Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Sufficient uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

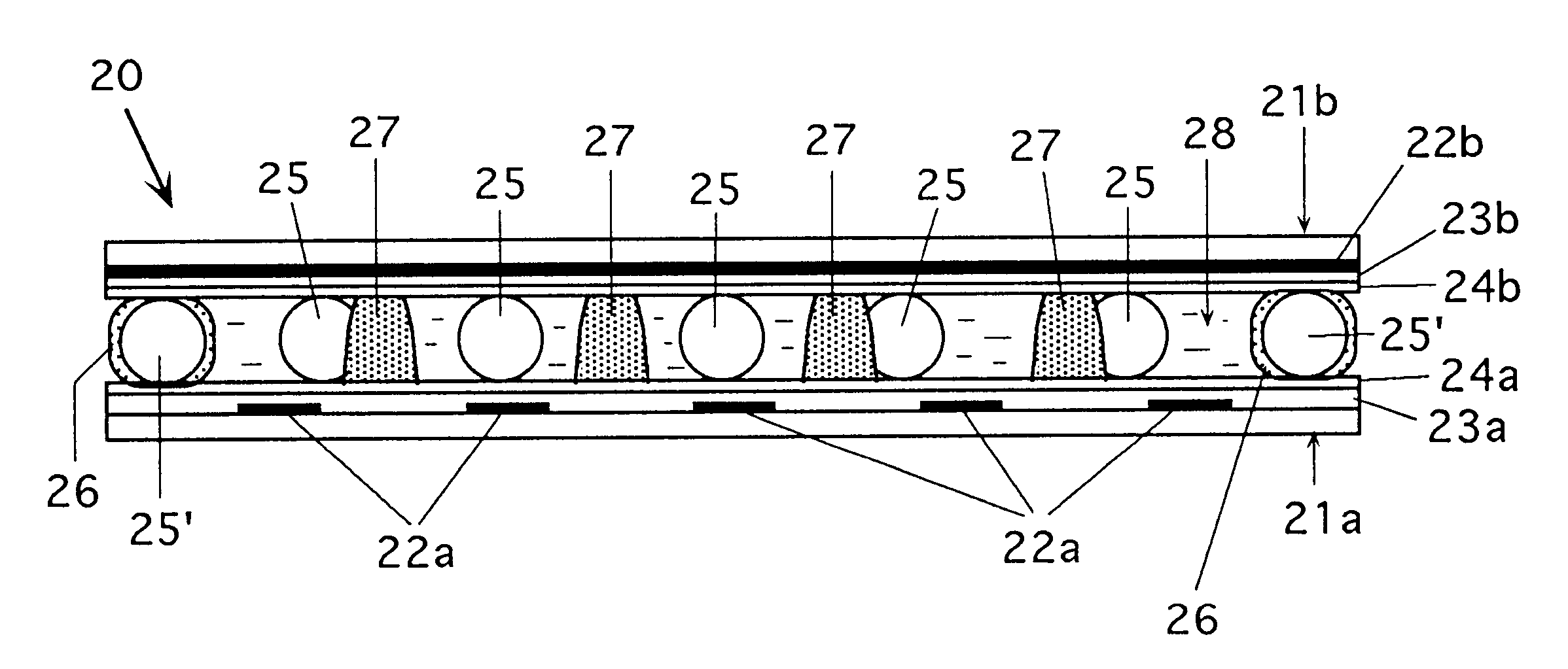

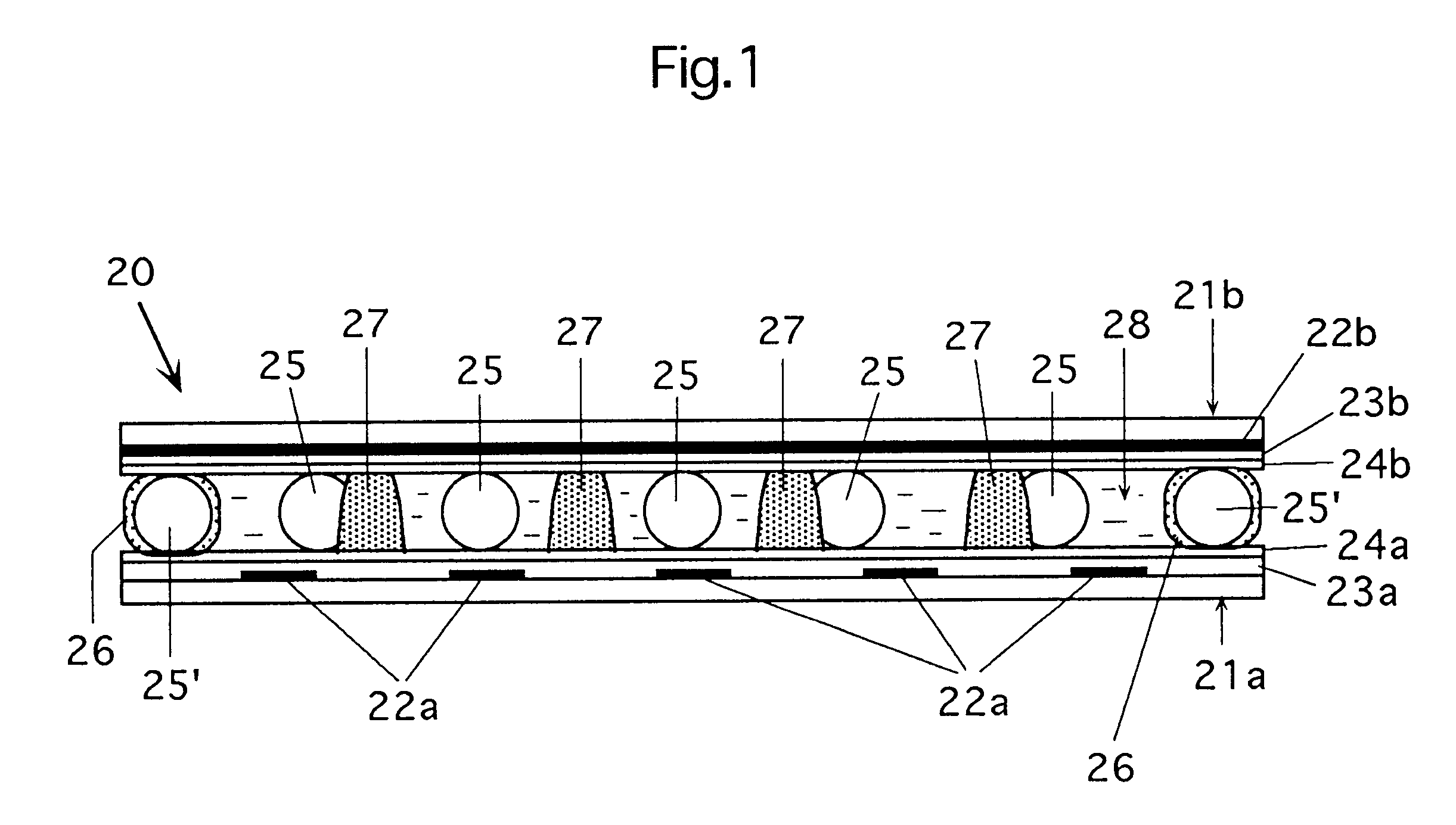

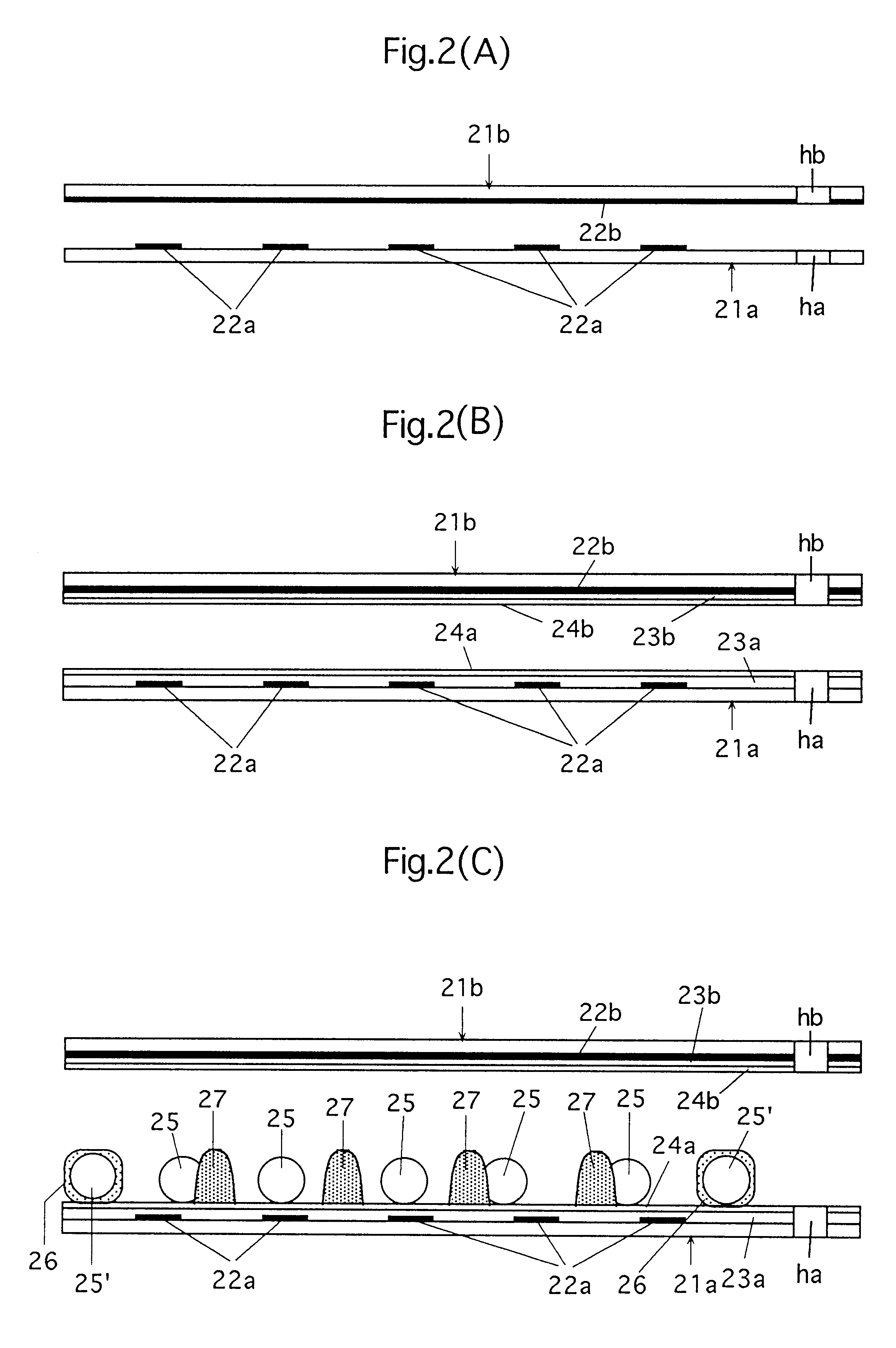

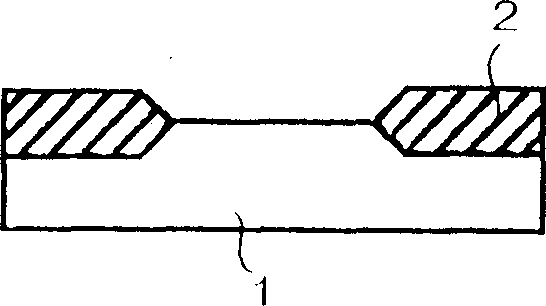

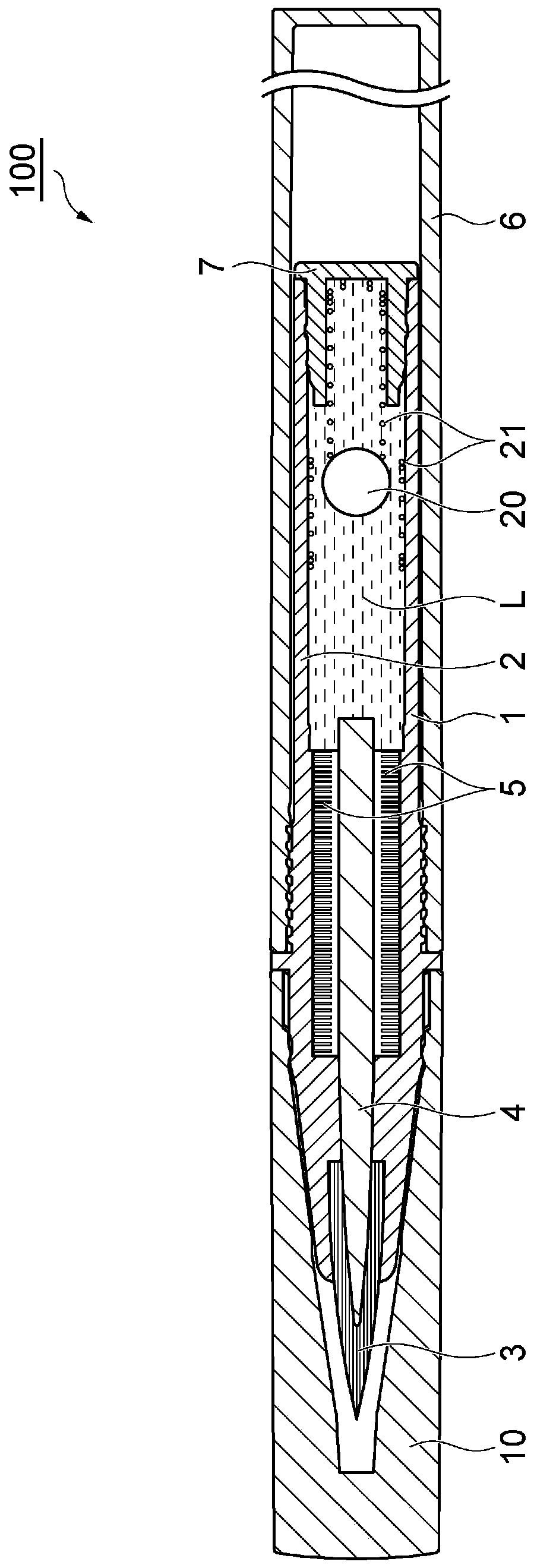

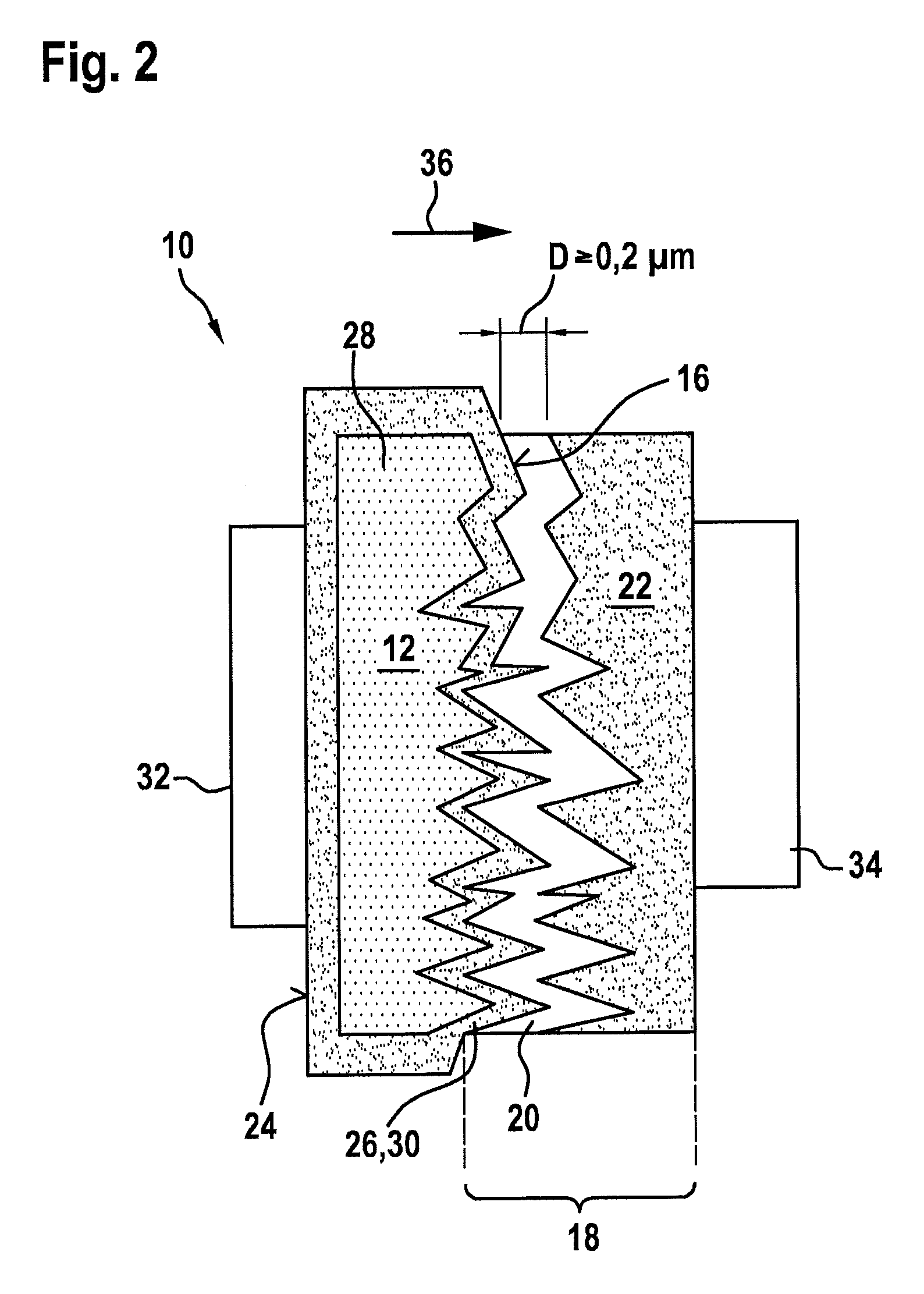

Method of manufacturing liquid crystal display element

InactiveUS6392736B1Simplify manufacturing stepsShort manufacturing timeStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

Method of manufacturing liquid crystal display element includes disposing adhesive on at least one of first and second substrates; disposing spacer particles on at least one substrate; supplying liquid crystal material onto at least one substrate; and fixing the substrates together with adhesive spacer particles and liquid crystal material therebetween. The substrates are fixed together by applying pressure and / or heat to the substrates from an end portion toward the other end portion thereof. An impulse applied to each spacer particle can be between 0.001 gf.sec and 0.1 gf.sec in substrate fixing step. Parameter X relating to heating in fixing step can satisfy 200<=X<=3000, where X=(T-20) / (V.D), T is temperature (°C), V is fixing speed (mm / sec) of substrates, and D is diameter of spacer particles (mm). The spacer particles can occupy an area ratio of 0.003 or more to unit area of the substrate.

Owner:MINOLTA CO LTD

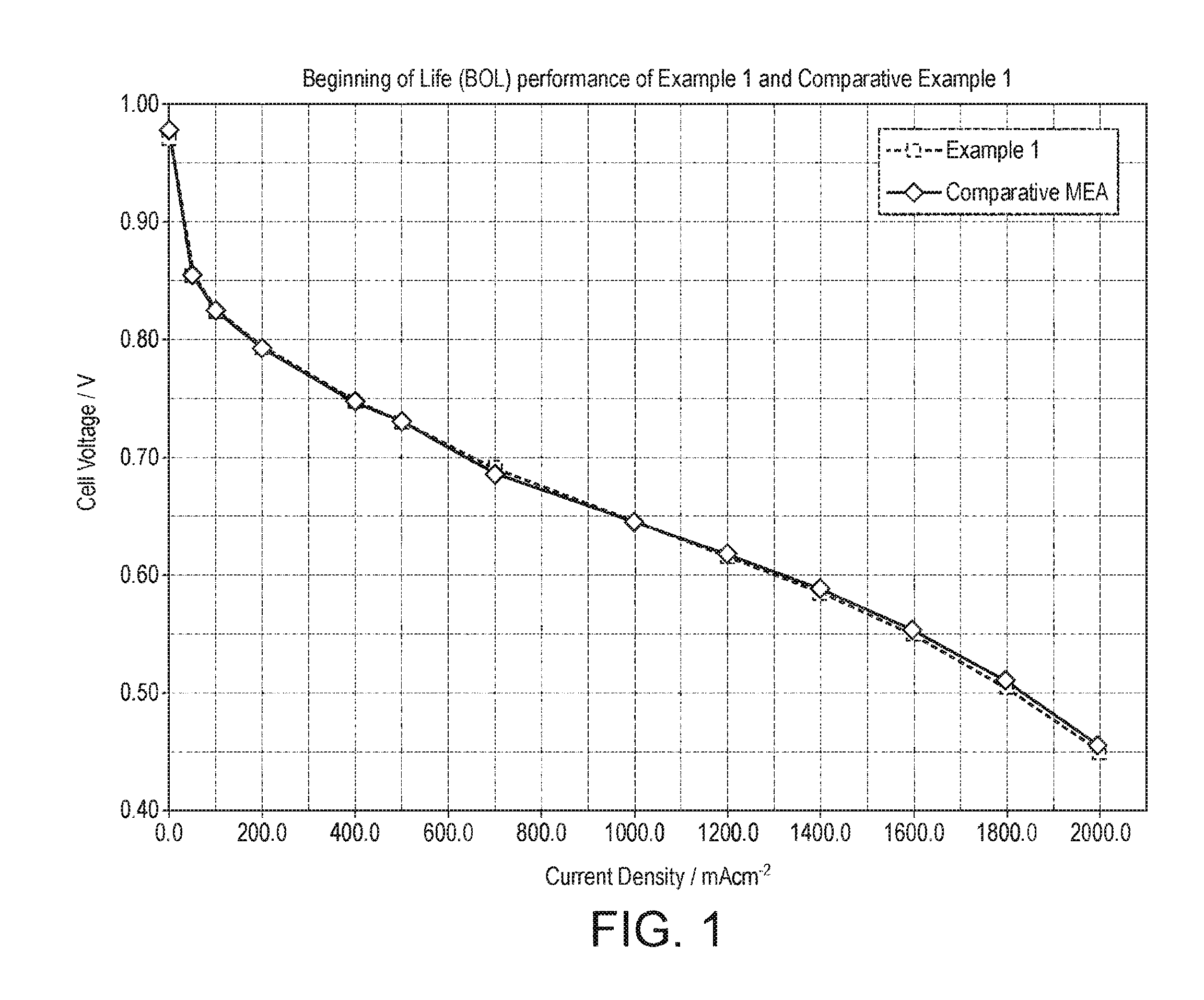

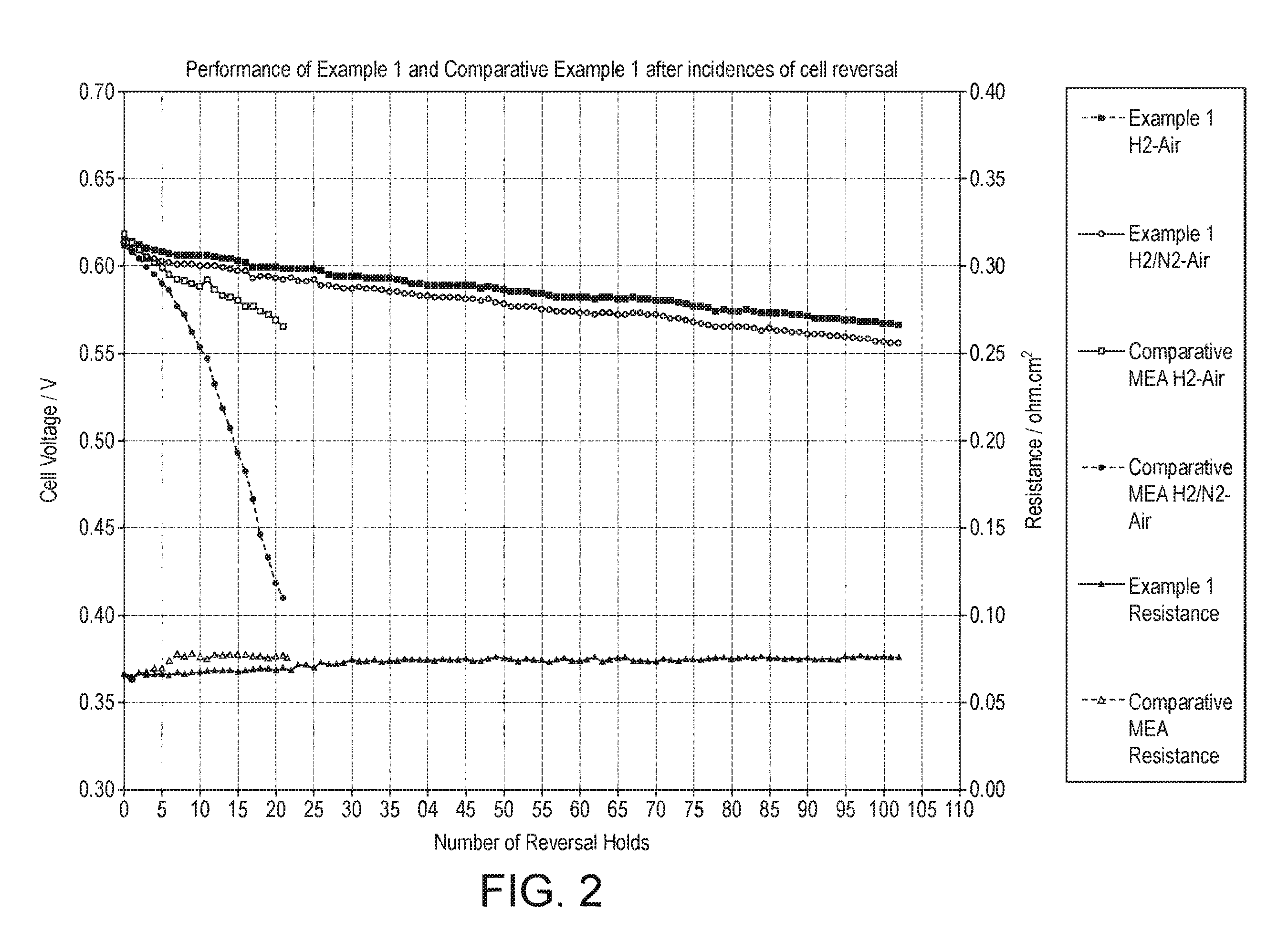

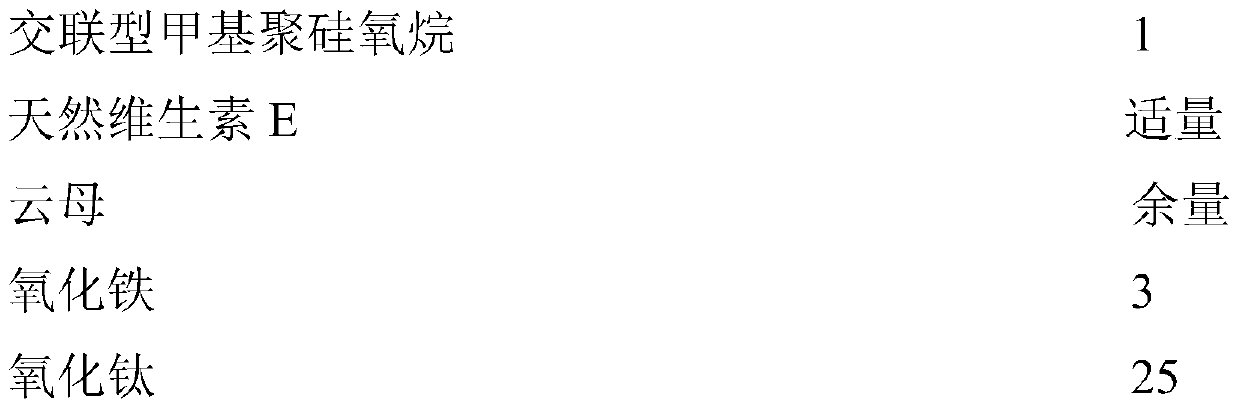

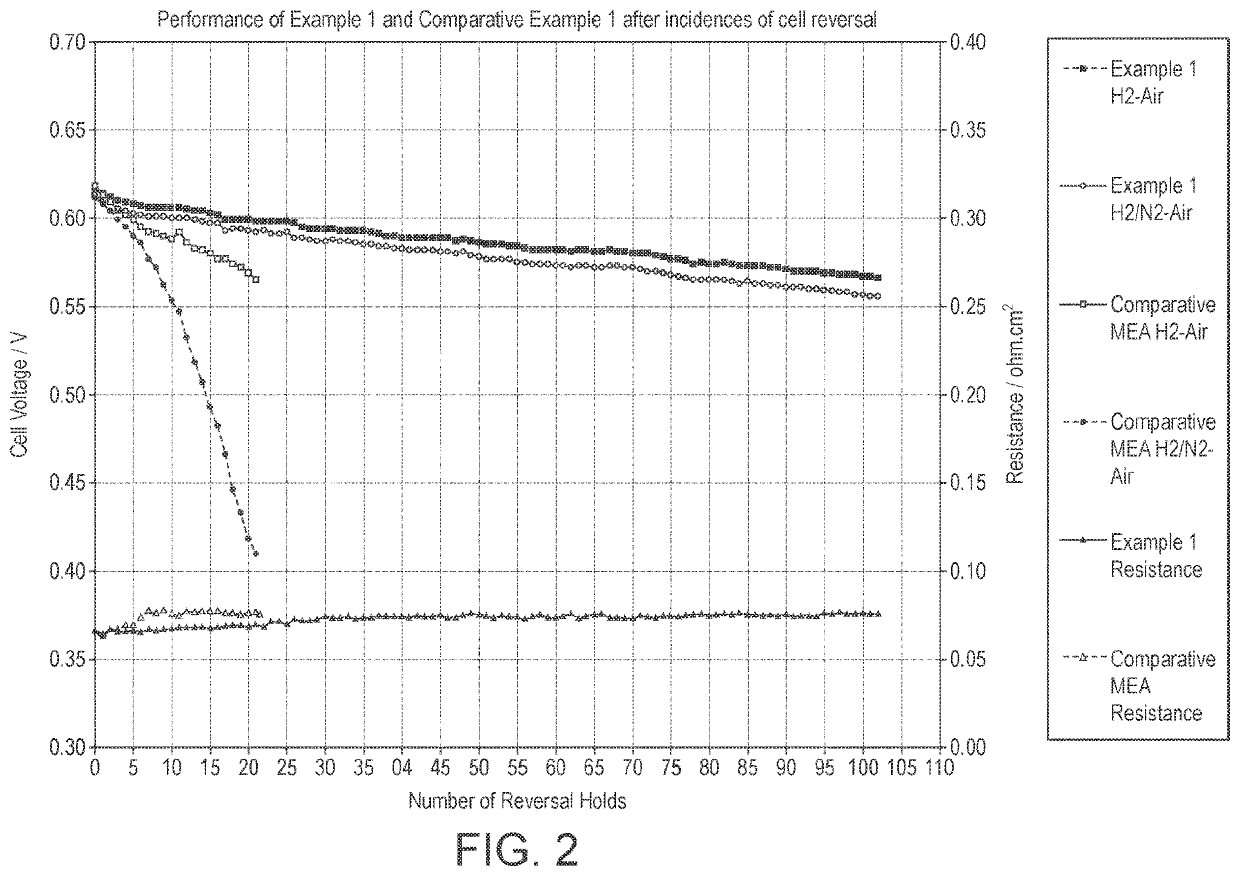

Catalyst layer

A catalyst layer including: (i) a platinum-containing electrocatalyst; (ii) an oxygen evolution reaction electrocatalyst; (iii) one or more carbonaceous materials selected from the group consisting of graphite, nanofibres, nanotubes, nanographene platelets and low surface area, heat-treated carbon blacks wherein the one or more carbonaceous materials do not support the platinum-containing electrocatalyst; and (iv) a proton-conducting polymer and its use in an electrochemical device are disclosed.

Owner:JOHNSON MATTHEY HYDROGEN TECH LTD

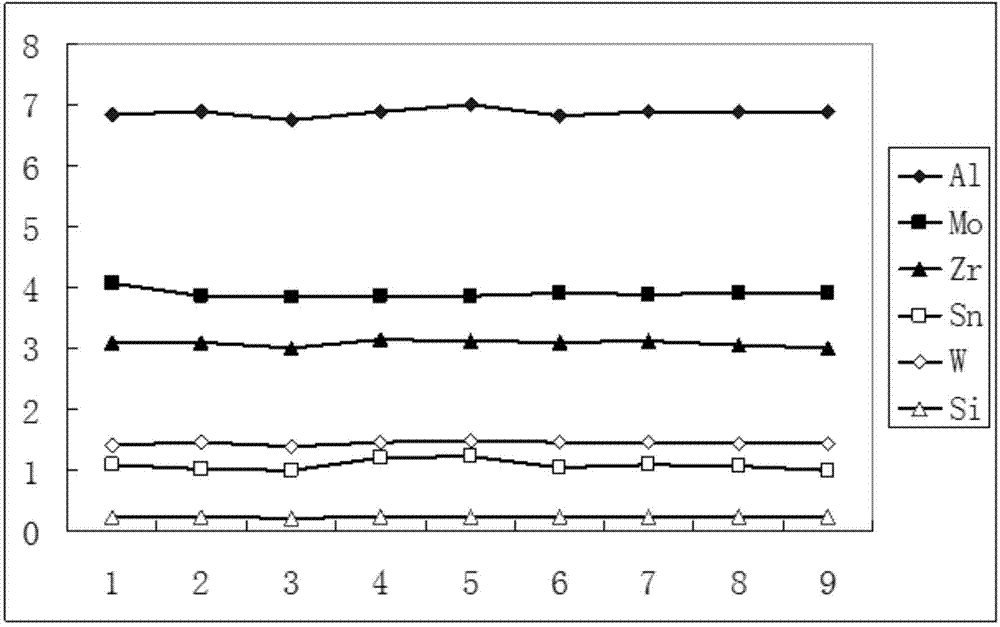

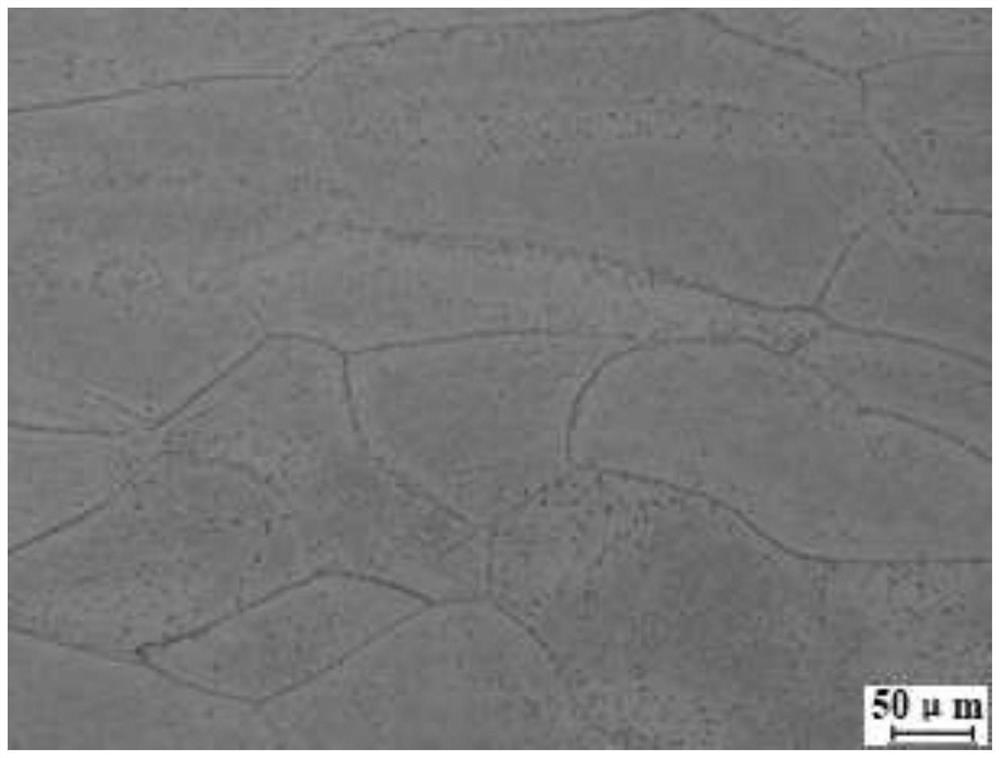

Preparation method for high-uniformity WSTi62441S titanium alloy ingot

The invention discloses a preparation method for a high-uniformity WSTi62441S titanium alloy ingot. The preparation method comprises the following steps of mixing 6.0 to 7.0 mass percent of Al, 1.0 to 2.5 mass percent of Sn, 3.5 to 4.5 mass percent of Mo, 3.0 to 4.5 mass percent of Zr, 0.20 to 0.25 mass percent of Si, 0.4 to 1.5 mass percent of W and the balance of Ti based on the total amount of 100 percent, performing electrode pressing and welding on the mixture to obtain a consumable electrode, and performing vacuum smelting on the consumable electrode for many times to obtain the high-uniformity WSTi62441S titanium alloy ingot. According to the preparation method, the problems of composition segregation, poor controllability in the content of impurities and an interstitial element and poor batch stability of the conventional preparation method are solved, the prepared WSTi62441S titanium alloy ingot is uniform in element composition and high in batch stability, and the preparation method is applied to the industrial production of WSTi62441S titanium alloy ingots in specifications of Phi560 to Phi720mm.

Owner:西部超导材料科技股份有限公司

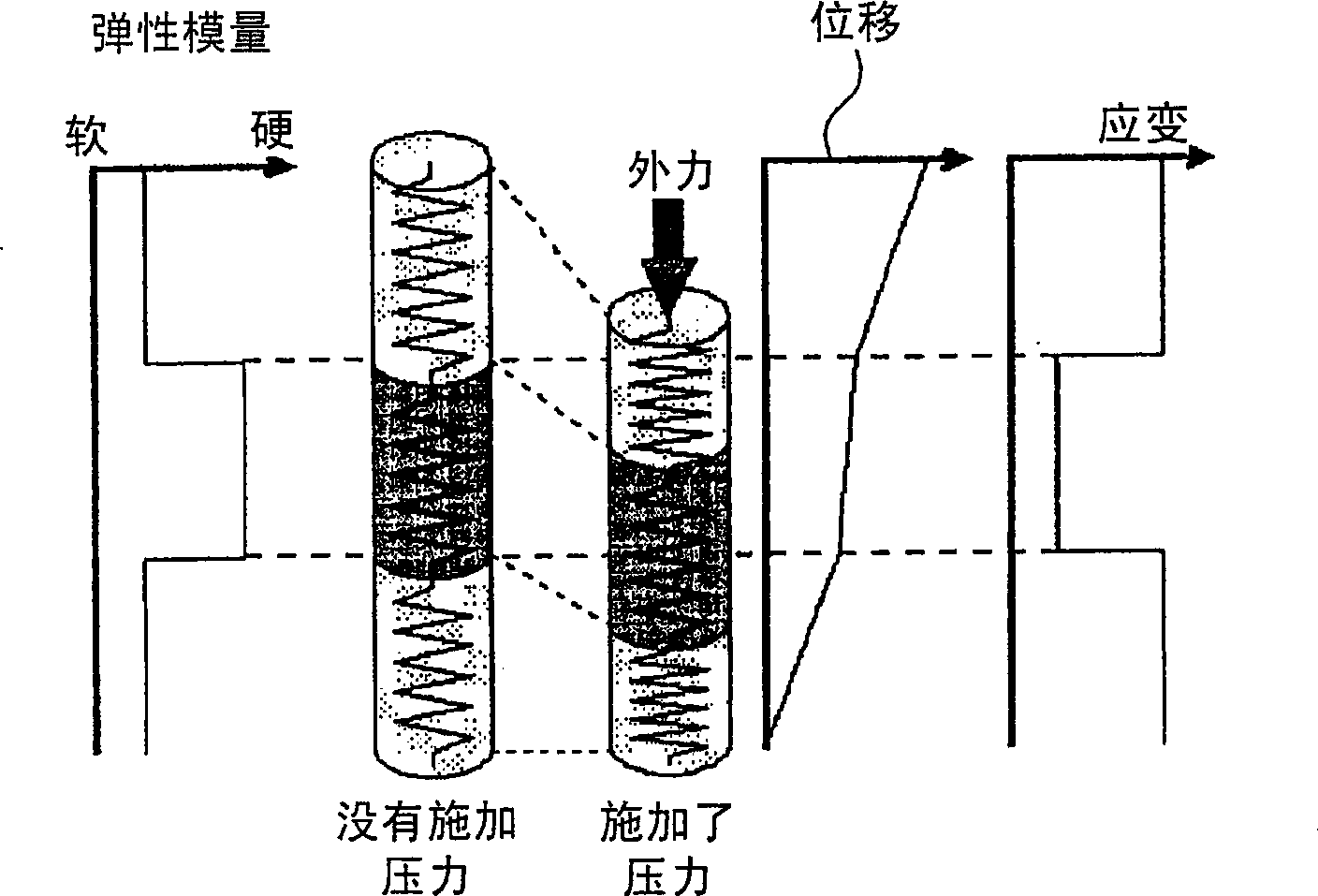

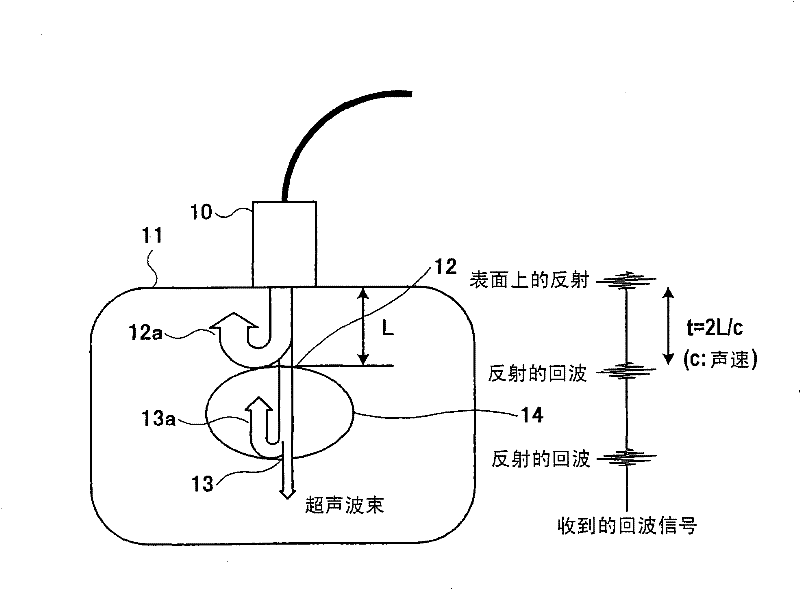

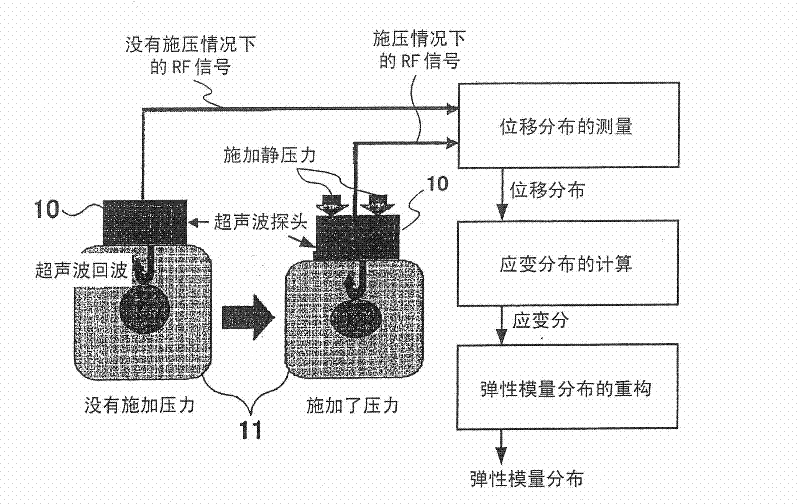

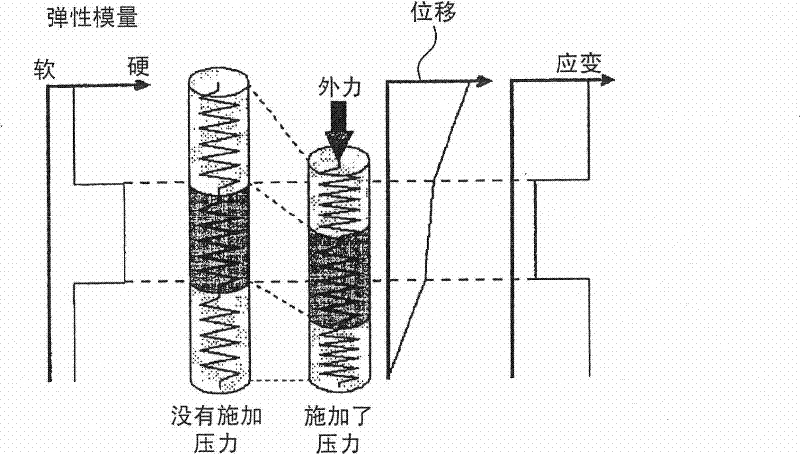

Ultrasonic diagnosis system

InactiveCN101530334ACalculation stableSimplified inversion problemOrgan movement/changes detectionProcessing detected response signalUltrasonic beamSonification

The invention provides an ultrasonic diagnosis system, a measurement point is set at frame data consisting of an envelope signal obtained by orthogonal detection of an RF signal output from an ultrasonic probe before and after compression of an examinee. The measurement point is moved in the ultrasonic beam direction -first dimensional direction, second dimensional direction or third dimensional direction with respect to the frame data so as to obtain a position where the envelope signal correlation coefficient before and after compression belonging to a correlation window surrounding the measurement point becomes maximum. According to this, the displacement of the measurement point accompanying the compression is obtained and the phase difference between the RF signals before and after the compression is obtained, so as to accurately obtain a displacement of the measurement point accompanying the compression by displacement measurement means. Thus, it is possible to estimate the displacement distribution without being restricted by the displacement amount, reduce the calculation time, and cope with a horizontal direction displacement.

Owner:HITACHI HEALTHCARE MFG LTD +1

Tetrodotoxin positive quality control sample as well as preparation method and application thereof

InactiveCN103983495AEasy to makeImprove stabilityPreparing sample for investigationPositive sampleTakifugu rubripes

The invention discloses a method for preparing a tetrodotoxin positive quality control sample. The method comprises the steps of selecting muscular tissues from fresh fugu rubripes, homogenizing, and measuring the content of tetrodotoxin in the muscular tissues to verify whether the muscular tissues contain the tetrodotoxin; if the muscular tissue is a positive sample, diluting the positive sample containing toxin with a negative sample and a dispersant, mixing uniformly, continuously measuring the content of the toxin in the sample, packaging the sample after the sample meets requirements, preserving at an appropriate temperature, and performing uniformity verification and stability analysis on the sample; if the muscular tissue is a negative sample, adding a tetrodotoxin standard solution into the negative samples, adding a dispersant, mixing uniformly, measuring the content of the tetrodotoxin in the sample, packaging the sample after the sample meets requirements, preserving at an appropriate temperature, and performing uniformity verification and stability analysis on the sample. The quality control sample is simple to operate, and has enough stability and uniformity and long preservation time, so that the quality control sample can be used for laboratory quality control.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

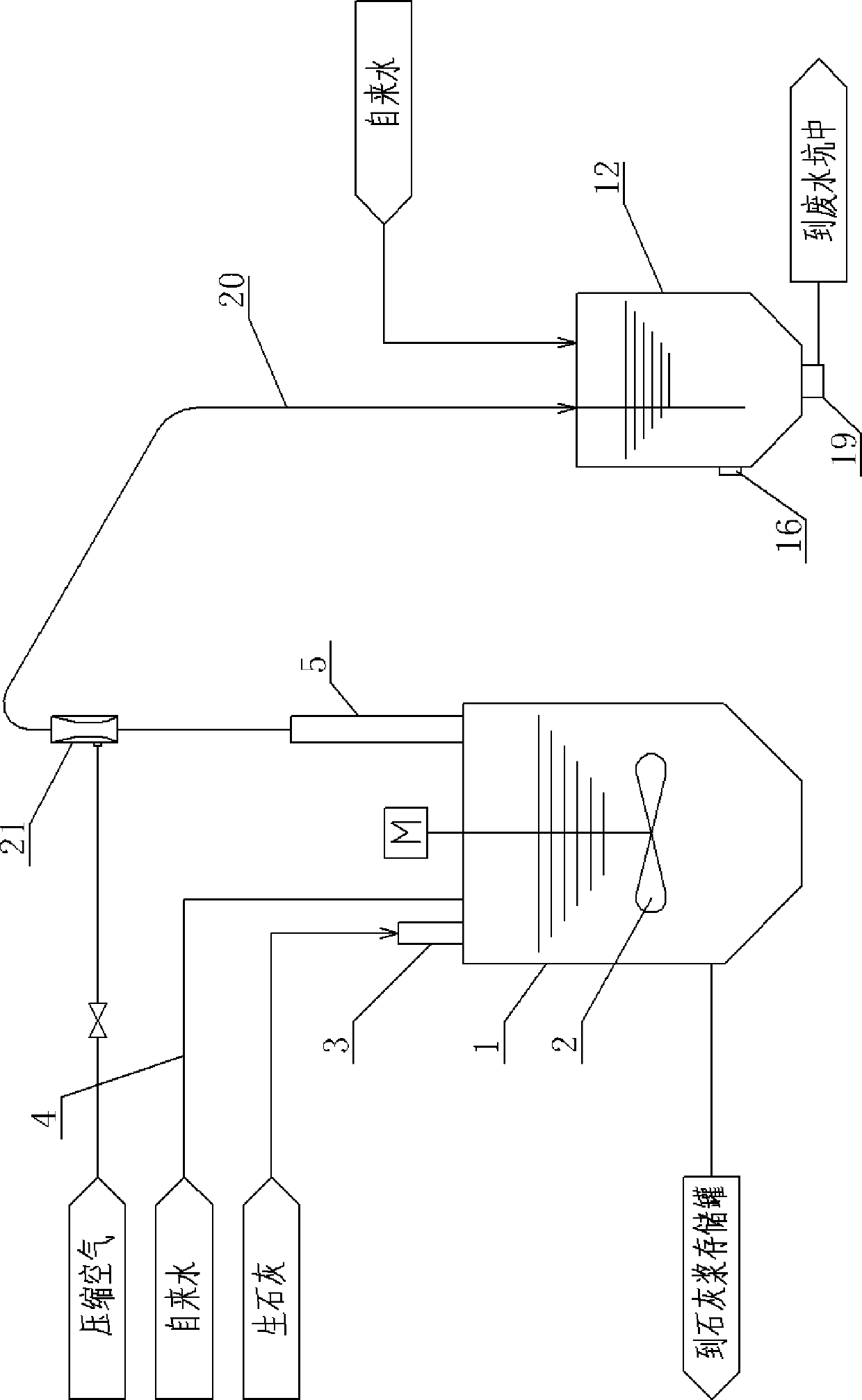

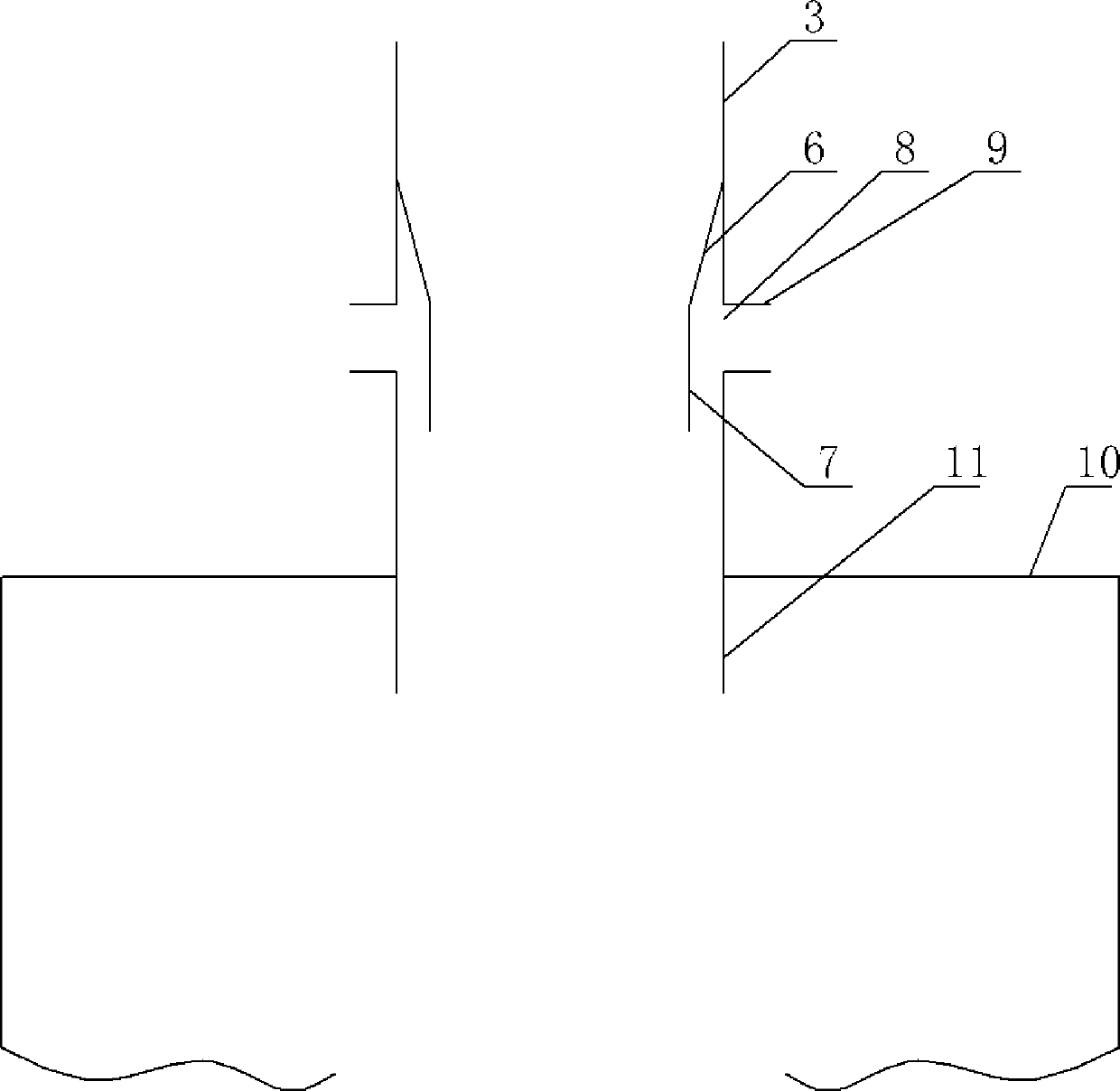

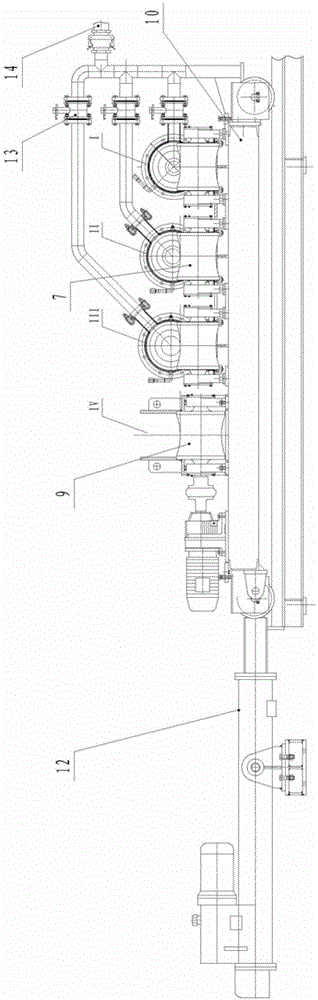

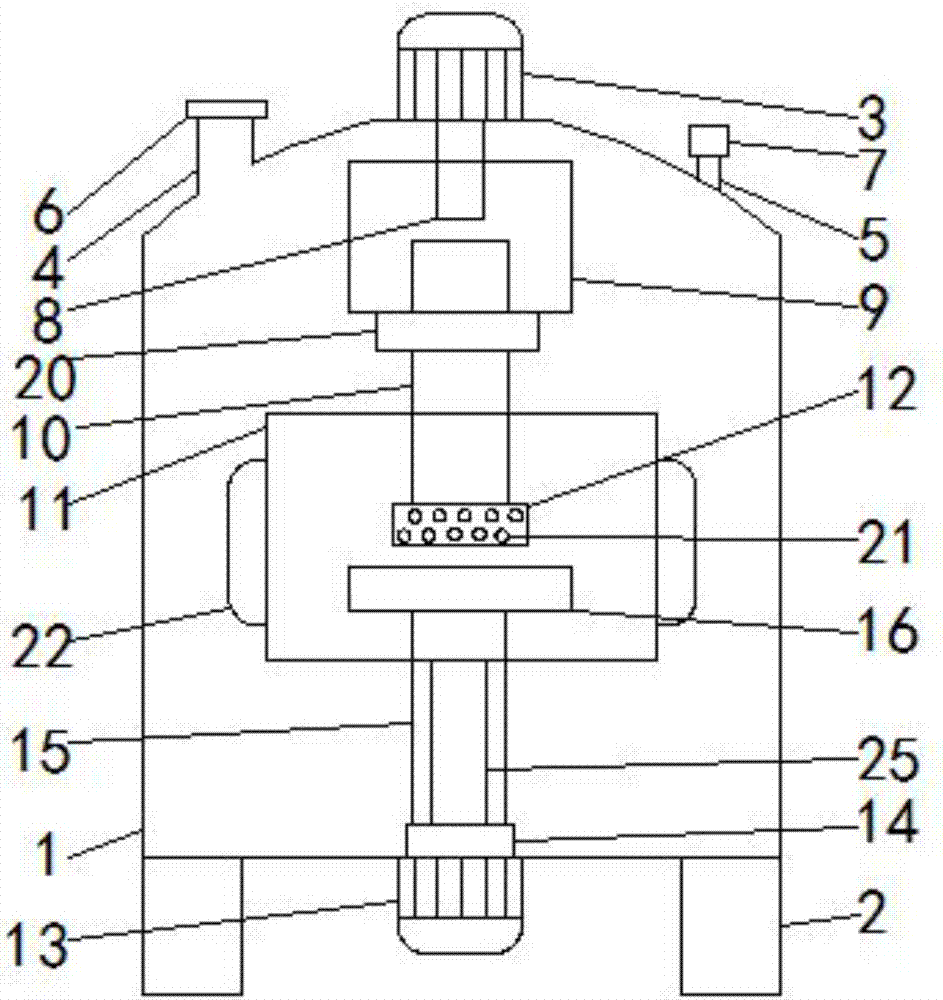

Lime slaking steam treatment device

ActiveCN104193193AGuaranteed uniformityEnsuring sufficient homogeneity of quicklimeUsing liquid separation agentSlurryGuide tube

The invention provides a lime slaking steam treatment device. According to the device, steam in a slaking tank can be smoothly discharged, so that the steam does not enter a lime discharging device, smooth discharging of the lime discharging device is ensured, the discharged steam is purified and discharged into an ambient environment, and environment friendliness is ensured. The lime slaking steam treatment device comprises a quick lime slaking tank, wherein a stirrer is arranged in the quick lime slaking tank; a feeding pipe, a water inlet pipe and a steam exhaust smoke pipe are respectively arranged on the quick lime slaking tank; and an outlet is formed in the bottom of the quick lime slaking tank and is communicated with a lime slurry storage tank. The lime slaking steam treatment device is characterized in that a lime guide tube structure which is closed up from top to bottom is formed in the middle of an inner cavity of the feeding pipe; an air supply hole is formed in an outer wall of the feeding pipe corresponding to the lime guide tube structure; an external air supply pipe is communicated with the air supply hole; the lime slaking steam treatment device further comprises a smoke washing tank which is of a closed structure; and the steam exhaust smoke pipe is communicated with the bottom of the smoke washing tank by virtue of an air delivery pipeline.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Standard steel wire and manufacturing method thereof

The invention relates to a standard steel wire and a manufacturing method thereof. The standard steel wire has enough uniformity and rod smoothness; different force values can be obtained through manufacturing steel wires of different diameters, namely one or more measuring value(s) can be used as a standard value(s); a simple and reliable standard sample is provided for daily inspection, stability tracking study, MSA (measurement systems analysis) and cross-over test among test rooms; the accuracy of tensile test data can be systematically ensured, so that the wrong action caused by inaccurate test data is avoided.

Owner:JIANGYIN FASTEN WIRE PRODUCTS CO LTD +1

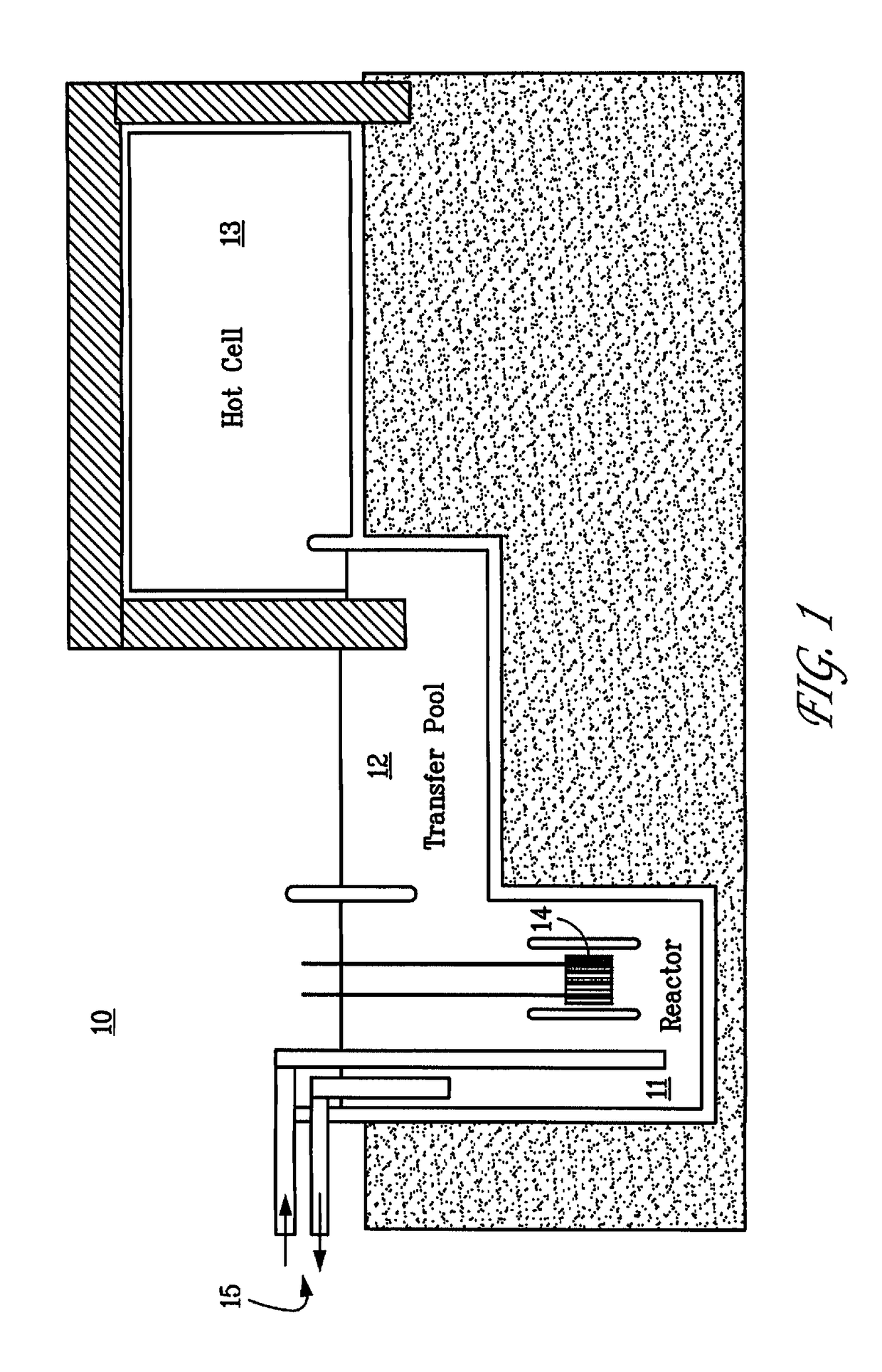

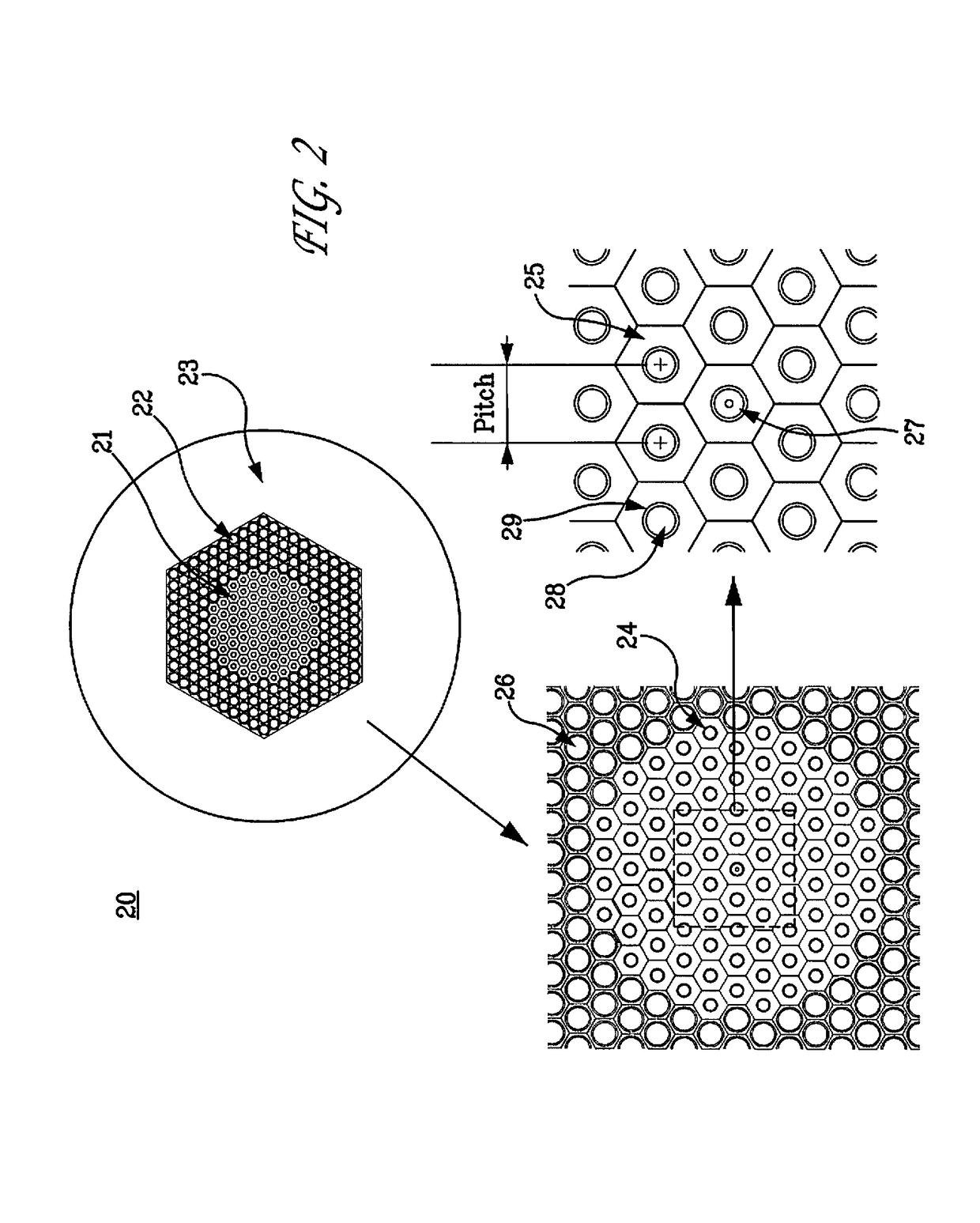

Target-fueled nuclear reactor for medical isotope production

ActiveUS9691511B1Improve uniformityImprove automationConversion outside reactor/acceleratorsConversion in nuclear reactorNuclear reactor coreNuclear reactor

A small, low-enriched, passively safe, low-power nuclear reactor comprises a core of target and fuel pins that can be processed to produce the medical isotope 99Mo and other fission product isotopes. The fuel for the reactor and the targets for the 99Mo production are the same. The fuel can be low enriched uranium oxide, enriched to less than 20% 235U. The reactor power level can be 1 to 2 MW. The reactor is passively safe and maintains negative reactivity coefficients. The total radionuclide inventory in the reactor core is minimized since the fuel / target pins are removed and processed after 7 to 21 days.

Owner:SANDIA

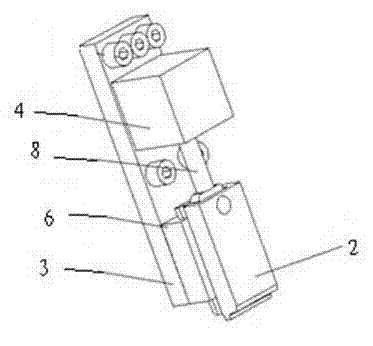

Plasma display panel (PDP) terminal hot-pressing head structure

InactiveCN102176400AThere is no parallelism problemThere will be no problems with excessive pressureCold cathode manufactureTemperature controlOperability

The invention discloses a plasma display panel (PDP) terminal hot-pressing head structure, which relates to the PDP terminal hot-pressing head structure realizing hot-pressing pressure and temperature control by distributing a plurality of pressing heads. The PDP terminal hot-pressing head structure provided by the invention aims to overcome the shortcomings of the prior art, and can effectively solve the problem of pressing head pressure and heating distribution and improve pressing head regulation processibility and pressing head maintenance operability. To fulfill the aims, the technical scheme adopted by the invention is that: the PDP terminal hot-pressing head structure comprises a base and the pressing heads; a bottom plate is detachably connected to the base by a connecting device;the PDP terminal hot-pressing head structure further comprises the plurality of pressing heads; the rear ends of each pressing head are connected with a pressure device; and the pressure devices control the actions of the pressing heads, can output constant pressure according to a set value, and are fixed on the bottom plate. The PDP terminal hot-pressing head structure is applied to tape carrierpackage (TCP) hot-pressing.

Owner:SICHUAN COC DISPLAY DEVICES

High-strength Al-Zn-Mg-Cu aluminum alloy and preparation method thereof

The invention discloses a high-strength Al-Zn-Mg-Cu aluminum alloy and a preparation method thereof, and relate to the field of aluminum alloy. The aluminum alloy comprises, by weight, less than or equal to 0.5% of Si, less than or equal to 0.5% of Fe, 5.0%-7.0% of Zn, 2.0%-3.0% of Cu, 1.5%-3.0% of Mg, 0.15%-0.35% of Sc, 0.1%-0.2% of Zr, 0.1%-0.3% of Y, and the balance aluminum and non-impurities.The preparation method comprises the following steps of smelting, die, refining and impurity removal and gas removal, pouring, homogenizing heat treatment, three-dimensional large deformation forgingpre-deformation, isothermal deformation processing and heat treatment. A casting mold adopts a metal mold as an inner mold, the casting mold is surrounded by a cooling pipe, a sand mold is used as aspecial combination mold of an outer mold, and a high-quality and high-performance casting is obtained; and the heat treatment comprisessolution treatment+gradient aging treatment. According to the prepared Al-Zn-Mg-Cu aluminum alloy, the strength reaches 650 MPa, the elongation is 10%-13%, the elongation is improved while the strength is improved, and the service life is prolonged; and the Al-Zn-Mg-Cu aluminum alloy has important value in the field of high-strength aluminum alloy.

Owner:CENT SOUTH UNIV

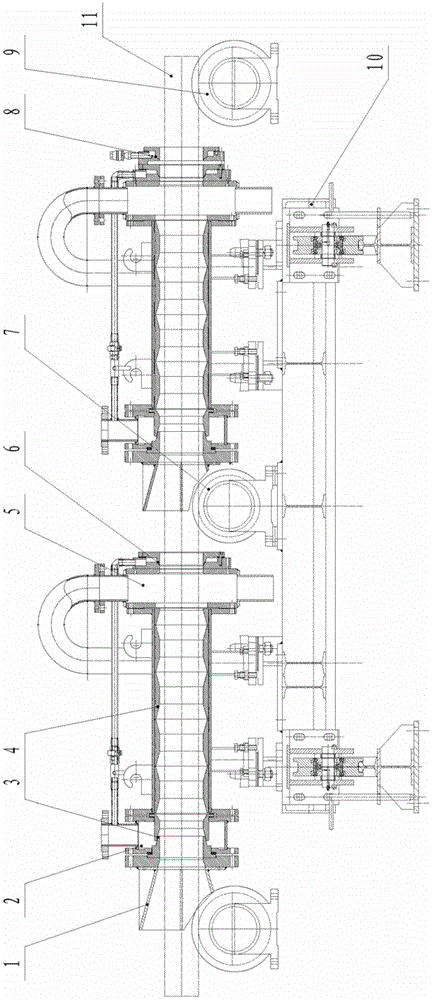

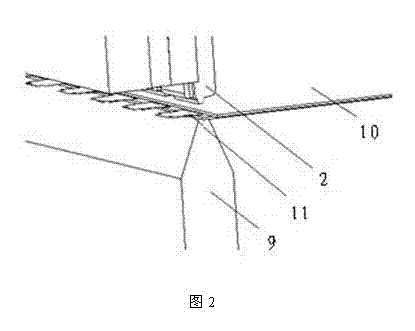

Cooling equipment for large bar material

ActiveCN103357677BImprove performanceImprove rapid cooling effectWork treatment devicesMetal rolling arrangementsManufacturing technologySpray nozzle

The invention discloses cooling equipment for a large bar material, which is used for cooling a bar material (11) after rolling. The cooling equipment is equipped with a short passing water cooler; the bar material (11) penetrates through the short passing water cooler; a water spraying box (2) is arranged on the short passing water cooler at the entering end part of the bar material (11); an annular nozzle (3) is arranged on the spraying box (2). Through adopting the technical scheme, the fast cooling capacity is improved, sufficient cooling is achieved, stability and uniformity of cooling are achieved, and the manufacture requirement of passing water cooling manufacture technology for rolling the large bar material (Phi 60-Phi 150 mm) is satisfied; the products can be manufactured are various and have a wide specification range; the position change is convenient and fast; the bar material product subjected to passing water cooling has increased performance with obvious economical benefits; the cooling equipment is safe and reliable in use, saves energy, protects the environment and is easy for popularization.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

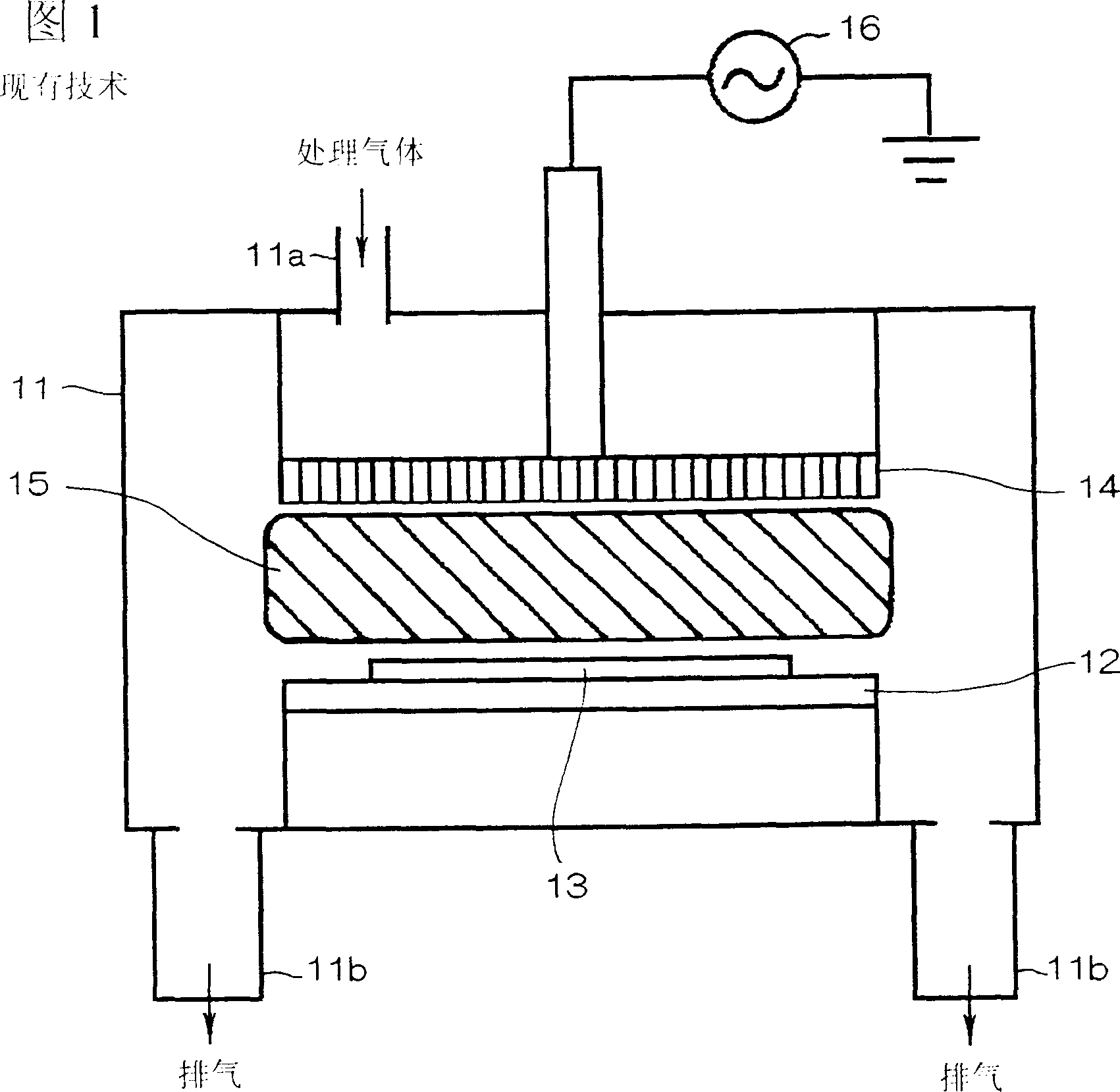

Plasma intensified chemical vapour deposition device

InactiveCN1117889CStable temperature controlAvoid direct exposureElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorProduct gas

There is provided a plasma-enhanced chemical vapor deposition apparatus including a reaction chamber into which a process gas is introduced and from which an exhausted gas is discharged, a susceptor having a first region on which a semiconductor substrate is to be placed and a second region other than the first region, and an electrode located in facing relation with the susceptor and cooperating with the susceptor to generate plasma therebetween for forming a thin film on the semiconductor substrate placed on the first region of the susceptor, characterized by a ceramics insulator located between the second region of the susceptor and the plasma.

Owner:NEC CORP

Photovoltaic plate frame corrosion resistance treatment method

InactiveCN104831205AImprove galvanizing qualityImprove mechanical propertiesHot-dipping/immersion processesWater basedAcid washing

The present invention discloses a photovoltaic plate frame corrosion resistance treatment method, which is used for surface corrosion resistance treatment on a photovoltaic plate frame and sequentially comprises washing, drying, hot zinc plating, and cooling, wherein the washing step sequentially comprises degreasing, inspection, acid washing, and water washing, the degreasing step is adopting a water-based metal degreaser to carry out an oil removing treatment on the photovoltaic plate frame surface, the hot zinc plating step comprises heating a zinc liquid to a temperature of 455-480 DEG C, placing the photovoltaic plate frame into the zinc liquid, maintaining for 1-1.5 min, and taking out, the zinc liquid contains 0.07-0.1% by mass of aluminum, and the leaching assisting step is set between the drying step and the hot zinc plating step. According to the present invention, the process route is simple, and the photovoltaic plate frame surface corrosion resistance quality is easily achieved.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

Anticorrosion processing method used for surface of metal member

InactiveCN104762581AImprove liquidityImprove mechanical propertiesHot-dipping/immersion processesSurface layerChloride

The invention discloses an anticorrosion processing method used for surface of a metal member, which is used for anticorrosion processing of surface of a photovoltaic flat rack. The anticorrosion processing method comprises the steps of cleaning, drying, galvanizing and cooling in order, and the cleaning step comprises the steps of degreasing, examining, pickling and washing in order, the drying and galvanizing steps also comprise an assistant leaching step, the assistant leaching step is characterized in that the photovoltaic flat rack is immersed into a plating auxiliary for 5-8 minutes, the temperature of the plating auxiliary is between 50-57 DEG C, the plating auxiliary contains zinc chloride and ammonium chloride, the mass ratio of zinc chloride to ammonium chloride is between 1 and 4 to 1 and 10, and the plating auxiliary also contains glycerin. According to the invention, the technology route is simple, and the method is benefit for obtaining smoother galvanizing layer surface layer and more uniform galvanizing layer composition.

Owner:CHENGDU ZHENZHONG ELECTRIC

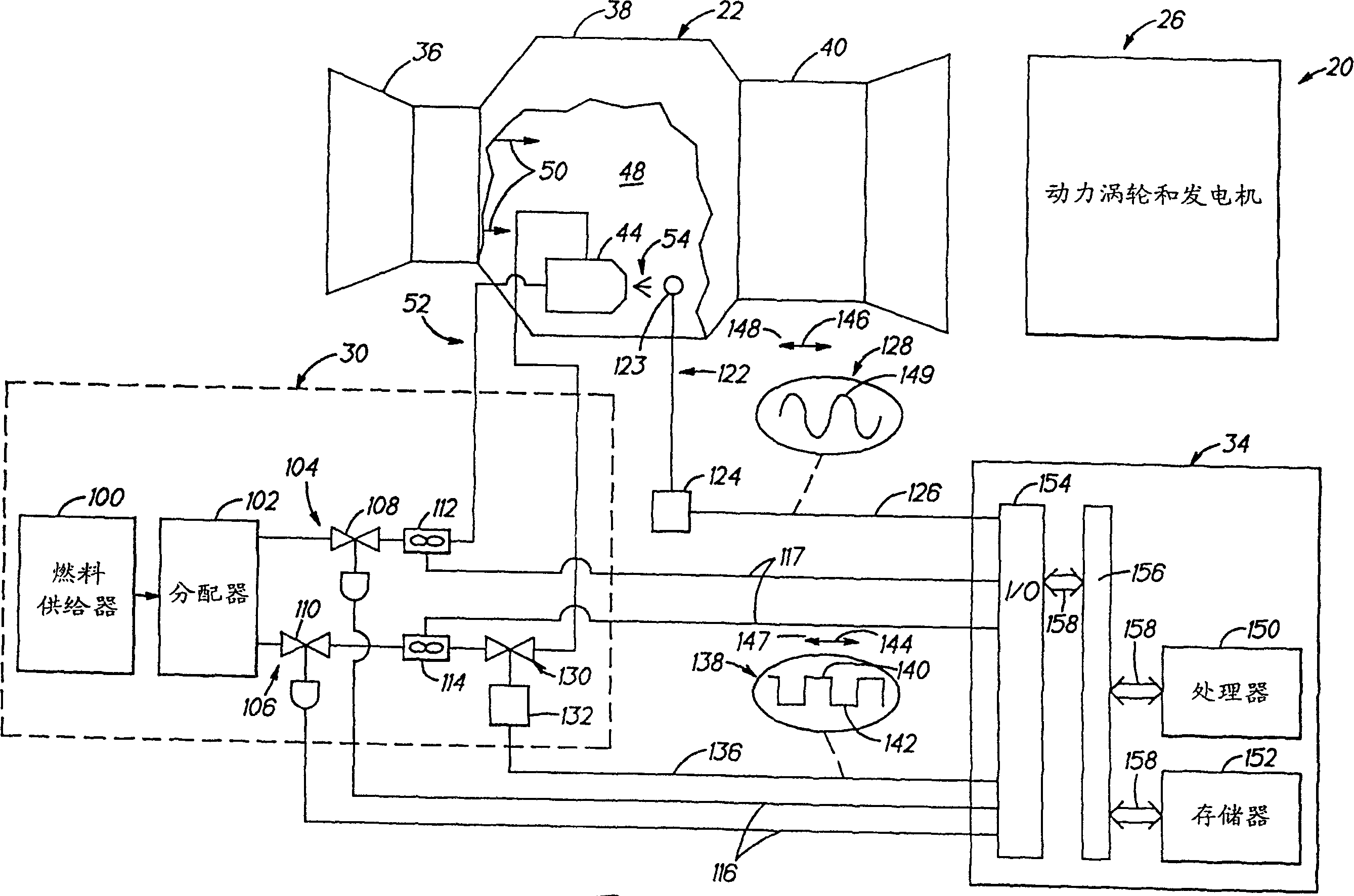

Method and device for gas burner

InactiveCN1143082CSufficient uniformityReduce energy consumptionBurnersContinuous combustion chamberNuclear engineeringLiquid fuel

An apparatus for use in a system having a gas fuel supply and a combustor includes a fuel actuator, a controller; and a premixer. The controller generates a command signal indicative of actuation sought from the fuel actuator. The actuator receives gas fuel from the liquid fuel supply and provides liquid fuel at a modulated rate of flow in response to the command signal. The premixer receives the fuel from the actuator, mixes the fuel with air, and provides the mixture to the combustor.

Owner:UNITED TECH CORP

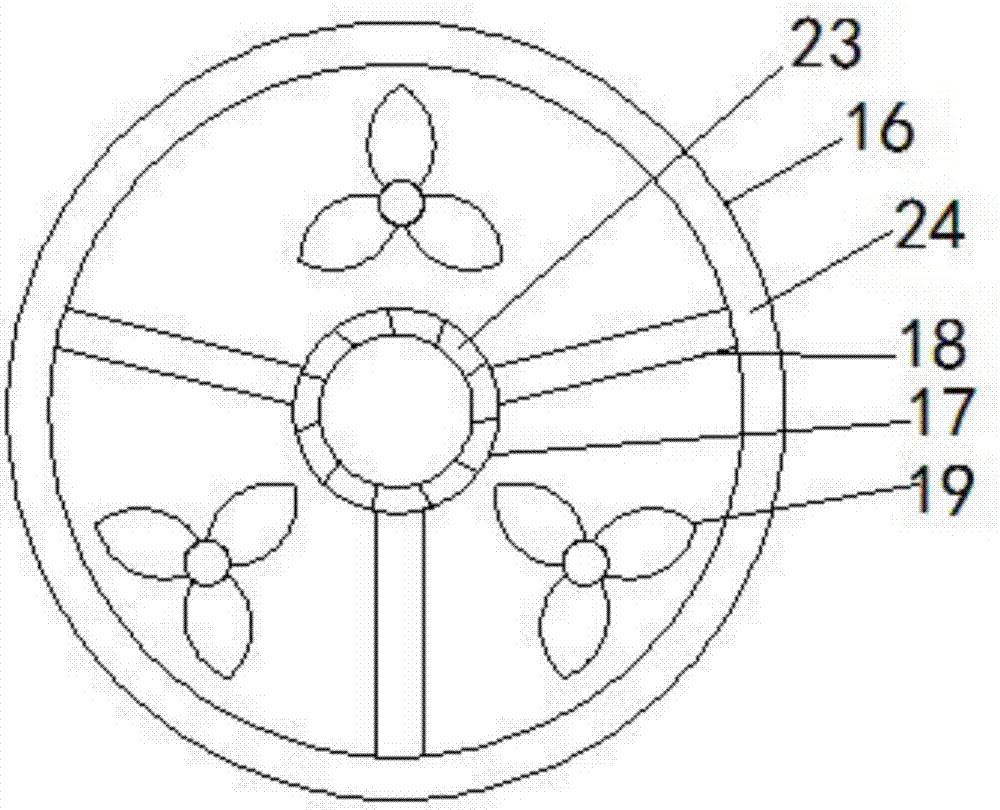

Reaction chamber air inlet device for metal organic chemical vapor deposition (MOCVD) equipment

ActiveCN103074674BIncrease flexibilityFunction increaseFrom chemically reactive gasesChemical vapor deposition coatingProduct gasEngineering

A reaction chamber air inlet device for metal organic chemical vapor deposition (MOCVD) equipment includes a cylinder body, a water cooling air uniform-distributing plate manufactured inside the cylinder body, an upper cover plate fixed on the cylinder body and forming an air inlet chamber with the water cooling air uniform-distributing plate, and an air separating device fixed on the upper cover plate and dividing the air inlet chamber into at least two air inlet chambers or communicating the two air inlet chambers. The reaction chamber air inlet device realizes diversity and flexibility of air inlet manner in the MOCVD reaction chamber, improves mixing uniformity of components and avoids serious pre-reaction.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of low-density Nb-Ti-Al-V-Zr-C niobium alloy bar

ActiveCN114855107AHigh elongationSmall sizeNuclear energy generationMetal-working apparatusCarbideIngot

The invention discloses a preparation method of a low-density Nb-Ti-Al-V-Zr-C niobium alloy bar. The method comprises the following steps: 1, carrying out primary extrusion on a low-density Nb-Ti-Al-V-Zr-C niobium alloy ingot to obtain a primary extruded bar; 2, performing secondary extrusion to obtain a secondary extrusion rod; 3, quenching treatment; 4, free forging processing; and fifthly, vacuum annealing is conducted, and the low-density Nb-Ti-Al-V-Zr-C niobium alloy bar is obtained. According to the method, the low-density niobium alloy bar is prepared through the technology of two-time extrusion, quenching and forging, the quenching treatment technology and the secondary extrusion technology are added, the carbide reinforced phase TiC is separated out and nucleated again after redissolution and is dispersed and distributed in a matrix, the size of the carbide reinforced phase is effectively reduced, and the dispersity of the carbide reinforced phase is improved; the elongation after fracture of the low-density niobium alloy bar is improved, so that the low-density niobium alloy bar shows room-temperature high-strength and high-plasticity mechanical properties.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Galvanizing technology good for uniformity of galvanizing layer thickness

InactiveCN104762580APrevent Galvanizing FailureSimple methodHot-dipping/immersion processesAluminiumHydrogen chloride

The invention discloses a galvanizing technology good for uniformity of galvanizing layer thickness, which is used for anticorrosion processing on the surface of a photovoltaic flat rack. The technology comprises the steps of cleaning, drying, galvanizing and cooling in order, and the cleaning comprise comprises the steps of degreasing, examining, pickling and washing in order, the degreasing step employs a water-based metal degreasing agent for removing oil on the surface of the photovoltaic flat rack, the pickling step is characterized in that when the temperature scope is between 30-35 DEG C, a pickle containing hydrogen chloride, hexamethylene tetramine and corrosion inhibitor are employed for washing the photovoltaic flat rack; the corrosion inhibitor contains a nitrogen compound-containing corrosion inhibitor and a sulfur compound-containing corrosion inhibitor; the galvanizing step is characterized in that zinc liquid is heated to 455-480 DEG C, the photovoltaic flat rack is placed in the zinc liquid for keeping for 1-1.5 minutes and then is taken out, and the zinc liquid contains aluminium. The galvanizing technology has simple process, and a galvanizing layer with better combination quality, thickness quality and uniformity quality can be conveniently obtained.

Owner:CHENGDU ZHENZHONG ELECTRIC

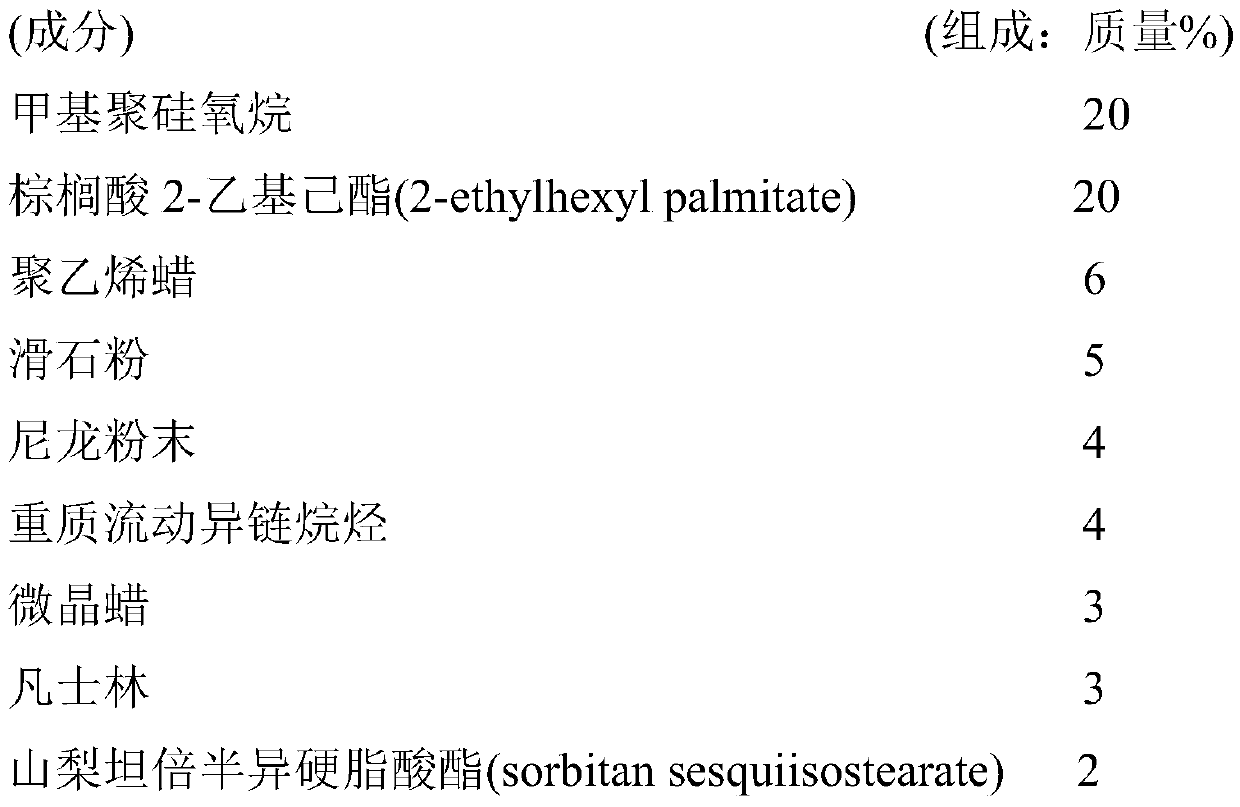

Aqueous liquid cosmetic material

ActiveCN111110591AFully portrayedFull color densityCosmetic preparationsMake-upPolymer scienceSulfosuccinic acid

A water-based liquid cosmetic containing diethylhexyl sodium sulfosuccinate, an inorganic coloring pigment, a water-soluble dispersant, and a film-forming polymer emulsion, wherein a content of diethylhexyl sodium sulfosuccinate is 0.01 to 1 mass % and a content of the inorganic coloring pigment is 3 to 20 mass %, based on a total amount of the cosmetic, and wherein the inorganic coloring pigmentcontains carbon black.

Owner:TOKIWA CORP

Catalyst layer

A catalyst layer including: (i) a platinum-containing electrocatalyst; (ii) an oxygen evolution reaction electrocatalyst; (iii) one or more carbonaceous materials selected from the group consisting of graphite, nanofibres, nanotubes, nanographene platelets and low surface area, heat-treated carbon blacks wherein the one or more carbonaceous materials do not support the platinum-containing electrocatalyst; and (iv) a proton-conducting polymer and its use in an electrochemical device are disclosed.

Owner:JOHNSON MATTHEY HYDROGEN TECH LTD

Selected area epitaxy one-dimensional electron gas gan-based hemt device and its preparation method

ActiveCN103400856BImprove high temperature and high pressure characteristicsImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesUltra high speedSelective area epitaxy

The invention discloses a one-dimensional electronic gas GaN-based HEMT (High Electron Mobility Transistor) device adopting selective area epitaxy and a preparation method thereof, and mainly solves the problems of poor high temperature and high voltage characteristics, frequency characteristic and power characteristic of an existing one-dimensional electronic gas device. The device comprises a substrate, a buffering layer, a passivation layer and a protection layer from bottom to top; the buffering layer adopts GaN; the buffering layer is provided with barrier layer strips and masking layer strips, which are periodically arranged at intervals; both ends of each barrier layer strip respectively are a source electrode and a drain electrode; the passivation layer is positioned on the barrier layer strips and the masking layer strips; the passivation layer is provided with a grid slot; a grid electrode is arranged in the grid slot; and the barrier layer strips adopt AlGaN and the width of each barrier layer strip is in nanometer dimension so as to form one-dimensional electronic gas. Compared with Si-based and GaAs-based one-dimensional electronic gas devices, due to the adoption of a wide bandgap semiconductor GaN with the outstanding material characteristics, the one-dimensional electronic gas GaN-based HEMT device adopting selective area epitaxy has excellent high temperature and high voltage characteristics, frequency characteristic and power characteristic, and the ultrahigh speed and low power consumption one-dimensional electronic gas device can be made.

Owner:云南凝慧电子科技有限公司

Soybean meal fermentation process

InactiveCN102283316BGuaranteed temperatureUniform fermentationFood processingAnimal feeding stuffAdditive ingredientAbsorption rate

The invention relates to a soybean meal fermentation process in the technical field of vegetable protein fermentation, which mainly comprises the following steps: raw material clearing, mixed inoculation, fermentation, puffing, drying, cooling, crushing, screening and finished product packaging. The invention is mainly characterized in that materials are fermented in a fermentation cabin so as toensure the temperature and humidity environment for the fermentation of the materials, the materials are provided with air at regular times and are stirred in the fermentation process so as to ensurethe materials to be fermented uniformly, and simultaneously follow-up treatments such as puffing, vacuum drying, cooling and the like are increased in the fermentation process to further prevent nutrient components in the fermented materials from being damaged. In addition, the materials are fermented by a multi-microorganism compound bacterial liquid, the fermentation time can be shortened through the multi-microorganism synergistic effect, the materials fermented by the process disclosed by the invention have uniform quality and high nutritional value, feed absorption rate of animals is increased, and the materials are convenient to store.

Owner:JIANGSU MUYANG GRP CO LTD

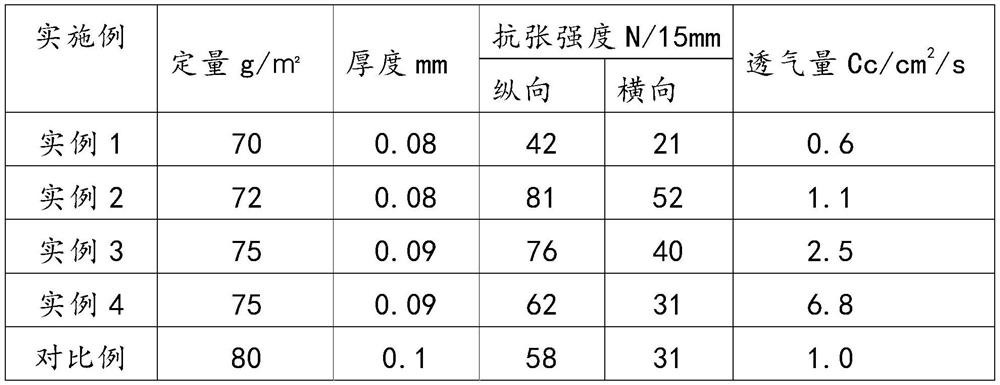

Preparation method of separation membrane composite support body

InactiveCN112501951AImprove heat resistanceHigh melting pointSemi-permeable membranesPaper/cardboardPolyesterFiber

The invention discloses a preparation method of a separation membrane composite support body, which comprises the following steps: 1. feeding hollow polyoxadiazole fibers and high-crystallinity polyester fibers according to a certain ratio at one time, defibering to prepare slurry, purifying, removing impurities, and dispersing to obtain slurry; 2, sequentially papermaking, squeezing and drying onthe pulp, and obtaining paper sheets; and 3, carrying out hot rolling on the paper sheet, and finishing by a calender to obtain the separation membrane composite support body. The preparation methodhas the beneficial effects that the preparation method is simple, the two raw materials are low in cost and easy to obtain, the two raw materials have high heat resistance and melting point, the high-crystallinity polyester fiber can be bonded and melted at high temperature to form a unique hole structure, and meanwhile, enough homogeneity can be kept; and the hollow polyoxadiazole fiber is used as a skeleton to provide enough mechanical strength, and the separation membrane composite support body has excellent uniformity, mechanical strength, heat resistance and air permeability.

Owner:JIANGSU ZANPOD NEW MATERIAL CO LTD

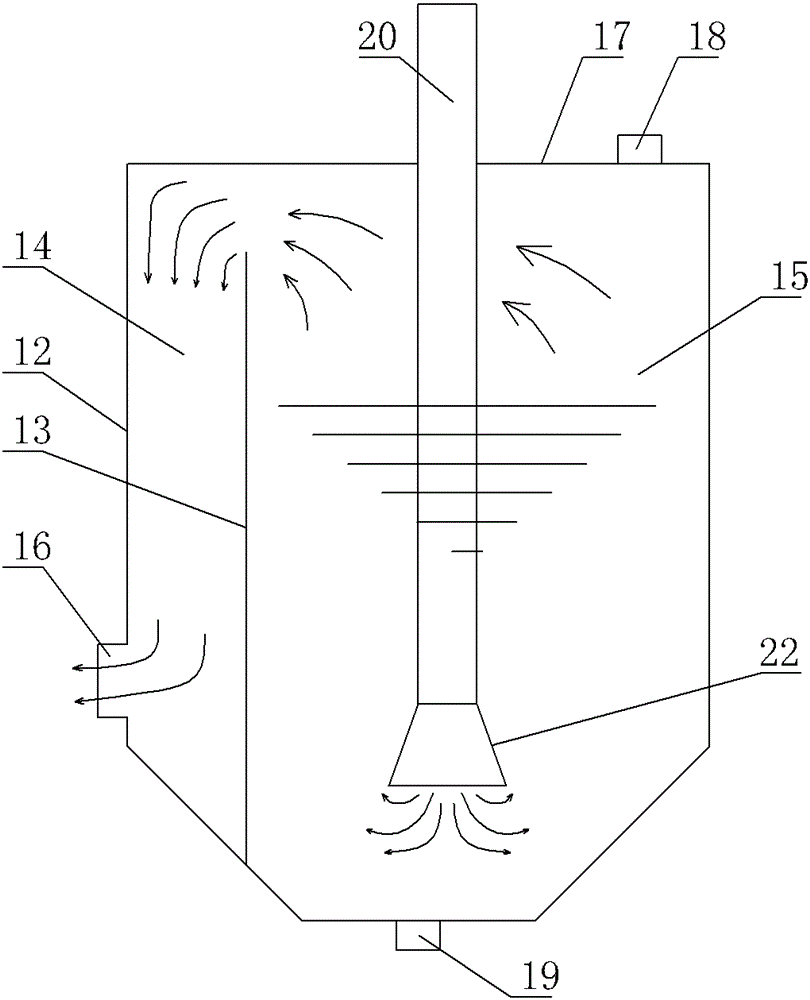

A lime digestion steam treatment device

ActiveCN104193193BGuaranteed uniformityEnsuring sufficient homogeneity of quicklimeUsing liquid separation agentPulp and paper industrySlurry

The invention provides a lime slaking steam treatment device. According to the device, steam in a slaking tank can be smoothly discharged, so that the steam does not enter a lime discharging device, smooth discharging of the lime discharging device is ensured, the discharged steam is purified and discharged into an ambient environment, and environment friendliness is ensured. The lime slaking steam treatment device comprises a quick lime slaking tank, wherein a stirrer is arranged in the quick lime slaking tank; a feeding pipe, a water inlet pipe and a steam exhaust smoke pipe are respectively arranged on the quick lime slaking tank; and an outlet is formed in the bottom of the quick lime slaking tank and is communicated with a lime slurry storage tank. The lime slaking steam treatment device is characterized in that a lime guide tube structure which is closed up from top to bottom is formed in the middle of an inner cavity of the feeding pipe; an air supply hole is formed in an outer wall of the feeding pipe corresponding to the lime guide tube structure; an external air supply pipe is communicated with the air supply hole; the lime slaking steam treatment device further comprises a smoke washing tank which is of a closed structure; and the steam exhaust smoke pipe is communicated with the bottom of the smoke washing tank by virtue of an air delivery pipeline.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Novel process for preparing charcoal/charcoal component by rapid chemical liquid-phase vaporization osmosis method

The invention discloses a process for preparing carbon / carbon components by a rapid chemical liquid-phase gasification infiltration method, which includes the following steps: (1) furnace installation (installing carbon / carbon component prefabricated bodies, graphite heating elements, thermocouples, etc.); (2) Feeding: add liquid precursors to the furnace body through the liquid precursor supply and return system; (3) pumping and filling protective gas: pump the air in the furnace body below 5kPa, and then fill the furnace body with protective gas (4) turn on the heating power supply and heat up; (5) heat preservation, gaseous precursor pyrolysis deposit carbon; (6) turn off the power supply and cool down; (7) take out the product: the obtained carbon / carbon component density reaches 1.60 to 1.70 g / cm3.

Owner:BEIHANG UNIV

Ultrasonic diagnosis system

InactiveCN101530334BCalculation stableSimplified inversion problemOrgan movement/changes detectionProcessing detected response signalCorrelation coefficientUltrasonic beam

The invention provides an ultrasonic diagnosis system, a measurement point is set at frame data consisting of an envelope signal obtained by orthogonal detection of an RF signal output from an ultrasonic probe before and after compression of an examinee. The measurement point is moved in the ultrasonic beam direction -first dimensional direction, second dimensional direction or third dimensional direction with respect to the frame data so as to obtain a position where the envelope signal correlation coefficient before and after compression belonging to a correlation window surrounding the measurement point becomes maximum. According to this, the displacement of the measurement point accompanying the compression is obtained and the phase difference between the RF signals before and after the compression is obtained, so as to accurately obtain a displacement of the measurement point accompanying the compression by displacement measurement means. Thus, it is possible to estimate the displacement distribution without being restricted by the displacement amount, reduce the calculation time, and cope with a horizontal direction displacement.

Owner:HITACHI HEALTHCARE MFG LTD +1

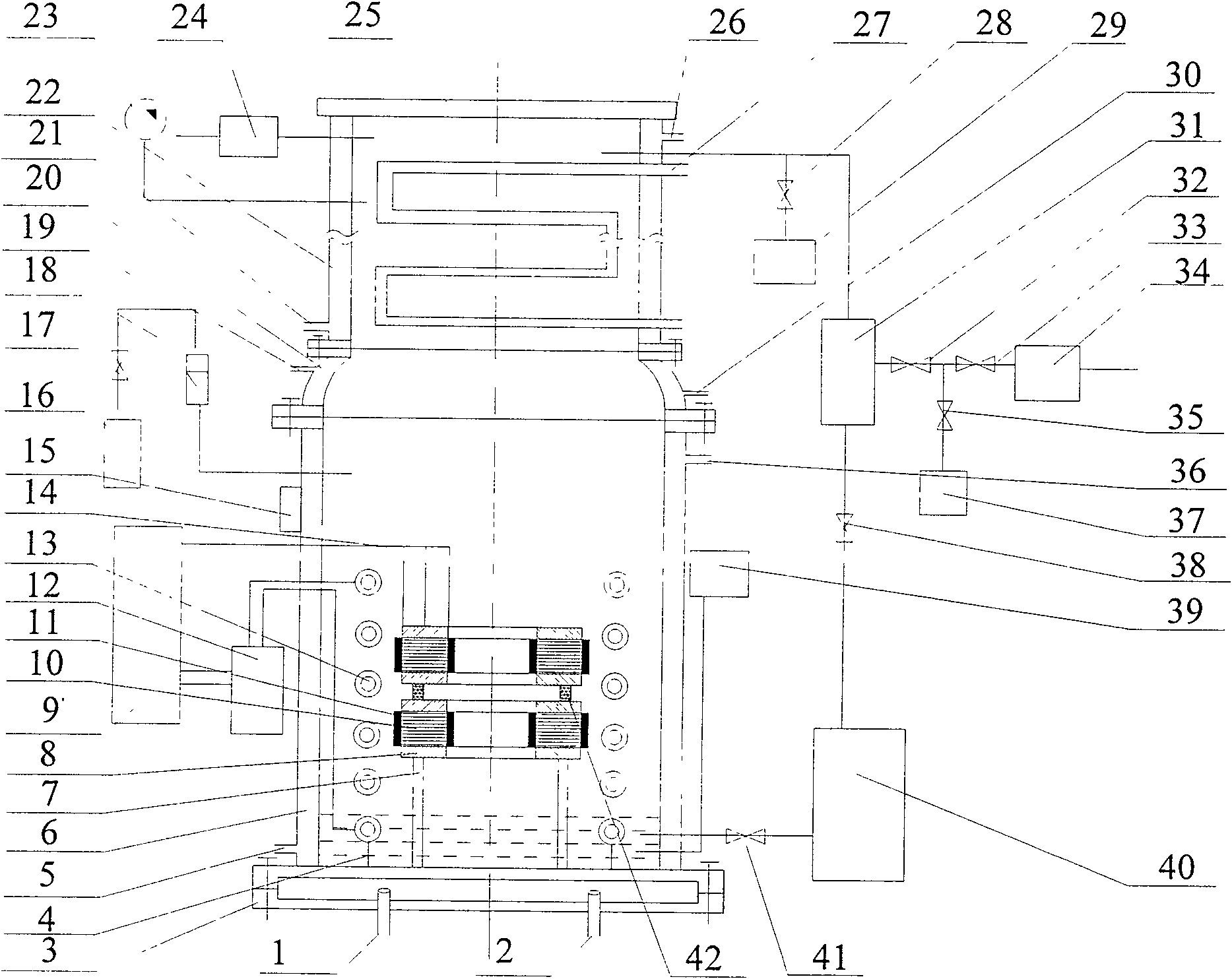

Chemical production reaction kettle

InactiveCN107149919ASmall diameterGood for shearing and mixingEnergy based chemical/physical/physico-chemical processesAir compressionCoupling

The invention discloses a chemical production reaction kettle, which comprises a casing, wherein foot margins are fixedly arranged at the two sides of the bottom end of the casing; a first motor is arranged in the center of the top of the casing; a feeding pipe and an air compression valve are respectively arranged at the top of the casing and positioned at the left side and the right side of the first motor; the bottom of the feeding pipe penetrates through the casing and extends into the casing; the top of the feeding pipe is connected with a feeding opening; a valve is arranged on the air compression valve; the bottom of the first motor is connected with a fixed shaft arranged inside the casing; the bottom of the fixed shaft is connected with a first rotating shaft arranged under the fixed shaft through the shaft coupler; a reaction cylinder is arranged in the center position inside the casing; the first rotating shaft penetrates through the reaction cylinder to extend into the reaction cylinder; a rotor arranged inside the reaction cylinder is fixedly arranged on the bottom of the first rotating shaft; a second motor is connected with the center of the bottom of the casing. The chemical production reaction kettle has the beneficial effects that the structure is simple; the operation is convenient; the reaction is sufficient; after the reaction, the media diameter is smaller; the effect is good; the work efficiency is high.

Owner:合肥速锐知识产权代理有限公司

Plasma display panel (PDP) terminal hot-pressing head structure

InactiveCN102176400BThere is no parallelism problemThere will be no problems with excessive pressureCold cathode manufactureTemperature controlOperability

Owner:SICHUAN COC DISPLAY DEVICES

Formula and preparation method of Gui powder for freshwater fish culture

InactiveCN114081108AEnsure safetyImprove melting effectAccessory food factorsWorking-up animal fodderVitamin b6Vitamin C

The invention provides a formula and preparation method of Gui powder for freshwater fish culture, and relates to the technical field of freshwater fish culture. The formula of the Gui powder for freshwater fish culture comprises magnesium, calcium, potassium, phosphorus, sulfur, carbon, zinc, sodium, folic acid, nicotinamide, calcium pantothenate, biotin, vitamin D3, vitamin E, vitamin K3, vitamin B1, vitamin B2, vitamin B6, vitamin B12, vitamin C and vitamin A. According to the invention, by selecting the phosphorus component raw material, the stability of the properties of the selected phosphorus in the processing and using processes is ensured, radioactive elements are not generated, the safety of the raw material of the Gui powder is further ensured, and 10% of water is retained in the finished product of the Gui powder, so that the finished product of the Gui powder has better water melting performance, the Gui powder can uniformly act on the culture water area of freshwater fish, and in terms of the quality of the finished product, the dosage of the finished product of the Gui powder is small, the proportion is reasonable, and the function is relatively good.

Owner:漆昆铭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com