Special-type sealing wax

A sealing wax and special technology, which can be applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of high price of special wax, and achieve the effects of safe and environmentally friendly preparation methods, cheap and easy-to-obtain raw materials, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

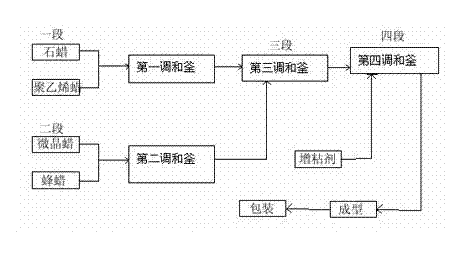

[0032] The preparation method of special sealing wax of the present invention comprises following concrete steps (as figure 1 shown):

[0033] Step 1 (i.e. the first stage), put paraffin wax and polyethylene wax in the first blending kettle according to the ratio of the above raw materials, stir and heat, at 130°C, the stirring speed is 70 rpm, and mix for 1 hour to obtain the first stage mixture ;

[0034] Step 2 (that is, the second stage), stir and heat the microcrystalline wax and beeswax in the second blending kettle according to the above raw material ratio, at 100°C, the stirring speed is 50 rpm, and mix for 0.5h to obtain the second stage mixture ;

[0035] Step 3 (that is, the third section), add the first-stage mixture obtained in step 1 and the second-stage mixture obtained in step 2 into the third blending tank and stir and heat, at 120°C, the stirring speed is 60- 70 revs / min, mix 1h, obtain the third stage mixture;

[0036] Step 4 (that is, the fourth stage)...

Embodiment 2-3 and comparative example 4-8

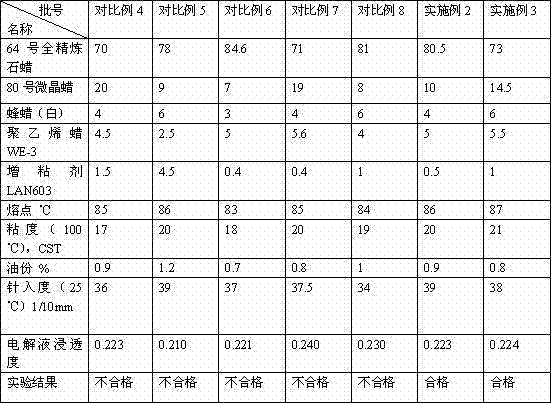

[0046] Using the four-stage processing technology of the present invention, the sealing wax is prepared by feeding according to the ratio in Table 3, and the performance test is carried out.

[0047] Table 3: Feeding situation and performance test of embodiment 2-3 and comparative example 4-8

[0048]

[0049] In some embodiments of the present invention, it is shown that the addition amount of polyethylene wax has a certain relationship with the melting point of the sealing wax product: when the addition amount is at 1-3%, the melting point rises faster, and when the addition amount is at 3-4% When the melting point rises relatively steadily, when the addition amount is 5-5.5%, the melting point can meet the requirements. But when the addition amount exceeds 5.5%, the melting point shows a downward trend.

[0050] In some embodiments of the present invention, experiments have shown that low molecular weight polyethylene wax should be selected to avoid wax cracking in low te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com