Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "The production process is reasonable and clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of aluminum bronze

InactiveCN107663598ANovel componentsThe production process is reasonable and clearMetallic materialsMetal

A method for manufacturing aluminum bronze, which belongs to the technical field of metal materials and heat treatment. The aluminum bronze is prepared according to the following mass percentages: Al 10.2%, Sn 2.0-3.8%, Mn 2.0-2.3%, Fe 0.03-0.06%, and the rest is Cu; The composition of the invention is novel, the production process is reasonable and clear, and the smelting process is easy to control; the invention makes the aluminum bronze have better wear resistance, corrosion resistance and corrosion resistance by reasonably quenching and tempering the formed aluminum bronze. It has better mechanical properties and can be used to cast heavy-duty, corrosion-resistant and wear-resistant parts.

Owner:叶秀兰

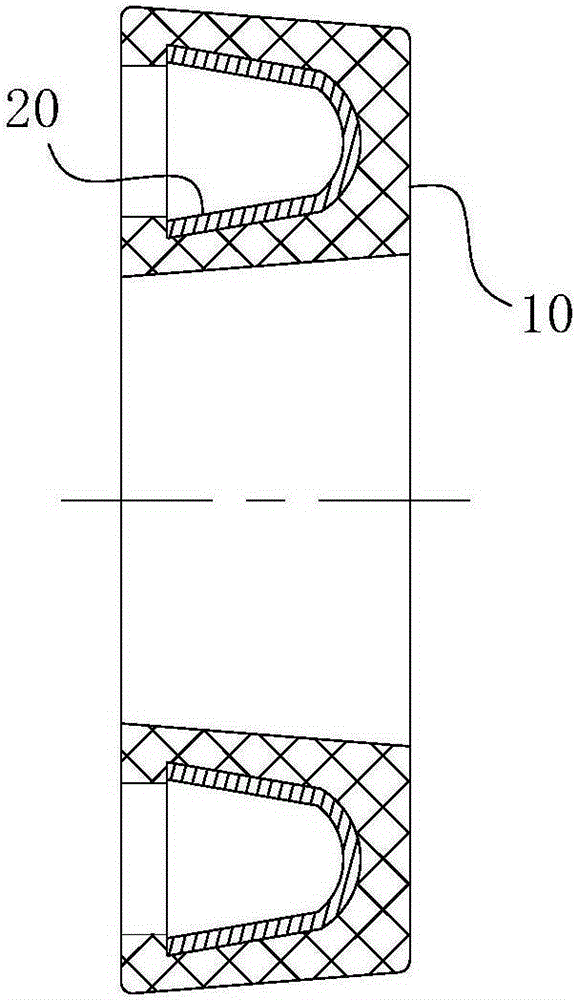

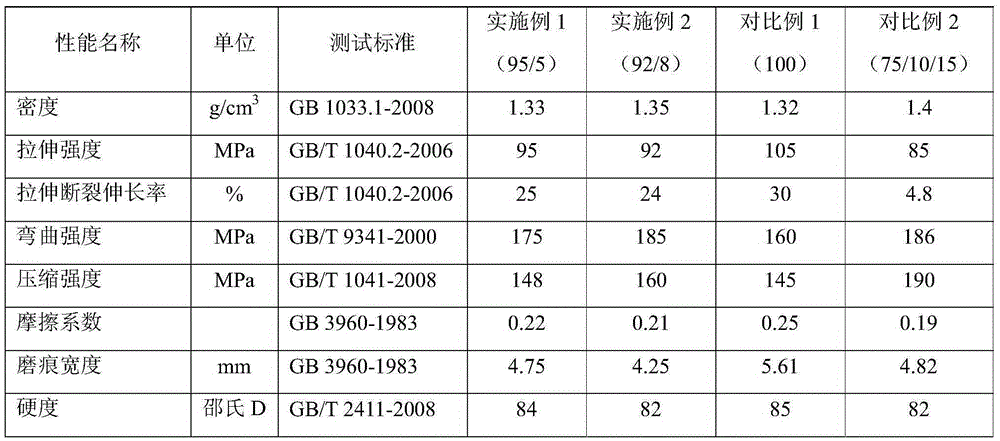

Polyaryletherketone composite material and preparation method thereof and sealing ring made of polyaryletherketone composite material

The invention belongs to the field of composite materials, and particularly relates to a polyaryletherketone composite material having high toughness, self-lubricating property, wear resistance and low hardness, a method for making the material and a sealing ring made of the material. The polyaryletherketone composite material consists of 92-95 parts by weight of copolyaryletherketone and 5-8 parts by weight of soft carbon, and also comprises a silane coupling agent added in an amount of 0.8-1.5 percent based on the weight of the soft carbon. The invention further discloses a simple preparation method of the material. The method mainly comprises the procedures of surface treatment, mixing, drying, hot pressing, cooling and demolding. The invention further discloses a sealing ring made of the material. By using the sealing ring, an efficient sealing effect can be achieved on a specified component of nuclear industrial equipment. The sealing ring made of the polyaryletherketone composite material can fully meet the sealing requirements under the special working conditions of high temperature, high pressure and the like in the field of nuclear industry. By using the sealing ring, leakage of nuclear media is prevented, and the safety of personnel and equipment is ensured.

Owner:HEFEI GENERAL MACHINERY RES INST

Spline for high manganese steel automobile clutch and manufacturing method thereof

InactiveCN106978573AImprove the lubrication effectImprove cooling effectFoundry mouldsSolid state diffusion coatingElectrochemical responseElectrolysis

The invention discloses a spline for a high manganese steel automobile clutch and a manufacturing method thereof, and belongs to the technical field of mechanical manufacturing. The spline comprises the following components in percentage by weight: 1.5-2.5% of Si, 0.5-0.75% of C, 1.2-1.8% of Cr, 6.4-7.5% of Mn, 0.26-0.52% of Ni, 0.036-0.046% of Ti, S less than 0.03%, P less than 0.018%, Zn less than 0.02%, and the balance of Fe and inevitable impurities. The plasticity and the toughness of steel are improved, so that the corrosion resistance of manganese steel is improved; a shot blasting technology is applied to remove iron oxide scales on the upper and lower surfaces of steel strips; scales can be repeatedly reduced and oxidized by electrolysis and acid washing for loosening; meanwhile, the surfaces of the steel strips generate the electrochemical reaction; and generated gas instantly blasts to peel off the loosened scales.

Owner:王涛

PTFE (polytetrafluoroethylene) composite, preparation method thereof and leakproof sealing ring using composite

InactiveCN110041646AGuaranteed wear resistanceKeep self-lubricatingMaterials scienceNuclear industry

The invention belongs to the field of composites and sealing parts and particularly relates to a PTFE (polytetrafluoroethylene) composite with anti-radiation, anti-wear and self-lubricating properties, a method for preparing the composite and a leakproof sealing ring using the composite. The disclosed PTFE composite is prepared from components in parts by weight as follows: 75-90 parts of suspending PTFE resin, 10-20 parts of thermosetting polyimide powder, 3-5 parts of ferroelectric ceramic powder and the like. The invention also discloses a preparation method of the material, which comprisesprocesses of drying, mixing, pressing, sintering, modification and the like. The invention also discloses the Z-shaped leakproof sealing ring prepared from the composite, which realizes the efficientsealing effect of a key host in the nuclear field. The sealing ring prepared from the PTFE composite can meet the sealing requirement under the dry friction work condition in the nuclear industry field, has excellent anti-radiation property and can guarantee effective operation of equipment and the safety of workers for a long term.

Owner:杨家义

Gray pig iron with good mechanical property and cutting machining property

InactiveCN107541645AImprove mechanical propertiesEasy to processSolid state diffusion coatingMechanical propertyMachinability

The invention discloses gray pig iron with the good mechanical property and cutting machining property, and belongs to the technical field of powder metallurgy. The gray pig iron is composed of raw materials including, by mass percent, 4.2 to 6.77% of C, 2.5 to 3.8% of Si, 1.05 to 1.55% of Mn, 0.05 to 0.128% of P, 0.125 to 0.625% of S, 0.45 to 0.85% of Cr, 0.62 to 0.98% of Cu, 0.07 to 0.12% of Sn,0.02% of Sb, 0.77% of Ni, 1.2% of W and the balance pure iron and impurities. The large gray pig iron product shrinkage tendency is solved, the gray pig iron produced through the production method ofthe gray pig iron and a casting cast through the method have the beneficial effects of being free of generating shrinkage and high in yield, and the special occasions with the high property and the good cutting property can be met.

Owner:叶秀兰

Machining technology of high-strength high-hardness gray pig iron

InactiveCN107541577AGood castabilityEasy to manageProcess efficiency improvementFoundryInduction furnace

The invention discloses a machining technology of high-strength high-hardness gray pig iron, and belongs to the technical field of powder metallurgy. Q235 waste steel, Q10 pig iron and foundry returnsserve as raw materials to be subjected to gray pig iron smelting. According to the technology, the manner that when a traditional medium-frequency induction furnace smelts high-grade gray pig iron, alloying elements of copper or tin are added is replaced, manufacturing cost is reduced, and management of foundry returns is facilitated. The method that silicon carbide and furnace burden are smeltedat the same time is adopted to carry out pretreatment on the molten iron, the pretreatment effect is ensured, an efficient nucleating agent, that is a silicon zirconium nucleating agent, is adopted to ensure the nucleating effect, 80% or above of A-type graphite is obtained from a gold phase of a casting body, the tensile strength of the casting body reaches 270 to 300, and the special occasion of high performance, good cutting performance and the like at present can be met.

Owner:叶秀兰

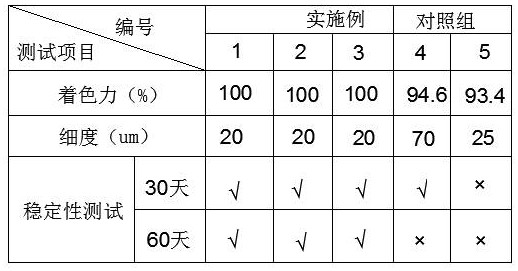

Gray iron oxide pigment dry-method manufacturing process

InactiveCN111763436AImprove performanceClear Dispersion TimePigment physical treatmentPigment treatment with non-polymer organic compoundsIron oxide blackPolyol

The invention provides a gray iron oxide pigment dry-method manufacturing process, and relates to the field of inorganic pigment production. The raw materials comprise iron oxide black, titanium dioxide, a body pigment, an aluminizing agent and polyol. The manufacturing process comprises the following steps: A, adding titanium dioxide, iron oxide black and the body pigment into a proportioning bin, and mixing to obtain a mixture a; B, feeding the mixture a into a ball mill; C, adding an aluminizing agent for stabilizing; D, after the ball mill finishes processing, taking out the mixture, crushing the mixture by a crusher, and filtering by a filter sieve; E, carrying out secondary crushing on large particles obtained by filtering, and carrying out filtering; and F, carrying out dry surfacetreatment. According to the invention, the performance of the iron oxide pigment can be greatly improved through dry surface treatment, the raw material mixture is subjected to ball-milling treatmentthrough a grinding machine, the raw materials of the mixture are sufficiently crushed, the formula is simple, the manufacturing process is clear, and the obtained pigment can achieve high coloring strength and a small color difference value and is high in practicability.

Owner:常德市正邦建筑装饰材料有限公司

High-hardness and high-abrasion-resistance high tungsten ledeburite gear steel and preparation method thereof

InactiveCN107435124AExtended service lifeImprove internal mechanical propertiesFurnace typesProcess efficiency improvementLedeburiteWear resistance

The invention discloses a high-hardness and high-abrasion-resistance high tungsten ledeburite gear steel and a preparation method thereof and belongs to the technical field of powder metallurgy. The high-hardness and high-abrasion-resistance high tungsten ledeburite gear steel is composed of the following raw materials of, by mass, 1. 8% of C, 0.5% of Si, 0.25% of Mn, 0.015% of S, 0.025% of P, 2.5% of Cr, 1.25% of Mo, 0.8% of V, 0.16% of Nb, 0.05% of Re, 0.12% of Ni, 0.30% of W and the balance Fe and impurities. The high-hardness and high-abrasion-resistance high tungsten ledeburite gear steel can replace cold working die steel such as Cr12MoV steel and D2 steel, the toughness and abrasion resistance of a die are improved, the service life is greatly prolonged so as to reduce the use cost and expand the use range, the problems of poor toughness, tipping or breaking and poor abrasion resistance under special use environments such as the large impact load, the high working speed, high precision and the long life can be effectively solved, and the use requirements of multiple high bearing and high rotating speed occasions are met.

Owner:鲍凡凡

High corrosion resistance chromium bronze manufacturing method

A method for manufacturing chromium bronze with high corrosion resistance, belonging to the technical field of metal materials and heat treatment, comprising the following preparation steps: the mass percentage of each component of chromium bronze is: Cr: 1.5-2.5%, and the rest is Cu; Add cathode copper, furnace charge and charcoal covering agent to the crucible, add enough charcoal at one time, the thickness is 120-140mm; raise the temperature to 1350°C to melt the copper rapidly; remove the charcoal, and quickly add pure Cr, the amount of Cr added is 1-1.5 times the nominal composition, wait for 2-5min, stir once; heat up and smelt for 10-15min before furnace inspection; quickly pour into shape after passing the inspection; turn and mill the molded parts; turn and mill the parts for 1.5 hours , solution treatment at a temperature of 900°C; aging treatment at 800°C for 6 hours.

Owner:叶秀兰

High-hardness and high-abrasion-resistance ledeburite alloy cast iron

High hardness and high wear resistance ledeburite alloy cast iron, which belongs to the field of powder metallurgy technology, is composed of the following raw materials in mass percentage, C 1.8%; Si 0.5%; Mn 0.25%; S 0.015%; P 0.025%; Cr 2.5%; Mo 1.25%; V 0.8%; Nb 0.16%; RE 0.05%; Ni 0.12%; W 0.30%; the rest is Fe and impurities. In order to improve the surface hardness of the alloy cast iron, the surface carburizing treatment is carried out after the alloy cast iron is formed, and the surface quenching treatment is carried out after the carburization is completed, which improves the hardness of the gear teeth and the surface strength of the gear teeth, reduces the wear of the tooth surface, and through normalizing And tempering treatment improves the internal mechanical properties of alloy cast iron, and its toughness and fatigue strength have been greatly improved. After the entire heat treatment is completed, grinding treatment is also used to improve the mechanical properties of the surface, especially the passivation of the surface. The stress, the service life of alloy cast iron has been greatly improved, to meet a variety of high load, high wear requirements.

Owner:周文前

Ductile iron for producing automobile bracket and preparation method of ductile iron

The invention discloses ductile iron for producing an automobile bracket, wherein the ductile iron is prepared from the following raw materials in percentage by mass: 1.5 to 2.1% of C, 1.7 to 2.0% ofSi, 0.7% to 0.9% of Mn, 0.01 to 0.02% of S, 0.05 to 0.07% of P, 0.1 to 0.22% of Cu, 0.12 to 0.28% of Cr, 0.006 to 0.009% of Sb, 0.04 to 0.08% of Mg, 0.02 to 0.45% of Re and the balance of Fe. The ductile iron provided by the invention has higher elongation while having higher strength; the casting performance is improved; the efficiency of metal materials is better exerted; the use requirement ofbracket casting of heavy-duty trucks is met. The invention further discloses a preparation method of the ductile iron.

Owner:TAIHU AIJIE MACHINE CASTING

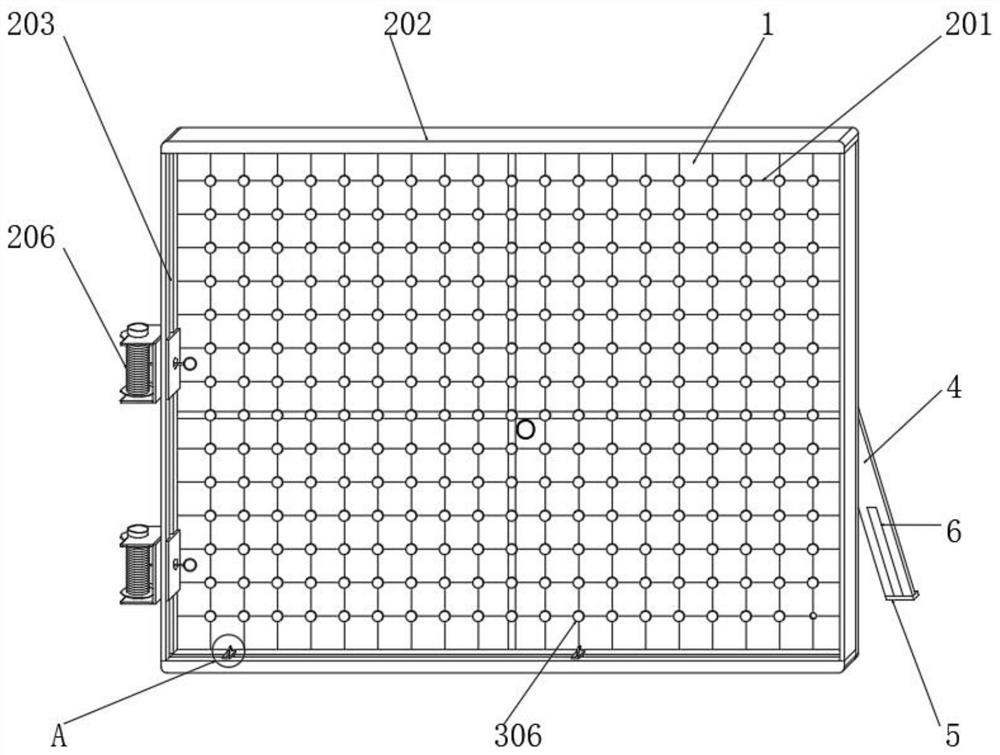

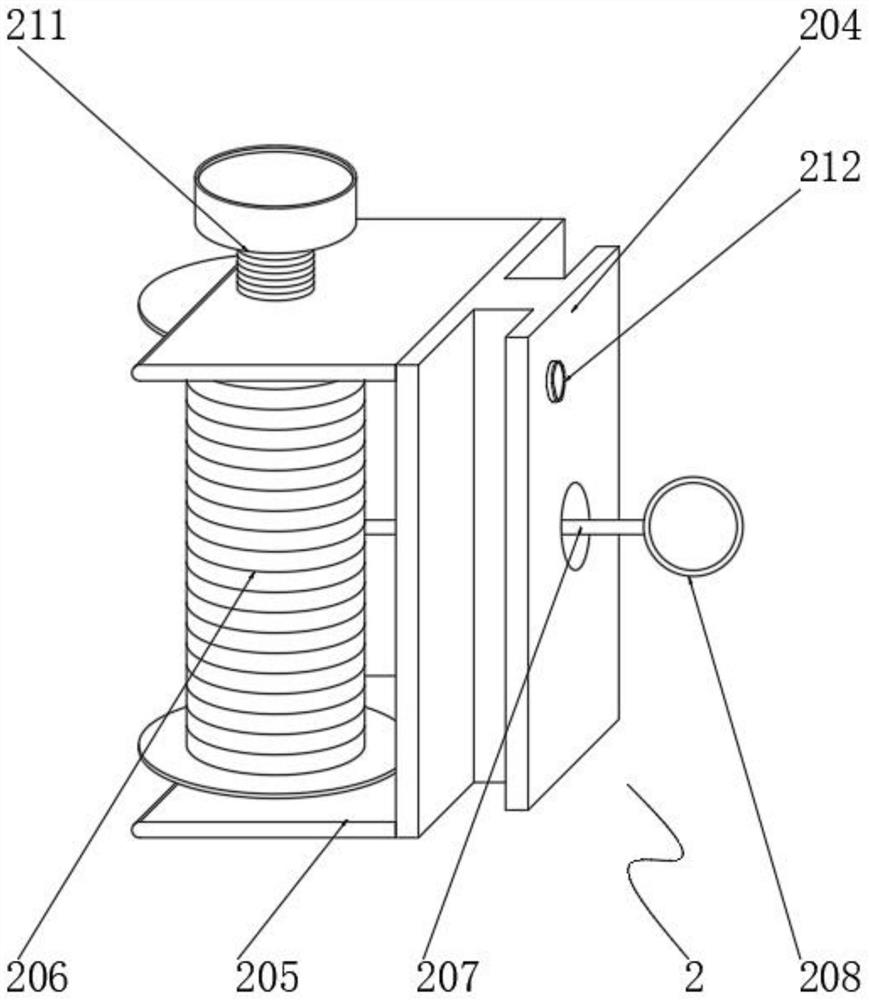

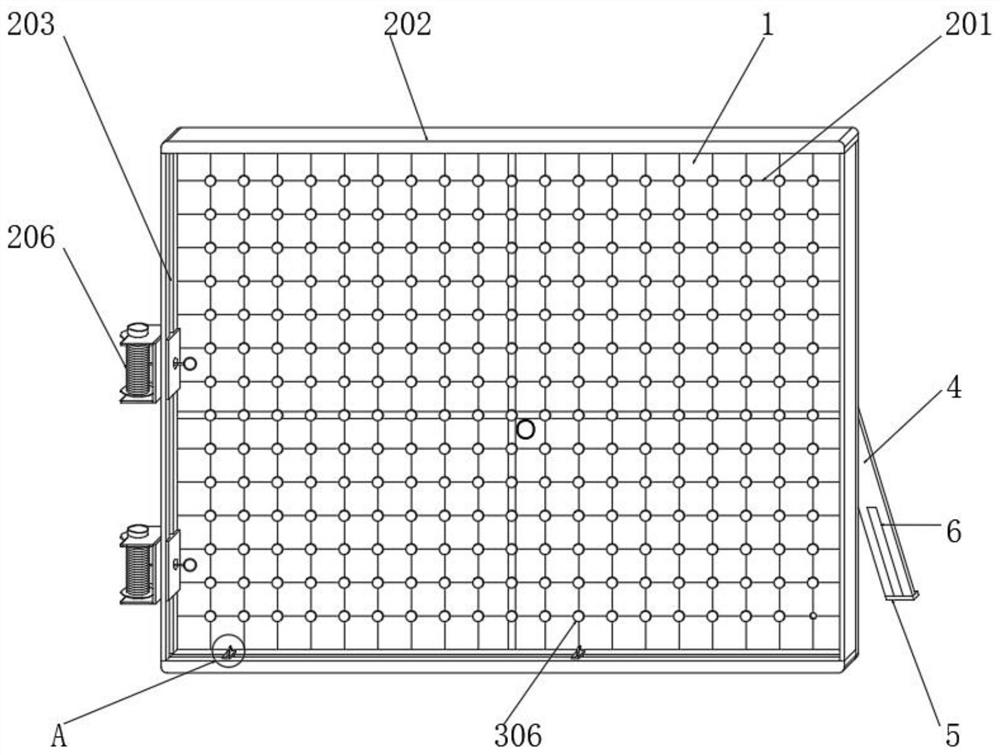

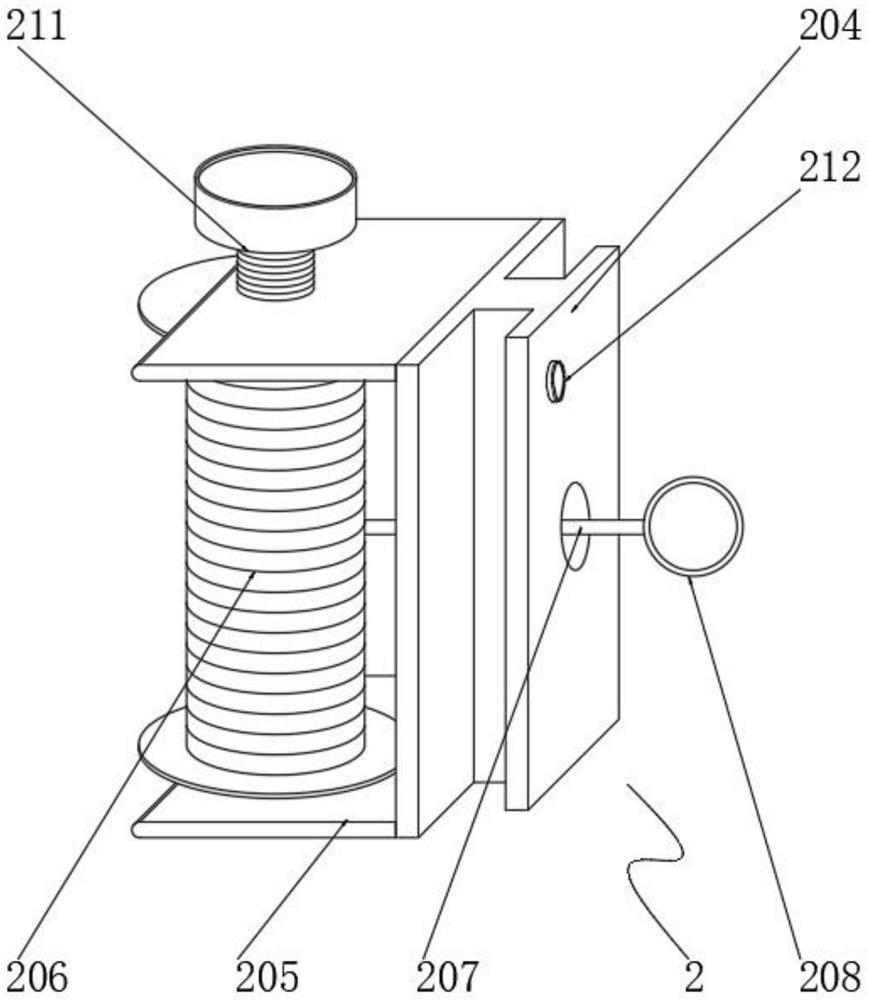

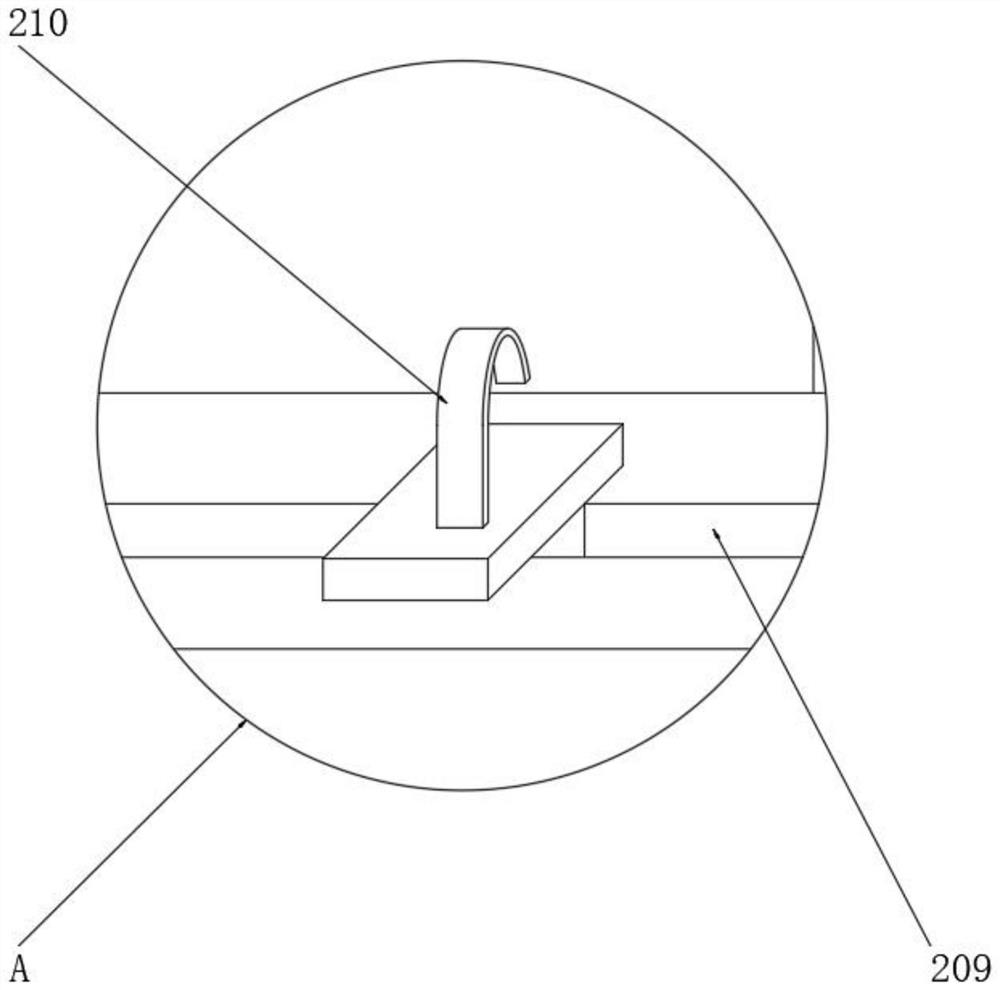

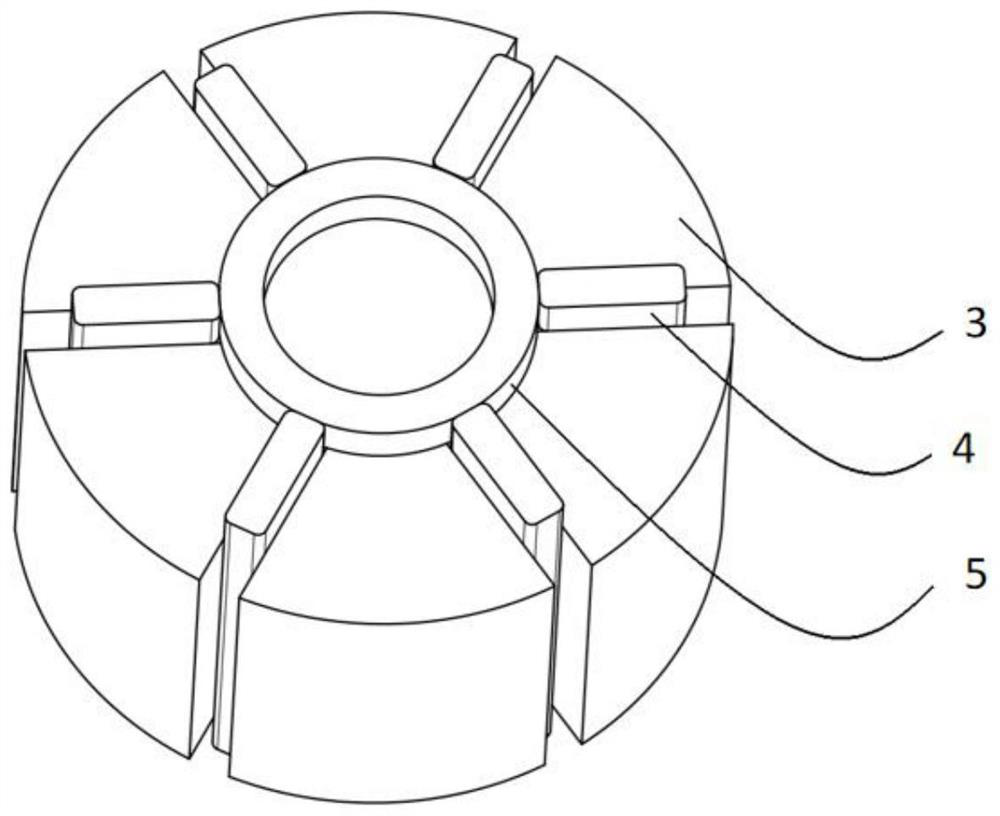

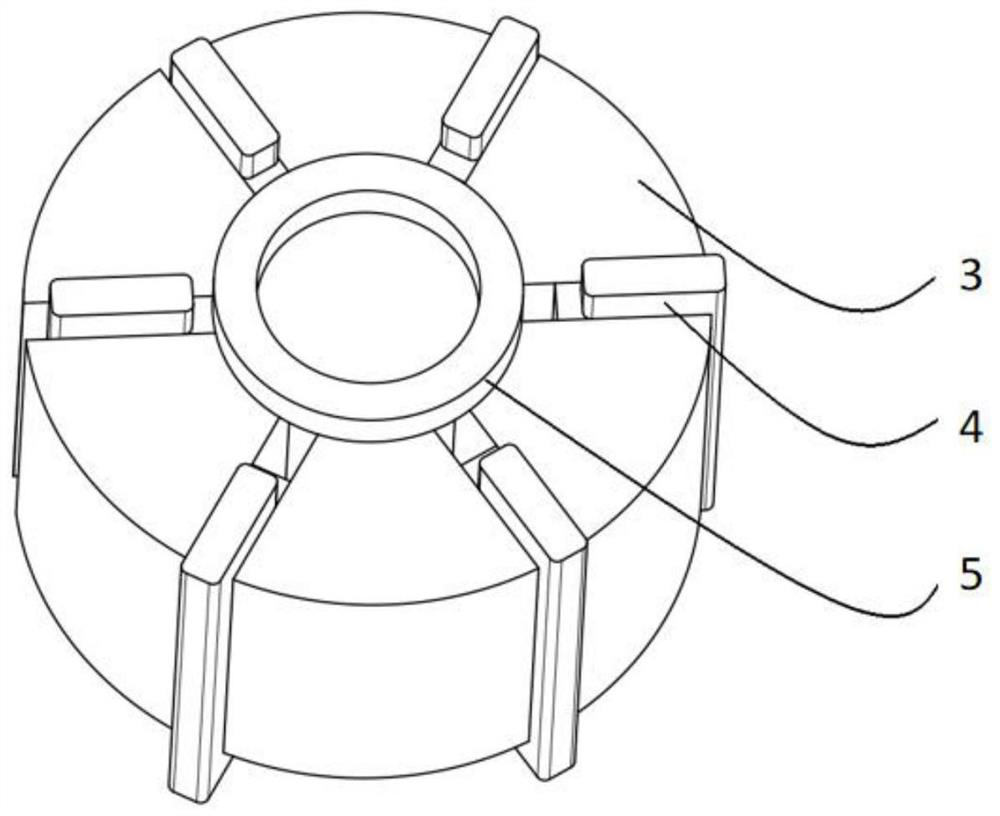

A kind of mathematical teaching aid for mathematical thinking training and its preparation device

ActiveCN112002188BScientific and reasonable structureEasy to useEducational modelsRubber ringEngineering

The invention discloses a mathematical teaching aid for mathematical thinking training and a preparation device thereof. A display component is arranged on the front of a coordinate base plate, an installation frame is installed at a position outside the stop frame of the installation block, a winding shaft is installed at the middle of the installation frame, and the intersecting point of the latitude and longitude grooves is located A fixed line assembly is installed through the center, a rubber ring is bonded to the side of the anti-slip sheet close to the coordinate base plate, a lower mold assembly is installed on the top surface of the backing plate, a half template is connected to the top surface of the support plate, and an upper mold assembly is installed on the top of the guide post , a uniform groove is opened on the top surface of the upper template, and the present invention utilizes the display line of the display assembly to bypass the round tube of the wire fixing assembly in turn, and the wire fixing assembly fixes the display line to complete the production of the function image. The image production process is simple and clear, and the display is convenient. After the raw material enters the upper mold assembly, it is extruded again so that the raw material is evenly distributed and formed, and the forming effect is good. After forming in the lower mold assembly, the two half-plates are separated from each other, which is convenient for cooling and taking out, and improves the molding efficiency.

Owner:MUDANJIANG NORMAL UNIV

Alloy steel gear with gear tooth surface with high abrasive resistance

InactiveCN107435725AHigh surface hardnessReduce wearPortable liftingGearing elementsHardnessGear tooth

An alloy steel gear with a high wear resistance tooth surface belongs to the technical field of powder metallurgy. The components of the gear and their weight percentages are: C 3.1-3.4%, Si 1.5-2.2%, Mn 0.1-0.3%, S 0.1 ~0.3%, P 0.1~0.4%, Te 0.013~0.021%, and the rest are Fe with metallographic structure of ferrite + austenite and unavoidable impurities. The invention has novel components, reasonable and clear manufacturing process, surface carburizing treatment improves the surface hardness of the gear, surface quenching treatment improves the hardness of the gear teeth and the surface strength of the gear teeth, reduces the wear of the tooth surface, and through normalizing And tempering treatment improves the internal mechanical properties of the gear, and its toughness and fatigue strength have been greatly improved. Finally, the grinding treatment is adopted, especially the stress on the surface is passivated, and the service life of the gear is greatly improved. , to meet the needs of a variety of high-load, high-speed occasions.

Owner:田静

Polyaryletherketone composite material, its preparation method and sealing ring using the material

The invention belongs to the field of composite materials, and particularly relates to a polyaryletherketone composite material having high toughness, self-lubricating property, wear resistance and low hardness, a method for making the material and a sealing ring made of the material. The polyaryletherketone composite material consists of 92-95 parts by weight of copolyaryletherketone and 5-8 parts by weight of soft carbon, and also comprises a silane coupling agent added in an amount of 0.8-1.5 percent based on the weight of the soft carbon. The invention further discloses a simple preparation method of the material. The method mainly comprises the procedures of surface treatment, mixing, drying, hot pressing, cooling and demolding. The invention further discloses a sealing ring made of the material. By using the sealing ring, an efficient sealing effect can be achieved on a specified component of nuclear industrial equipment. The sealing ring made of the polyaryletherketone composite material can fully meet the sealing requirements under the special working conditions of high temperature, high pressure and the like in the field of nuclear industry. By using the sealing ring, leakage of nuclear media is prevented, and the safety of personnel and equipment is ensured.

Owner:HEFEI GENERAL MACHINERY RES INST

White cast iron with higher impact resistance and manufacturing method thereof

The invention discloses white cast iron with higher impact resistance and a manufacturing method thereof, and belongs to the technical field of iron-carbon alloy. The white cast iron is prepared fromthe following components in percentage by weight: 8-12% of C, 0.05-0.25% of Si, 6.0-7.0% of Cr, 0.2-0.38% of Mn, 3.6-4.2% of Ni, less than or equal to 0.98% of Mo, less than or equal to 0.045% of P, less than or equal to 0.06% of S and the balance of Fe. The components of the white cast iron with higher impact resistance are more reasonable, the manufacturing process is reasonable and clear, the quenching and tempering temperatures are determined through two times of quenching and tempering, the quenching and tempering temperatures are determined through experiments, and the treatment is carried out at the temperatures, so that the toughness and wear resistance of the white cast iron are greatly improved, the working life is longer, the manufacturing is easier, the mechanical properties ofthe white cast iron can be greatly improved, and the use requirements of strong impact and the like can be met.

Owner:徐州艾梅尼克工程机械有限公司

Mathematical teaching aid for mathematical thinking training and preparation device thereof

ActiveCN112002188AScientific and reasonable structureEasy to useEducational modelsRubber ringMechanical engineering

The invention discloses a mathematical teaching aid for mathematical thinking training and a preparation device thereof. A display assembly is arranged on the front of a coordinate base plate, a mounting rack is mounted on the mounting block and positioned on the outer side of the baffle frame, a winding shaft is mounted in the middle of the mounting frame, a wire fixing assembly is installed at the intersection of the longitude and latitude grooves in a penetrating mode, a rubber ring is adhered to one side, close to the coordinate bottom plate, of the antiskid sheet, a lower die assembly isinstalled on the top face of the base plate, a top surface of the support plate is connected with a half template, upper die assemblies are installed at top ends of the guide columns, and a uniform groove is formed in a top surface of the upper template. According to the mathematical teaching aid, a display line of the display assembly sequentially bypasses the circular tube of the line fixing assembly, a line fixing assembly fixes the display line, manufacturing of a function image is completed, the image manufacturing process is simple and clear, displaying is convenient, after raw materialsenter the upper die assembly, the raw materials are extruded again to be evenly distributed and then formed, the forming effect is good, after forming is conducted in the lower die assembly, two halfdie plates are separated, cooling and taking-out are convenient, and forming efficiency is improved.

Owner:MUDANJIANG NORMAL UNIV

A self-lubricating, highly wear-resistant non-metallic sealing slider and its manufacturing method

The invention discloses a self-lubricating, highly wear-resistant non-metallic sealing slider and a manufacturing method thereof, belonging to the field of sealing materials. The components include by weight: 40-50 parts of non-metal inorganic fiber yarn, 40-55 parts of self-lubricating resin, and 3-5 parts of inorganic ceramic powder. The manufacturing method of the sealing slider includes processes such as weaving, mixing, dipping, pre-sintering, alternate bedding, hot pressing, and demoulding. The invention also discloses a T-shaped sealing slider used for the air pump, which can realize high-efficiency vacuuming after the unit is in operation. The sealing slider prepared by the invention has excellent self-lubrication and wear resistance, high rigidity, not easy to bend, can meet the sealing requirements under high-speed and dry friction conditions, and can quickly discharge the pipeline connected to the air pump cavity after the unit is running The gas in the pump can realize the vacuum of the pipeline and achieve the purpose of quickly extracting other media. The whole operation process is highly efficient and energy-saving, and has no pollution to other media and the environment.

Owner:合肥一密科技有限公司

High-strength and high-toughness ball-milling iron casting and manufacturing method thereof

The invention discloses a high-strength and high-toughness ball-milling iron casting. The high-strength and high-toughness ball-milling iron casting is prepared from the following raw materials in percentage by mass: 1.5 to 2.1 percent of C, 1.7 to 2.0 percent of Si, 0.7 to 0.9 percent of Mn, 0.01 to 0.02 percent of S, 0.05 to 0.07 percent of P, 0.1 to 0.22 percent of Cu, 0.12 to 0.28 percent of Cr, 0.006 to 0.009 percent of Sb, 0.04 to 0.08 percent of Mg, 0.02 to 0.45 percent of Re and the balance of Fe. The ball-milling iron casting has higher strength and higher elongation rate; casting performance is improved; the efficiency of the metal material is brought into full play; and the application requirement of heavy vehicle on driving axle shell and bracket casting is met. The invention further discloses a manufacturing method thereof.

Owner:TAIHU AIJIE MACHINE CASTING

High-yield-point white cast iron and manufacturing method thereof

The invention discloses high-yield-point white cast iron and a manufacturing method thereof and belongs to the technical field of iron-carbon alloys. The high-yield-point white cast iron comprises chemical components including, by mass percent, 7.7%-18% of C, 3%-15% of Si, 3.5%-6.5% of Mn, not more than 0.006% of P, not more than 0.005% of S and the balance Fe. The components are novel, the manufacturing process is reasonable and clear, the chemical component proportion of the white cast iron is provided, the form of carbide is improved in an isothermal cooling and aging manner, the yield point of a cast is increased, the high-yield-point white cast iron is easier to manufacture, the mechanical performance of the white cast iron can be greatly improved, and alternating loads and other theusing occasions can be met.

Owner:靖江市新东机械零部件制造有限公司

Alloy steel gear capable of reducing gear face plastic deformation

InactiveCN107435119AReduce wearNovel componentsSolid state diffusion coatingFurnace typesUltimate tensile strengthGear tooth

The alloy steel gear that can reduce the plastic deformation of the tooth surface belongs to the field of powder metallurgy technology. The components and weight percentage of the gear are: C 1.2-1.6%, Si 1.05-1.8%, Mn 0.125-0.325%, Cr 0.03-0.06% , W 0.015~0.185%, S 0.1~0.3%, P 0.12~0.325%, Zn 0.013~0.021%, Ti 0.005~0.018%, and the rest is Fe with metallographic structure of ferrite + austenite and unavoidable Impurities. The surface carburizing treatment of the present invention improves the surface hardness of the gear, and the surface quenching treatment improves the hardness of the gear teeth and the surface strength of the gear teeth, reduces the wear of the tooth surface, and improves the gear's hardness through normalizing and tempering treatment. The internal mechanical properties, toughness and fatigue strength have been greatly improved. Finally, the grinding treatment is adopted, especially the stress on the surface is passivated. The use requirements of speed occasions.

Owner:鲍凡凡

High-corrosion-resistance white cast iron and manufacturing method thereof

A high-corrosion-resistant white cast iron and a manufacturing method thereof belong to the technical field of iron-carbon alloys. The chemical composition of the white cast iron in terms of mass percentage is as follows: C 21%-31%, Si 22%-30%, High carbon steel wire with Mn 3.5~6.5%, P<0.006%, S<0.005%, and the rest is Fe. The composition of the invention is novel, the production process is reasonable and clear, it provides the chemical composition ratio of the high-temperature-resistant and wear-resistant white cast iron, improves the shape of the carbide, improves the hardness and wear resistance of the casting, and strengthens the support of the matrix to the carbide It also stabilizes the high temperature hardness and wear resistance of castings; reduces the crack tendency of castings; improves the hardenability of castings. Its corrosion resistance is also better than that of existing white iron castings, and it is especially suitable as a wear-resistant workpiece working under high temperature conditions.

Owner:鲍凡凡

White cast iron with anti-fracture property and heat treatment technology

White cast iron with anti-fracture performance and heat treatment process, belonging to the technical field of iron-carbon alloys, the chemical composition in terms of mass percentage is as follows: C 2.0-2.8%, Si 0.6-0.9%, Cr 6.0-7.0%, Mn 0.2 ~0.38%, Ni 3.6~4.2%, Mo ≤0.98%, P ≤0.045%, S ≤0.06%, Fe balance. The composition of the invention is novel, the production process is reasonable and clear, through two times of quenching and tempering, and the quenching and tempering temperature is determined through experiments, and the treatment is carried out at this temperature, which can greatly improve the toughness and wear resistance of nickel hard white cast iron , so that the cast iron is not easy to produce cracks during use, which improves the service life. The hardness after heat treatment in the as-cast state reaches 53HRC, and greatly saves the processing time of heat treatment and improves production efficiency.

Owner:鲍凡凡

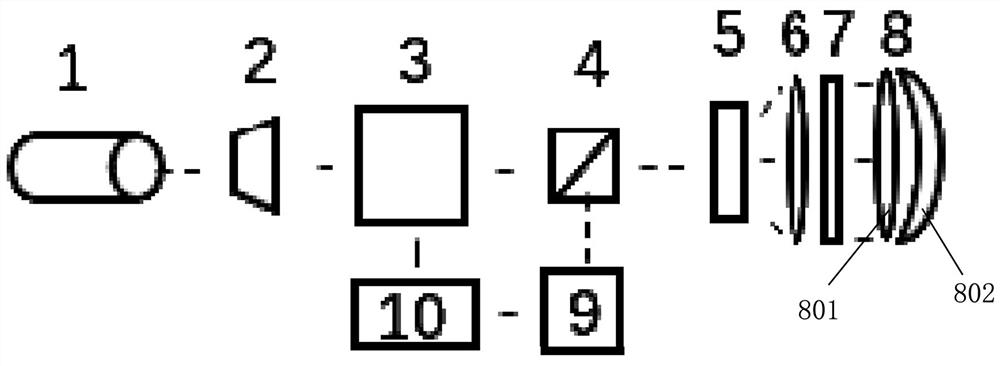

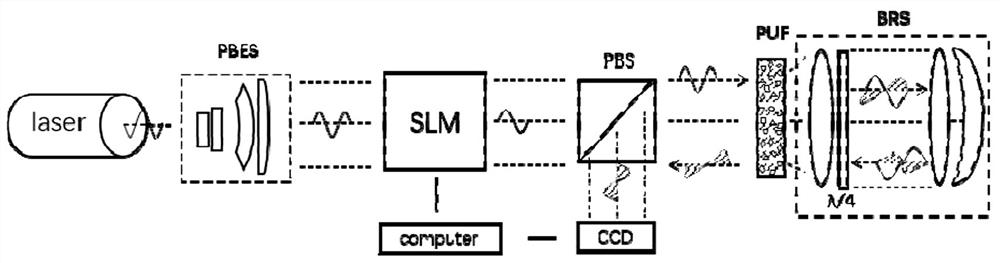

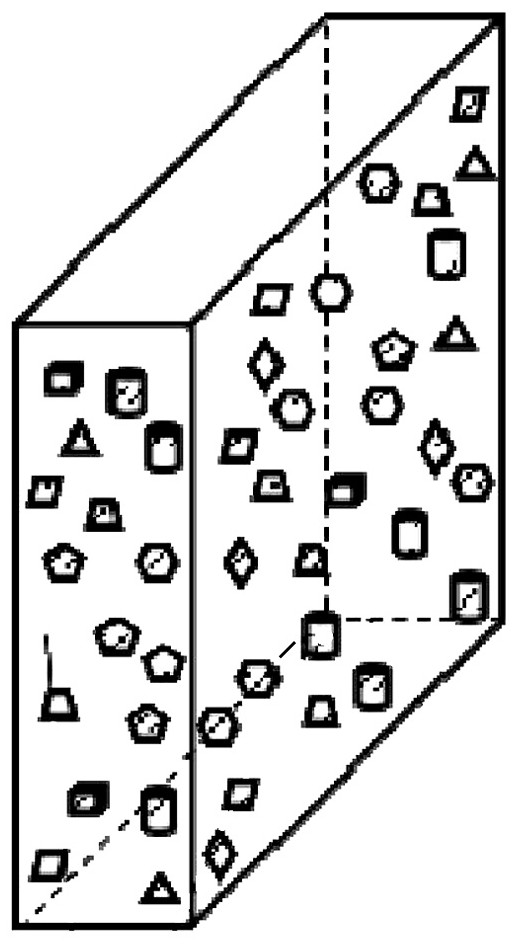

Two-way interference type identity verification system based on photorefractive crystal PUF

ActiveCN113541964AImprove securityImprove completenessUser identity/authority verificationElectromagnetic transmittersBeam splittingPrism

The invention discloses a two-way interference type identity authentication system based on a photorefractive crystal PUF, and relates to the field of information security and identity authentication. The system comprises a light intensity modulation module, a polarization beam splitting module, an optical PUF module and a light beam lens module which are sequentially arranged from left to right, and also comprises a data processing module, wherein the light intensity modulation module comprises a light source, a beam expanding collimation system (PBES) and a spatial modulator (SLM); the polarization beam splitting module comprises a polarization beam splitting prism (PBS); the optical PUF module is composed of two glass plates and zirconium-iron double-doped lithium niobate LiNbO3Fe, Zr granular crystals; the light beam lens module comprises a positive lens I, a 1 / 4 lambda wave plate and a reflector group; the reflector group is composed of a positive lens II and a concave mirror; and the data processing module comprises a CCD camera and a computer; the CCD camera is connected to a computer through a serial data port; and the computer includes an extraction program. According to the invention, the identity verification system has higher security and decoding resistance.

Owner:TAIYUAN UNIV OF TECH

Self-lubricating and high-wear-resistance non-metal sealing sliding block and manufacturing method thereof

The invention discloses a self-lubricating and high-wear-resistance non-metal sealing sliding block and a manufacturing method thereof, and belongs to the field of sealing materials. The sealing sliding block comprises the following components in parts by weight: 40-50 parts of non-metal inorganic fiber yarn, 40-55 parts of self-lubricating resin and 3-5 parts of inorganic ceramic powder. The manufacturing method of the sealing sliding block comprises weaving, mixing, dipping, presintering, alternate laying, hot pressing, demolding and the like. The invention further discloses a T-shaped sealing sliding block for an air pump, and efficient vacuumizing can be achieved after a unit operates. The sealing sliding block prepared by the invention has excellent self-lubricating property and wearresistance and is high in rigidity, not prone to bending and capable of meeting the sealing requirement under the high-speed and dry friction working condition, gas in a pipeline connected with the air pump cavity can be rapidly exhausted after a unit operates, so that pipeline vacuum is achieved and the purpose of rapidly pumping other media is achieved, the whole operation process is efficient and energy-saving, and no pollution is caused to other media and the environment.

Owner:合肥一密科技有限公司

High-weatherability BOPP release film and preparation method thereof

InactiveCN107722447AGood weather resistanceImprove mechanical propertiesMasterbatchManufacturing technology

A BOPP release film with high weather resistance and its preparation method belong to the field of film manufacturing technology. The production process of the present invention is reasonable and clear. The present invention adopts BOPP as the main component of the composite film, and adds BOPP weather-resistant masterbatch at the same time, so that the prepared The weather resistance of the release film is greatly enhanced, and nano-silica is added at the same time, which can improve the mechanical properties of the product and increase its tensile strength by about 150%. In this way, the prepared product is a kind of product with good weather resistance The release film with excellent performance and mechanical properties further expands the application range; it is also convenient for the next step to disperse the matrix and inorganic fillers evenly, and the components are mixed evenly, and the prepared film material is balanced, and natural latex is also added to enhance the viscosity and Flexibility, and finally add some auxiliary additives such as defoamers and thickeners, so that the prepared Harima material has more balanced and superior performance.

Owner:YANGZHOU ALVIN FILM

Magnesium alloy and manufacturing method thereof

A magnesium alloy and a manufacturing method thereof, belonging to the technical field of metal materials and heat treatment, the magnesium element, whose weight percentage is 85% of the total composition of the alloy; the lithium element, whose weight percentage is 12% of the total alloy composition; the zinc element, whose weight percentage The percentage is 2% of the total composition of the alloy; the weight percentage of manganese element is 0.3% of the total composition of the alloy; the weight percentage of silicon element is 0.2% of the total composition of the alloy. The composition of the invention is novel, and the production process is reasonable and clear, so that after the alloy melt is solidified into an ingot and extruded into a magnesium-lithium alloy material, while reducing the material density, its overall structure is uniform and fine, and lithium and aluminum elements will The aluminum-lithium phase is precipitated by the reaction, or the magnesium silicide compound is precipitated by the reaction of the magnesium element and the silicon element, so as to improve the rigidity and strength of the magnesium alloy without damaging its ductility.

Owner:叶秀兰

High-hardness oil spray nozzle and manufacturing method thereof

InactiveCN107841690AEasy to manufactureNovel componentsFuel injection apparatusFurnace typesWorking lifeSpray nozzle

A high-hardness fuel injector and a manufacturing method thereof belong to the technical field of diesel engine equipment. The components of the fuel injector by mass percentage are as follows: C 0.7-2.11%, Cr 15-25%, Mo 0.5-1.7%, Si≤0.08%, Ni 0.05~0.2%, Mn 0.07~1.02%, P≤0.08%, S≤0.06%, the balance is Fe. The composition of the invention is novel, and the manufacturing process is reasonable and clear. In the process, thermal insulation and cooling after pouring are adopted to prevent the thermal cracking tendency of the fuel injector. Compared with the traditional manufacturing method of the fuel injector, the components of the fuel injector of the present invention It is more reasonable, has a longer working life, and is easier to manufacture. It greatly improves the mechanical properties of the fuel injector and meets the needs of high temperature, high hardness and high wear resistance.

Owner:徐州艾梅尼克工程机械有限公司

Alloy steel gear resistant to fatigue pitting

InactiveCN107435724ANovel componentsThe production process is reasonable and clearPortable liftingGearing elementsLedeburiteUltimate tensile strength

An alloy steel gear anti-fatigue pitting belongs to the technical field of powder metallurgy. The components of the gear and their weight percentages are: C 0.2-4.3%, Si 0.7-1.2%, Mn 0.125-0.25%, Cr 0.01-0.03% , W 0.015~0.125%, S 0.1~0.2%, P 0.25~0.35%, Zn 0.015~0.025%, Ti 0.015~0.018%, and the rest is Fe with metallographic structure of ferrite + ledeburite and unavoidable Impurities. After the gear is formed, the surface carburizing treatment, quenching treatment, normalizing, tempering and grinding are carried out successively, which improves the internal mechanical properties of the gear, its toughness and fatigue strength have been greatly improved, and the mechanical properties of the surface are improved, especially The stress on the surface is passivated, the service life of the gear is greatly improved, and it meets the needs of various high-load and high-speed applications.

Owner:周文前

Nodular cast iron with high-temperature resistance and high abrasion resistance

The invention belongs to the technical field of casting and discloses nodular cast iron with high-temperature resistance and high abrasion resistance. The nodular cast iron with high-temperature resistance and high abrasion resistance is composed of, by mass, 2.77% of carbon, 2%-3% of chrome, 3%-6% of manganese, 1.2%-1.5% of silicon, 0.1%-0.5% of vanadium, 0.05-0.1% of boron, 0.5%-0.8% of tungsten, 0.03%-0.04% of magnesium, 0.003%-0.004% of aluminum, 0.6%-0.8% of copper, 0.3%-0.4% of phosphorus, less than 0.05% of impurities, and the balance iron. The nodular cast iron with high-temperature resistance and high abrasion resistance has the beneficial effects that the constituents are novel, the manufacturing process is reasonable and clear, the nodular cast iron is adopted as a main constituent, the nodular cast iron with the high-temperature strength and excellent oxidative resistance and ductility can be manufactured with low cost by means of the composition, the production cost of enterprises is reduced, the production efficiency and the abrasion resistance of the cast iron are improved, and the service life of the cast iron is effectively prolonged.

Owner:田静

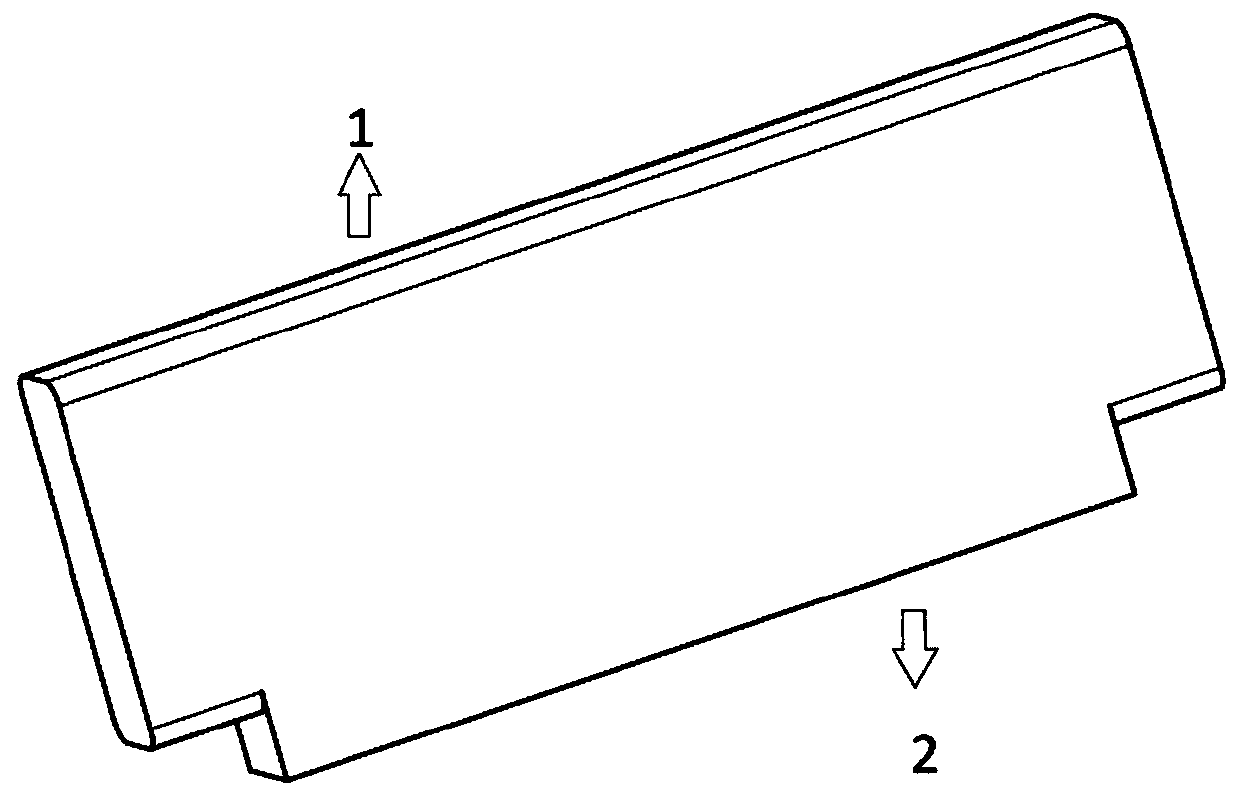

Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m

PendingCN111349405AThe production process is reasonable and clearImprove smoothnessPolyurea/polyurethane coatingsFilm/foil adhesive release linersPolymer chemistrySilicone oil

The invention discloses a preparation method of a PET low-longitudinal-grain release film with a thickness of less than 38 [mu]m. The method comprises the following steps: respectively coating the front side surface and the back side surface of a PET base film with a thickness of 20 [mu]m with a release agent liquid and a silicone oil surface liquid, and then carrying out resistance test. According to the invention, after the characteristics of the release film are not influenced, the thickness of the release film is greatly reduced by selecting the thin base film and reducing the coating liquid on the surface of the release film.

Owner:扬州万润光电科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ced8d44b-8d62-4ac5-b0e5-a5eb04bcb456/RE-FDA0002003012960000011.png)

![Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ced8d44b-8d62-4ac5-b0e5-a5eb04bcb456/RE-FDA0002003012960000021.png)

![Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m Preparation method of PET low-longitudinal-grain release film with thickness of lower than 38 [mu]m](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ced8d44b-8d62-4ac5-b0e5-a5eb04bcb456/RE-GDA0002003012970000021.png)