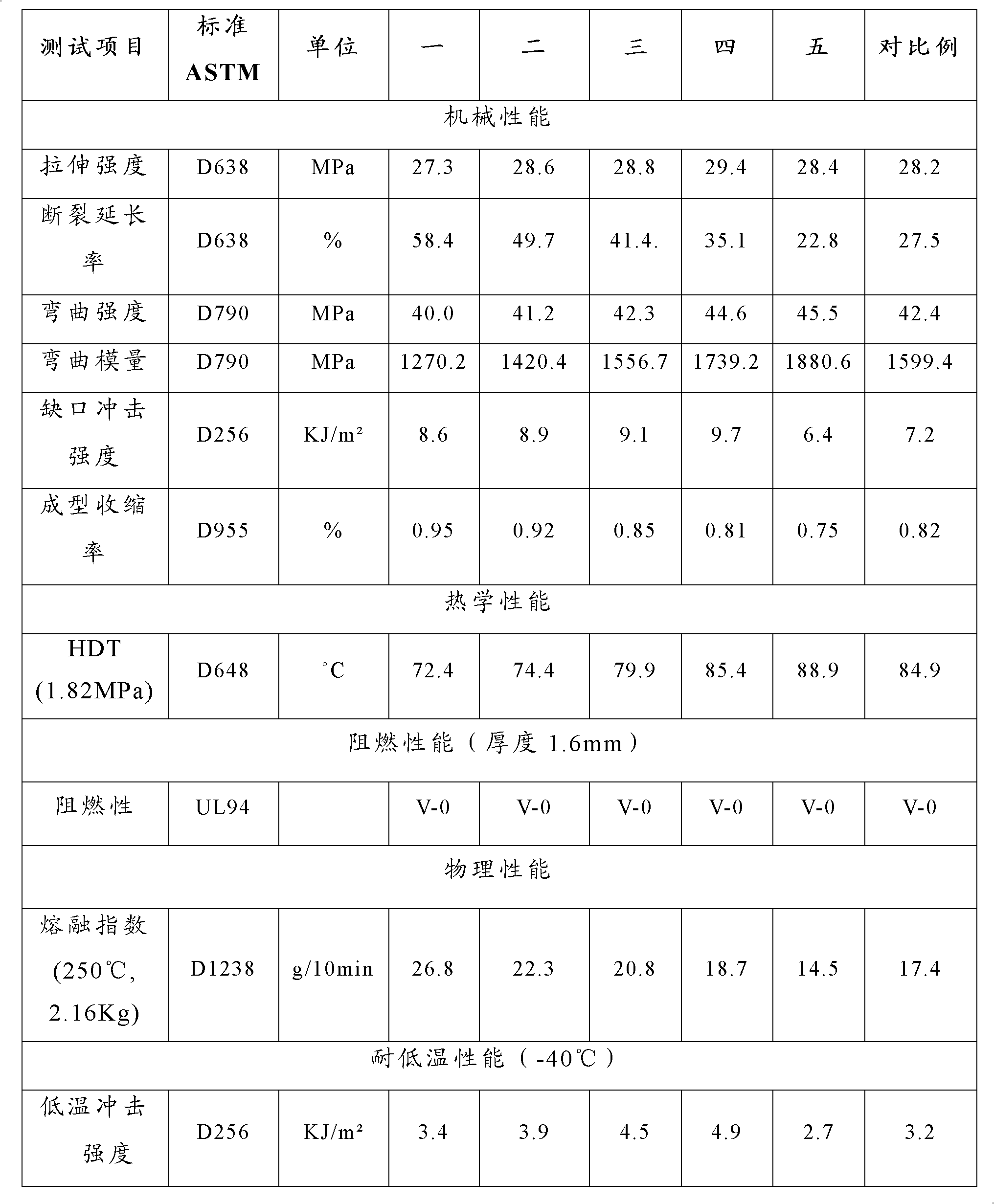

Examples

preparation example Construction

[0041] The embodiment of the present invention further provides a method for preparing a plastic alloy, which includes the following steps:

[0042] S01: Surface treatment of kaolin with a surface treatment agent to obtain activated kaolin;

[0043] S02, mixing PP resin, PPO resin and compatibilizer, stirring, dehumidifying when the temperature reaches 75-85°C and adding the active kaolin, stirring to obtain a premix, extrusion granulation to obtain a plastic alloy material.

[0044] Specifically, in step S01, the surface treatment agent and kaolin are the same as before, and the description is not repeated here. Step S01 is specifically:

[0045] The kaolin is stirred to dehumidify when the temperature reaches 70°C to 85°C, and the surface treatment agent is added when the temperature reaches 115°C to 155°C, and stirred for 3 to 8 minutes to obtain an active kaolin precursor, which is cooled to obtain the active kaolin. The cooling step is specifically carried out by putting the act...

Embodiment 1

[0054] The preparation method of the plastic alloy in the embodiment of the present invention includes the following steps:

[0055] (1) Preparation of 6000 mesh active kaolin

[0056] Put 10 parts by weight of 6000 mesh active kaolin powder into a high-speed mixer and stir at high speed. When the temperature reaches 70°C, dehumidification starts and the temperature reaches 115°C. Add 0.5 parts by weight of silane coupling agent and mix and stir for 3 minutes , And then put the mixture in the high-mixer into a cold mixer for cooling, and then discharge after cooling to 40°C to obtain a surface-treated 6000 mesh activated kaolin;

[0057] (2) Preparation of 6000 mesh activated kaolin filled modified PP / PPO alloy material premix

[0058] Put 37.2 parts by weight of PP, 16 parts by weight of PPO resin, 17 parts by weight of maleic anhydride, 7.5 parts by weight of bromotriazine and 7.5 parts by weight of antimony trioxide into the high-mixer Mix and stir, and start dehumidification when...

Embodiment 2

[0062] The preparation method of the plastic alloy in the embodiment of the present invention includes the following steps:

[0063] (1) Preparation of 4000 mesh active kaolin

[0064] Put 15 parts by weight of 4000 mesh active kaolin powder into a high-speed mixer and stir at high speed. When the temperature reaches 75°C, dehumidification starts and the temperature reaches 120°C. Add 0.5 parts by weight of titanate coupling agent and mix and stir. 4 minutes, then put the mixture in the high-mixer into the cold mixer for cooling, cool to 45°C and then discharge, to obtain surface-treated 4000 mesh activated kaolin;

[0065] (2) Prepare 4000 mesh activated kaolin filled modified PP / PPO alloy material premix

[0066] Put 32.2 parts by weight of PP, 16 parts by weight of PPO resin, 17 parts by weight of polypropylene grafted maleic anhydride, 9 parts by weight of bromotriazine and 6 parts by weight of antimony trioxide. Mix and stir in a high mixer, and start dehumidification when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com