Preparation method of separation membrane composite support body

A technology of composite support and separation membrane, applied in separation methods, filtration separation, semi-permeable membrane separation, etc., can solve the problems of long process, complex process, easy to produce curls, wrinkles, etc., achieve high heat resistance and melting point, and prepare The method is simple and the effect of excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

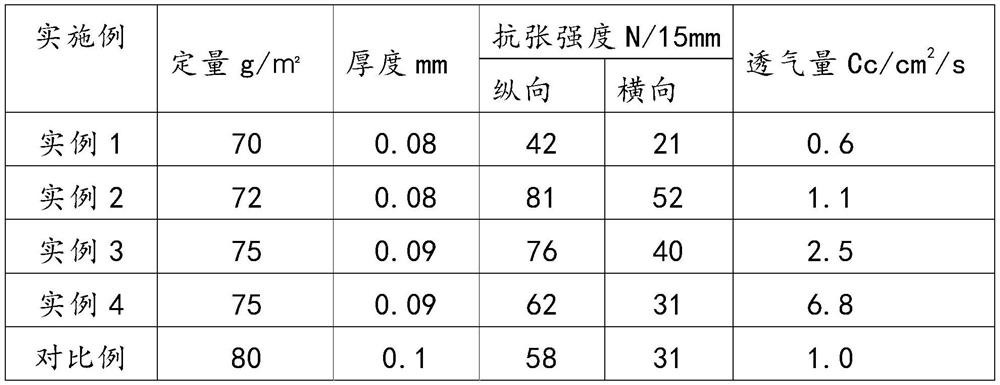

Examples

preparation example Construction

[0024] A preparation method for a separation membrane composite support, the preparation method comprising the following steps:

[0025] Step 1. Feed the hollow polyoxadiazole fiber and the high crystallinity polyester fiber in a certain proportion at one time, and decompose to make a slurry, and then purify and remove impurities and then disperse to obtain the slurry;

[0026] Step 2, making, pressing and drying the slurry in sequence to obtain paper sheets;

[0027] Step 3: hot-rolling the paper sheet, and finishing with a calender to obtain a separation membrane composite support.

[0028] The hollow polyoxadiazole fiber mentioned in the above step 1 has a diameter of 10-30um and a length of 2-20mm, and a high crystallinity polyester fiber has a diameter of 5-20um and a length of 2-8mm. To meet the diameter and length requirements, the following conditions must also be met:

[0029] Hollow polyoxadiazole fibers must have at least one of the following characteristics: spec...

Embodiment 1

[0036] Step 1. The hollow polyoxadiazole fiber with a diameter of 20um and a length of 6mm and the high crystallinity polyester fiber with a diameter of 18um and a length of 6mm are fed at a rate of 30%: 70% by mass, and the concentration is 1wt% in the hydraulic In the deflagging machine, decompose to make slurry, then use a cone-shaped impurity remover to purify and remove impurities twice, then disperse, and add a dispersant with a concentration of 0.1wt% during dispersion to obtain a slurry;

[0037] Step 2: Pass the slurry through the stabilizing box to adjust the online head of the slurry. In the headbox, the slurry is evenly distributed on the forming net with a concentration of 0.06wt%. When the slurry runs along the forming net, with the help of couch roll function, the water is filtered out to obtain a wet paper sheet, the wet paper sheet leaves the forming wire, is further dehydrated by pressing, and enters the drying section for drying to obtain a paper sheet;

[0...

Embodiment 2

[0040]In Example 1, the hollow polyoxadiazole fiber with a diameter of 20um and a length of 6mm and the high-crystallinity polyester fiber with a diameter of 18um and a length of 6mm are 30% by mass: 70% and can be replaced by a ratio of 20um in diameter and 6mm in length. The hollow polyoxadiazole fiber with a length of 6 mm and the high crystallinity polyester fiber with a diameter of 18 um and a length of 6 mm are fed at a time in a ratio of 70% by mass: 30%, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com