Preparation method for high-uniformity WSTi62441S titanium alloy ingot

A homogeneous, titanium alloy technology, applied in the field of preparation of high-uniformity WSTi62441S titanium alloy ingots, can solve the problems of poor control of impurities and interstitial elements, composition segregation, low batch stability, etc., to achieve batch stability Good, uniform effect of elemental composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

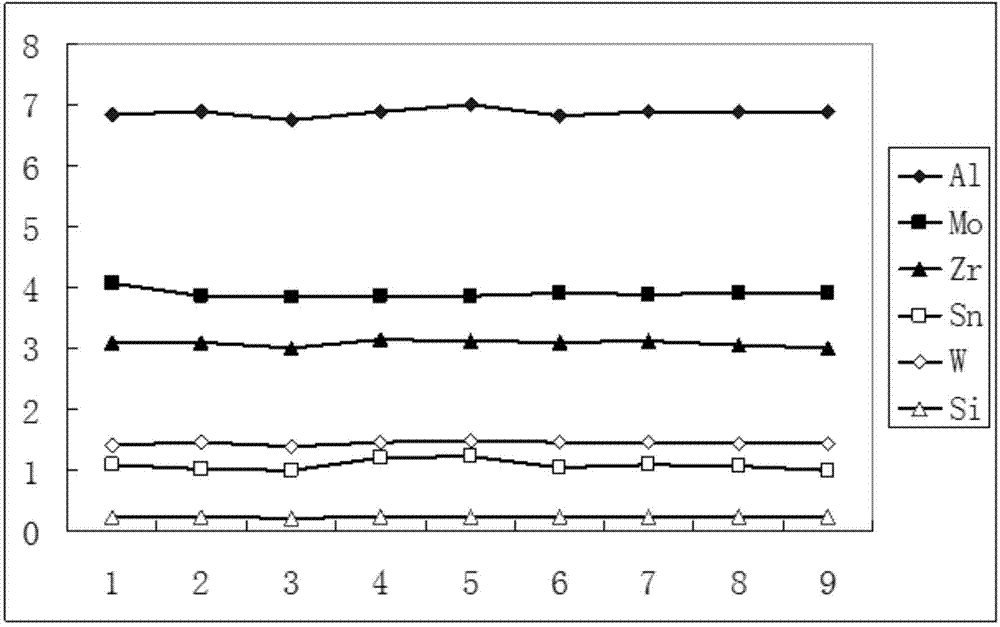

[0031] A kind of preparation method of high uniformity WSTi62441S titanium alloy casting ingot of the present invention, specifically comprises the following steps:

[0032] Step 1: Mixing

[0033] Select grade 1 or grade 0 sponge titanium, mix it with the intermediate alloy Al-Mo alloy according to the Mo content ratio of 3.5%~4.5%, Ti-Sn alloy according to the Sn content ratio of 1.0%~2.5%, and AlMoWTi alloy according to the W content ratio of 0.4% %~1.5%, the Al content is added at a ratio of 6.0%~7.0%, the zirconium sponge is added at a ratio of Zr content of 3.0%~4.5%, and the Ti-Si alloy is added at a Si content of 0.2%~0.25%. The single-block mixing method is used for mixing, and the mass percentage of the alloy ratio obtained is: 6.0%-7.0% for Al, 1.0%-2.5% for Sn, 3.5%-4.5% for Mo, and 3.0%-4.5% for Zr, Si is 0.20% to 0.25%, W is 0.4% to 1.5%, the rest is Ti, and the sum of the mass percentages of each element is 100%;

[0034] Step 2: Consumable electrode pressing ...

Embodiment 1

[0043] Step 1: Mixing

[0044]Sponge titanium of grade 1 or above is selected, mixed with the intermediate alloy Al-Mo alloy at a ratio of Mo content of 4.0%, Ti-Sn alloy at a ratio of Sn content of 1.0%, AlMoWTi alloy at a ratio of W content of 1.5%, and an Al content of The ratio of 7.0% is added, the zirconium sponge is added according to the ratio of Zr content of 3.0%, and the Ti-Si alloy is added according to the content of Si 0.23%. The single block mixing method is used for mixing, and the mass percentage of the alloy ratio is obtained: Al is 7.0%, Sn is 1.0%, Mo is 4.0%, Zr is 3.0%, W is 1.5%, Si element is 0.23%, the rest is Ti, and the sum of the mass percentage of each element is 100%;

[0045] Step 2: Consumable electrode pressing and welding

[0046] Use a large-scale hydraulic machine to carry out electrode compression on the material mixed in step 1. The pressing pressure is 20MPa, and the pressure holding time is 6s. Use a non-tungsten argon shielded plasma b...

Embodiment 2

[0054] Step 1: Mixing

[0055] Grade 0 sponge titanium is selected, and the intermediate alloy Al-Mo alloy is mixed with a Mo content of 4.5%, the Ti-Sn alloy is mixed with a Sn content of 1.5%, the AlMoWTi alloy is mixed with a W content of 0.5%, and the Al content is 6.0% % proportion, the sponge zirconium is mixed according to the Zr content of 4.5%, the Ti-Si alloy is mixed according to the Si content of 0.25%, and the single block mixing method is used for mixing, and the mass percentage of the alloy ratio is obtained: Al is 6.0% %, Sn is 1.5%, Mo is 4.5%, Zr is 4.5%, W is 0.5%, Si element is 0.25%, the rest is Ti, and the sum of the mass percentage of each element is 100%;

[0056] Step 2: Consumable electrode pressing and welding

[0057] Use a large hydraulic press to compress the electrodes mixed in step 1. The pressing pressure is 23MPa, and the holding time is 4s. Use a non-tungsten argon shielded plasma box to weld the pressed electrode block into a consumable ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com