Gray iron oxide pigment dry-method manufacturing process

A technology of iron oxide pigments and iron oxide black, which is applied in the treatment of inorganic pigments, chemical instruments and methods, and the treatment of dyed low-molecular organic compounds, and can solve the problems of unsatisfactory properties of iron oxide pigments, poor dispersion and suspension, and sedimentation speed. Fast and other problems, to achieve the effect of clear production process, slow down the sedimentation speed, and improve the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

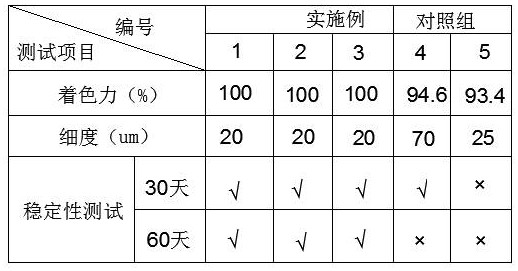

Examples

Embodiment 1

[0024] A dry process for producing gray iron oxide pigments, comprising the following constituent materials in parts by weight: 100 parts of iron oxide black, 10 parts of titanium dioxide, 8 parts of body material, 5 parts of aluminizing agent, and 4 parts of polyhydric alcohol.

[0025] A kind of gray iron oxide pigment dry method manufacturing process is characterized in that: comprises the following steps:

[0026] A. Add titanium dioxide, iron oxide black, and body materials in proportion to the batching bin and mix to obtain mixture a;

[0027] B. Send the mixture a into the ball mill, add the raw materials to about 90% of the capacity of the ball mill, and gradually increase the speed of the ball mill;

[0028] C. When the ball milling time reaches 2 / 3 of the total time, add an aluminizing agent to stabilize the color matching;

[0029] D. After the ball mill processing is finished, take out the mixture in the ball mill, pulverize it with a pulverizer, and then filter i...

Embodiment 2

[0033] A gray iron oxide pigment, comprising raw materials in parts by weight: 90 parts of iron oxide black, 9 parts of titanium dioxide, 6.5 parts of body material, 4 parts of aluminizing agent, and 3 parts of polyhydric alcohol.

[0034] A kind of gray iron oxide pigment dry method manufacturing process is characterized in that: comprises the following steps:

[0035] A. Add titanium dioxide, iron oxide black, and body materials in proportion to the batching bin and mix to obtain mixture a;

[0036] B. Send the mixture a into the ball mill, add the raw materials to about 90% of the capacity of the ball mill, and gradually increase the speed of the ball mill;

[0037] C. When the ball milling time reaches 2 / 3 of the total time, add an aluminizing agent to stabilize the color matching;

[0038] D. After the ball mill processing is finished, take out the mixture in the ball mill, pulverize it with a pulverizer, and then filter it with a sieve;

[0039] E. The large particles ...

Embodiment 3

[0042] A gray iron oxide pigment, comprising raw materials in parts by weight: 100 parts of iron oxide black, 10 parts of titanium dioxide, 8 parts of body material, 5 parts of aluminizing agent, and 4 parts of polyhydric alcohol.

[0043] A kind of gray iron oxide pigment dry method manufacturing process is characterized in that: comprises the following steps:

[0044] A. Add titanium dioxide, iron oxide black, and body materials in proportion to the batching bin and mix to obtain mixture a;

[0045] B. Send the mixture a into the ball mill, add the raw materials to about 90% of the capacity of the ball mill, and gradually increase the speed of the ball mill;

[0046] C. When the ball milling time reaches 2 / 3 of the total time, add an aluminizing agent to stabilize the color matching;

[0047] D. After the ball mill processing is finished, take out the mixture in the ball mill, pulverize it with a pulverizer, and then filter it with a sieve;

[0048] E. The large particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com