Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "The preparation method is safe and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

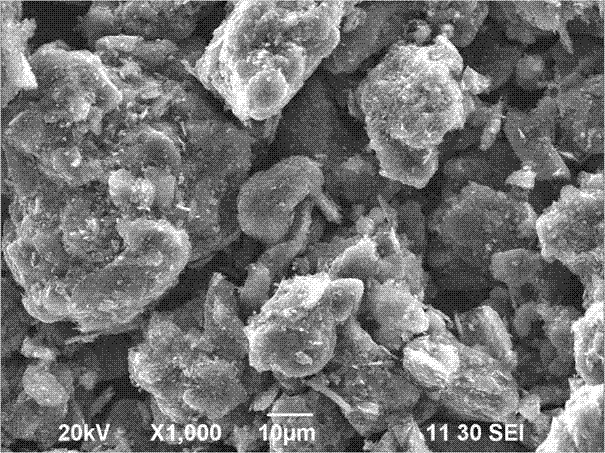

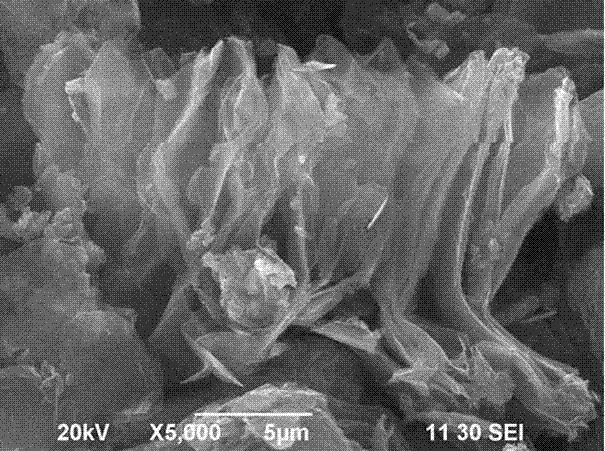

Preparation method of silicon-based/graphene composite

ActiveCN103094573AEvenly distributedDoes not pose a health and safety riskCell electrodesLithium-ion batteryElectric field

The invention belongs to the technical field of new materials for a lithium ion battery, and particularly relates to a preparation method of a silicon-based / graphene composite. The preparation method comprises the following steps of: taking a pole of the silicon-based / graphene composite as a working electrode and the pole of a lithium source-containing material as a counter electrode, assembling a battery together with propylene carbonate and lithium salt-containing electrolyte and a diaphragm; charging and discharging the battery to co-embed lithium ions and carbonate propylene ester into graphite layers under the action of electric field, so as to enable the graphite layers to be stripped; dismantling the battery, placing a lithium-embedded silicon-based / graphene composite precursor into dimethyl carbonate solution for soaking, and vaccumizing and drying; and conducting ultrasonic cleaning and lithium removal in diluted hydrochloric acid, vacuumizing and filtering, drying, and burning under inert gas atmosphere. Compared with the prior art, the preparation method is simple and controllable in procedures, low in cost, safe and environment-friendly and incapable of causing environment and health security risk; and a great deal of hydrogen can also be collected in the preparation process of the composite, so that economic benefits are obvious.

Owner:DONGGUAN AMPEREX TECH

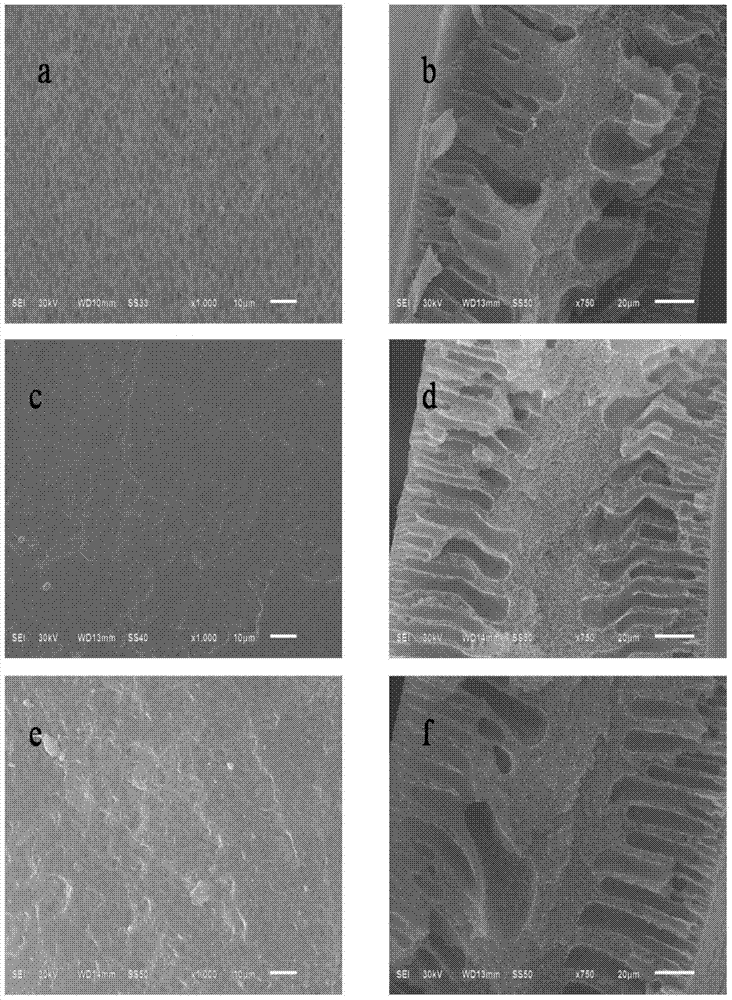

Preparation method of porous metal film

InactiveCN109745870AStrengthen the bridging effectLess prone to defectsSemi-permeable membranesFoaming agentMass ratio

The invention relates to a preparation method of a porous metal film. The preparation method specifically comprises the following steps: respectively weighing 3-10 percent by weight of bonding agent,0.45-1 percent by weight of dispersing agent, 0.05-0.3 percent of a de-foaming agent and the balance of deionized water, wherein the sum of the mass percents of the components is 100 percent; mixing and dissolving the weighted bonding agent, dispersing agent, de-foaming agent and deionized water to prepare slurry; pouring metal powder and the prepared slurry into a stirring tank according to the mass ratio of 1:(0.8-1.5) and uniformly mixing to prepare mixed liquid; spraying the prepared mixed liquid onto the surface of a rotary tubular porous metal supporting body by adopting a spray gun, disassembling a metal film after the completion of absorption and successively performing drying, degreasing and sintering treatment on the metal film to prepare the porous metal film. The porous metal film prepared by the preparation method provided by the invention is high in permeability, good in film layer uniformity, high in filtering precision and high in finished product rate.

Owner:WESTERN BAODE TECH CO LTD

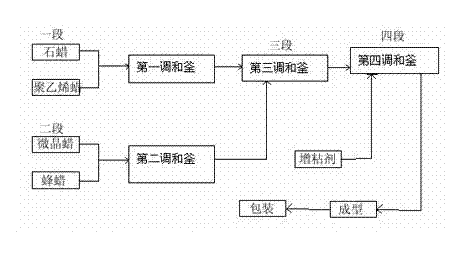

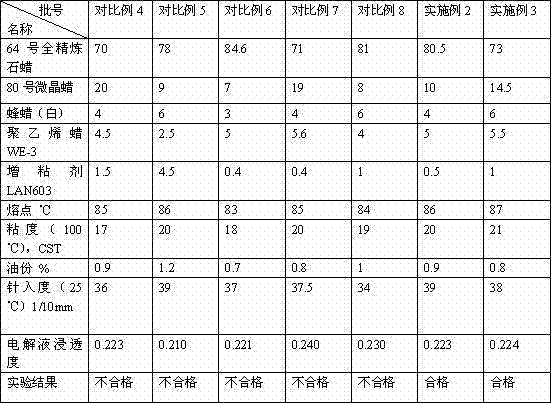

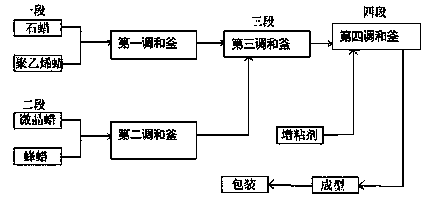

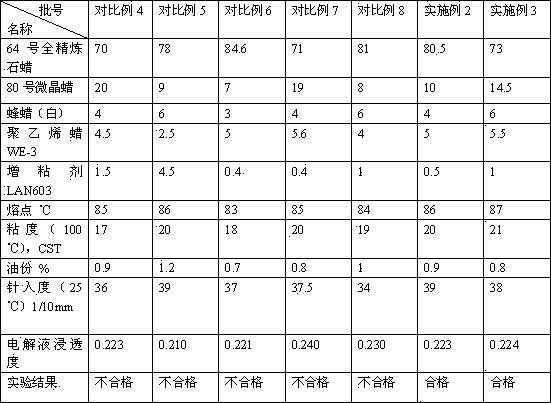

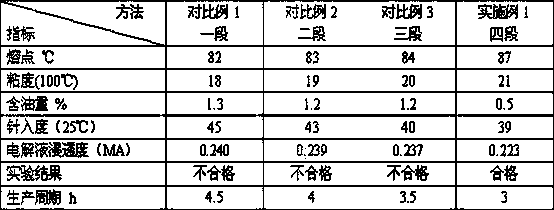

Special-type sealing wax

The invention discloses a special-type sealing wax which comprises the following raw materials in percentage by weight: 73-80.5% of high-meltiong-point paraffin, 10-14.5% of high-melting-point microcrystalline wax, 4-6% of beeswax, 5-5.5% of polyethylene wax and 0.5-1% of tackifier. The preparation method has the advantages of high safety, environmental protection and low energy consumption; and the special-type sealing wax disclosed by the invention has the advantages of cheap and accessible raw materials and high product quality, can satisfy the requirements for sealing waxes in dry batteries as well as special-type waxes for fiber communication cables and oil transport pipeline sealing hot-melt adhesive tapes, and has wide application prospects.

Owner:上海绿菱特种蜡制品厂

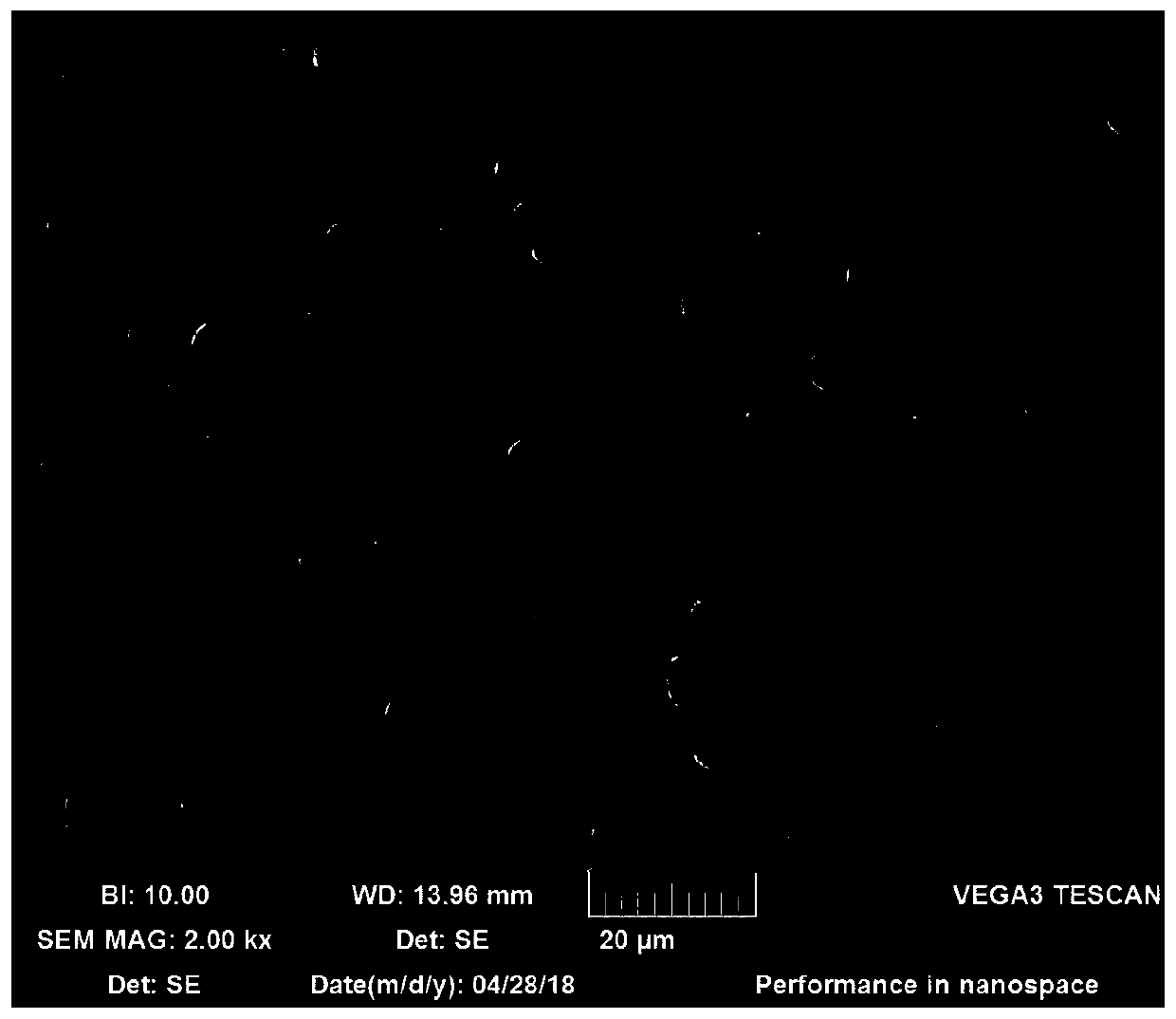

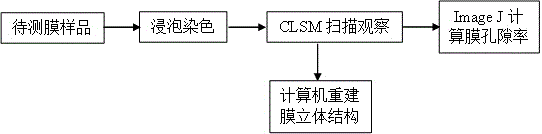

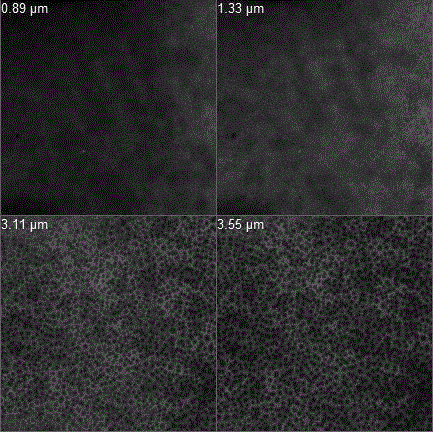

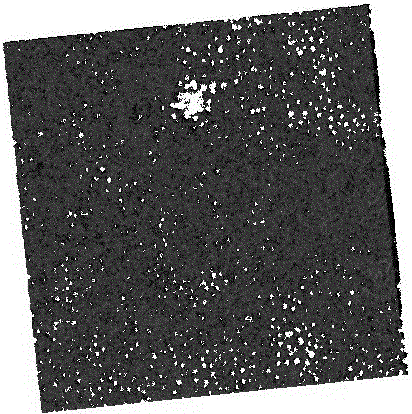

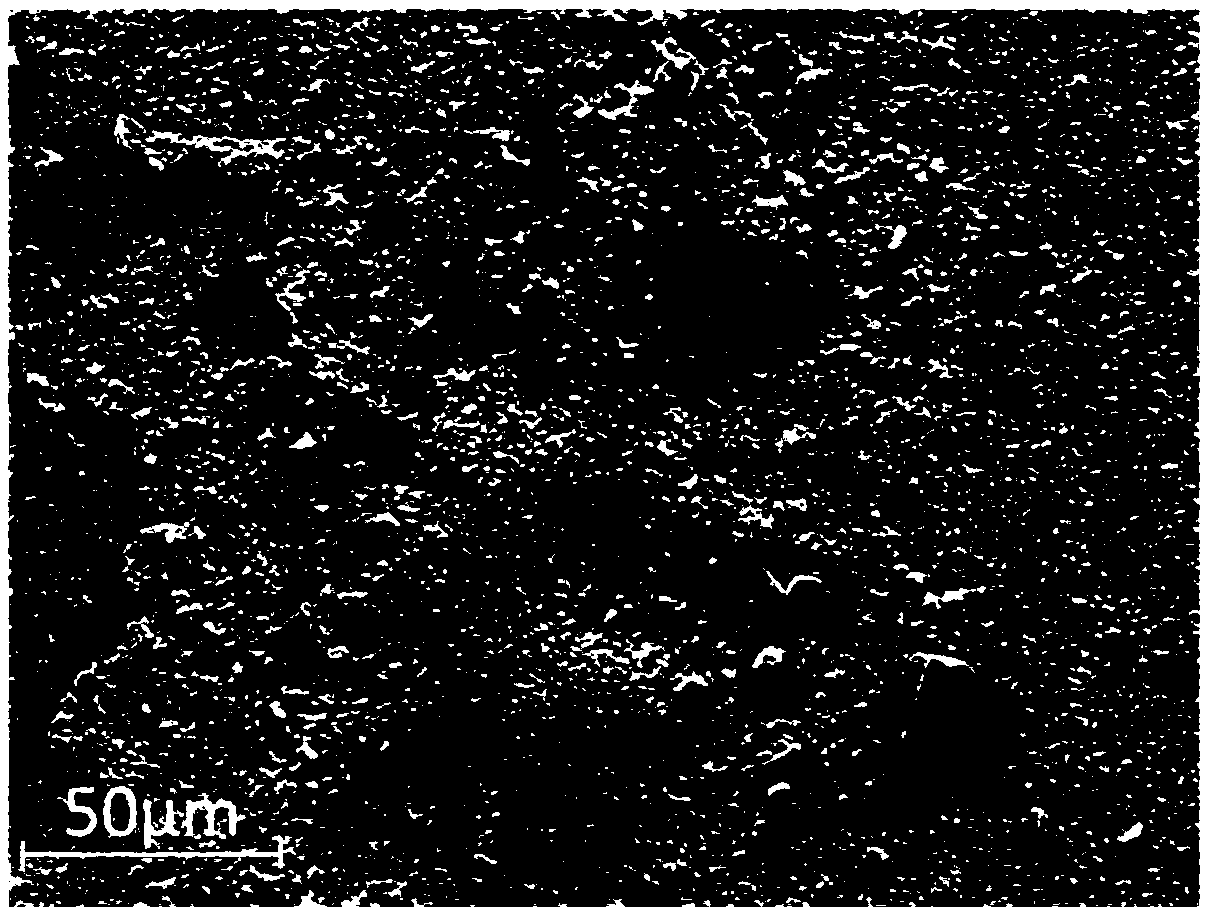

Membrane pore structure and porosity testing method based on confocal laser scanning microscopy

InactiveCN106353234AUniform dyeingSimple and fast manufacturing methodPermeability/surface area analysisPorosityFluorescence

The invention provides a membrane pore structure and a porosity testing method based on CLSM (confocal laser scanning microscopy), comprising: preparing a sample, observing the sample, processing data and the other steps. Traditional testing methods include scanning electron microscopy, transmission electron microscopy, mercury intrusion method, nitrogen adsorption method and other methods and have their respective disadvantages; for example, high pressure required in the testing process of the mercury intrusion method may deform membrane structure; sample preparation in the transmission electron microscopy and scanning electron microscopy is high in time consumption and results in big damage to samples. Membrane pore structure and porosity are tested by means of confocal laser scanning microscopy, it is only required to perform single dyeing on a sample under test with fluorescent dye, information in the sample can be acquired without destroying the sample, operating is simple, and little damage is caused to the sample; in addition, sample testing herein has no need for drying, namely, a sample can be tested in an environment similar to a membrane when a liquid separation membrane is under test, and the results are more accurate and reliable.

Owner:王凯军 +2

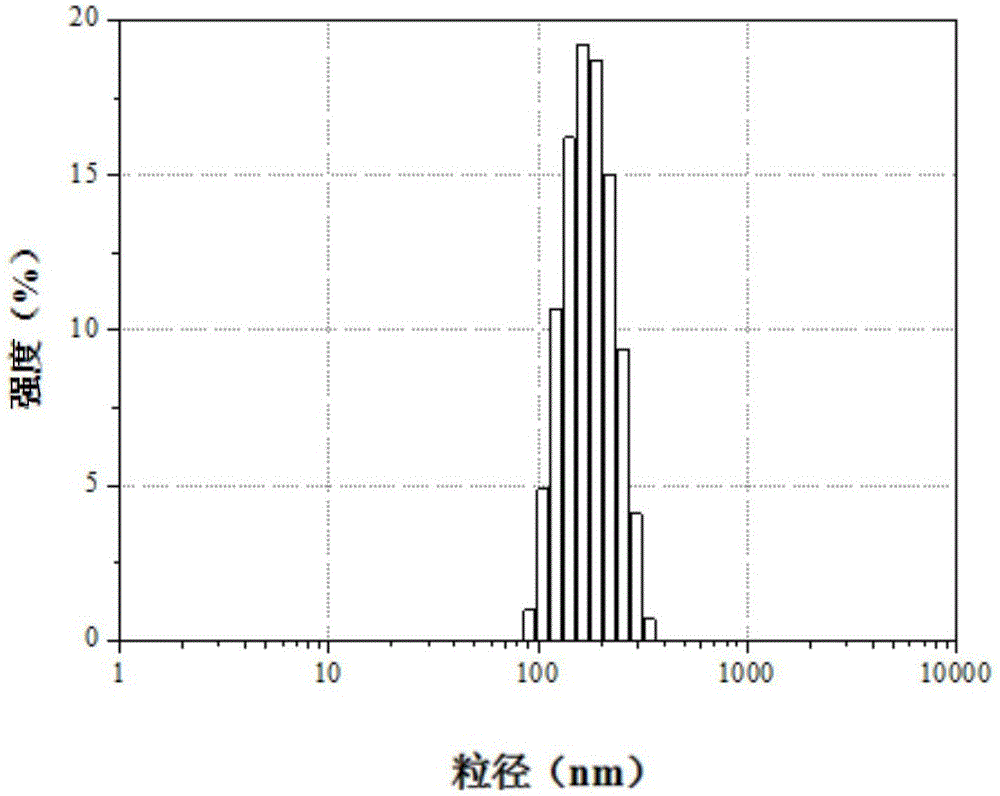

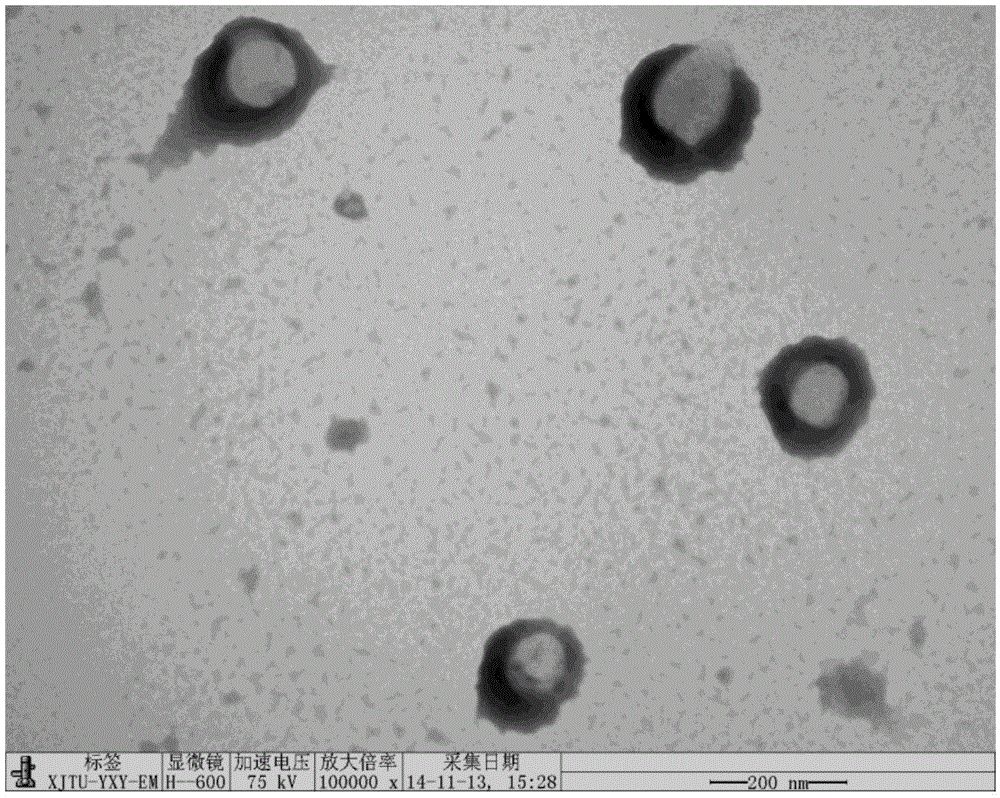

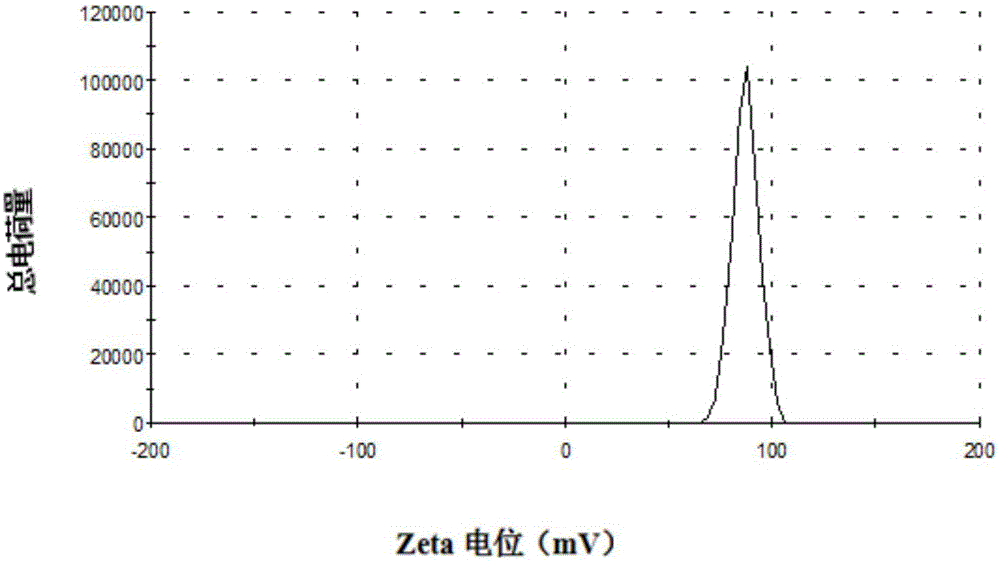

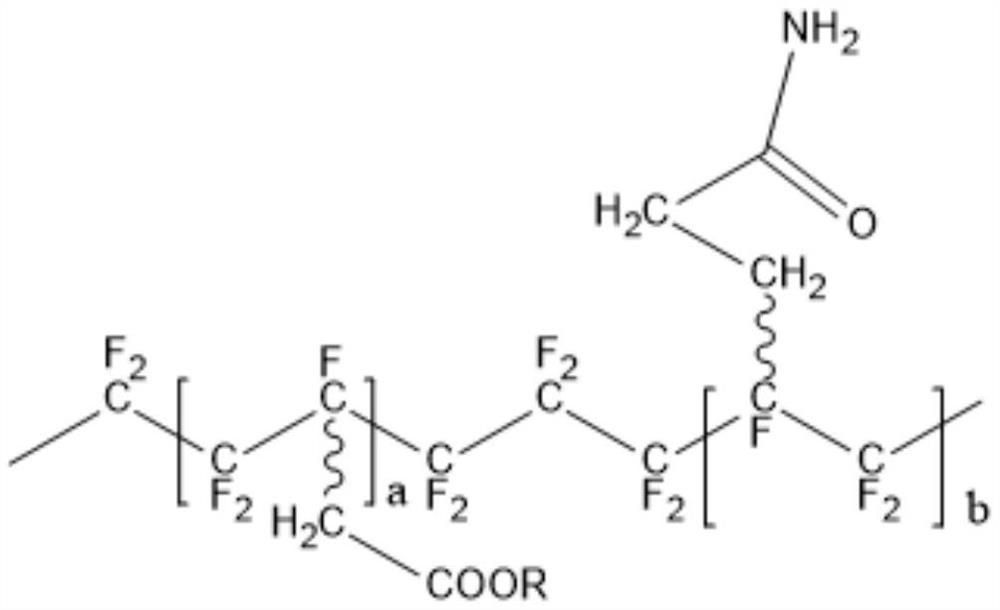

Preparation method of cationic type fluorine-containing soap-free emulsion

The invention discloses a preparation method of a cationic type fluorine-containing soap-free emulsion. The preparation method comprises the steps: using azodiisobutyronitrile, 2-(dimethylamino)ethyl methacrylate, 1,4-dioxane, S-1-dodecyl-S'-(alpha,alpha''-dimethyl-alpha''-acetic acid)trithiocarbonate to prepare poly[2-(dimethylamino)ethyl methacrylate]; purifying poly[2-(dimethylamino)ethyl methacrylate] for two times with n-hexane, and drying to obtain a product after purification; dissolving the product after purification in diluted hydrochloric acid, and forming a mixed solution; preparing an amphiphilic block copolymer from the mixed solution, 2,2'-azobis[2-methylpropionamidine]dihydrochloride, a hexafluorobutyl acrylate agent and deionized water; and combining the prepared mixed monomer with the amphiphilic block copolymer and an initiator aqueous solution to prepare the cationic type fluorine-containing soap-free emulsion. The fluorine-containing soap-free emulsion obtained by the preparation method disclosed by the invention has the characteristics of good stability, small latex particle size, and core-shell structure.

Owner:SHAANXI UNIV OF SCI & TECH

Low-temperature wool staining method

The invention discloses a low-temperature wool staining method. The method includes the steps that wool is soaked in a plant staining agent to be heated to 50 DEG C to 60 DEG C, mordant is added 25 to 35 min later, then the wool is taken out after being kept at the temperature of 50 DEG C to 60 DEG C for 25 min to 35 min, the wool is cleaned up with clean water after being naturally air-dried, and the stained wool can be obtained. The low-temperature wool staining method is safe and environmentally friendly, the used staining agent is a plant staining agent which is natural and free of toxin, the stained wool is natural in color and luster, bright, high in color fastness and the like, the comprehensive performance of the stained wool is improved, and the stained wool is free of pungent odor, allergy, and heavy metal.

Owner:贵州省工程复合材料中心 +1

Flame-retardant water-based emulsion for coating glass fiber sleeve and preparation method of emulsion

The invention discloses a flame-retardant water-based emulsion for coating a glass fiber sleeve and a preparation method of the emulsion. The flame-retardant water-based emulsion is obtained through emulsion polymerization of an acrylate soft monomer, a hard monomer, a hydrophilic functional monomer, an organic silicon monomer and a bromine-containing flame retardant monomer, wherein the bromine-containing flame retardant monomer is one or more of 2,4,6-tribromophenyl methacrylic acid ester, 2,4,6-tribromophenyl maleimide, 2,4,6-tribromophenyl allyl ether, dibromostyrene and tribromostyrene. The invention also discloses a glass fiber sleeve coating material containing the flame-retardant water-based emulsion. The flame-retardant water-based emulsion is good in stability and small in grain size; the formed latex film is excellent in water resistance, mechanical properties and flame retardant property; as a result, even though the coating material added with a small amount of flame retardant is applied to coating the glass fiber sleeve, a coating layer which is excellent in flexibility and insulativity and high in flame retardant rating can be obtained, and the coating layer is applicable to occasions having high requirement for the flame retardant property.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

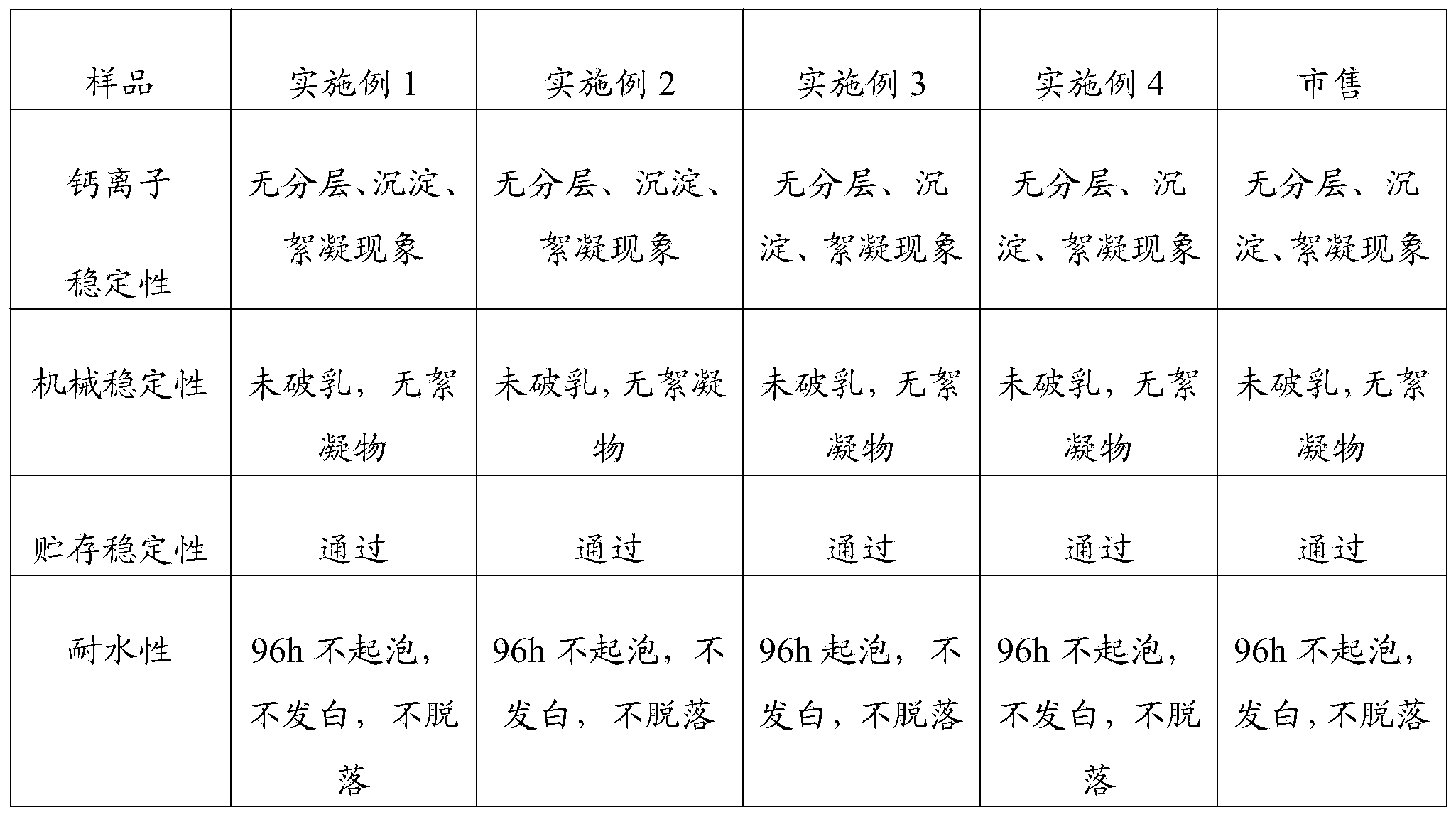

Special waterproof anti-slip coating for outer wall as well as preparation method and application of special waterproof anti-slip coating

PendingCN114163884AHas strong sticky and anti-skid characteristicsCoating safety and environmental protectionCoatingsUltimate tensile strengthPolymer emulsion

The invention provides a waterproof non-slip coating special for an outer wall and a preparation method and application thereof, and relates to the technical field of building materials, the coating comprises the following components: 21-27 parts of modified asphalt, 1-2 parts of an anionic slow-breaking emulsifier, 40-50 parts of an organosilicon modified polymer emulsion, 0.2-0.5 part of a thixotropic agent, 0.2-0.5 part of a rheological agent, 0.1-0.2 part of a defoaming agent, 0.2-0.5 part of a silane coupling agent and 20-25 parts of water. The prepared coating has high bonding strength, water resistance and anti-sliding performance, is excellent in anti-sagging performance, very high in ductility and high in base layer deformation adaptability, and can be compatible with multiple types of coiled materials.

Owner:河南蓝翎环科防水材料有限公司

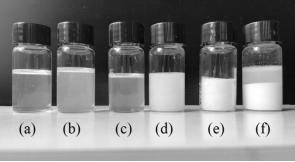

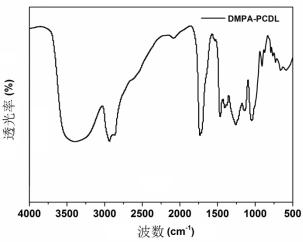

Preparation method of hydrophilic polycarbonate diol

The invention provides a preparation method of hydrophilic polycarbonate diol. The method specifically comprises the following steps: adding carbonate, diol and a hydrophilic monomer into a reaction kettle, carrying out ternary polymerization, adding a certain amount of catalyst and entrainer, gradually removing low-boiling-point byproducts generated in the reaction process by a fractionating device, gradually reducing reaction pressure, and carrying out staged reduced pressure distillation operation. According to the present invention, the segmented polymerization process is combined with theintroduction of the azeotropic solvent to promote the forward proceeding of the reaction, reduce the azeotropic temperature, avoid the escape of the azeotrope formed by the carbonic ester and the alcohol compound, and after the product achieves the ideal viscosity, the system is cooled to room temperature to obtain the waterborne polycarbonate diol product; and the technological process is simple, controllability and reproducibility are good, the product is free of micromolecular monomer residues and high in purity, and preparation of waterborne polyurethane with excellent performance is facilitated.

Owner:WEIFANG YUANLI CHEM

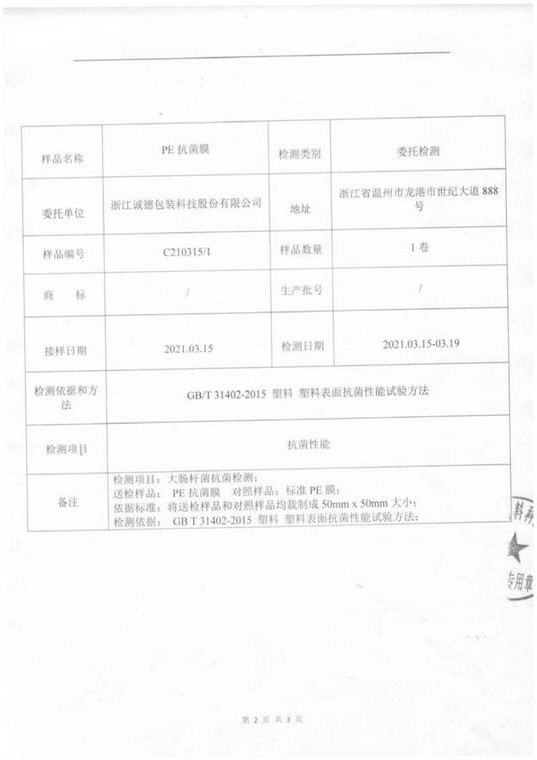

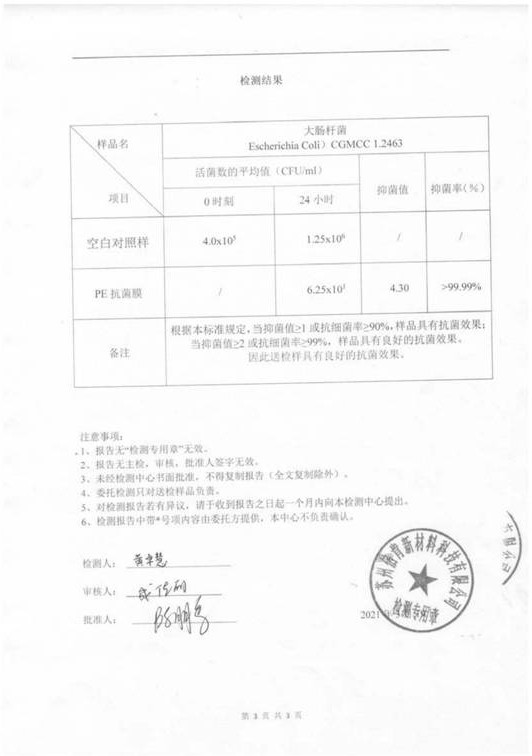

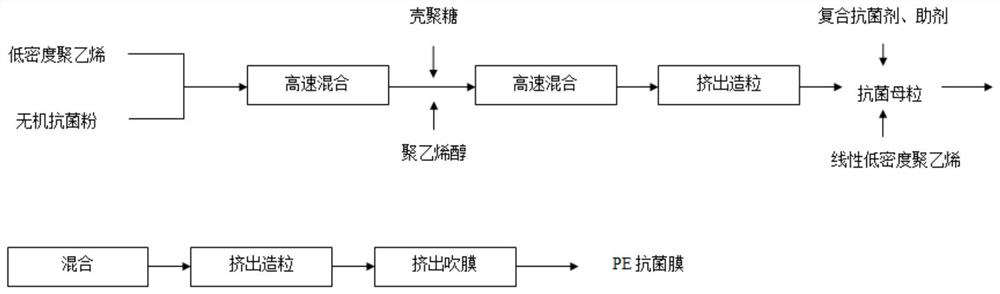

PE antibacterial film and preparation method thereof

InactiveCN113321865ABroad-spectrum potent antibacterial propertiesImprove mechanical propertiesLinear low-density polyethyleneLow-density polyethylene

The invention discloses a PE (polyethylene) antibacterial film and a preparation method thereof. The PE antibacterial film is prepared from the following raw materials in parts by weight: 100-150 parts of linear low-density polyethylene, 25-40 parts of antibacterial master batch, 18-25 parts of a composite antibacterial agent, 15-20 parts of hexanediol butyl ether acetate, 8-16 parts of glycerol, 0.5-1.5 parts of an antioxidant and 0.5-0.8 parts of a preservative. The antibacterial master batch is prepared from the following components in parts by weight: 50-70 parts of low-density polyethylene, 20-35 parts of polyvinyl alcohol, 10-20 parts of chitosan and 3-7 parts of inorganic antibacterial powder. The antibacterial master batch and the composite antibacterial agent are added into the linear low-density polyethylene, and the PE antibacterial film is prepared through the processes of extrusion granulation and extrusion film blowing. The antibacterial rate of the finally prepared PE antibacterial film on escherichia coli is larger than or equal to 99.99%, and meanwhile, the antibacterial rate on staphylococcus aureus and the antibacterial rate on candida albicans are larger than or equal to 99.14%. The PE antibacterial film has broad-spectrum and high-efficiency antibacterial performance, good mechanical performance and high tensile strength.

Owner:ZHEJIANG CHENGDE PACKAGING

Co-doped ZnO quantum dot/attapulgite nano composite antibacterial agent and preparation method thereof

InactiveCN110521733AInhibitory complexHigh antibacterial activityBiocideDisinfectantsEnvironmental resistanceEscherichia coli

The invention discloses a Co-doped ZnO quantum dot / attapulgite nano composite antibacterial agent and a preparation method thereof. According to the preparation method, APT is used as a carrier, cobalt acetate tetrahydrate is used as a dopant, a novel photoelectric functional material ZnO quantum dot is used as a main antibacterial component, the size limitation effect and the quantum confinementeffect of ZnO quantum dot are utilized, and combination with coupling of ZnO quantum dot and Co < 2 + > is adopted, so that the combination of ZnO surface photo-induced electrons and holes is effectively inhibited; the surface of the attapulgite is loaded with the Co-doped ZnO quantum dots; under the effect of the huge specific surface area and high absorptivity of APT, bacteria are adsorbed to the surfaces, and then cobalt (Co) doped zinc oxide quantum dots (ZnO QDs) cooperatively loaded on attapulgite surfaces and among pore channels are provided with efficient antibacterial effects. The preparation method has the advantages of being safe, environmentally friendly, high in drug resistance and the like, and the inhibition rate of the prepared nano-composite antibacterial agent on escherichia coli can reach 85.71%.

Owner:SHAANXI UNIV OF SCI & TECH

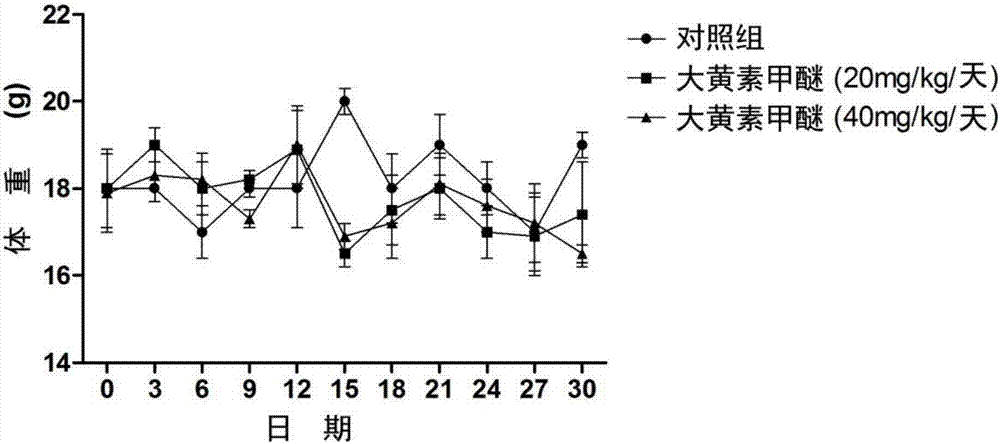

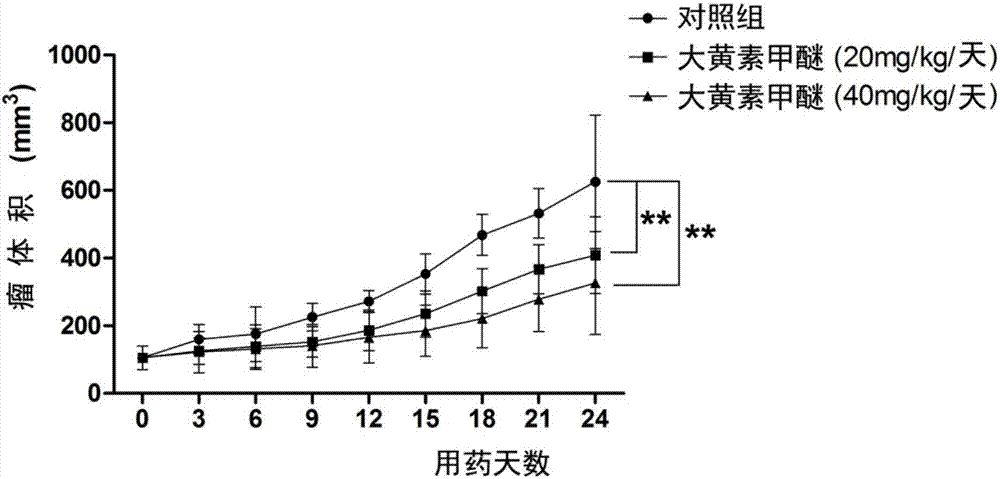

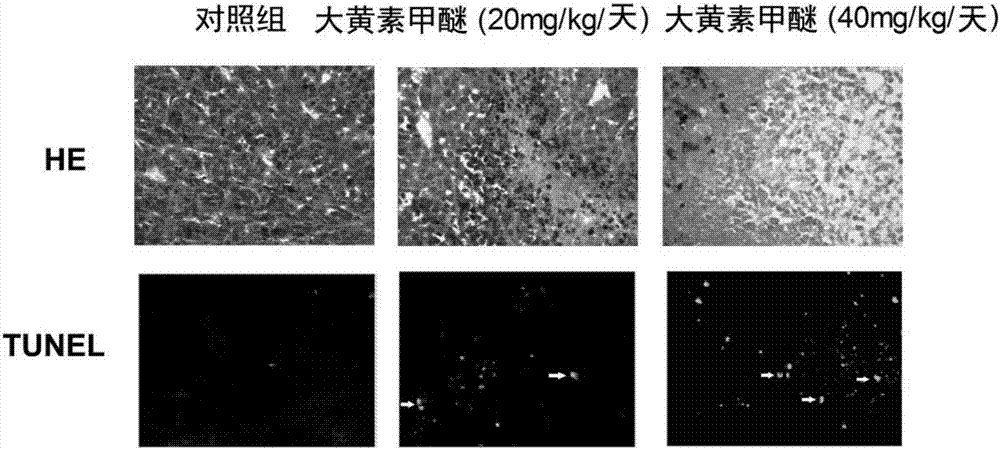

Rheochrysidin and micro-capsule of derivative of rheochrysidin as well as preparation method and application of rheochrysidin

InactiveCN107184563AConducive to exert anti-tumor effectImprove anti-tumor effectOrganic active ingredientsPharmaceutical non-active ingredientsBULK ACTIVE INGREDIENTBioavailability

The invention belongs to the field of pharmaceutical preparations, and in particular relates to rheochrysidin and a micro-capsule of a derivative of rheochrysidin as well as a preparation method and application of rheochrysidin. The invention provides an enteric-coated preparation including rheochrysidin used as an active ingredient or the derivate of the rheochrysidin, and sodium alginate-chitosan used as a capsule material. According to the rheochrysidin prepared by the invention and the enteric-coated preparation as the derivative of the rheochrysidin, the phenomenon that a conventional oral preparation is hydrolyzed and inactivated by gastric acid when the oral preparation flows through the stomach is avoided; meanwhile, by utilizing a slow release effect, the bioavailability is improved, and anti-tumor effects of the rheochrysidin and the derivate thereof are facilitated. In a preparation process of the enteric-coated preparation, a preparation technology is optimized, and the simple, feasible, safe and environment-friendly preparation method can be obtained. The multi-batch rheochrysidin and the enteric-coated preparation as the derivate of the rheochrysidin prepared according to an optimized condition are naturally dried to form white particles, and the white particles are spherical and round, uniform in size and good in dispersibility; the particle size, the drug-loading rate and the entrapment rate all keep stable, and the white particles are applied to large-scale industrial production.

Owner:潘小平

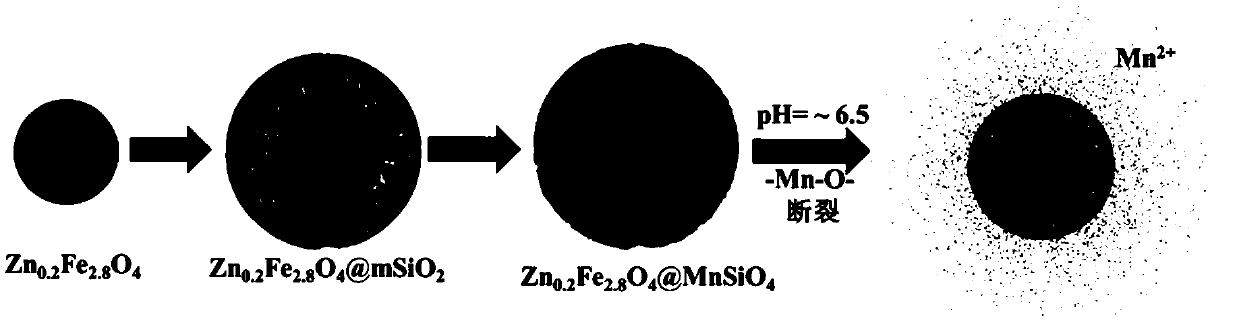

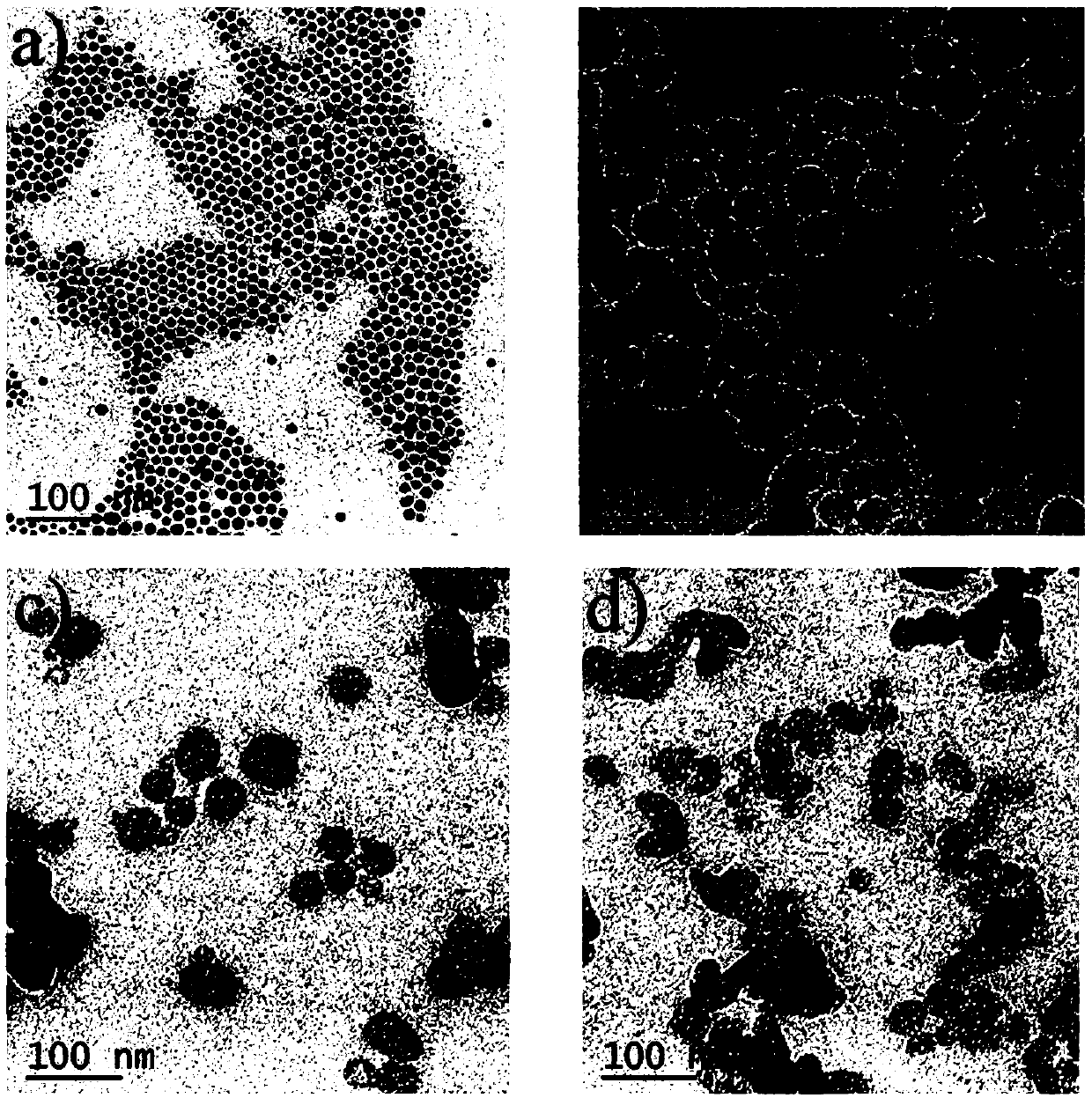

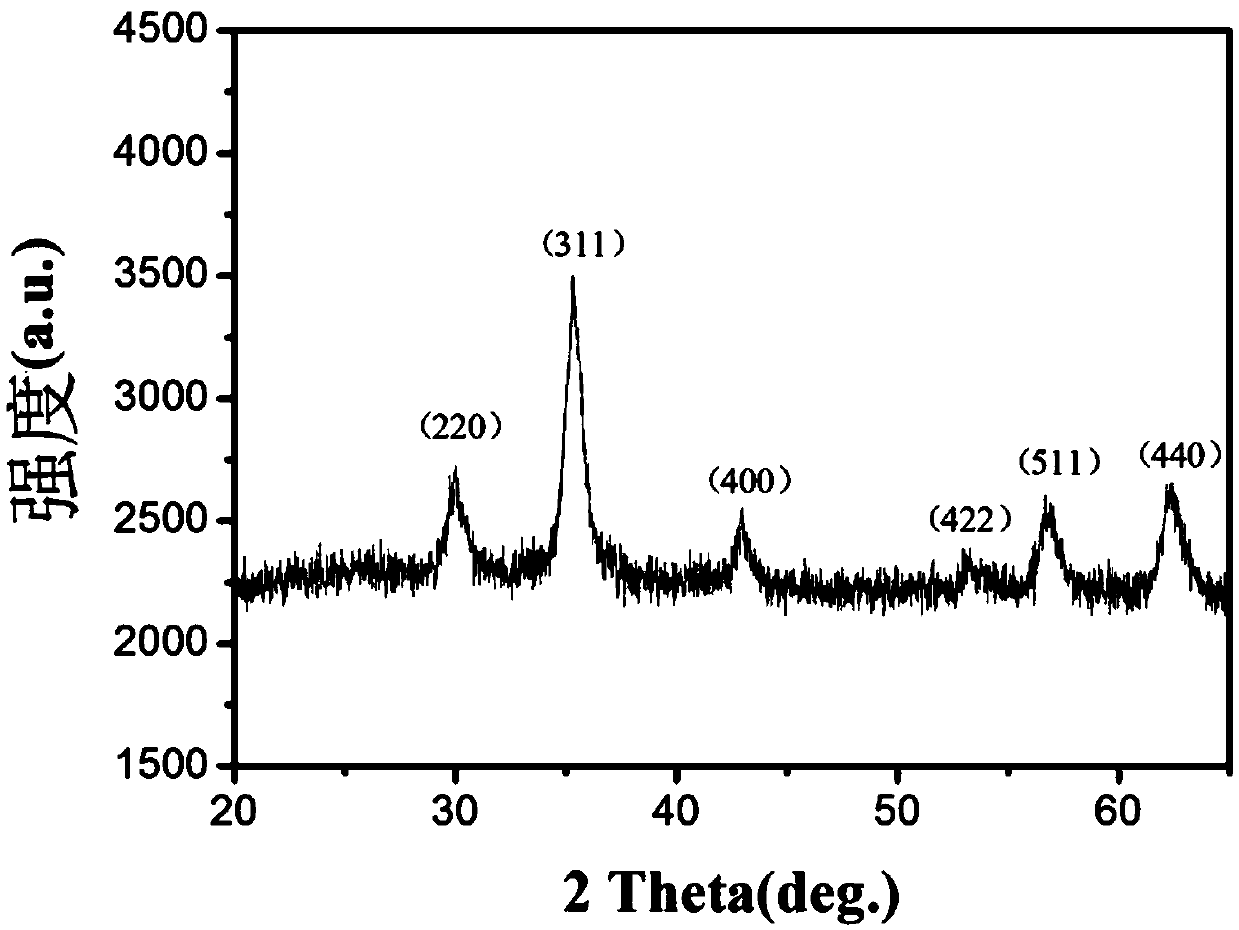

Magnetic composite nanomaterial and preparation method and application thereof

InactiveCN109529060AEfficient preparation methodImprove imaging effectInorganic non-active ingredientsEmulsion deliveryMRI contrast agentImage detection

The invention relates to a magnetic composite nanomaterial and a preparation method and application of the magnetic composite nanomaterial. In particular, the invention discloses a nanocomposite taking a metal-doped ferrite material as a core and an acid-responsive mesoporous material as a shell. The magnetic nanocomposite can enhance the MRI T1 weighted imaging effect based on magnetic resonanceharmonic theories. The magnetic nanocomposite is applied to magnetic resonance imaging, thereby being capable of obtaining a high-quality MRI contrast agent with obviously excellent imaging performances, high acid sensitivity and rich T1 signals, so that the identification and detection of serious diseases such as tumors can be improved by the contrast agent to obviously reduce errors in medical image detection and treatment costs.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

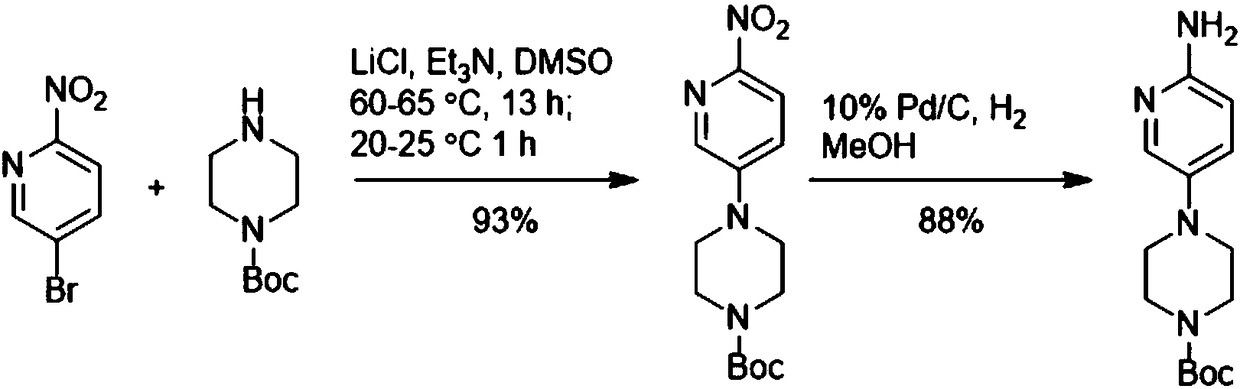

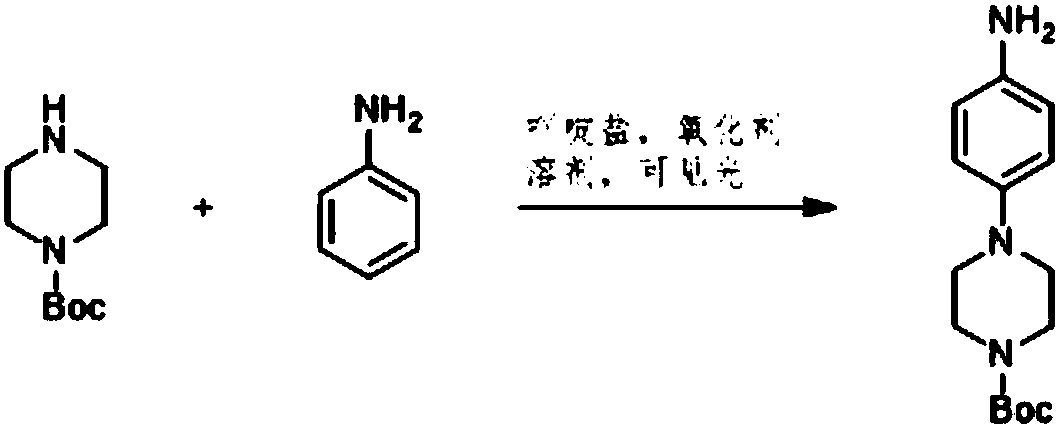

Method for preparing 4-(6-aminopyridin-3-yl) piperazine-1-carboxylate tert-butyl ester

The invention discloses a method for preparing 4-(6-aminopyridin-3-yl) piperazine-1-carboxylate tert-butyl ester. The method for preparing 4-(6-aminopyridin-3-yl) piperazine-1-carboxylate tert-butyl ester comprises the following steps: 2-aminopyridin, piperazine-1-formate tert-butyl ester and NSP-SA-NHS photo catalyst is added to the solvent, and the light reaction is carried out under the condition of the presence of an oxidizing agent to generate 4-(6-aminopyridin-3-yl) piperazine-1-carboxylate tert-butyl ester. According to the method, 4-(6-aminopyridin-3-yl) piperazine-1-carboxylate tert-butyl ester is synthesized by one step. On the one hand, the synthetic route of 4-(6-aminopyridin-3-yl) piperazine-1-carboxylate tert-butyl ester is effectively shortened, the generation of by-productsis effectively reduced and the yield of the target product is improved. On the other hand, only photo catalyst and oxidizing agent are used, so that the preparation method is safe and environment-friendly and low in cost.

Owner:深圳蓝新科技有限公司

Preparation method for chiral separation benzenesulfonic acid amlodipine molecularly imprinted membrane

InactiveCN104725661AThe preparation method is safe and environmentally friendlyEasy to prepareOther chemical processesSeparation technologyAmlodipine besilate

The invention discloses a preparation method for a chiral separation benzenesulfonic acid amlodipine molecularly imprinted membrane. The method comprises the following steps of mixing S-benzenesulfonic acid amlodipine and 4-vinylpyridine into trichloromethane to obtain a pre-polymer system; adding ethylene glycol dimethacrylate and azodiisobutyronitrile to obtain a polymeric system; soaking a PVDF film into the polymeric system, and then transferring the PVDF film subjected to soaking treatment into a vacuum system to be subjected to polymeric reaction; washing the PVDF film after reaction with acetic acid and methyl alcohol, and preparing the S-benzenesulfonic acid amlodipine molecularly imprinted hollow fiber membrane. The molecularly imprinted membrane takes the PVDF membrane which is good in performance and low in cost in market as a basal membrane, has the advantage of selectivity of molecular imprinting technology and the advantage of simplicity and easiness in amplification of the membrane separation technology, has good adsorption and separation functions, and can be combined with a membrane separation component to perform amplification and technological separation.

Owner:XIANGTAN UNIV

Preparation method of modified protein-base adhesive

InactiveCN106634816AImprove adhesionImprove crack resistanceNon-macromolecular adhesive additivesProtein adhesivesCrack resistanceGutta-percha

The invention relates to a preparation method of a modified protein-base adhesive, belonging to the technical field of adhesives. In order to solve the problems of low binding strength, and nonideal toughness, peeling resistance and cracking resistance after use in the existing biomass adhesive, the invention provides a preparation method of a modified protein-base adhesive. The preparation method comprises the following steps: a peanut cake obtained by peanut oil extraction is used as the raw material and separated to obtain peanut proteins; the peanut proteins are mixed with soybean proteins in soybean cake powder, and weakly-acidic sodium bisulfite is utilized to destroy intermolecular hydrogen bonds of the soybean proteins; meanwhile, intermolecular sulfide bonds of the proteins are destroyed under the actions of salts so as to destroy the space structure of the proteins, so that the active groups of the proteins are exposed; and the proteins are subjected to crosslinking modification treatment by gutta-percha to enhance the water resistance and binding strength of the adhesive, thereby obtaining the modified protein-base adhesive.

Owner:周益铭

Preparation method of stainless steel aluminum coating

InactiveCN108624839AHigh bonding strengthSimple manufacturing methodSolid state diffusion coatingReaction temperatureChloride

The invention discloses a preparation method of a stainless steel aluminum coating. The method comprises the step that pre-processed stainless steel reacts in a mixture of 'fluoride melting salt and / or molten chloride melt' and aluminum in an inert atmosphere; and the reaction temperature is 500-700 DEG C. The method is simple, feasible, safe, environmentally friendly, and easy to operate and control; the equipment manufacturing and processing costs are decreased; a stable metallurgic combination structure can be formed; the combination strength of an aluminum layer and a substrate is high; in addition, the coating structure is uniform, and the thickness is controllable; small requirements are provided to the product shape; complex parts can be processed; and industrial production can becarried out.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

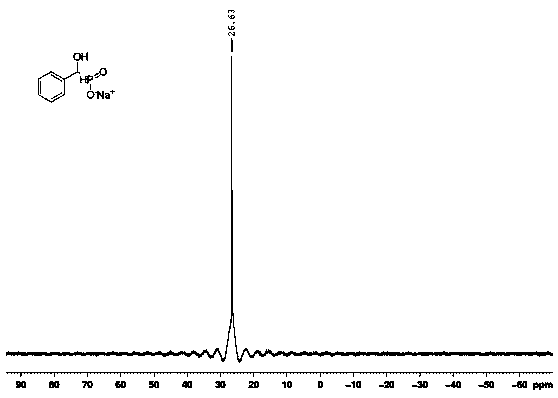

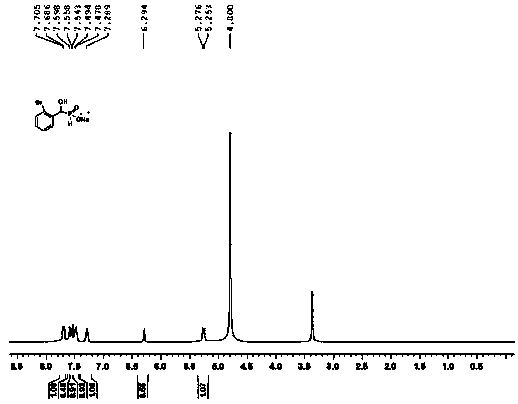

Preparation method of organic phosphine flame retardant 1-hydroxyl phosphate

InactiveCN109796490AThe preparation method is safe and environmentally friendlyLow costGroup 5/15 element organic compoundsSolventChemistry

The invention discloses a preparation method of an organic phosphine flame retardant 1-hydroxyl phosphate. The method includes the following steps that hypophosphite and aldehyde serve as raw materials, DMF / DMSO / DMP serve as solvents, a heating reaction is carried out, filtering and alcohol washing is performed after the reaction, and 1-hydroxyl alkyl phosphate is obtained; the pH value of 1-hydroxyl alkyl phosphate is adjusted to be 2-3, and 1-hydroxyl alkyl phosphate reacts with melamine, aluminum salt and zinc salt to obtain the product. According to the method, a one-pot method is utilizedto obtain1-hydroxyl alkyl phosphate, the production process is simple, the operation is easy, and the solvent and the raw materials can be repeatedly used.

Owner:QUANZHOU NORMAL UNIV

Long-acting and antibacterial chitosan essence microcapsule preparation method

InactiveCN110026139AHigh flavor contentWide adaptabilityMicroballoon preparationMicrocapsule preparationPEG 400Electronic analytical balance

The invention provides a long-acting and antibacterial chitosan essence microcapsule preparation method, which specifically comprises: 1, preparing materials and experimental equipment, wherein essence, a chitosan quaternary ammonium salt, polyethylene glycol 400 (PEG) and glutaraldehyde are selected as materials; 2, carrying out experimental operation on an aseptic operation table, weighing the raw materials by using an electronic analytical balance, weighing 5-7 g of the chitosan quaternary ammonium salt, placing in a 250 ml flask, adding water, and dissolving to achieve a weight of 50-70 g;and 3, adding 0.02-1 g of the polyethylene glycol 400 (PEG) and 15-30 g of the essence to the flask, and stirring for 25-35 min by using a heat collection type constant temperature heating magnetic stirrer at a mechanical stirring speed of 1000 rpm / min to emulsify. According to the present invention, the microcapsules produced by the method have high essence content, have wide adaptability compared with other commercially available essence microcapsules, and further have advantages of efficient antibacterial property; and with the long-acting and antibacterial chitosan essence microcapsule, the fragrance forming effect on fabrics is good, the time of the fragrance retained on fabrics is long, the fragrance explosion after kneading can be achieved, and the fragrance is retained on the fabric after the fabric is washed five times.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

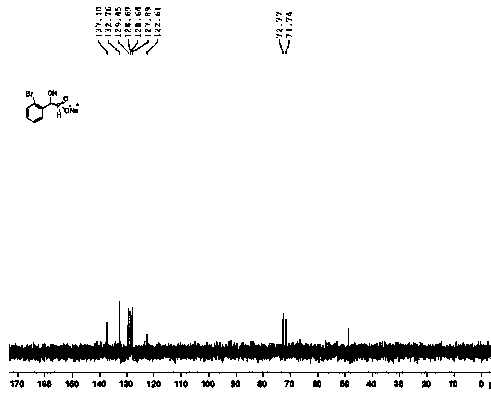

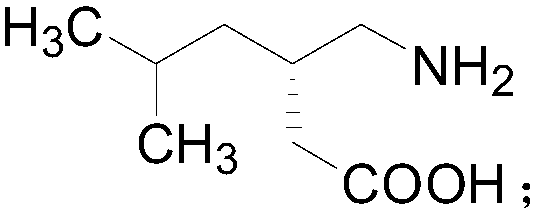

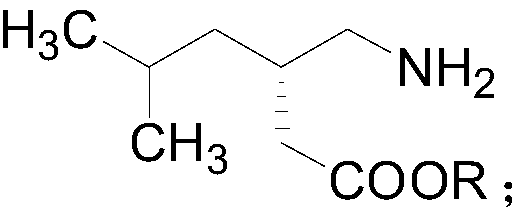

Preparation method of pregabalin

InactiveCN109503401AHigh purityThe preparation method is safe and environmentally friendlyOrganic compound preparationOrganic chemistry methodsHydrolysisMedicinal chemistry

The invention provides a preparation method of pregabalin. The method comprises the following steps: taking pregabalin racemate as an initiator, forming pregabalin chiral ester under the action of lipase, and ensuring that the pregabalin chiral ester is subjected to hydrolysis reaction, so as to form the pregabalin. The preparation method ensures that the pregabalin is high in purity, convenient to operate, and safer and more environmentally friendly.

Owner:ZHUOHE PHARM GRP CO LTD

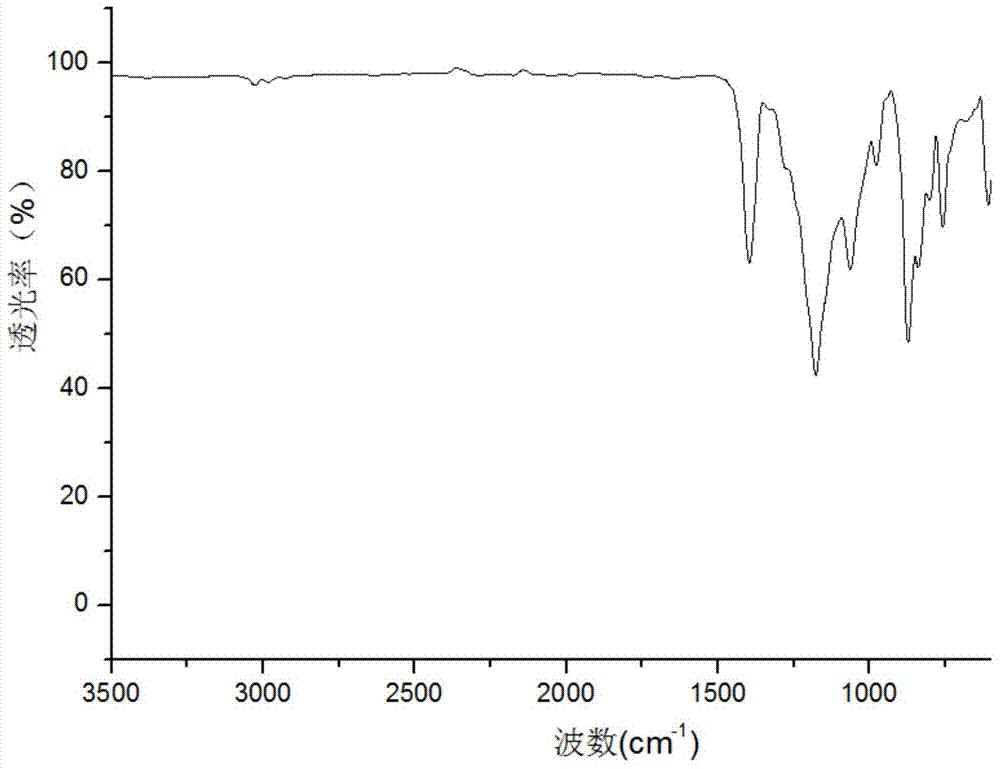

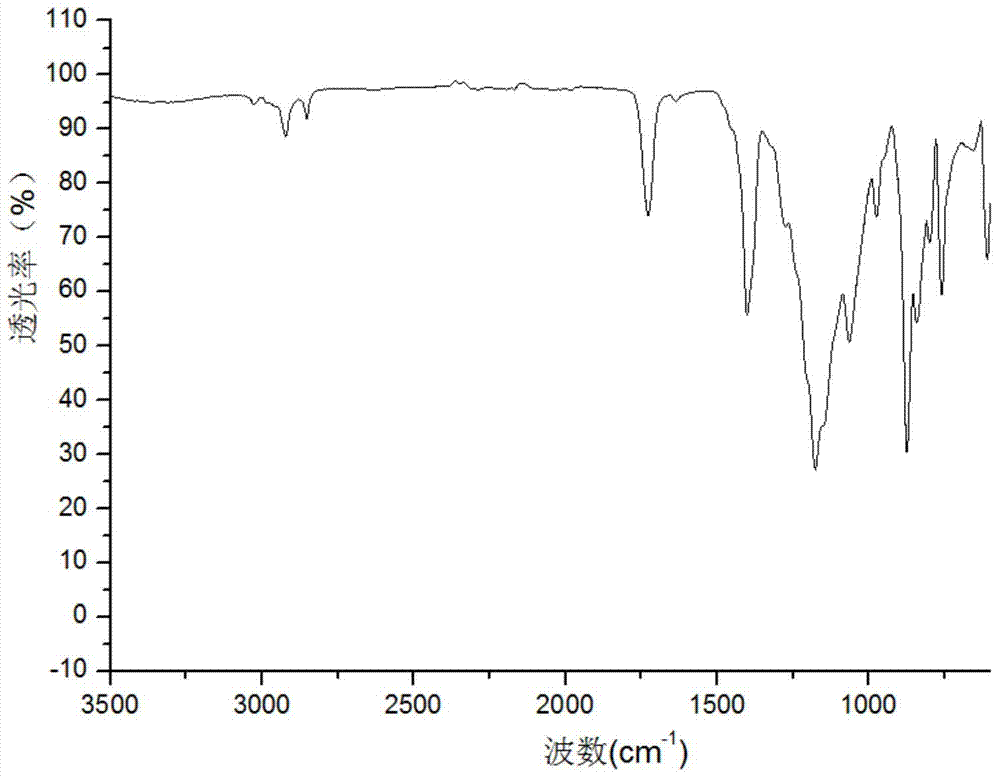

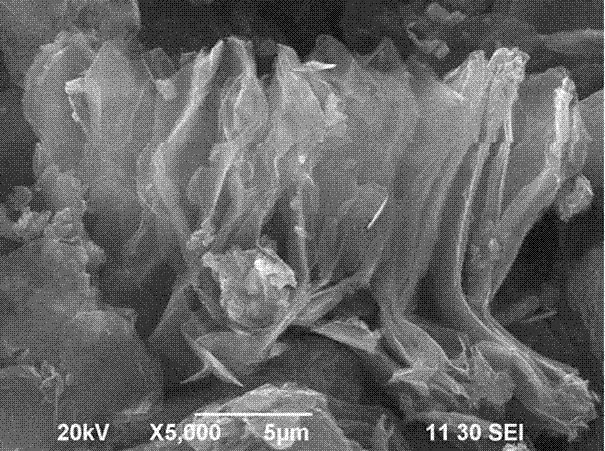

Graphene/polyaryl ether sulfone ketone conductive film and preparation method thereof

The invention belongs to the technical field of nanocomposites, and particularly relates to a graphene / polyaryl ether sulfone ketone conductive film and a preparation method thereof. The method comprises the following steps: fully dispersing a certain amount of graphene oxide in a solvent by utilizing ultrasound to form a uniform stable solution, after mixing the uniform stable solution with a polyaryl ether sulfone ketone resin solution with a certain concentration, placing the mixed solution in a microwave generator for in-situ reduction of the graphene oxide, and then obtaining a polyaryl ether sulfone ketone film containing graphene by adopting a solution coating film forming process. The graphene / polyaryl ether sulfone ketone film prepared by the invention is excellent in electrical properties, uniform in dispersion of graphene and relatively high in mechanical strength, and is widely applied in multiple fields such as electromagnetic shielding, antistatic property and flexible sensors.

Owner:SHENYANG AEROSPACE UNIVERSITY

Modified acrylic resin energy-saving and environment-friendly coating material for cabinet of washing machine

InactiveCN106752513AExtended service lifeImprove mechanical propertiesFireproof paintsAnti-corrosive paintsBenzoic acidEpoxy

The invention discloses a modified acrylic resin energy-saving and environment-friendly coating material for a cabinet of a washing machine. The modified acrylic resin energy-saving and environment-friendly coating material is prepared from the following raw materials in parts by weight: 20 to 40 parts of thermosetting acrylic resin, 18 to 35 parts of water-borne epoxy resin, 15 to 30 parts of water-borne polyurethane resin, 0.6 to 2 parts of oxidized graphene, 2 to 5 parts of magnesium oxide, 1 to 3 parts of nano silica, 3 to 8 parts of expanded graphite, 3 to 8 parts of kaolin, 1 to 3 parts of a non-ionic surfactant, 2 to 4 parts of a water-borne defoaming agent, 2 to 4 parts of a water-borne antirust agent, 1 to 5 parts of benzoic acid, 10 to 20 parts of polyol and 25 to 50 parts of water. Compared with a traditional coating material, the dispersibility, the adhesive ability, the heat resistance and the flame resistance of the modified acrylic resin energy-saving and environment-friendly coating material are effectively increased, the modified acrylic resin energy-saving and environment-friendly coating material has the characteristics of safety and environment protection, a preparation method of the modified acrylic resin energy-saving and environment-friendly coating material is simple, the preparation cost is low, the modified acrylic resin energy-saving and environment-friendly coating material is used for spraying the cabinet of the washing machine, the glossiness is good, very good protection and decoration functions can be achieved, the service life of the washing machine can be effectively prolonged, and the modified acrylic resin energy-saving and environment-friendly coating material is worthy of promotion.

Owner:MOBAO CO LTD

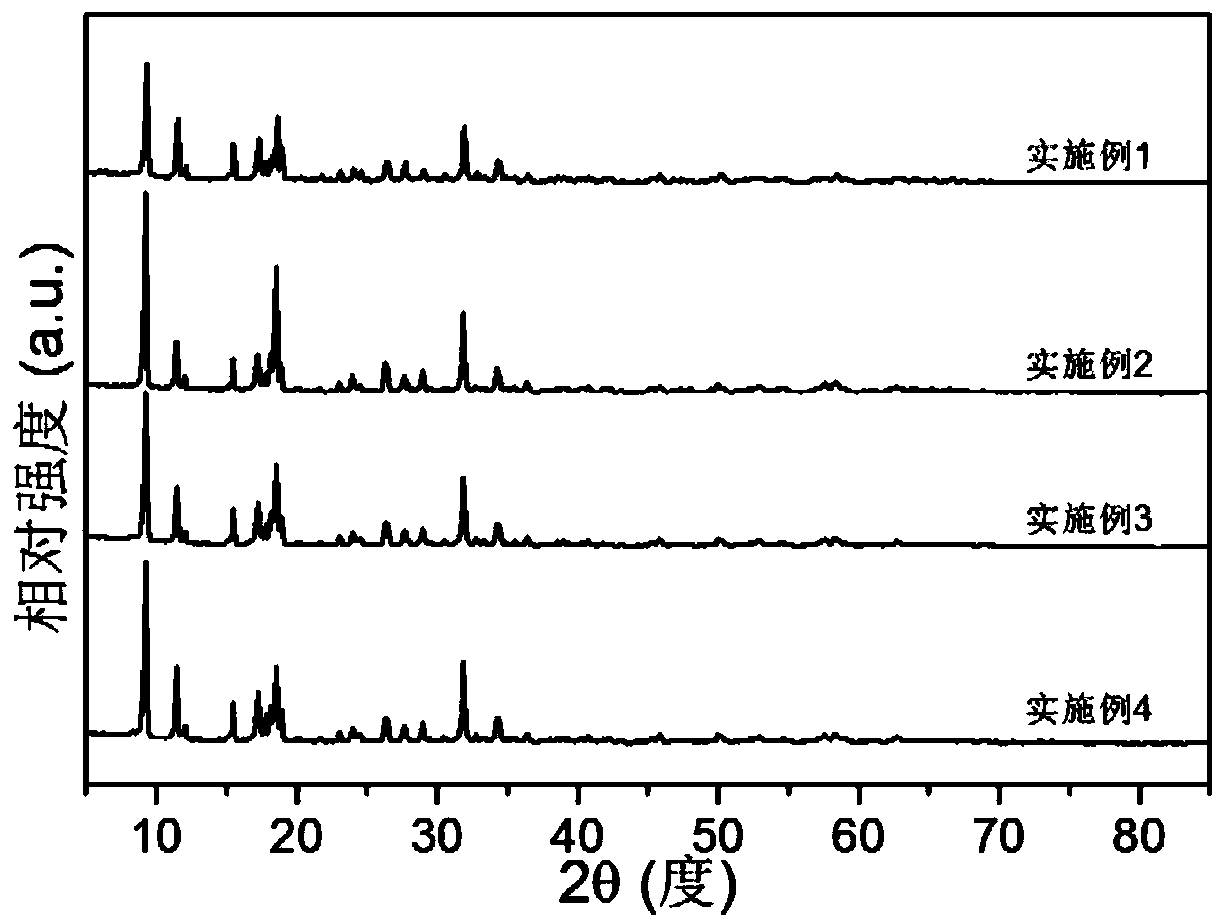

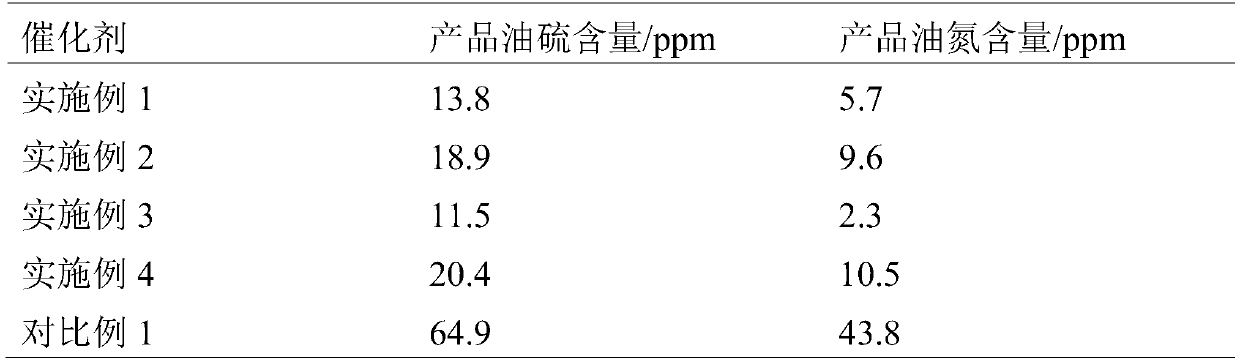

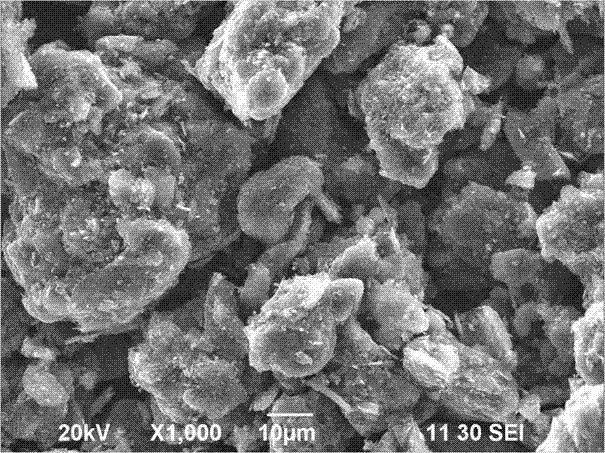

Bulk phase catalyst capable of doing not generate waste liquid, and preparation method thereof and hydrogenation catalyst containing bulk phase catalyst

PendingCN110975910AAvoid pollutionEliminate cumbersome processing stepsPhysical/chemical process catalystsHydrocarbon oils treatment productsProcess engineeringHydrogenation reaction

The invention discloses a bulk phase catalyst capable of doing not generate waste liquid, and a preparation method thereof and a hydrogenation catalyst containing the bulk phase catalyst, wherein thebulk phase catalyst is used for hydrogenation reactions of petroleum products. The preparation method comprises the following steps: 1, dissolving a compound containing VIB group elements in a solventto prepare a solution, and adjusting the pH value of the solution to 6-11; 2, mixing the solution obtained in the step 1 and a powdery compound containing VIII family elements, and uniformly stirringto obtain a mixture; 3, putting the mixture obtained in the step 2 into a closed container, and carrying out a reaction for at least 10 minutes at a reaction temperature of 5-75 DEG C; and 4, heatingthe mixture to 80-200 DEG, carrying out a reaction for at least one hour, and drying to obtain the bulk phase catalyst, wherein the volume of the solvent is 1-2 times the saturated water absorption volume of the compound containing the VIII group element. The method has the characteristic of no reaction waste liquid in the catalyst preparation process, and the obtained catalyst has high catalyticactivity.

Owner:PETROCHINA CO LTD

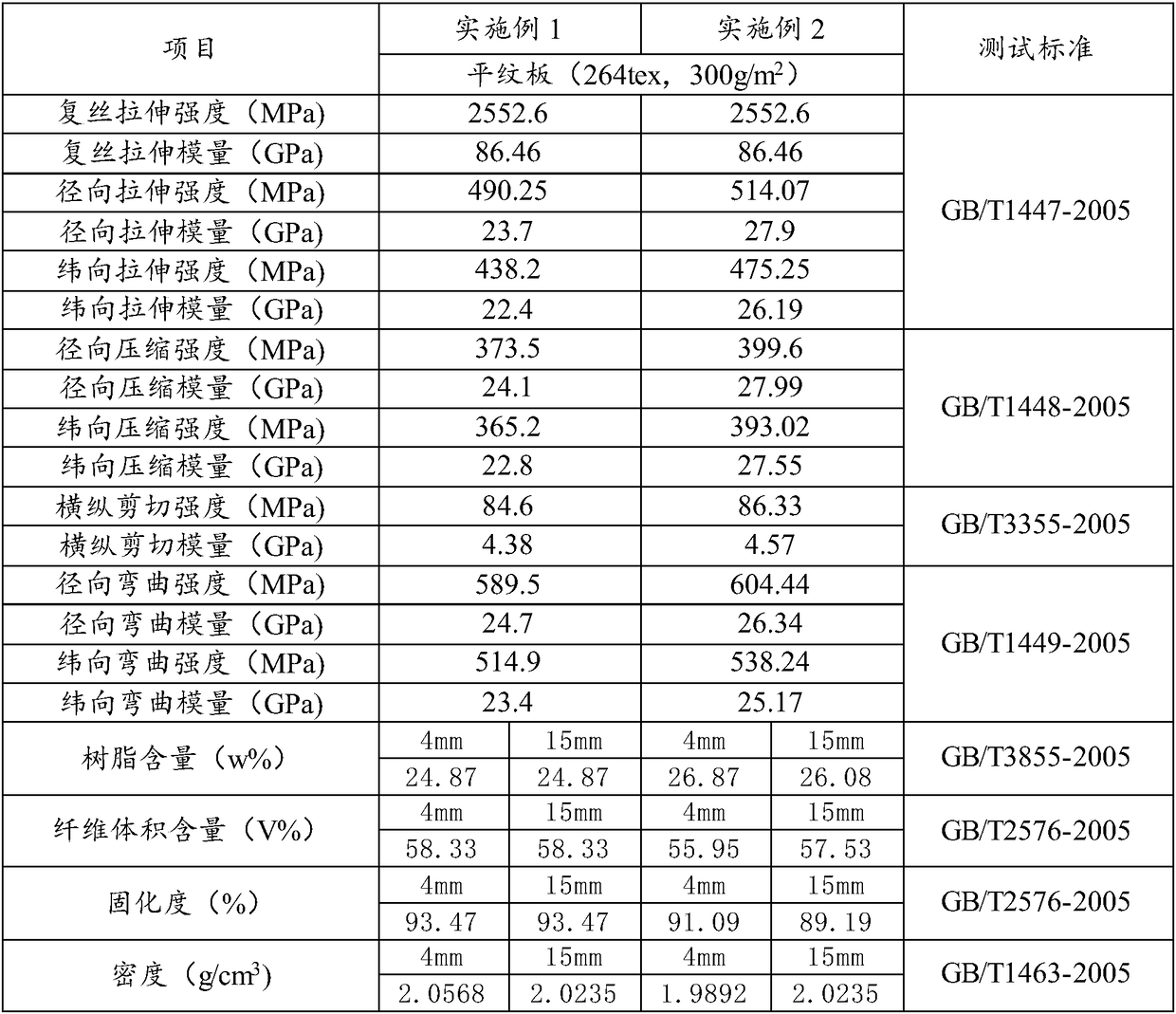

Basalt composite material, and preparation method and application thereof

InactiveCN109294268AThe preparation method is safe and environmentally friendlyLow costState of artVolumetric Mass Density

The invention provides a preparation method of a basalt composite material. The preparation method comprises the following steps: a) mixing a resin material with a curing agent to obtain a colloidal solution; and b) fully contacting the colloidal solution obtained in step a) with basalt fibers under a vacuum condition, and then performing curing to obtain the basalt composite material, wherein themonofilament diameter of the basalt fibers is 6-15 [mu]m, and the areal density is 270-330 g / m<2>; and a mass ratio of the colloidal solution to the basalt fibers is (2.6-4.3):7.5. Compared with theprior art, the preparation method allows the basalt composite material to be prepared by adopting the basalt fibers as a matrix material and adopting specific technologies and conditions; and the basalt composite material obtained by the preparation method has the advantages of light mass, high strength, high extension and moderate price, and is suitable for being applied as a toy car body material.

Owner:吉林省华阳新材料研发有限公司

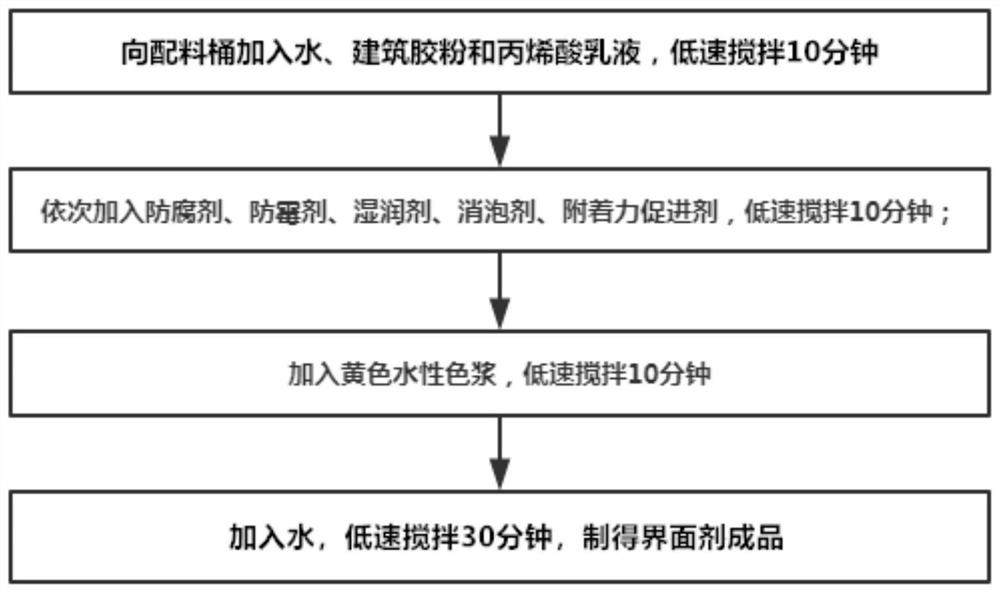

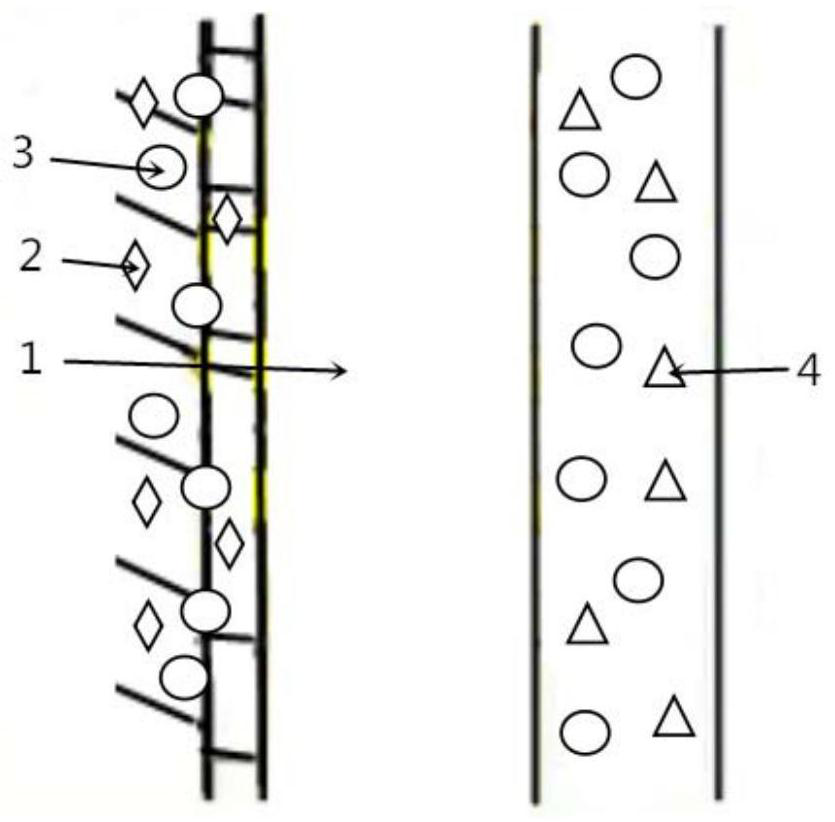

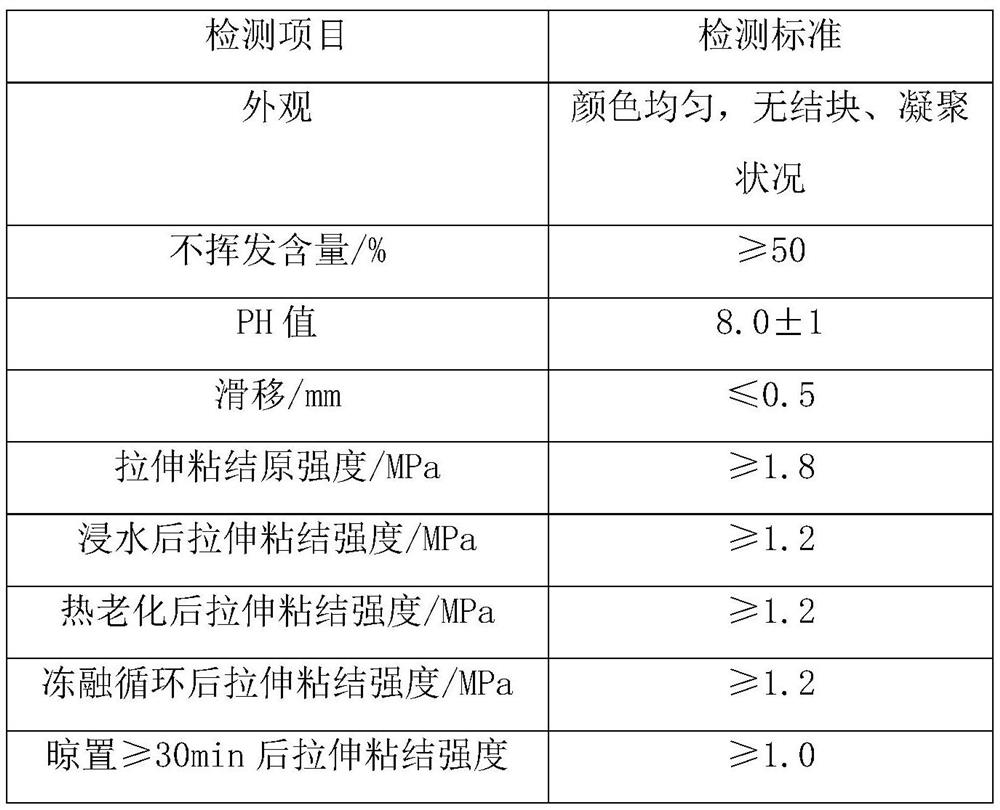

Quick-drying interface agent for wall surface base layer and preparation method of quick-drying interface agent

The invention relates to a quick-drying interface agent for a wall surface base layer and a preparation method of the quick-drying interface agent. The interface agent is prepared from the following raw materials and components: 43 to 53 parts of acrylic emulsion, 3 to 5 parts of building glue powder, 38 to 46 parts of water, 2 to 4 parts of yellow water-based color paste, 0.5 to 1.5 parts of a preservative, 0.5 to 1.5 parts of a mildew preventive, 0.5 to 1.5 parts of a wetting agent, 0.5 to 1.5 parts of a defoaming agent and 0.5 to 1.5 parts of an adhesion promoter. The interface agent is high in drying speed, the time in actual production and engineering is greatly shortened, and the production and engineering efficiency is effectively improved. In the using process, the interface agent can permeate in two directions, the adhesion force is improved, and it is guaranteed that a wall surface base layer and cement paste are bonded together. In addition, the preparation method of the quick-drying interface agent is safe, environment-friendly, simple, convenient and quick, has low requirements on production equipment, and is beneficial to reducing the production cost of enterprises.

Owner:广东盛世宝建筑新技术有限公司

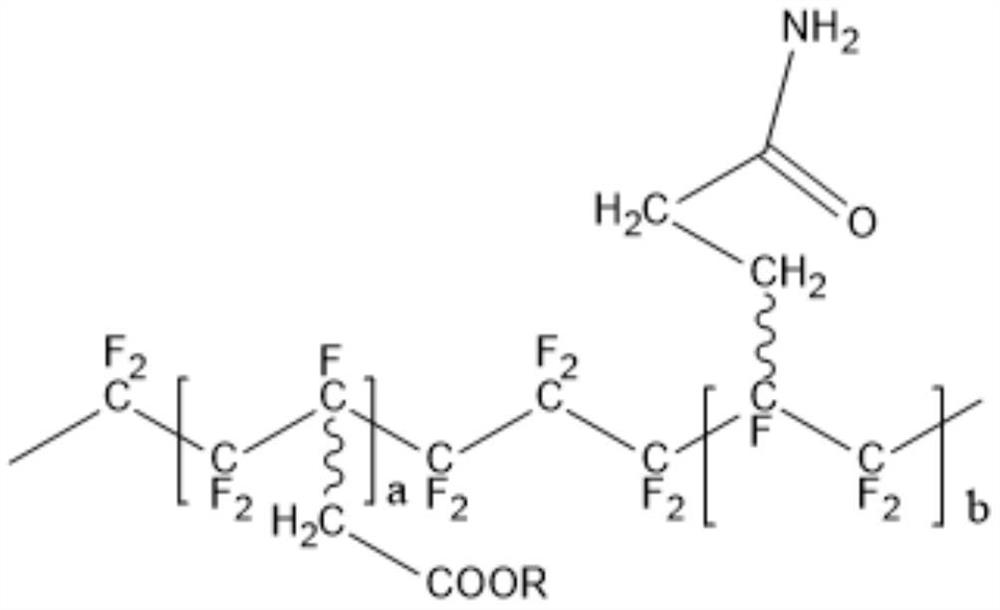

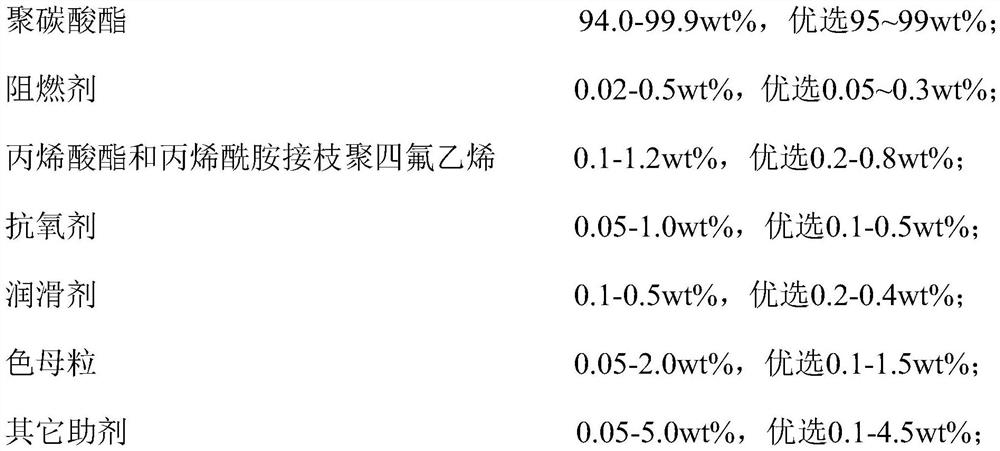

Acrylate and acrylamide grafted polytetrafluoroethylene and highlight mirror surface wear-resistant flame-retardant polycarbonate material

The invention discloses an acrylate and acrylamide grafted polytetrafluoroethylene and high-gloss mirror surface wear-resistant flame-retardant polycarbonate material. The high-gloss mirror-surface wear-resistant flame-retardant polycarbonate material is prepared from polycarbonate, a flame retardant, acrylate and acrylamide grafted polytetrafluoroethylene, an antioxidant, a lubricant and color master batches. The acrylic ester and the acrylamide are grafted on the surface of the polytetrafluoroethylene, so that the binding force between the polytetrafluoroethylene and the surface of the polycarbonate is improved, the dispersion of the polytetrafluoroethylene in a polycarbonate matrix is improved, the appearance pocking marks of a workpiece caused by agglomeration of the polytetrafluoroethylene are eliminated, and the surface glossiness of the polycarbonate is further improved; and the wear resistance of the polycarbonate is improved, so that the high-gloss mirror-surface wear-resistant flame-retardant polycarbonate material is prepared.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

Special-type sealing wax

ActiveCN102816444BRaw materials are cheap and easy to getThe preparation method is safe and environmentally friendlyOther chemical processesParaffin waxFiber

The invention discloses a special-type sealing wax which comprises the following raw materials in percentage by weight: 73-80.5% of high-meltiong-point paraffin, 10-14.5% of high-melting-point microcrystalline wax, 4-6% of beeswax, 5-5.5% of polyethylene wax and 0.5-1% of tackifier. The preparation method has the advantages of high safety, environmental protection and low energy consumption; and the special-type sealing wax disclosed by the invention has the advantages of cheap and accessible raw materials and high product quality, can satisfy the requirements for sealing waxes in dry batteries as well as special-type waxes for fiber communication cables and oil transport pipeline sealing hot-melt adhesive tapes, and has wide application prospects.

Owner:上海绿菱特种蜡制品厂

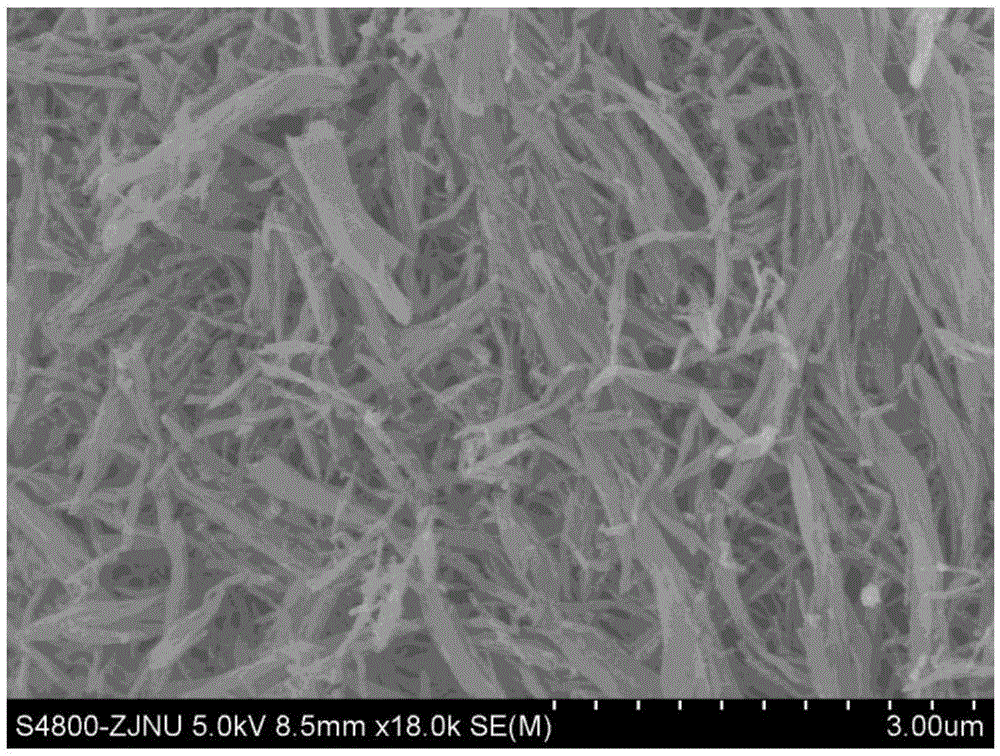

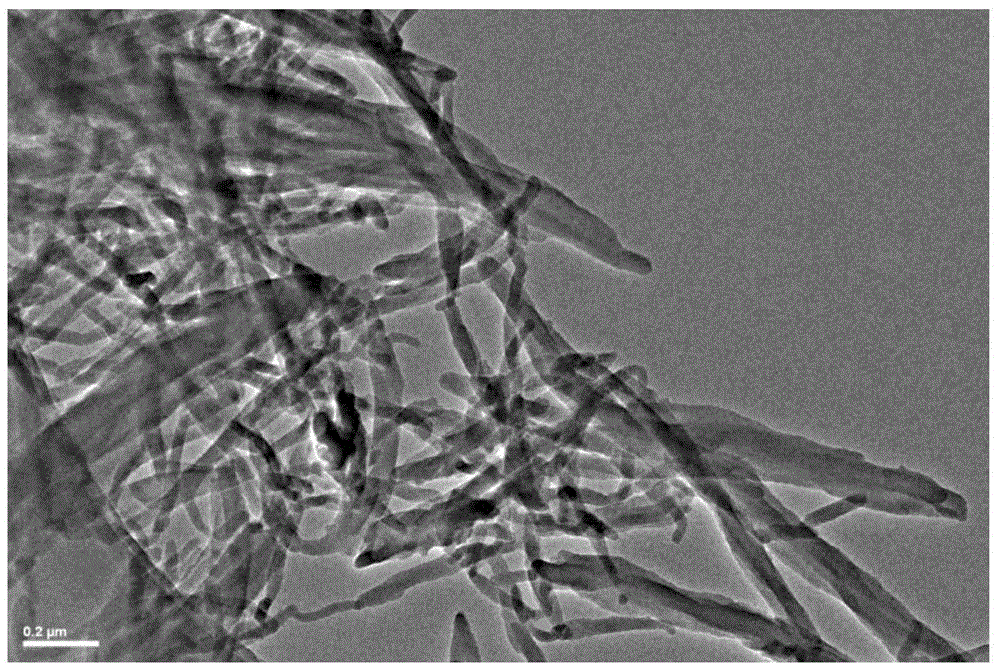

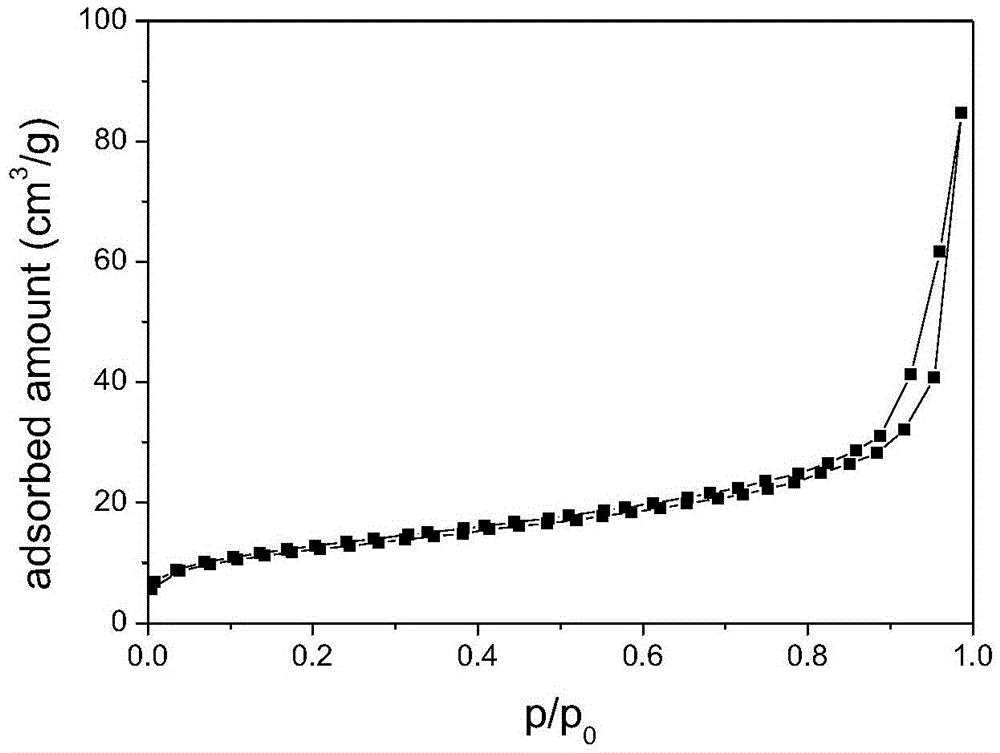

Nano fiber and preparing method thereof

A nano fiber and a preparing method thereof are provided; the nano fiber is a melamine-phloroglucinol-formaldehyde resin nano fiber; the preparing method comprises the steps: adding phloroglucinol into water, stirring to dissolve, continuing to add a formaldehyde solution, and stirring to obtain a solution A; adding melamine into water, stirring to dissolve, continuing to add a formaldehyde solution, and stirring to obtain a solution B; mixing the solution A and the solution B in a certain proportion, stirring, and carrying out a reaction; and filtering, washing and drying to obtain the product. The preparation method is simple, safe, environmentally friendly, and prone to scale production.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of preparation method of silicon base/graphene composite material

ActiveCN103094573BEvenly distributedDoes not pose a health and safety riskCell electrodesLithium-ion batteryElectric field

The invention belongs to the technical field of new materials for a lithium ion battery, and particularly relates to a preparation method of a silicon-based / graphene composite. The preparation method comprises the following steps of: taking a pole of the silicon-based / graphene composite as a working electrode and the pole of a lithium source-containing material as a counter electrode, assembling a battery together with propylene carbonate and lithium salt-containing electrolyte and a diaphragm; charging and discharging the battery to co-embed lithium ions and carbonate propylene ester into graphite layers under the action of electric field, so as to enable the graphite layers to be stripped; dismantling the battery, placing a lithium-embedded silicon-based / graphene composite precursor into dimethyl carbonate solution for soaking, and vaccumizing and drying; and conducting ultrasonic cleaning and lithium removal in diluted hydrochloric acid, vacuumizing and filtering, drying, and burning under inert gas atmosphere. Compared with the prior art, the preparation method is simple and controllable in procedures, low in cost, safe and environment-friendly and incapable of causing environment and health security risk; and a great deal of hydrogen can also be collected in the preparation process of the composite, so that economic benefits are obvious.

Owner:DONGGUAN AMPEREX TECH

Ultraviolet degradation method for preparing high-quality graphene material

The invention discloses an ultraviolet degradation method for preparing a high-quality graphene material, which comprises the following steps: (Step 1) graphene oxide is added into deionized water, adispersant is added, and after uniform agitation, ultrasonic reaction is carried out for 1 to 2 hours, so that graphene oxide dispersion liquid is obtained; (Step 2) the graphene oxide dispersion liquid is added into an agitating kettle, an initiator is added, and uniform agitation is carried out, so that a graphene oxide mixed liquor is obtained; (Step 3) the graphene oxide mixed liquor is addedinto an illuminating reaction kettle, a photocatalytic block is added, sealed illuminated circulated aeration reaction is carried out for 5 to 7 hours, and filtration is carried out, so that a mixed graphene precipitate is obtained; (Step 4) the mixed graphene precipitate and a photocatalytic block are added into absolute ethyl alcohol to ultrasonically react for 2 to 4 hours, the photocatalytic block is removed, and after filtration, drying is carried out, so that the graphene material is obtained. The ultraviolet degradation method solves the problems of pollution and unsafety existing in sgraphene material oxidation-reduction method in the prior art; by adopting the ultraviolet degradation method, an environment-friendly method can be adopted to prepare the graphene material, which issafe and environmentally friendly, and moreover, the photocatalytic material is recyclable, so the cost is reduced.

Owner:张静娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com