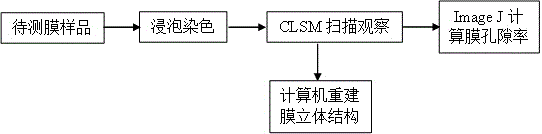

Membrane pore structure and porosity testing method based on confocal laser scanning microscopy

A laser confocal, testing method technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. , to achieve the effect of safe and environmentally friendly test method, simple sample preparation method and wide test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

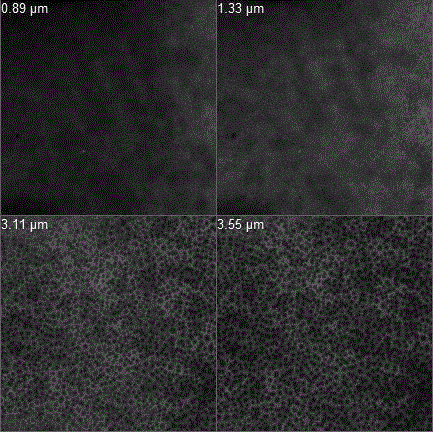

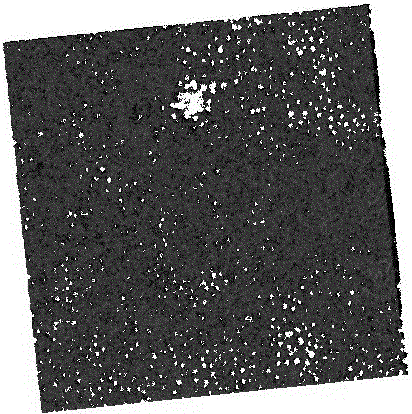

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below.

[0022] In the process of testing membrane pore structure and porosity, traditional testing methods include scanning electron microscopy, transmission electron microscopy, bubble point pressure method, mercury porosimetry and nitrogen adsorption method, etc., but each of them has many shortcomings, such as sample preparation consumes Time-consuming, complex preparation process, large trauma to the sample, narrow test range, high toxicity and high cost of reagents used in the test process, high requirements for testers’ experimental skills, and the test must be performed under dry conditions. In the sample preparation of the present invention, only the sample to be tested needs to be soaked in the fluorescent dye solution for dyeing, without drying, ultra-thin sectioning and other treatments. It has low toxicity and low cost, and requires low experimental skills for testers. At the same time, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com