A self-lubricating, highly wear-resistant non-metallic sealing slider and its manufacturing method

A sealing slider, non-metallic technology, applied in engine sealing, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of inability to dry-run air pumps, low toughness of graphite materials, and insufficient self-lubricating properties , to achieve the effect of breaking through the shackles of formula design and production methods, increasing the hardness, and making the production methods simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] S1, weaving

[0044] Get the alkali-free glass fiber yarn of 45 parts by weight, weave on weaving equipment, become the fiber sheet of plain weave, the thickness of fiber sheet is 0.1mm, and the pore size is 0.5mm;

[0045] S2, mixing

[0046] 3 parts by weight of silicon nitride powder (particle size 20nm) and 75 parts by weight of polytetrafluoroethylene resin emulsion (solid content is 55%) are metered into the mixing chamber of the ultrasonic stirring homogenizer, the equipment is turned on, and mixed for 10 minutes , observe with the naked eye whether there is agglomeration phenomenon, if not, get a mixed emulsion;

[0047] S3, impregnation, pre-sintering

[0048] Measure the mixed emulsion prepared by S2 into the pool of the dipping heat treatment machine, put the glass fiber woven sheet into the designated position of the pool, start impregnation, take it out from the pool after soaking for 3 minutes, and enter the drying area at 100 °C , dry for 8 minutes, th...

Embodiment 2

[0052] S1, weaving

[0053] Get 43 parts by weight of carbon fiber yarn and weave it on a weaving device to form a twill-shaped carbon fiber sheet with a thickness of 0.1mm and a pore size of 0.5mm;

[0054] S2, mixing

[0055] 5 parts by weight of silicon oxide powder (particle diameter 20nm) and 65 parts by weight of polytetrafluoroethylene resin emulsion (solid content is 65%) are metered into the mixing chamber of the ultrasonic stirring homogenizer, the equipment is turned on, and mixed for 10 minutes. Observe with the naked eye whether there is any agglomeration, and if there is no agglomeration, a mixed emulsion will be obtained;

[0056] S3, impregnation, pre-sintering

[0057] Pour the mixed emulsion into the material tank of the dipping and heat treatment machine, put the carbon fiber woven sheet into the designated position of the material tank, and start to impregnate. Then enter the drying zone at 320°C, bake for 5 minutes, and finally enter the pre-sintering z...

Embodiment 3

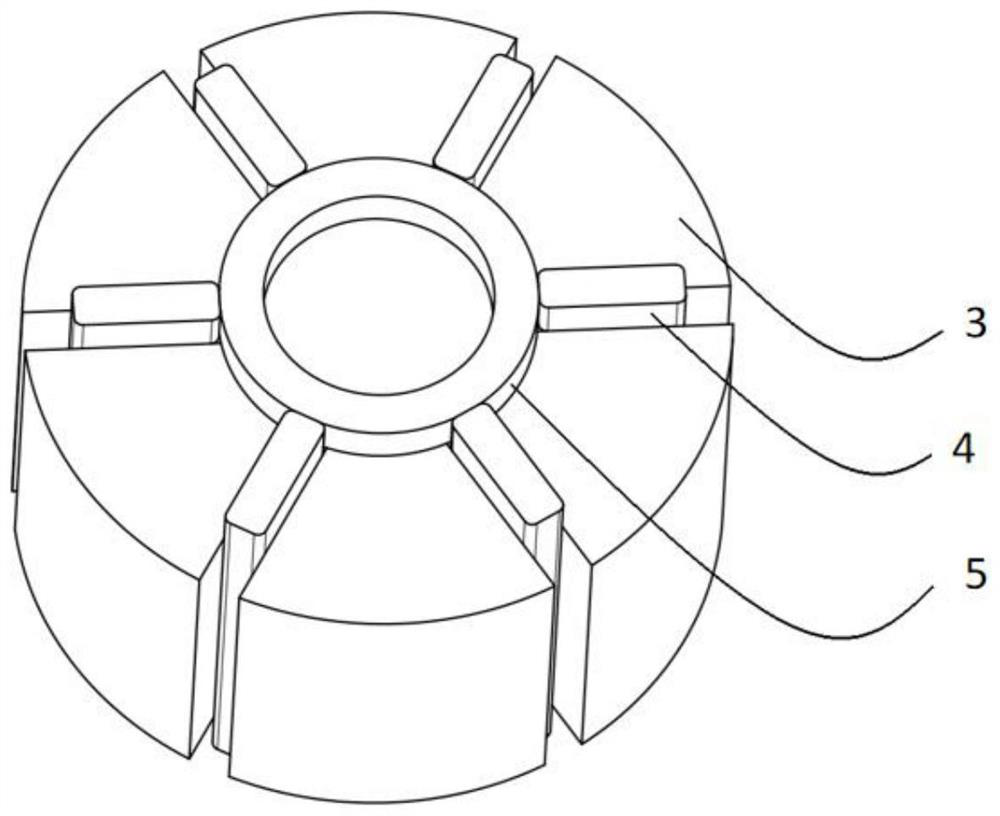

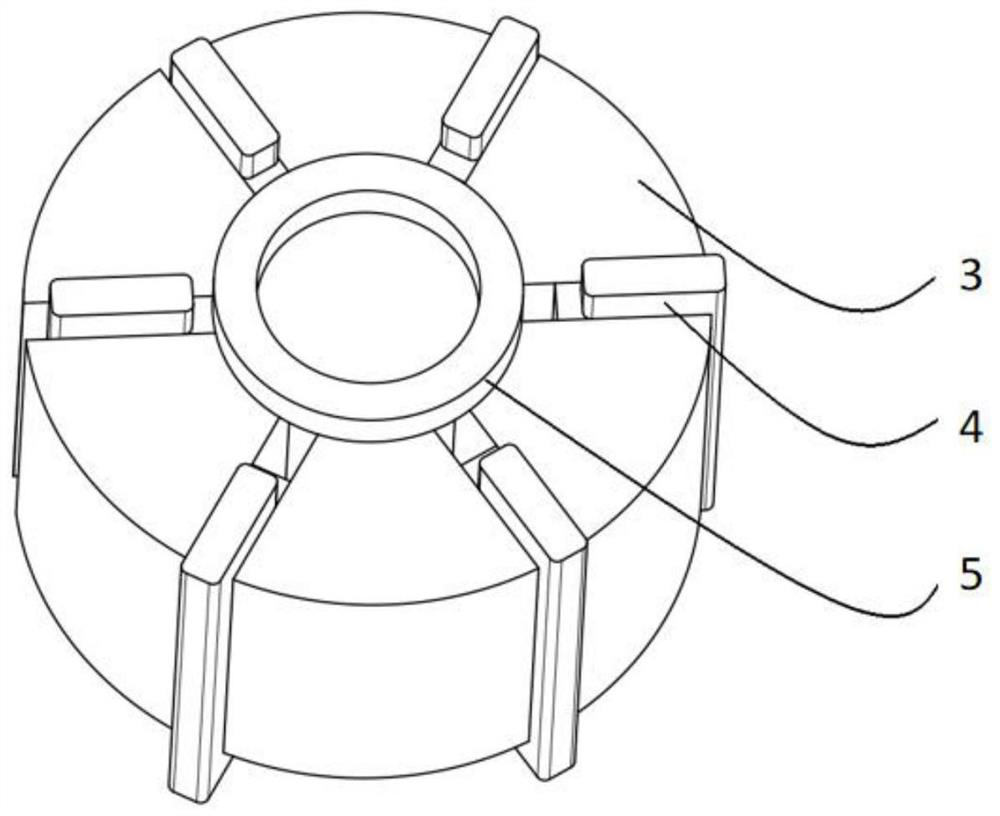

[0079] Such as figure 1 , install the "T" shaped seal slider produced by the embodiment of the present invention in the axial groove of the eccentric rotor 3, the force-bearing surface 2 faces the center of the eccentric rotor 3, the sealing surface 1 faces the cylinder, and the force-bearing surface 2 is close to In spacer ring 5, see the specific location figure 2 . Such as image 3 As shown, when the eccentric rotor 3 starts to rotate, the sealing slider 4 moves toward the cylinder side under the action of centrifugal force, the sealing surface 1 is in contact with the cylinder, and the moving distance of the sealing slider 4 in each groove is different. Under the action of the cylinder, a circular trajectory is always maintained, and a certain space is formed between the eccentric rotor 3, the sealing slider 4 and the cylinder, and the volume of the space changes periodically, so as to achieve the effects of vacuuming and gas compression.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com