Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Subsequent separation is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

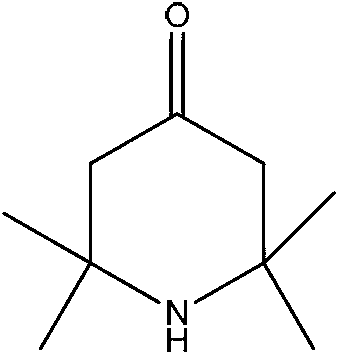

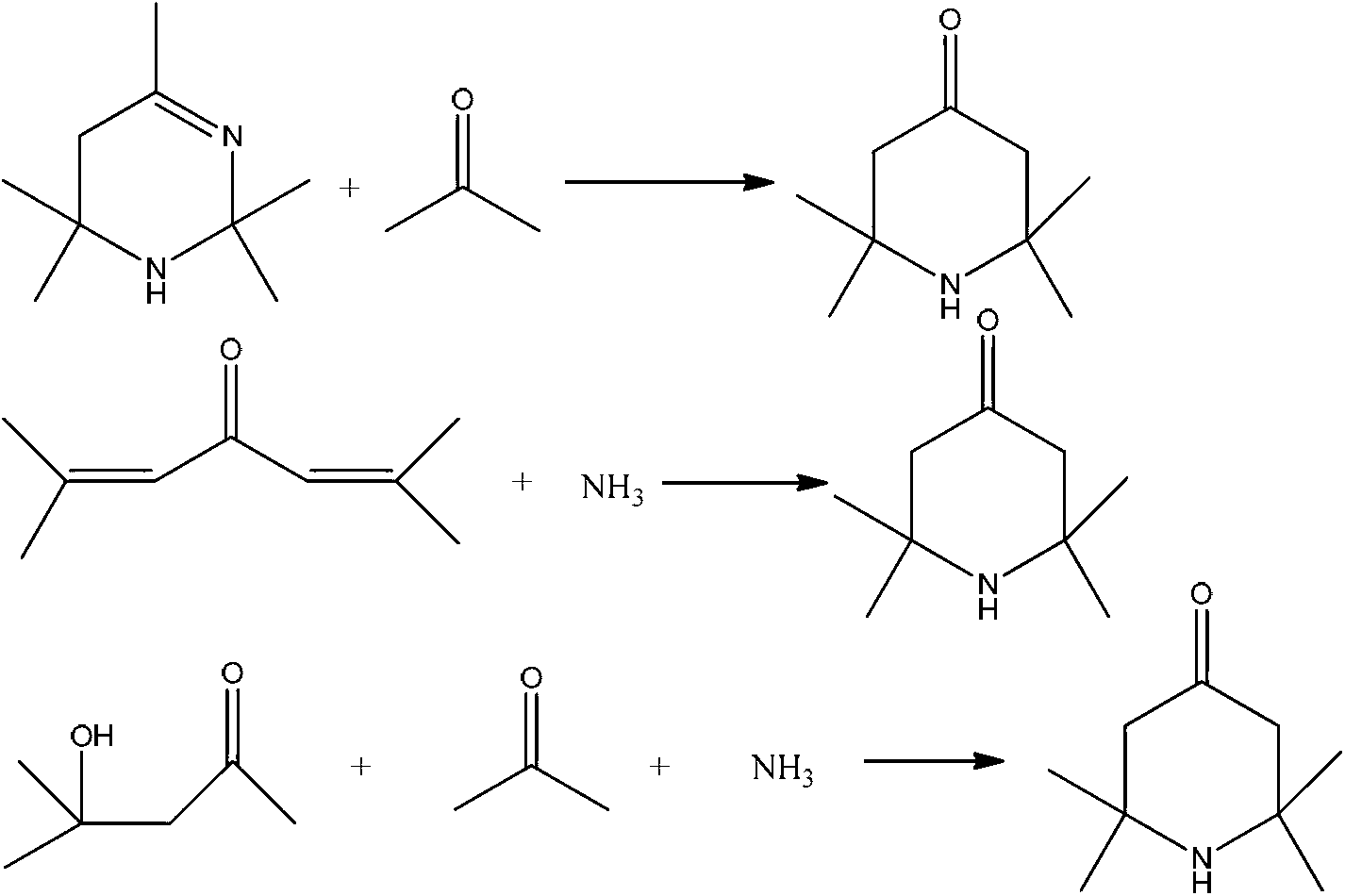

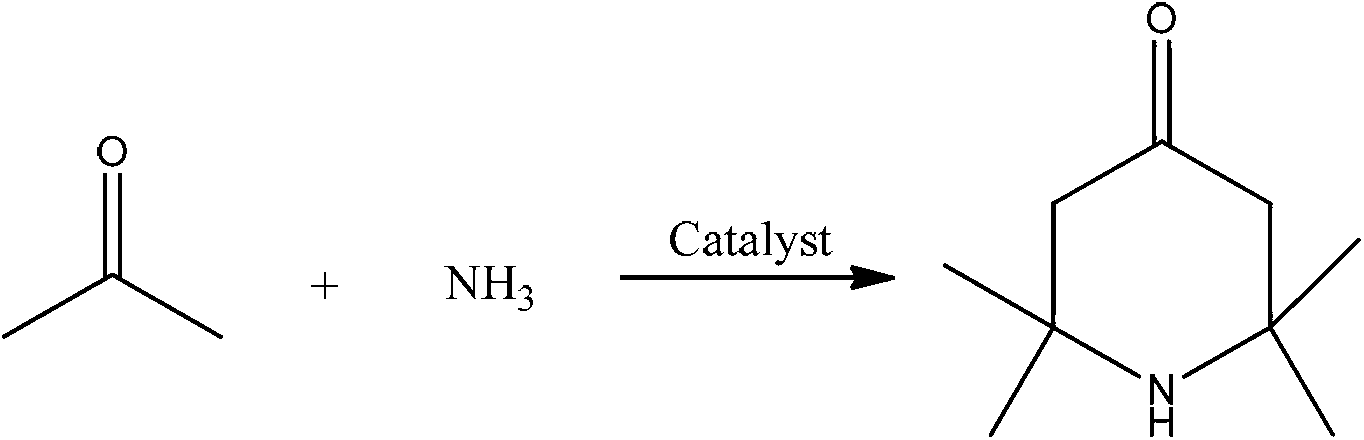

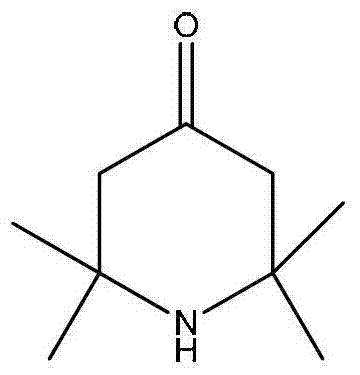

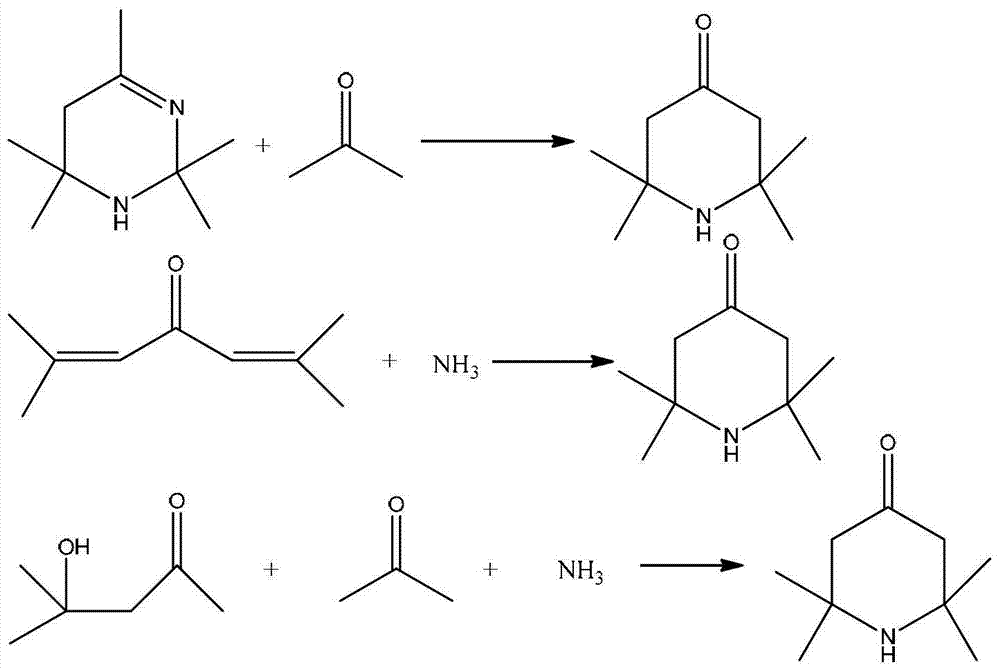

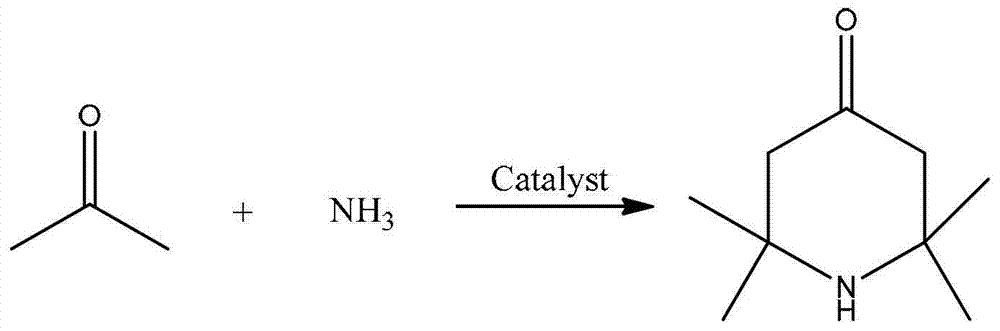

2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method

ActiveCN103224465ASubsequent separation is simpleAvoid pollutionOrganic chemistrySynthesis methodsFixed bed

The invention discloses a 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method. The 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method comprises the following steps of 1, filling an acidic resin into a fixed bed reactor, and carrying out heating so that a temperature of the fixed bed reactor is in a range of 40 to 70 DEG C, and 2, feeding acetone and ammonia gas into the fixed bed reactor according to a mole ratio of 3-9: 1 under the conditions of acetone hourly space velocity of 0.15 to 1.17h<-1> and ammonia gas hourly space velocity of 5.25 to 124.20h<-1>, and cooling the product to obtain a 2,2,6,6,-tetramethyl-4-piperidone crude product. The 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method has simple processes and a low cost, is suitable for industrial continuous production, does not adopt an organic solvent or water as a solvent, avoids the pollution produced by the organic solvent on the environment, has mild reaction conditions, can be carried out at a temperature of 40 to 70 DEG C, has low energy consumption, and avoids the influence caused by impurities produced at a high temperature on the product.

Owner:安徽兴欣新材料有限公司

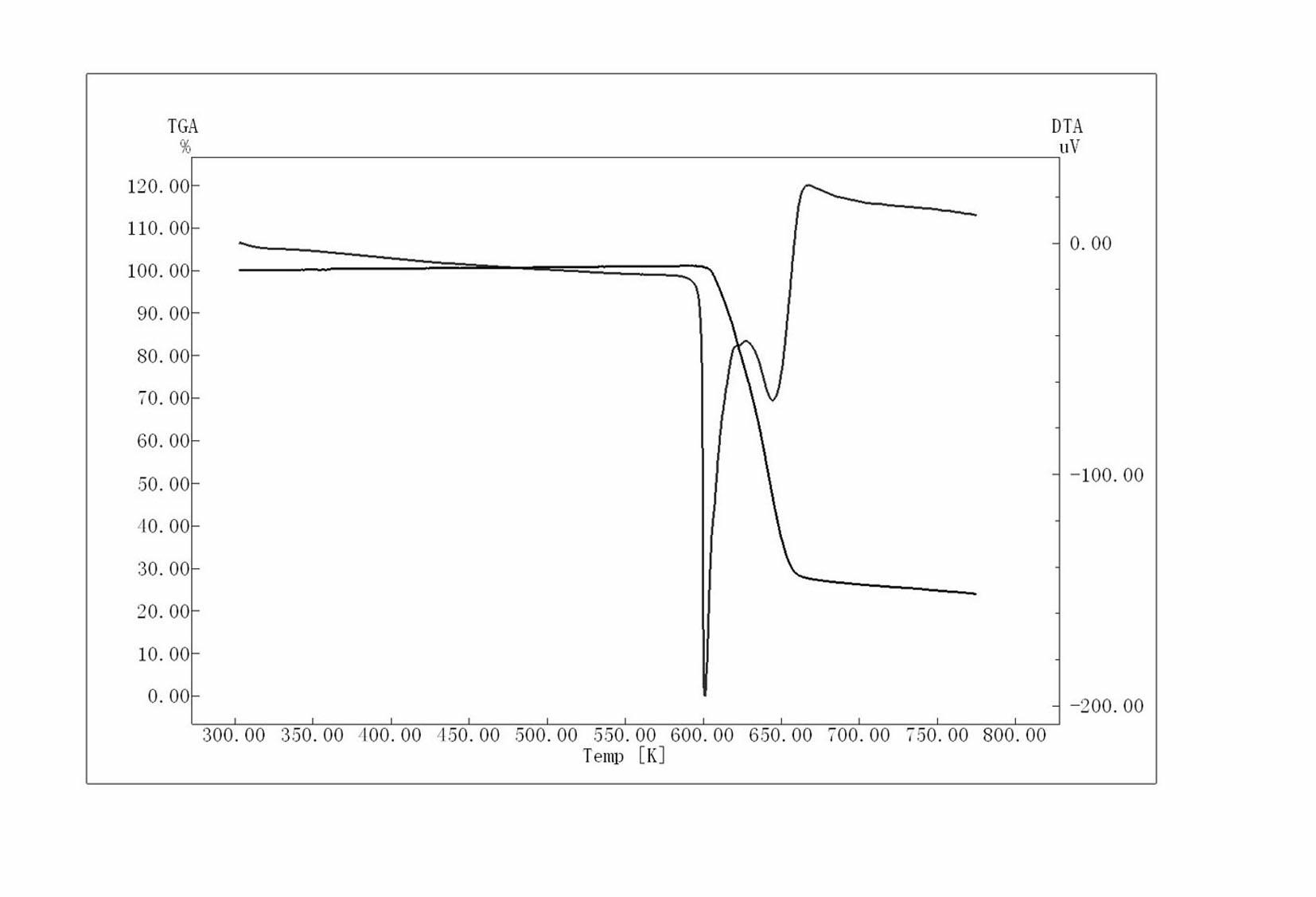

Method for preparing taurine by adopting sulfonation of ammonium sulfite

InactiveCN102633689ASimple operation processMild reaction conditionsOrganic compound preparationSulfonic acid preparationTaurineSulfuric Acid Esters

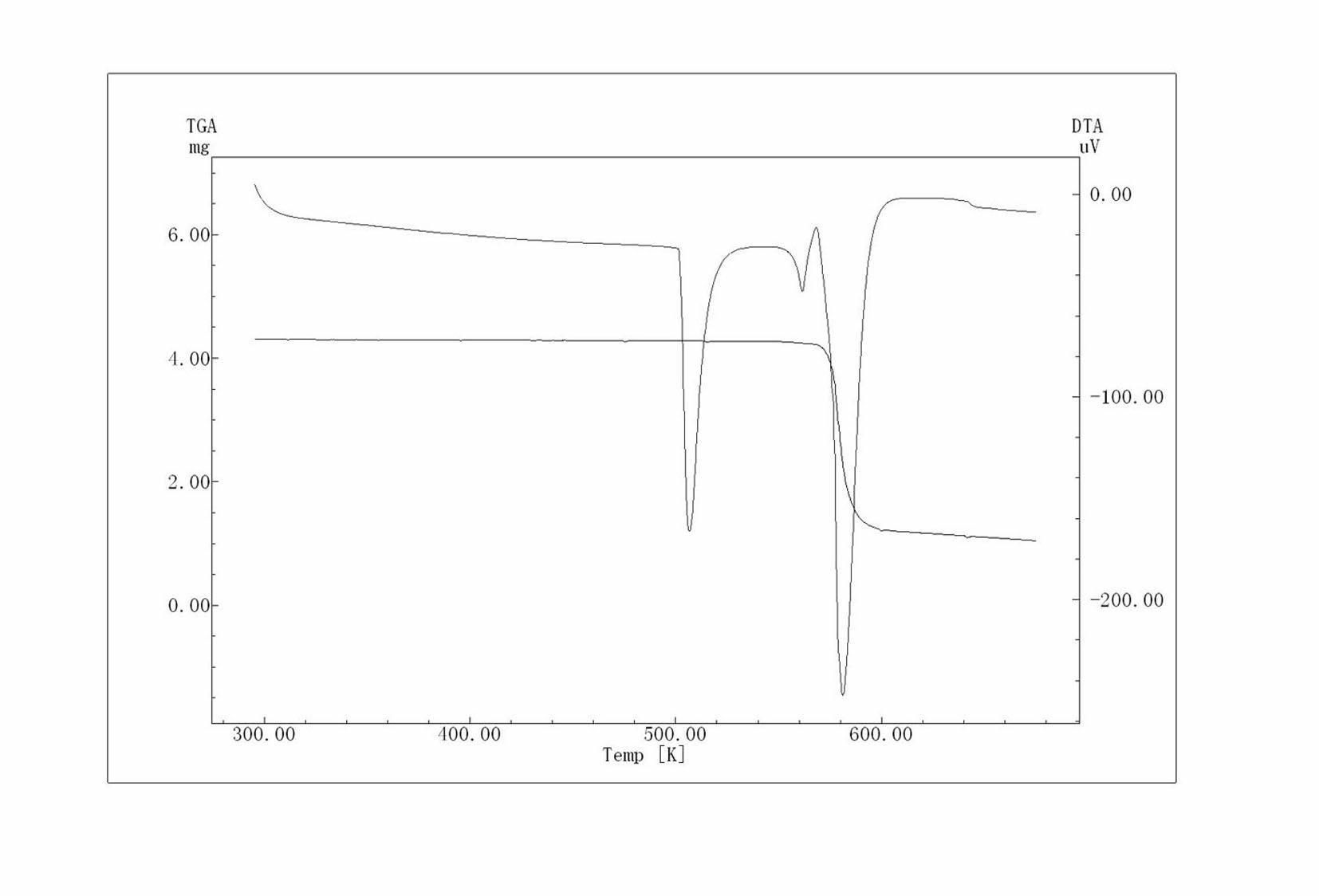

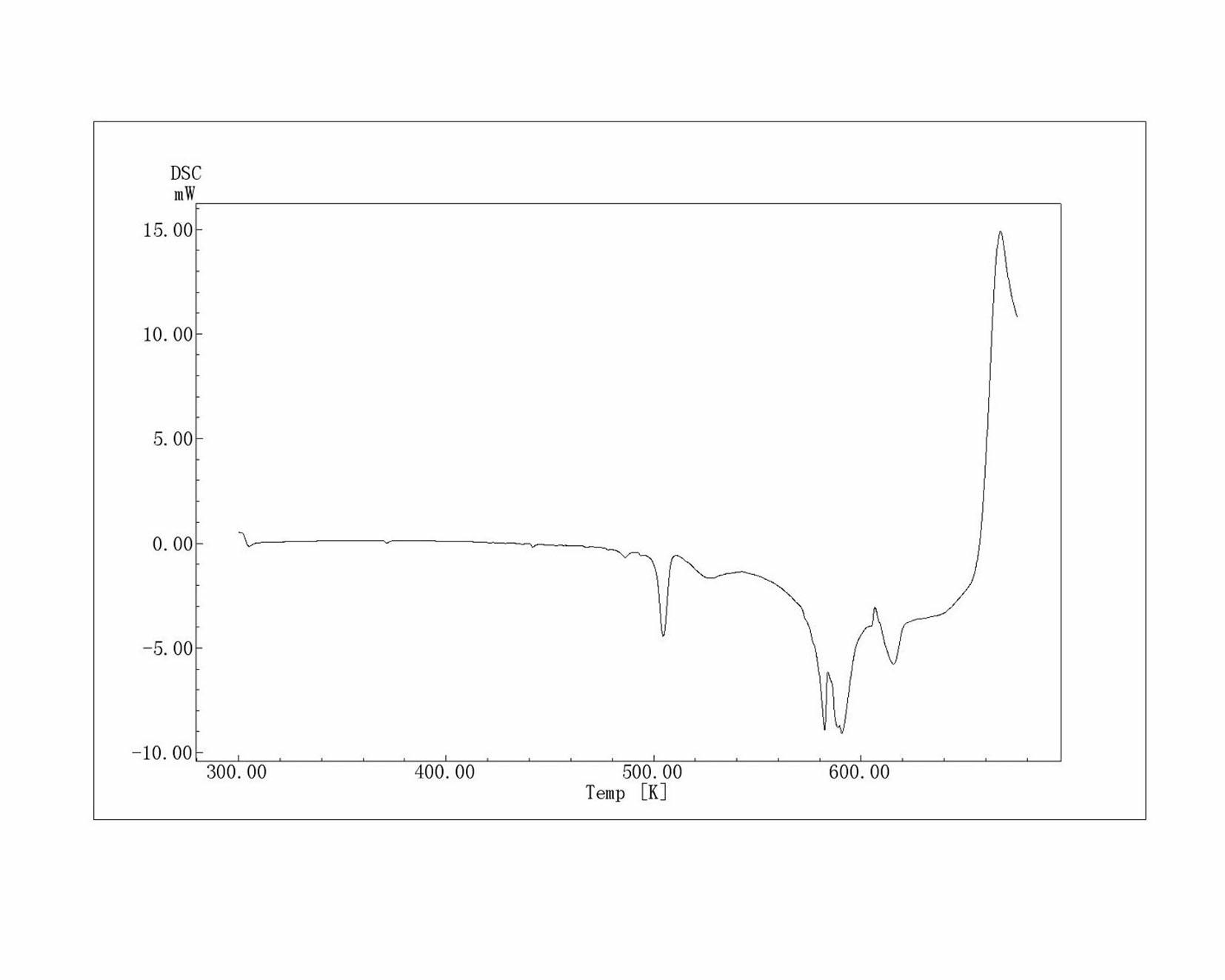

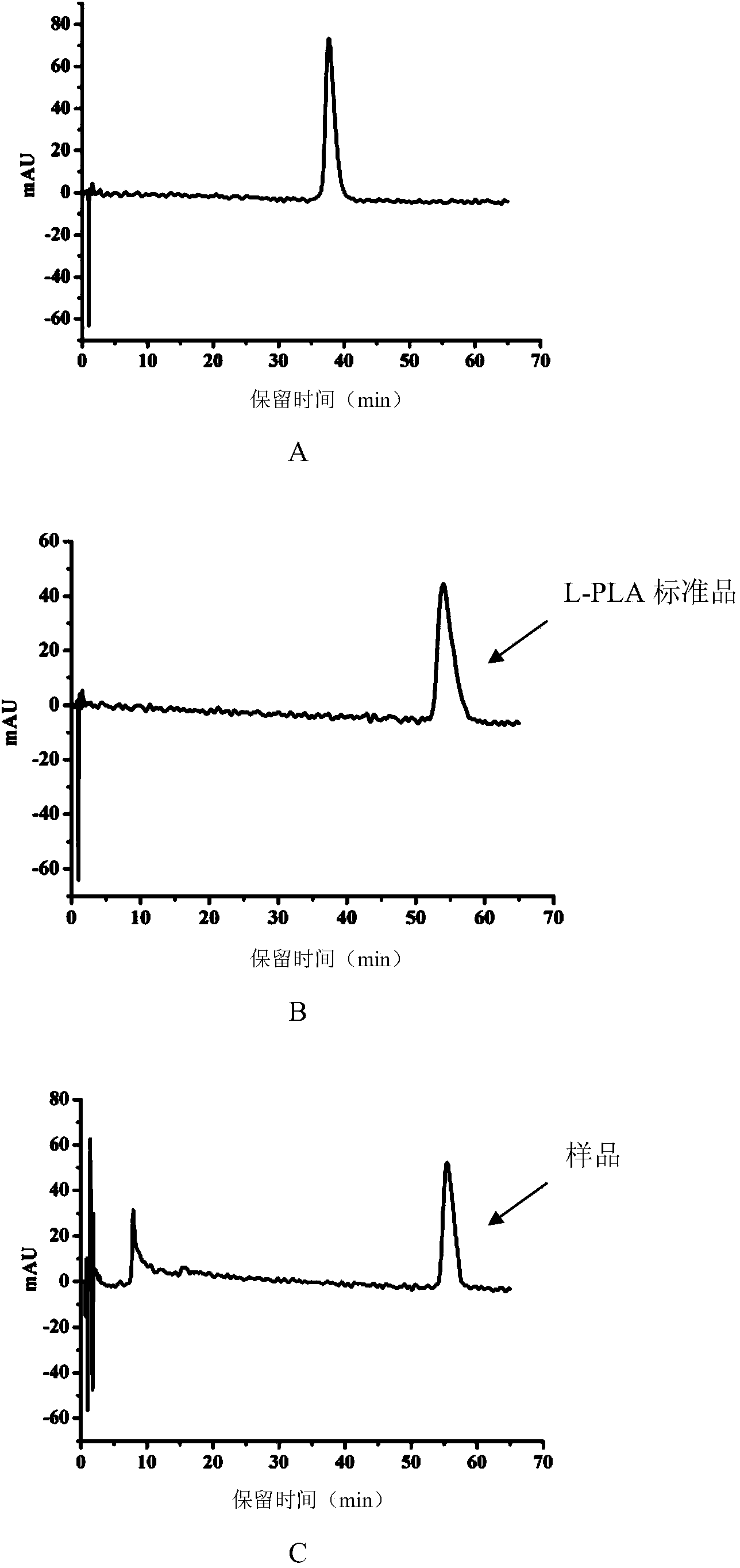

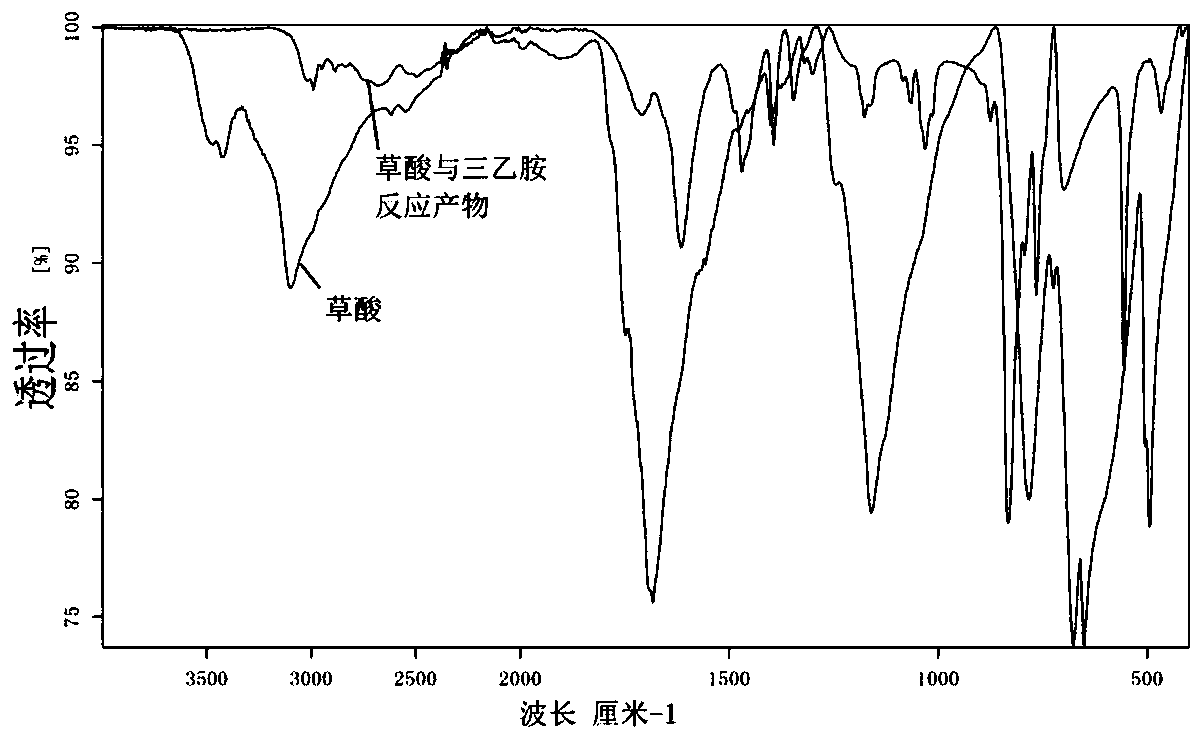

The invention discloses a method for preparing taurine by adopting sulfonation of ammonium sulfite. The method comprises the steps of: firstly carrying out esterification reaction to synthetize an intermediate 2-aminoethanol sulfate by taking concentrated sulfuric acid and ethanolamine as raw materials; carrying out sulfonation reaction to prepare taurine by taking ammonium sulfite and 2-aminoethyl sulfate as the raw materials, wherein ammonia is introduced to protect before the reaction, the temperature of the reaction solution is reduced after the sulfonation reaction is finished, and the conversion ratio of 2-aminoethyl sulfate is analyzed by adopting a sodium thiosulfate inverse titration method; cooling the reaction solution to room temperature, adding calcium hydroxide, heating, agitating and filtering to remove calcium sulfate, removing ammonia in mother liquor and repeatedly utilizing the mother liquor; then purifying the taurine by a cooling and crystallizing method to obtain crystal, carrying out suction filtration and baking the obtained crystal, and analyzing the taurine crystal by a thermal analysis method. The method disclosed by the invention is an integrated preparation method of combining the synthesis and separation of the taurine. The method is the preparation method of the taurine with simple operating process and mild reaction condition, wherein the primary conversion rate of 2-aminoethyl sulfate can be up to 79% and the desalination efficiency is 99.12%.

Owner:ZHENGZHOU UNIV

Method for preparation of bromelin

InactiveCN101319208AReduce enzyme activitySubsequent separation is simpleHydrolasesFiltrationFreeze-drying

The method relates to a manufacturing method for bromelin, in particular to a new method for the industrialized extraction of the bromelin with pineapple stems (plant) as a main raw material. The method comprises the following steps of: (1) cleaning pineapple stems; 2) crushing the pineapple stems; (3) pressing and extracting juice; (4) carrying out coarse filtration; (5) carrying out heat exchange; (6) centrifuging; (7) carrying out micro-filtration; (8) carrying out ultrafiltration; (9) refining and synthesizing; (10) vacuum freeze-drying; and (11) crushing, concocting, packaging, and manufacturing a finished product. The manufacturing method for the bromelin can save energy and reduce production cost with an enzyme extraction reclaiming rate up to 0.2 percent, high enzyme purity, high enzyme activity above 3,000G DU / g and good stability.

Owner:广西美仑生物科技有限公司

Escherichia coli with coexpression of L-lactate dehydrogenase and formate dehydrogenase as well as construction method and application of escherichia coli

ActiveCN104130967ANotable featuresRemarkable effectBacteriaMicroorganism based processesEscherichia coliL-Lactate dehydrogenase

The invention discloses escherichia coli with coexpression of L-lactate dehydrogenase and formate dehydrogenase. The escherichia coli is characterized in that L-lactate dehydrogenase genes ldhL from bacillus coagulans and formate dehydrogenase genes fdh from candida boidinii are introduced into the escherichia coli, wherein the register number of GenBank of nucleotide sequences of the L-lactate dehydrogenase genes ldhL is KF386111; the register number of GenBank of nucleotide sequences of the formate dehydrogenase genes fdh is AJ011046. The invention further discloses a construction method and an application of the reconstructed escherichia coli. The method has the characteristics of being simple to operate, low in cost, high in product synthesis efficiency and high in optical purity. Thus, an effective way for biosynthesis of L-phenyllactic acid is provided.

Owner:深圳市华利康纤生物科技有限公司

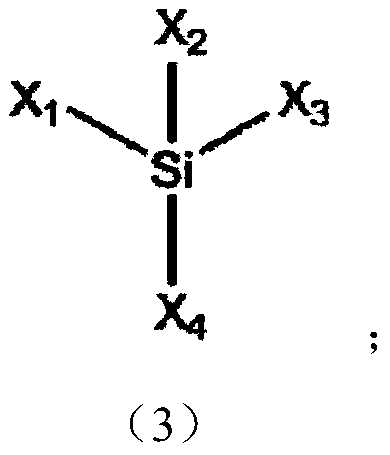

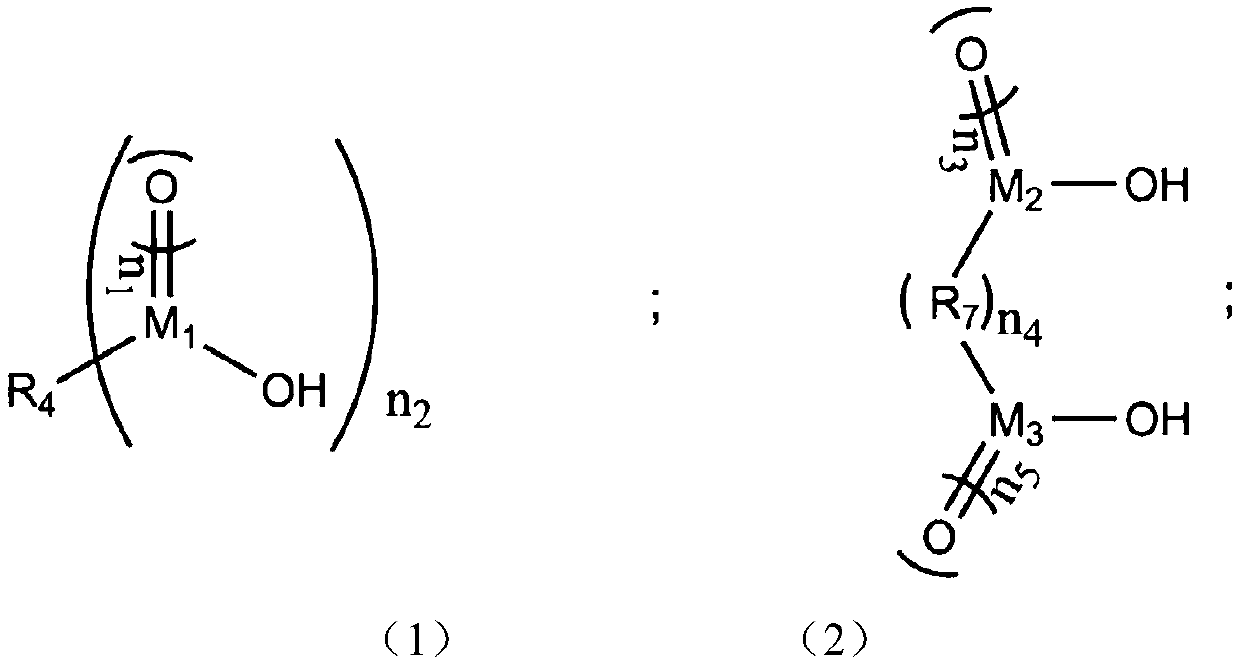

Preparation method of silicon-based ester compound, silicon-based ester compound, electrolyte containing silicon-based ester compound and secondary battery

ActiveCN111217850AHigh yieldHigh purityGroup 4/14 element organic compoundsSecondary cellsElectrolytic agentOrganic acid

The invention relates to a preparation method of a silicon-based ester compound, the silicon-based ester compound, an electrolyte containing the silicon-based ester compound and a secondary battery. The preparation method of the silicon-based ester compound comprises the following steps: adding organic alkali and organic acid into a solvent and carrying out reacting to obtain an intermediate, andthen, adding halogenated silane to react with the intermediate to obtain the silicon-based ester compound, wherein the intermediate is ionic liquid. The preparation method provided by the invention can relieve the problems of long reaction time, difficult treatment of byproducts, complex operation caused by step-by-step reaction, high cost, difficult industrial scale-up production and the like inthe existing synthesis method.

Owner:微宏先进材料公司

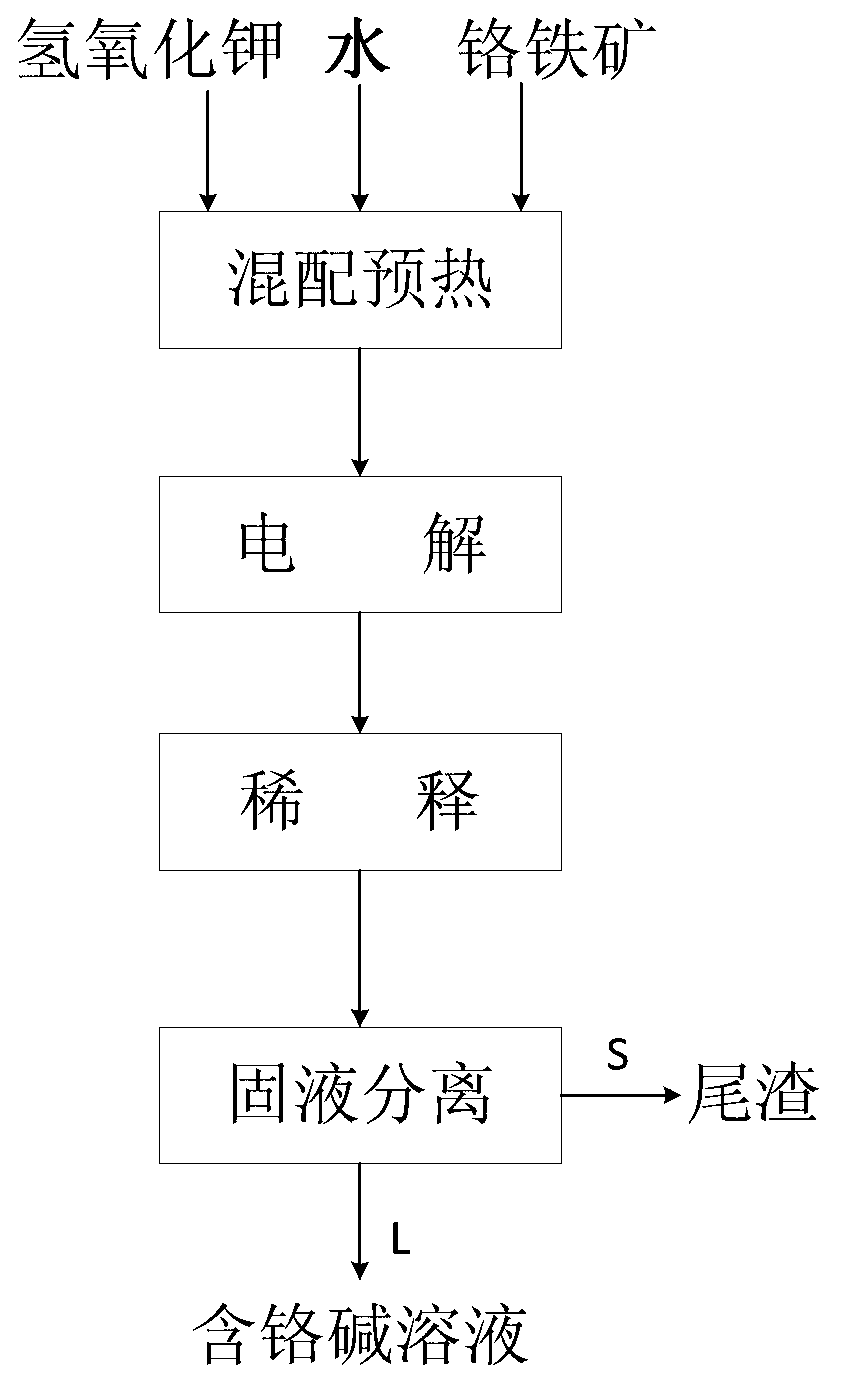

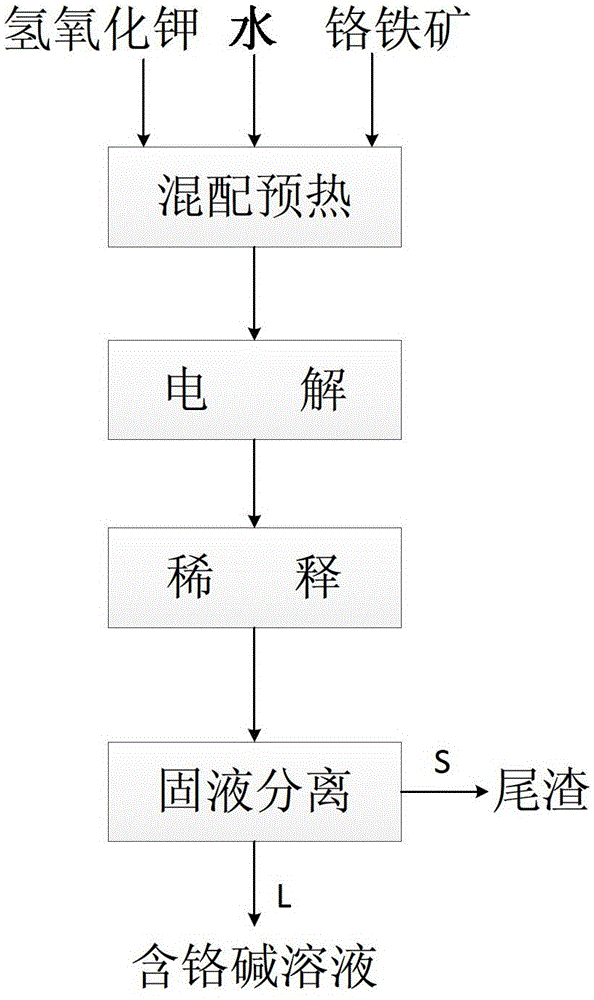

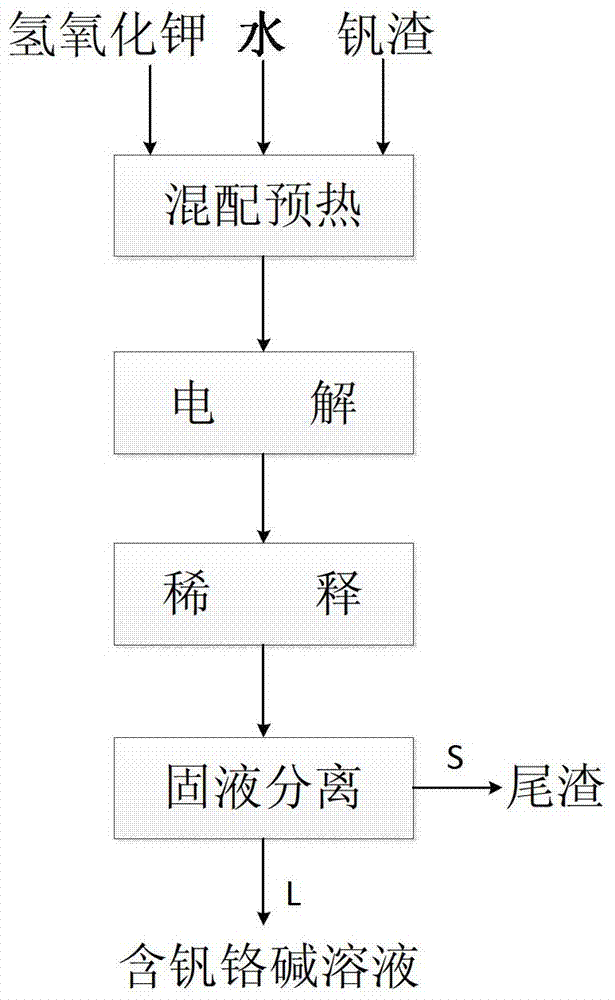

Method for extracting chromium by electrochemically decomposing chromite in potassium hydroxide solution

InactiveCN103060838ASubsequent separation is simpleLow reaction temperatureElectrolysis componentsElectrolytic organic productionPotassium hydroxideSlurry

The invention relates to a method for extracting chromium by electrochemically decomposing chromite in a potassium hydroxide solution. The method comprises the steps as follows: filling oxidizing gas into mixed slurry containing chromite, potassium hydroxide and water; carrying out electrochemical oxidization reaction; and after the reaction, carrying out solid-liquid separation on the mixed slurry to obtain tailings and a chromium alkali solution. The method is low in cost, high in extraction efficiency, pollution-free and moderate in process conditions, and the chromium extraction rate can reach more than 95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for vanadium extracting through low liquid-solid-ratio ammonification

ActiveCN106676273AReduce usageReduce ammonia volatilizationProcess efficiency improvementChemical industrySlag

The invention relates to the field of vanadium slag wet process metallurgy and vanadium chemical industry, in particular to a method for vanadium extracting through low liquid-solid-ratio ammonification. According to the method, after raw materials containing vanadium is roasted, clinkers, water and ammonium salt are mixed according to a certain proportion; materials with a low liquid-solid ratio are formed and subjected to the low-temperature ammonification reaction, the vanadium in the clinkers reacts with the ammonium salt to form ammonium metavanadate, and the ammonium metavanadate formed at the low temperature exists in mixed slurry in a crystalline mode; after the mixed slurry is subjected to hydrotherm dissolution, a solution rich in the ammonium metavanadate is obtained; and after slurry filtering, filtrate cooling and crystallizing and separating and ammonium vanadate roasting, vanadium pentoxide products are obtained. Compared with a conventional vanadium extracting through ammonification, according to the method for vanadium extracting through low liquid-solid-ratio ammonification, the using quantity of the water and the ammonium salt are greatly reduced in the ammonification process, and volatilization of ammonia gas is obviously inhibited; and the slurry can be directly subjected to hydrotherm leaching to obtain the ammonium metavanadate solution after ammonification, the process of vanadium extracting through ammonification is greatly simplified, the process is easy to operate and control, efficient and clean extracting of the vanadium can be achieved, and the extracting rate of the vanadium reaches 90% or more.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

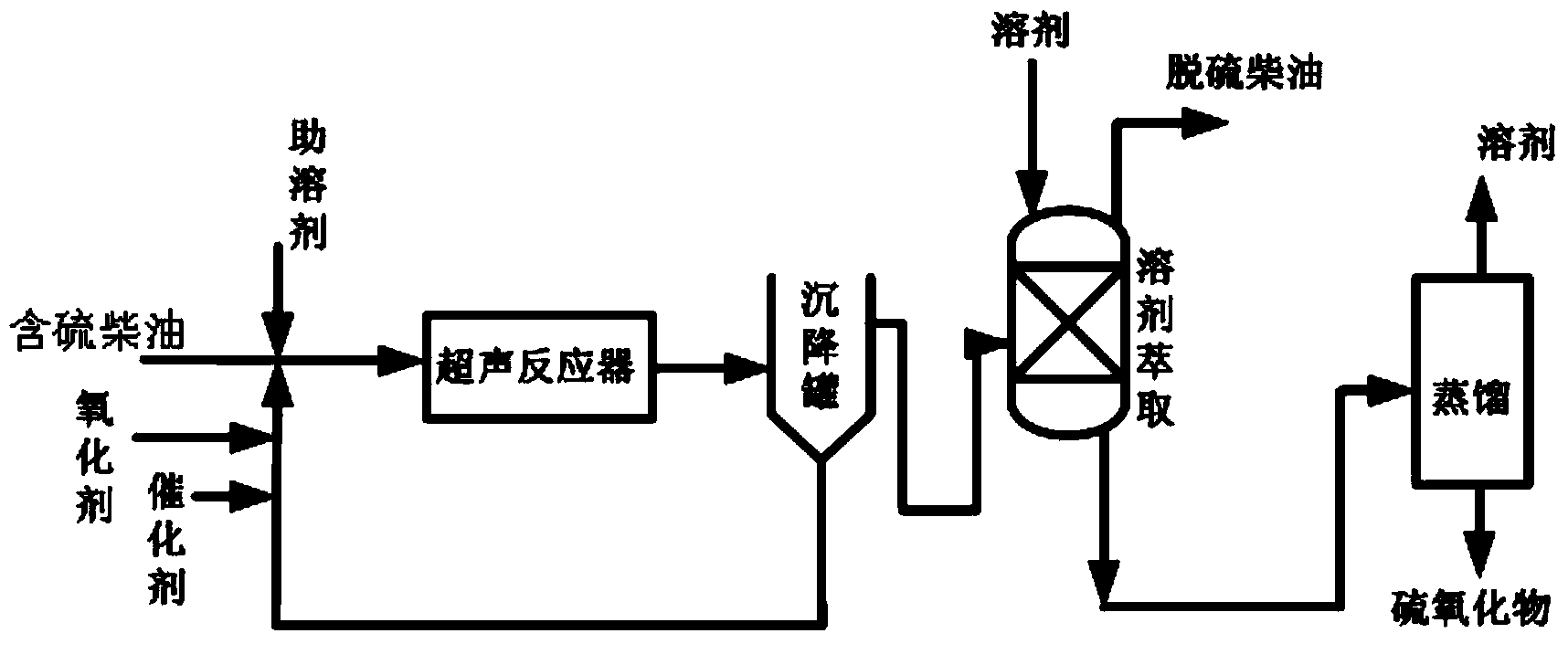

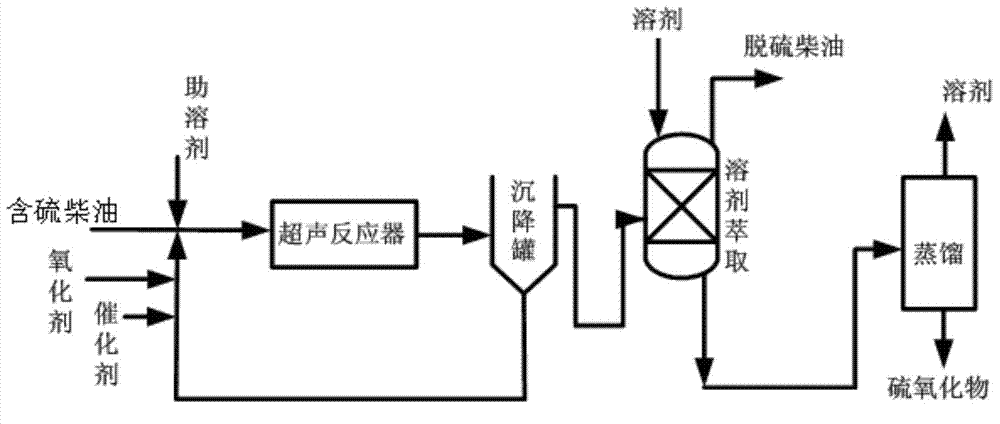

Ultrasonic oxidation-extraction and deep desulfurization method for diesel oil

InactiveCN103450931AImprove oxidation capacityReduce lossesTreatment with plural serial refining stagesDistillationSulfur containing

The invention discloses an ultrasonic oxidation-extraction and deep desulfurization method for diesel oil. The method comprises the steps: firstly, uniformly mixing an oxidizing agent, a cosolvent and a catalyst, then, mixing the mixture with sulfur-contained diesel oil on line, and next, carrying out ultrasonic oxidative desulphurization reaction in an ultrasonic reactor; delivering the mixture after reacting into a settling tank for separating to obtain a catalyst-contained solvent to be recycled and diesel oil to be subjected to solvent extraction, and separating organic sulfur in the diesel oil to obtain desulfurized diesel oil; carrying out reduced pressure distillation on the extracted solvent, recycling the separated solvent, and retreating the separated organic sulfur. By using the ultrasonic oxidation-extraction and deep desulfurization method, not only can the oxidation performance of the oxidizing agent to organic sulfur be improved, but also the cosolvent can be used for extracting organic sulfur in the diesel oil to obtain the solvent in the ultrasonic oxidation reaction, a phase transfer catalyst is not needed to be additionally added, the subsequent separation operation is easy, and the sulfur content of the desulfurized diesel oil is not higher than 10ppm. In addition, the ultrasonic oxidation-extraction and deep desulfurization method has the advantages of no adoption of organic acid capable of corroding equipment, short process route and low oil loss.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Novel method for preparing pitch-based mesocarbon microbeads

InactiveCN109650375ASolve for uniformitySolving Carbon MicrospheresCarbon preparation/purificationCoking carbonaceous materialsMicrosphereFiltration

The invention relates to a novel method for preparing pitch-based mesocarbon microbeads, and belongs to the technical field of carbon material preparation. The method comprises the steps that the medium-temperature asphalt and mesophase asphalt which are mixed according to a certain proportion serve as raw materials, a thermal polymerization product is obtained through three different temperaturereaction stages of thermal pre-treatment, thermal pre-polymerization and thermal polymerization of the raw materials, and subjected to three separation methods of thermal filtration, centrifugal sedimentation and solvent extraction and washing to obtain a powder product and mesophase asphalt, the powder product is subjected to vacuum drying at a certain temperature to obtain the mesocarbon microbeads with the particle size of 1-3 micron, and the separated mesophase asphalt can be used as the raw material. The novel method has broad application prospects.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

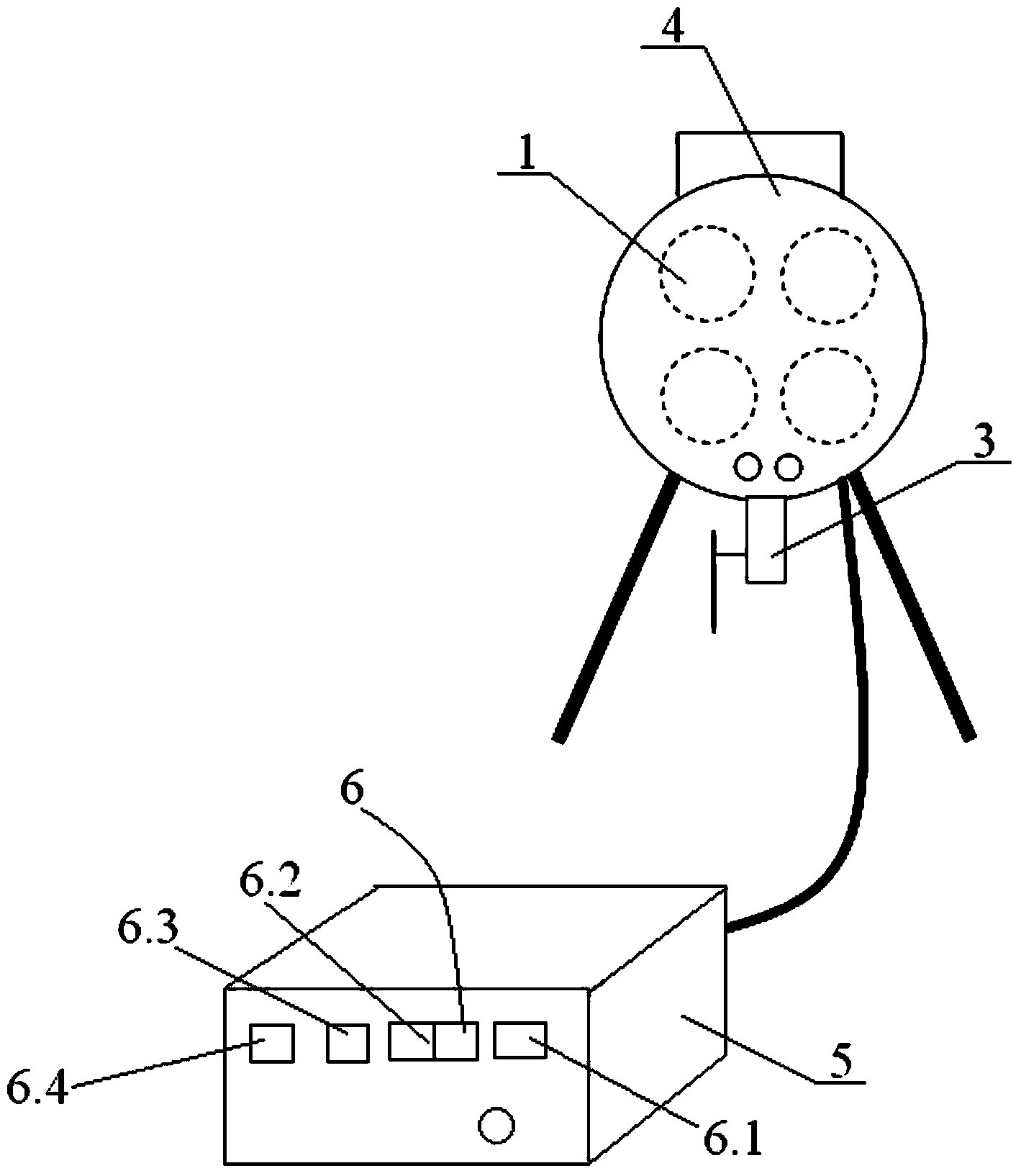

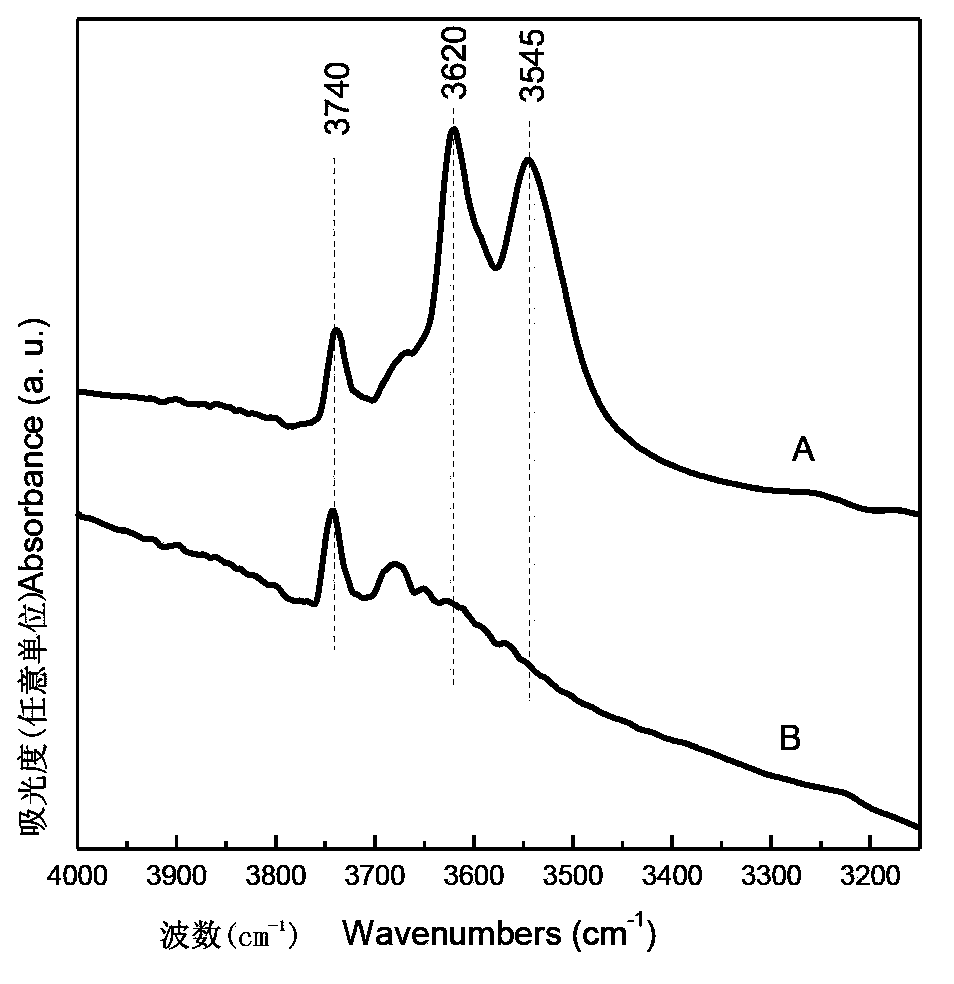

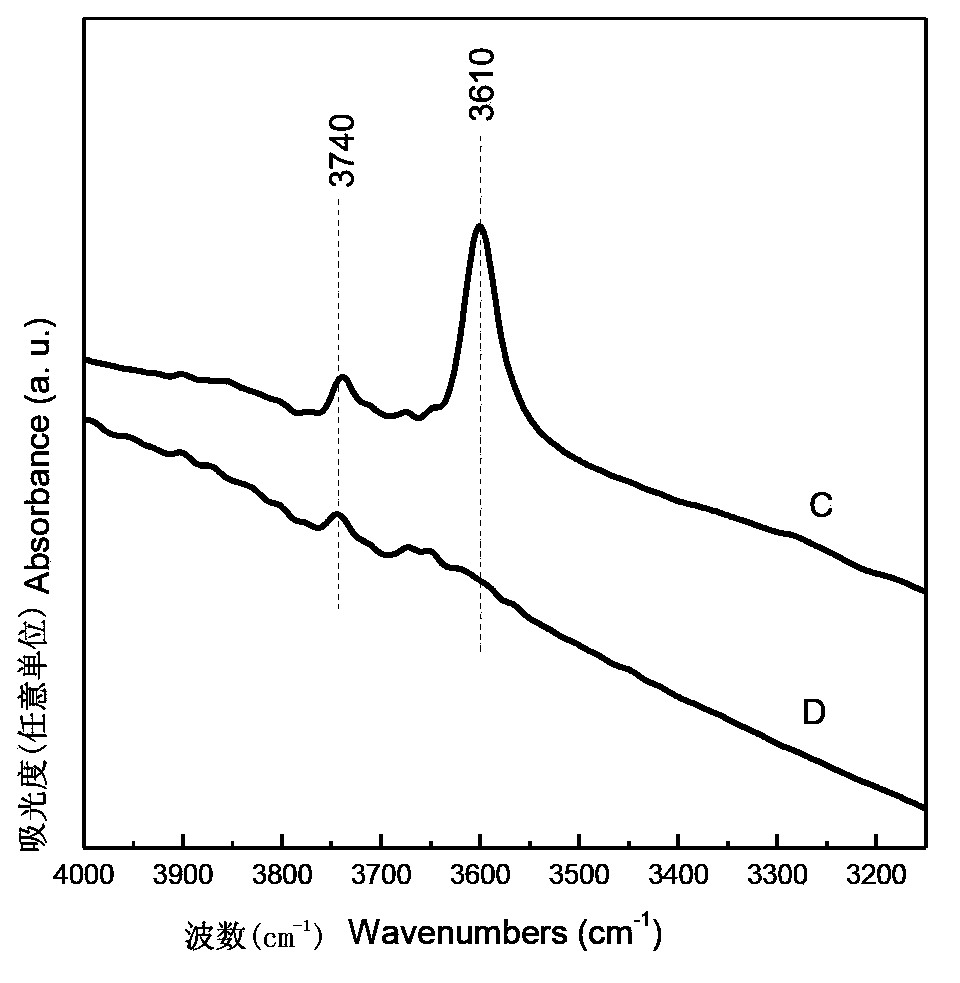

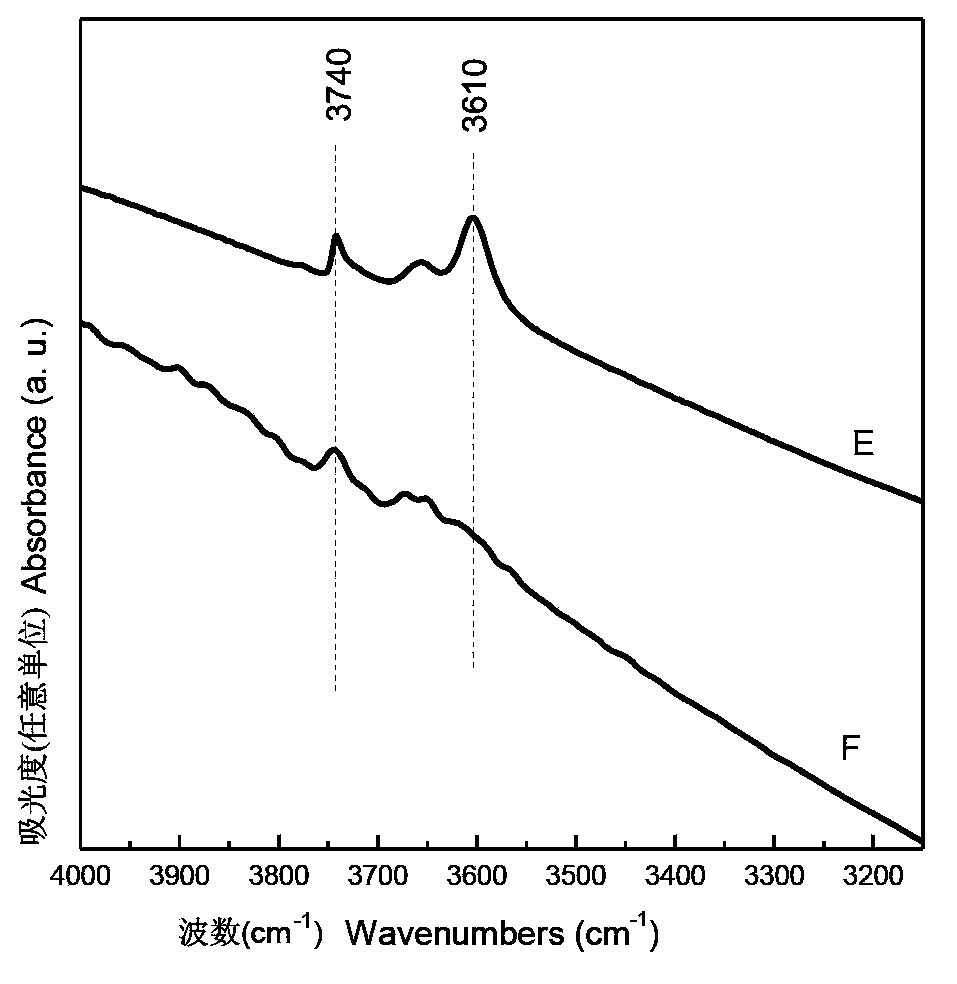

Preparation method of iron ion exchange modified molecular sieve

ActiveCN103657742AIncrease the degree of exchangeNo protectionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveIron powder

The invention provides a preparation method of an iron ion exchange modified molecular sieve. The preparation method comprises the following steps of (1) adding reduced iron powder and a matrix molecular sieve in an iron salt solution for carrying out ion exchange reaction; (2) carrying out solid-liquid separation on the iron salt solution after finishing the reaction; (3) washing an obtained solid product for removing the residual iron salt; (4) drying the product after washing; and (5) placing the product in a magnetic field for carrying out magnetic separation, so as to remove the iron powder. The preparation method provided by the invention has the advantages that the iron ion exchange modified molecular sieve with high exchange degree is obtained through once exchange, oxidation of ferrous ions is prevented without protection of inert environment, the generated residual matters which are not exchanged on the molecular sieve in a process are removed, and the pure exchange product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method

ActiveCN103224465BSubsequent separation is simpleAvoid pollutionOrganic chemistrySynthesis methodsFixed bed

The invention discloses a 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method. The 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method comprises the following steps of 1, filling an acidic resin into a fixed bed reactor, and carrying out heating so that a temperature of the fixed bed reactor is in a range of 40 to 70 DEG C, and 2, feeding acetone and ammonia gas into the fixed bed reactor according to a mole ratio of 3-9: 1 under the conditions of acetone hourly space velocity of 0.15 to 1.17h<-1> and ammonia gas hourly space velocity of 5.25 to 124.20h<-1>, and cooling the product to obtain a 2,2,6,6,-tetramethyl-4-piperidone crude product. The 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method has simple processes and a low cost, is suitable for industrial continuous production, does not adopt an organic solvent or water as a solvent, avoids the pollution produced by the organic solvent on the environment, has mild reaction conditions, can be carried out at a temperature of 40 to 70 DEG C, has low energy consumption, and avoids the influence caused by impurities produced at a high temperature on the product.

Owner:安徽兴欣新材料有限公司

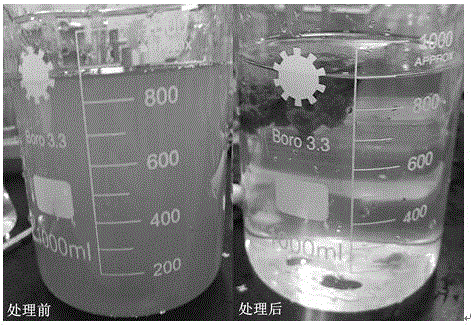

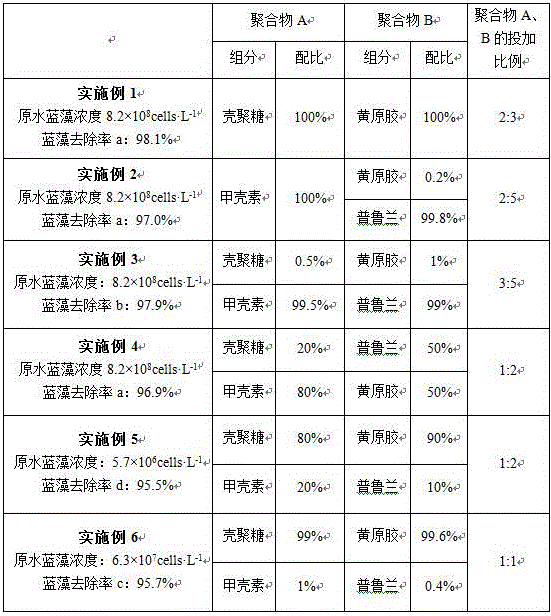

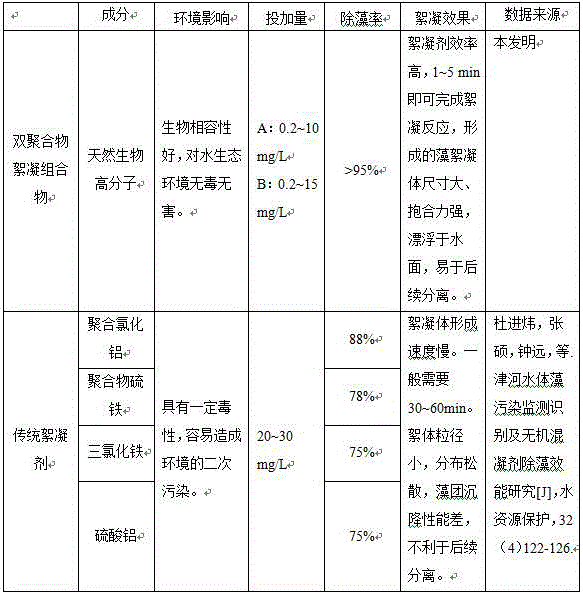

Method for flocculating and removing blue algae through dual-polymer composition and application of dual-polymer composition

InactiveCN106365282ALow priceEasily biodegradableWater/sewage treatment by flocculation/precipitationContaminated waterways/lakes/ponds/rivers treatmentPullulanLow speed

The invention discloses a method for flocculating and removing blue algae through a dual-polymer composition. The dual-polymer composition is prepared from a natural cationic polymer A and a natural anionic polymer B; the polymer A is a mixture formed by one or two of chitosan and chitin according to a mass ratio of (1 : 200) to (100 : 1); the polymer B is a mixture formed by one or two of xanthan gum and pullulan according to a mass ratio of (1 : 500) to (300 : 1). The method for flocculating and removing the algae through the dual-polymer composition is characterized by comprising the following steps: firstly adding the polymer A into blue algae water according to a final concentration ratio of 0.2mg / L to 10mg / L, uniformly mixing, then adding the polymer B into the blue algae water according to a final concentration ratio of 0.2mg / L to 30mg / L, the adding ratio range of the polymer A and the polymer B being (1 : 1) to (1 : 3), adjusting pH of the algae water to be 3-7, stirring for 0.5-5 minutes under 100-500 rpm, standing or stirring for 0.5-10 minutes at a low speed to form massive dense blue algae floccules, and removing the algae floccules via a filtering or fishing manner.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

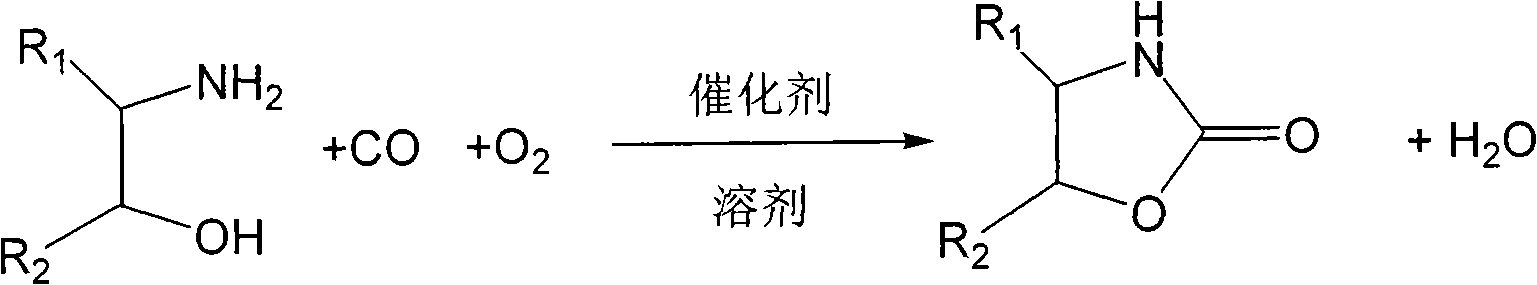

Method for synthesizing oxazoline-2-ketone

A method for synthesizing or substituting oxazoline-2-ketone comprises the steps of performing cyclocarbonylation with beta-amino alcohols as reactant and CO as carbonylation reagent and in the presence of selenium catalyst to obtain oxazoline-2-ketone, wherein the molar ratio of selenium catalyst and the reactant is 1-20% (mol), the reaction time is 2-20 hours, the reaction temperature is 10-100 DEG C, and the CO pressure is 1atm. By using the inventive method, the product has selectivity over 99% and has no racemization to chiral substrates, both the selenium catalyst and the solvent can be recycled, and the catalytic activity is substantially unchanged, so as to solve the difficulty of difficult separation of a catalyst and a product in a homogeneous catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

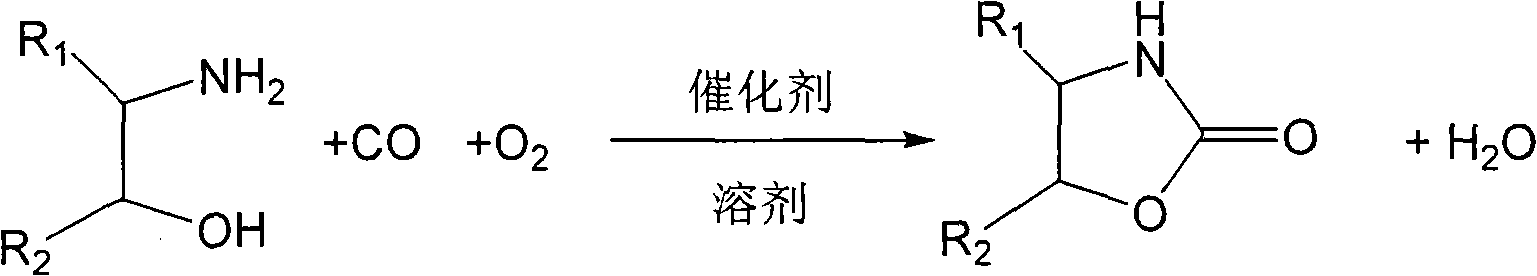

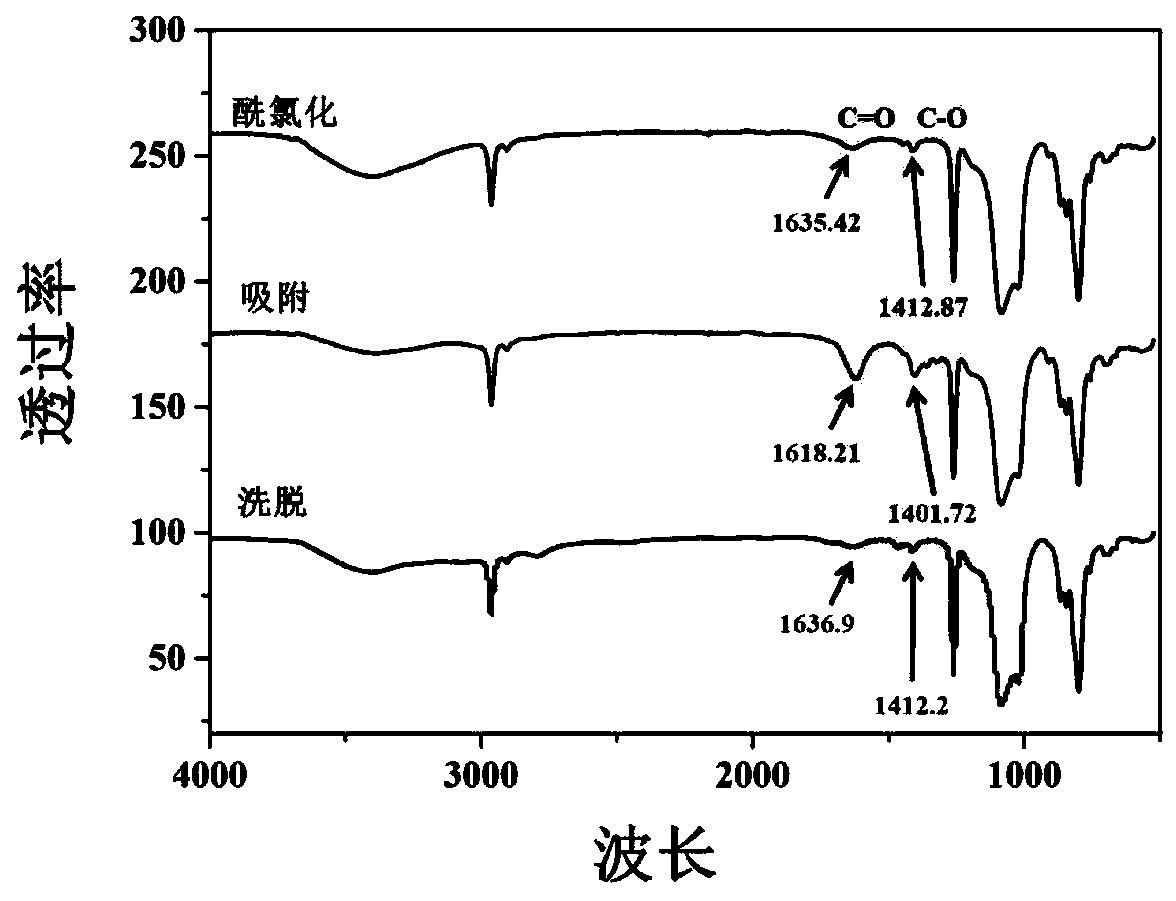

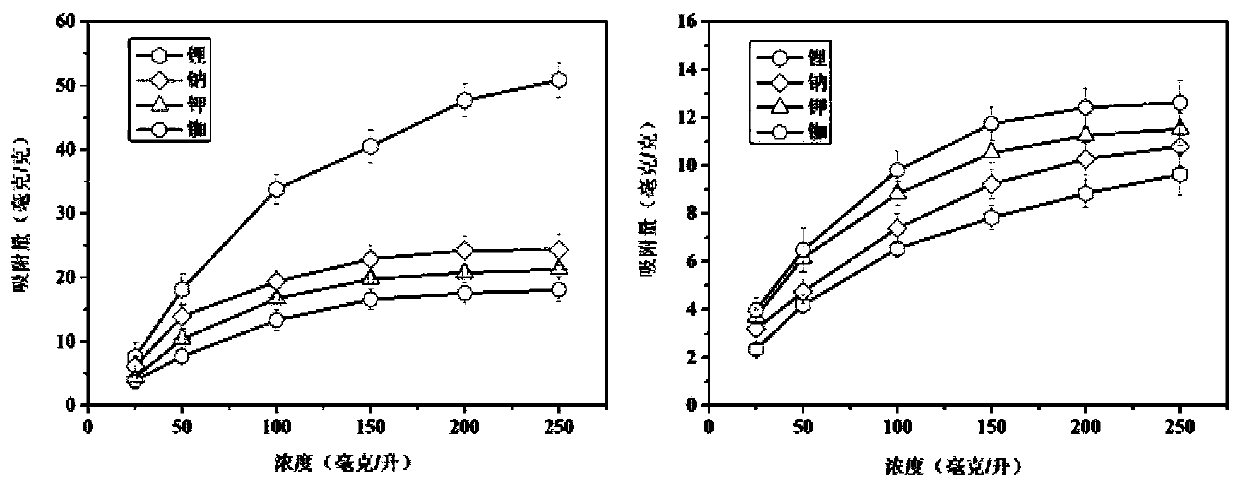

Preparation method and application of Li-IIMs ion imprinted membrane

ActiveCN111229174AEasy to useEasy to recycleIon-exchange process apparatusOther chemical processesCalixareneHydrolysis

The invention belongs to the technical field of functional material preparation, and particularly relates to a preparation method and application of a Li-IIMs ion imprinted membrane. According to thepreparation method, polydimethylsiloxane is modified through a self-polymerization reaction of dopamine to form a highly viscous dopamine layer, succinic anhydride is hydrolyzed to form carboxyl on the surface of a dopamine functionalized substrate, and carboxyl-modified PDMS is further modified to construct ester-modified PDMS; furthermore, calix[4]arene is used as a ligand, ethylenediaminetetraacetic acid is used as an eluent, and the Li-IIMs imprinted membrane is prepared. Compared with a preparation method of a traditional membrane material, the imprinted membrane prepared by the disclosedmethod has the advantages of easiness in recovery, convenience in subsequent separation, no secondary pollution to separated substances and the like, and the defects of difficulty in recovery, easiness in secondary pollution generation and the like of an existing lithium ion separation polymer are well overcome.

Owner:JIANGSU UNIV

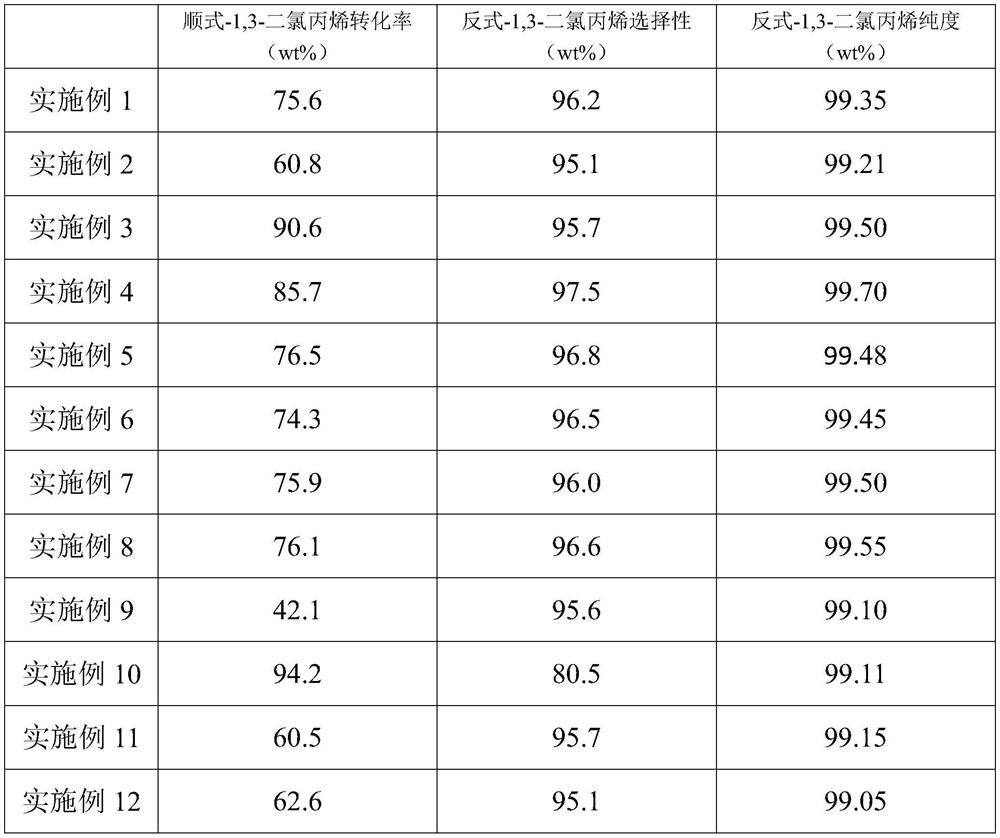

Preparation method of trans-1, 3-dichloropropene

ActiveCN112898118AMild reaction conditionsSimple processOrganic chemistry methodsChemical recyclingPtru catalystEngineering

The invention provides a preparation method of trans-1, 3-dichloropropene, the preparation method adopts a specific catalyst to convert cis-1, 3-dichloropropene into trans-1, 3-dichloropropene, only needs the catalyst and illumination, does not need to add other solvents and assistants, and has the advantages of mild reaction conditions, simple process and easy industrial implementation. Few byproducts are produced in the reaction process, the subsequent separation is simple, and the application prospect is wide.

Owner:JIANGSU YANGNONG CHEM GROUP

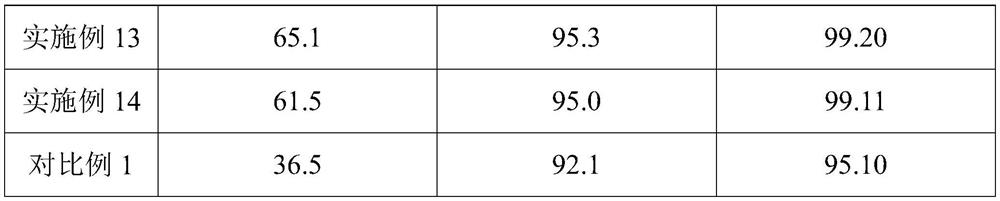

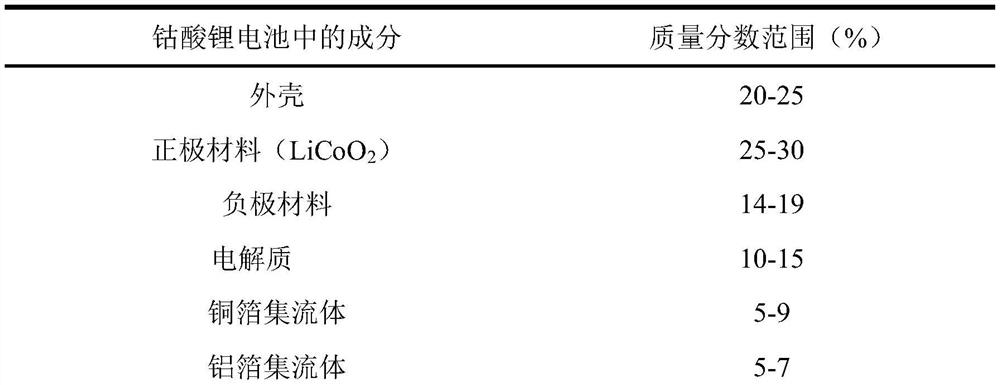

Method for selectively leaching metal components in waste lithium cobalt oxide battery by using polyethylene glycol-citric acid solvent

ActiveCN113061727AEasy to makeLow costWaste accumulators reclaimingProcess efficiency improvementPolythylene glycolPhysical chemistry

The invention discloses a method for selectively leaching metal components in a lithium cobalt oxide battery by using a polyethylene glycol-citric acid mixed solvent. The method comprises the following steps of 1) mixing and stirring polyethylene glycol and citric acid under a heating condition to form a uniform mixed solvent; 2) obtaining the waste lithium cobalt oxide battery; (3) adding the waste battery into the mixed solvent prepared in step (1), and performing full stirring and heating for leaching; and 4) adding water for dilution, filtering out insoluble impurities in a solution obtained after step 3) to obtain a leaching solution, and recovering the metal components in the waste battery. The method adopts the polyethylene glycol-citric acid solvent to leach the metal components in the lithium cobalt oxide battery, cobalt and lithium are selectively leached, aluminum foil and copper foil of a current collector do not need to be peeled off in a pretreatment stage, the leaching rate is high, the selectivity is good, the economical efficiency is good, and the method is environment-friendly and has relatively high industrial popularization value.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

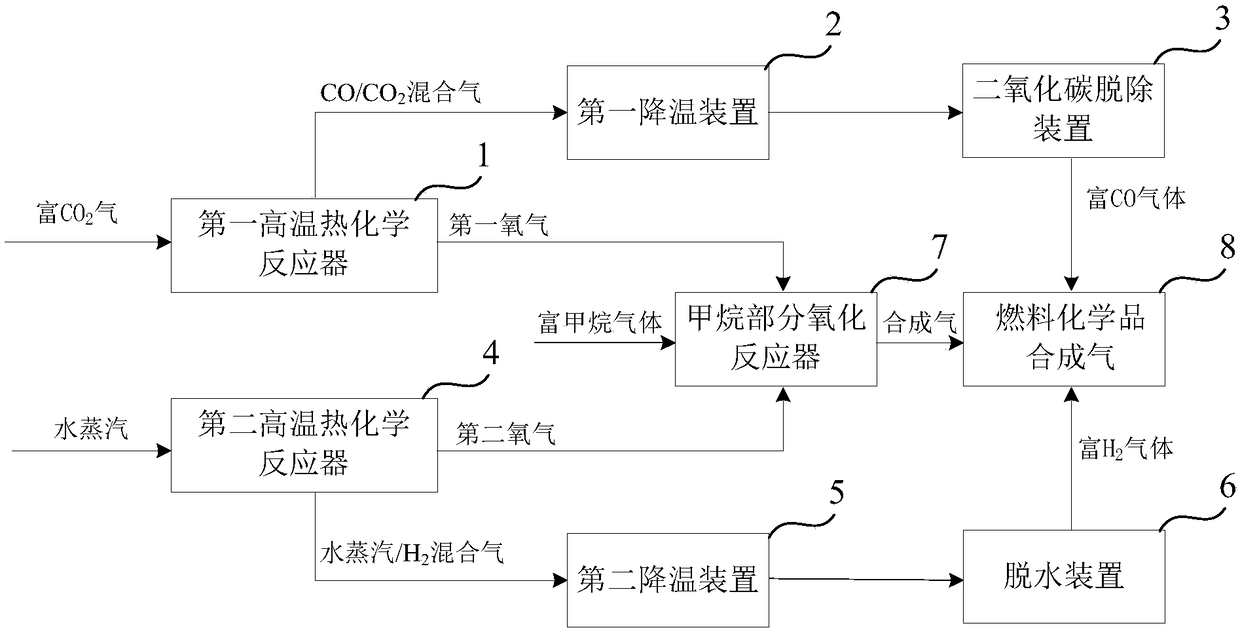

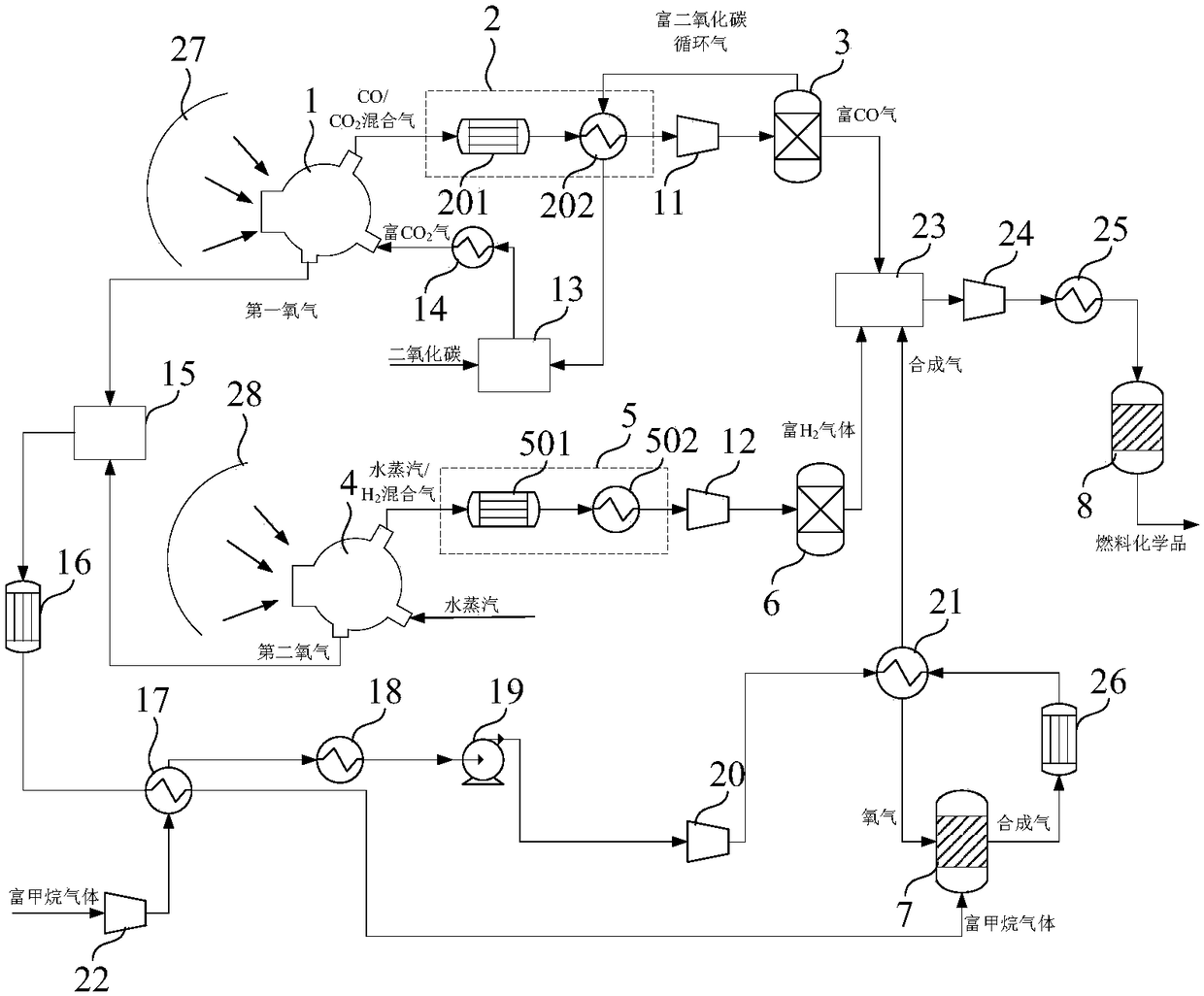

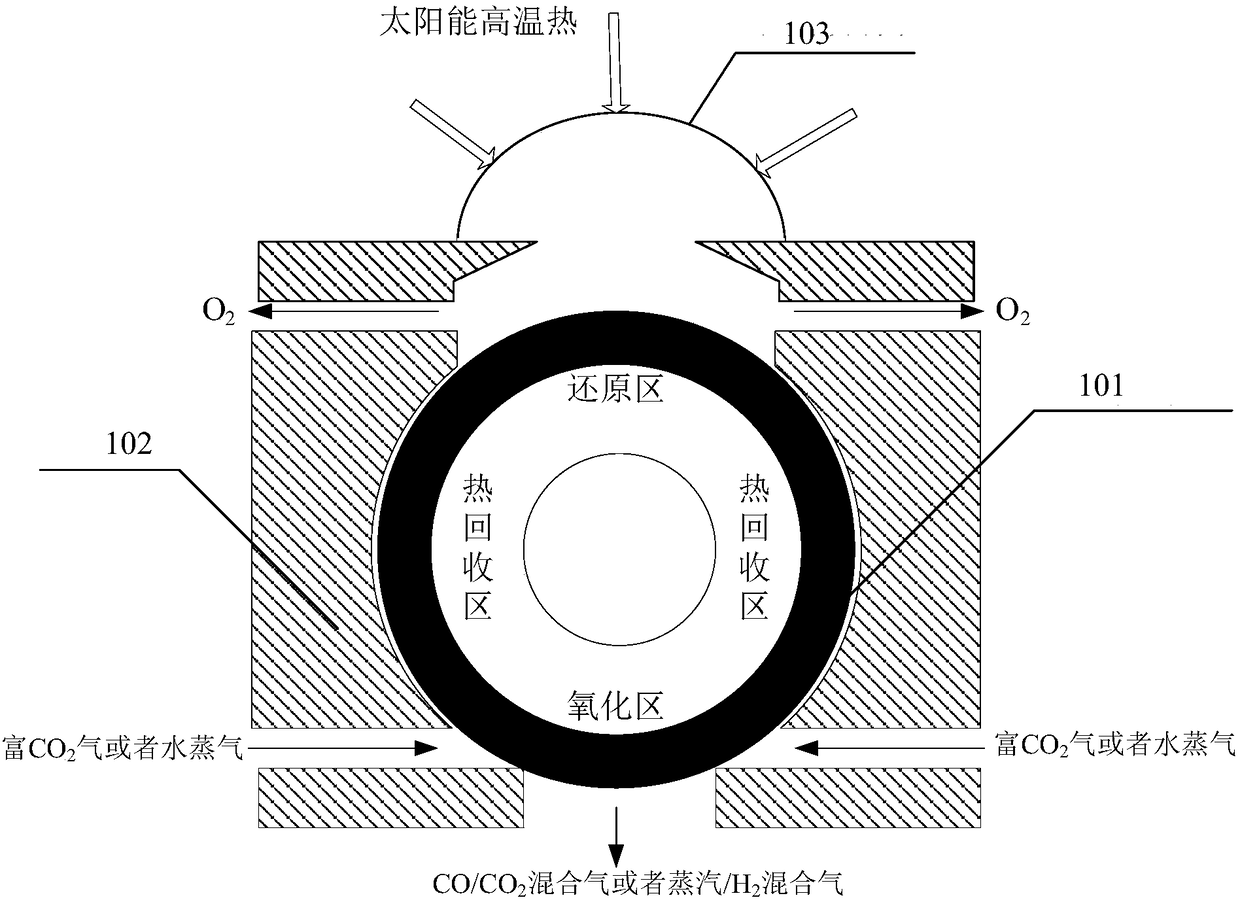

System and method for producing fuel chemicals by conducting solar high-temperature thermal-coupling on methane

InactiveCN108456547AEasy to separateSubsequent separation is simpleOrganic compound preparationChemical industryChemical synthesisCo2 removal

The invention provides a system and method for producing fuel chemicals by conducting solar high-temperature thermal-coupling on methane. The method includes the steps of introducing CO2-enriched gasinto a first high-temperature thermochemical reactor, carrying out a thermochemical decomposition reaction to produce a gas mixture of CO and CO2 and first oxygen under irradiation of first sunlight,and making the gas mixture of CO and CO2 sequentially pass a first temperature reducing device and a CO2 removal device to become CO-enriched gas; introducing water vapor into a second high-temperature thermochemical reactor, carrying out a thermochemical decomposition reaction to produce a gas mixture of water vapor and H2 and second oxygen under irradiation of second sunlight, and making the gasmixture of water vapor and H2 sequentially pass a second temperature reducing device and a dewatering device to become H2-enriched gas; after mixing methane-enriched gas with the first oxygen and thesecond oxygen, carrying out a reaction in a methane partial-oxidation reactor to produce synthesis gas; mixing the synthesis gas, the CO-enriched gas and the H2-enriched gas to be introduced into a fuel chemical synthesis tower for reacting to obtain the fuel chemicals.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

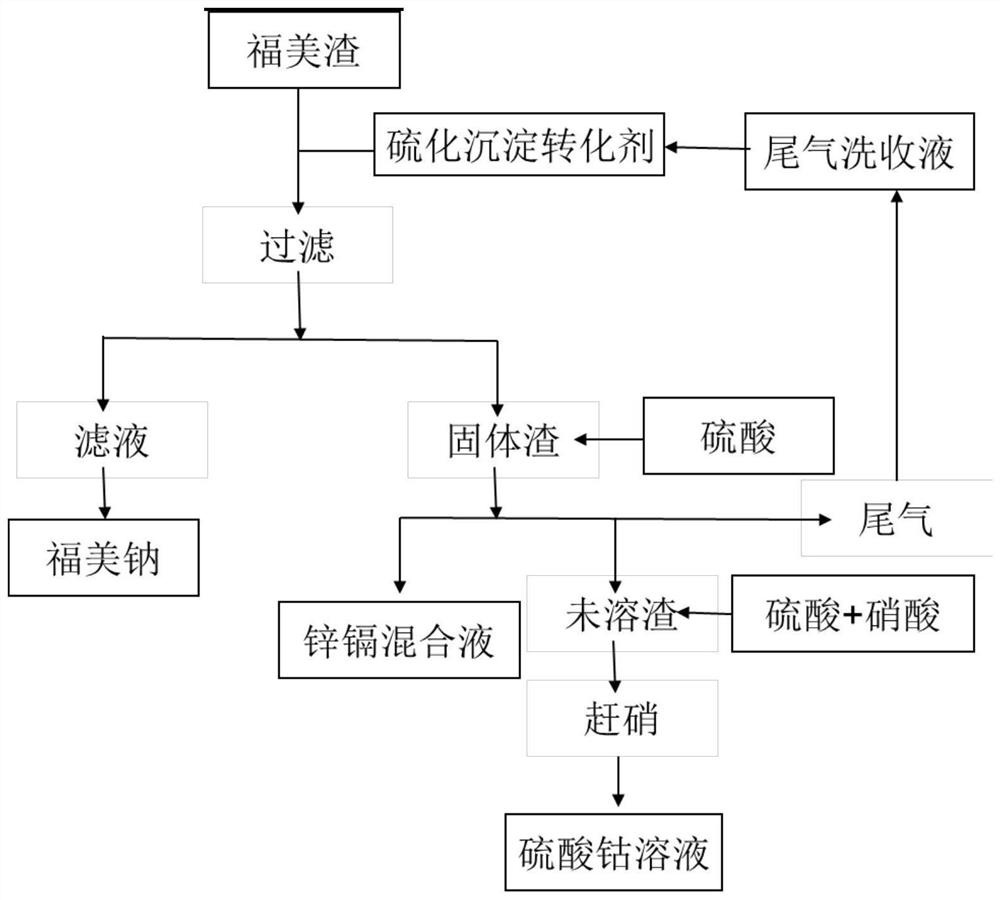

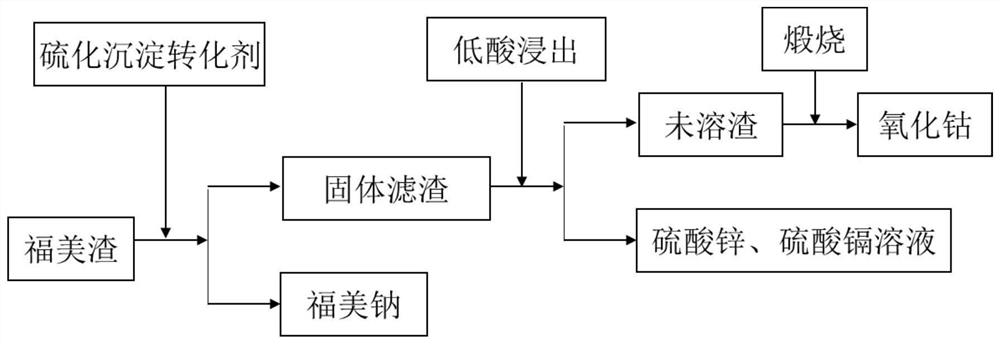

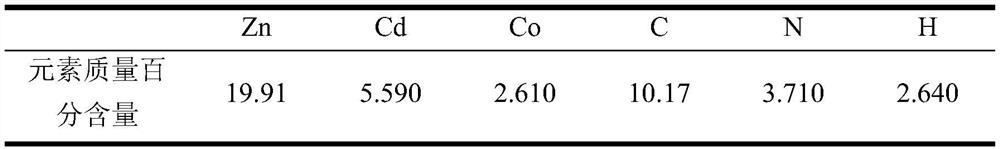

A kind of recycling method of fumei slag

ActiveCN113845455BGreen recyclingEfficient recyclingOrganic chemistryProcess efficiency improvementSlagNonferrous metal

Owner:LANZHOU UNIVERSITY +1

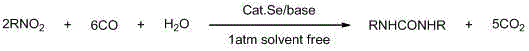

Method for synthesizing symmetric urea compounds from nitrocompounds

ActiveCN103113265BLess investmentSimple and safe operationUrea derivatives preparationOrganic compound preparationNitro compoundPtru catalyst

Owner:LIAONING UNIVERSITY

A kind of method for electrochemically decomposing chromite in potassium hydroxide solution to extract chromium

InactiveCN103060838BSubsequent separation is simpleLow reaction temperatureElectrolysis componentsElectrolytic organic productionPotassium hydroxideSlurry

The invention relates to a method for electrochemically decomposing chromite in a potassium hydroxide solution to extract chromium. Chemical oxidation reaction, after the reaction, the mixed slurry undergoes solid-liquid separation to obtain a solution of tailings and chromium-containing alkali. The method has the advantages of low cost, high extraction efficiency, no pollution, mild process conditions, and the extraction rate of chromium can reach more than 95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Ultrasonic oxidation-extraction and deep desulfurization method for diesel oil

InactiveCN103450931BImprove oxidation capacityReduce lossesTreatment with plural serial refining stagesOrganic acidDistillation

The invention discloses an ultrasonic oxidation-extraction and deep desulfurization method for diesel oil. The method comprises the steps: firstly, uniformly mixing an oxidizing agent, a cosolvent and a catalyst, then, mixing the mixture with sulfur-contained diesel oil on line, and next, carrying out ultrasonic oxidative desulphurization reaction in an ultrasonic reactor; delivering the mixture after reacting into a settling tank for separating to obtain a catalyst-contained solvent to be recycled and diesel oil to be subjected to solvent extraction, and separating organic sulfur in the diesel oil to obtain desulfurized diesel oil; carrying out reduced pressure distillation on the extracted solvent, recycling the separated solvent, and retreating the separated organic sulfur. By using the ultrasonic oxidation-extraction and deep desulfurization method, not only can the oxidation performance of the oxidizing agent to organic sulfur be improved, but also the cosolvent can be used for extracting organic sulfur in the diesel oil to obtain the solvent in the ultrasonic oxidation reaction, a phase transfer catalyst is not needed to be additionally added, the subsequent separation operation is easy, and the sulfur content of the desulfurized diesel oil is not higher than 10ppm. In addition, the ultrasonic oxidation-extraction and deep desulfurization method has the advantages of no adoption of organic acid capable of corroding equipment, short process route and low oil loss.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

A kind of preparation method of iron ion exchange modified molecular sieve

ActiveCN103657742BIncrease the degree of exchangeNo protectionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveIron powder

The invention provides a preparation method of an iron ion exchange modified molecular sieve. The preparation method comprises the following steps of (1) adding reduced iron powder and a matrix molecular sieve in an iron salt solution for carrying out ion exchange reaction; (2) carrying out solid-liquid separation on the iron salt solution after finishing the reaction; (3) washing an obtained solid product for removing the residual iron salt; (4) drying the product after washing; and (5) placing the product in a magnetic field for carrying out magnetic separation, so as to remove the iron powder. The preparation method provided by the invention has the advantages that the iron ion exchange modified molecular sieve with high exchange degree is obtained through once exchange, oxidation of ferrous ions is prevented without protection of inert environment, the generated residual matters which are not exchanged on the molecular sieve in a process are removed, and the pure exchange product is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for extracting vanadium by ammonification with low liquid-solid ratio

ActiveCN106676273BReduce usageReduce ammonia volatilizationProcess efficiency improvementChemical industrySlag

The invention relates to the field of vanadium slag wet process metallurgy and vanadium chemical industry, in particular to a method for vanadium extracting through low liquid-solid-ratio ammonification. According to the method, after raw materials containing vanadium is roasted, clinkers, water and ammonium salt are mixed according to a certain proportion; materials with a low liquid-solid ratio are formed and subjected to the low-temperature ammonification reaction, the vanadium in the clinkers reacts with the ammonium salt to form ammonium metavanadate, and the ammonium metavanadate formed at the low temperature exists in mixed slurry in a crystalline mode; after the mixed slurry is subjected to hydrotherm dissolution, a solution rich in the ammonium metavanadate is obtained; and after slurry filtering, filtrate cooling and crystallizing and separating and ammonium vanadate roasting, vanadium pentoxide products are obtained. Compared with a conventional vanadium extracting through ammonification, according to the method for vanadium extracting through low liquid-solid-ratio ammonification, the using quantity of the water and the ammonium salt are greatly reduced in the ammonification process, and volatilization of ammonia gas is obviously inhibited; and the slurry can be directly subjected to hydrotherm leaching to obtain the ammonium metavanadate solution after ammonification, the process of vanadium extracting through ammonification is greatly simplified, the process is easy to operate and control, efficient and clean extracting of the vanadium can be achieved, and the extracting rate of the vanadium reaches 90% or more.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

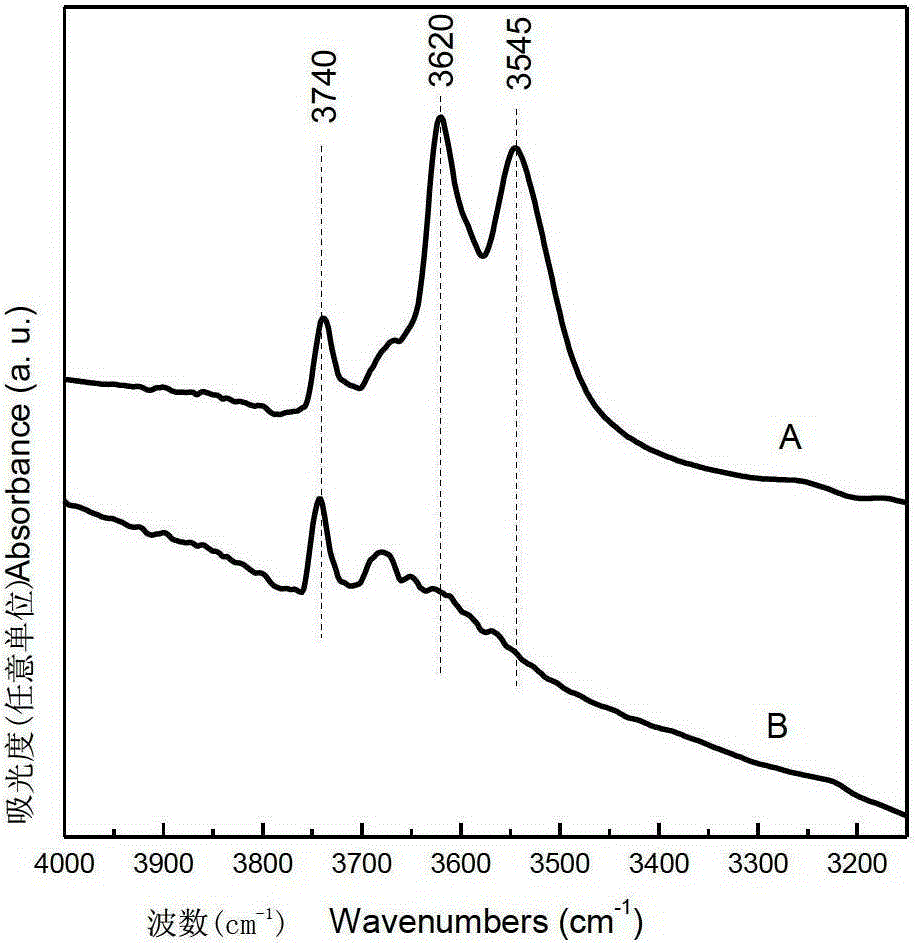

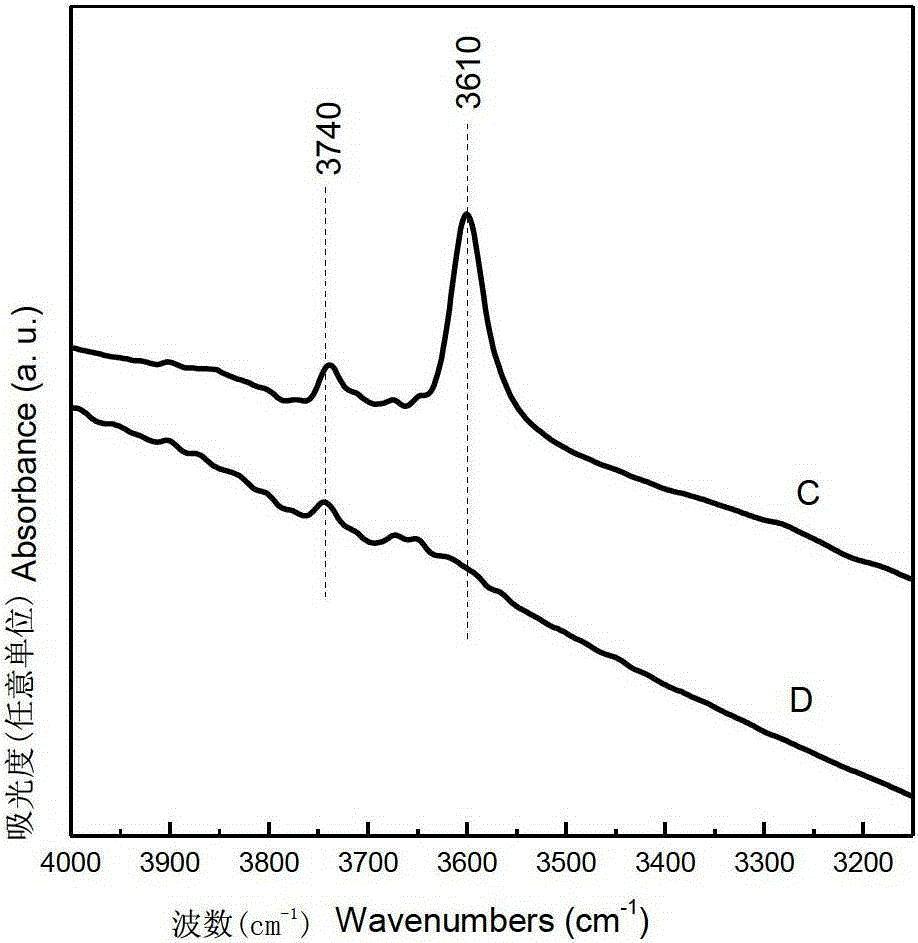

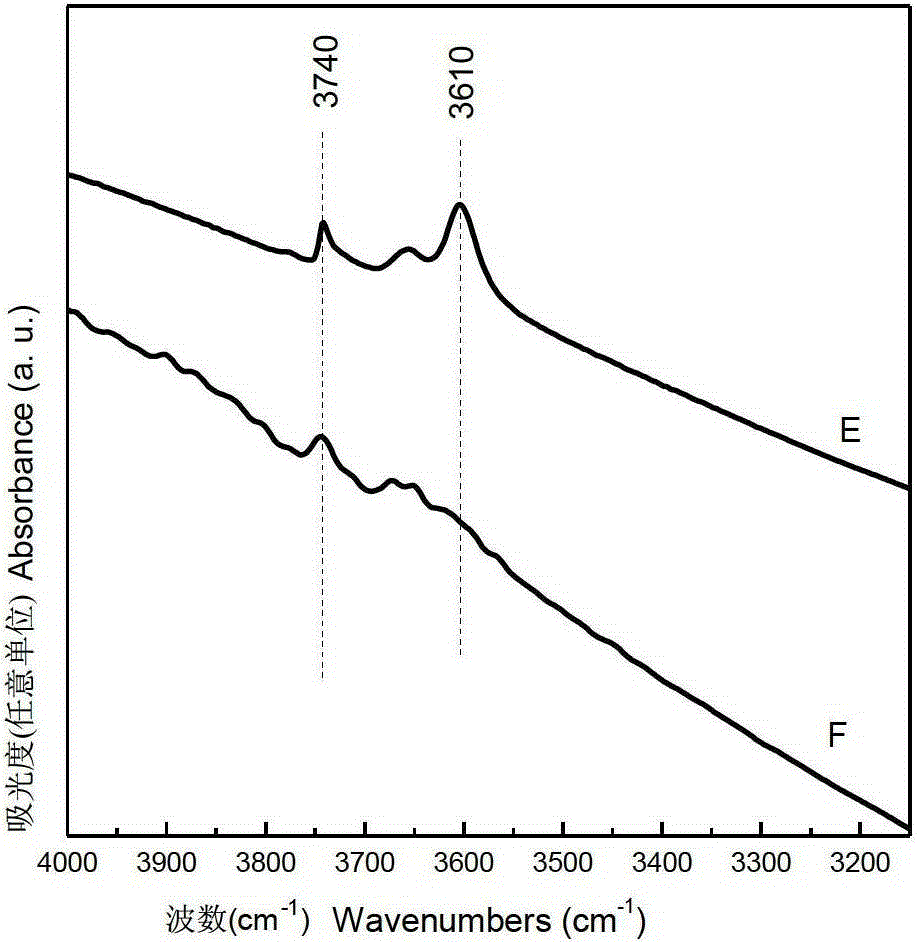

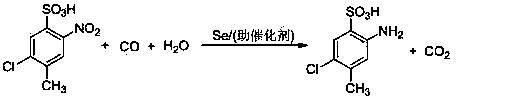

Method for synthesizing CLT acid

ActiveCN102675162BLess investmentSimple and safe operationChemical recyclingSulfonic acid preparationPtru catalystOrganic base

The invention relates to a method for synthesizing CLT acid, which has the technical scheme that 2-nitro-4-methyl-5-chlorobenzenesulfonic acid is taken as raw material; under the condition that carbon monoxide and water exist, selenium is taken as catalyst, inorganic base or organic base is taken as catalyst promoter; and reaction is carried out at high temperature and high pressure, so that the CLT acid can be synthesized by a one-step method. The method is simple, convenient and safe, realizes aqueous phase reaction, and is easy in obtaining of raw material, free from pollution, high in selectivity and high in yield; and the catalyst can be recycled after the reaction.

Owner:LIAONING UNIVERSITY

A kind of manufacture method of bromelain

InactiveCN101319208BReduce enzyme activitySubsequent separation is simpleHydrolasesFreeze-dryingUltrafiltration

The invention relates to a method for producing bromelain, in particular to a new method for industrially extracting bromelain with pineapple stems (plants) as the main raw material. It includes the following steps: (1) Pineapple stem cleaning → (2) Pineapple stem crushing → (3) Squeezing juice → (4) Coarse filtration → (5) Heat exchange → (6) Centrifugation → (7) Microfiltration → (8) Ultrafiltration → (9) Refining → Synthesis → (10) Vacuum freeze drying → (11) Crushing → Preparation → Packaging → Finished product. The method for producing bromelain has high enzyme extraction recovery rate (up to 0.2%), high enzyme purity, high enzyme activity (up to 3000GDU / g or more), good stability, energy saving and reduced production cost.

Owner:广西美仑生物科技有限公司

Lactic acid-producing streptococcus bovis and separation method thereof

PendingCN114045245APromote proliferationSubsequent separation is simpleBacteriaMicroorganism based processesStreptococcus bovisAgar

The invention provides lactic acid-producing streptococcus bovis and a separation method thereof, and relates to the technical field of streptococcus bovis separation. The separation method of the lactic acid-producing streptococcus bovis comprises the following steps: S1, preparation of raw materials: taking 100 grams of normal cattle manure, diluting the normal cattle manure, filtering out impurities, leaving a filtrate, filling a sterile anaerobic sealing bag with the filtrate, and sealing the sterile anaerobic sealing bag; and S2, preparation of a culture medium: with water as a solute, adding, in parts by mass, 2.0 to 4.0 grams of soluble starch, 10 to 30 grams of glucose, 0.5 to 1.5 grams of dipotassium phosphate, 3 to 5 grams of calcium carbonate, 0.2 to 0.4 gram of magnesium sulfate, 0.4 to 0.6 gram of yeast powder, 20 to 40 grams of agar and 1 milliliter of a crystal violet solution with a concentration of 1% into the water. According to the invention, starch and agar are added into common culture medium components, so the growth rate of streptococcus bovis can be increased and is higher than the growth rates of other bacteria, rapid proliferation can be achieved, dominant flora can be formed, and follow-up separation is easier; and the crystal violet solution is added into the common culture medium components, so colors are easy to distinguish, and the streptococcus bovis can be quickly selected from other bacteria.

Owner:TARIM UNIV

Solvent-free method for synthesizing water-soluble vitamin E polyethylene glycol succinic acid ester

ActiveCN101787118BReduce recyclingRaw materials are easy to getOrganic chemistryReaction rateDistillation

The invention discloses a method for preparing water-soluble vitamin E polyethylene glycol succinic acid ester. In the method, vitamin E succinic acid ester and polyethylene glycol are taken as raw materials and the method comprises the steps of performing an esterification reaction on the raw materials after catalysis reaction by using an acid catalyst, cooling the products to the room temperature and performing after-treatment on a reaction product to obtain the water-soluble vitamin E polyethylene glycol succinic acid ester. In the method, the water-soluble vitamin E polyethylene glycol succinic acid ester is synthesized by a one-step method without a reaction solvent, and has the advantages of no solvent consumption, readily available raw materials, high reaction concentration, capability of greatly accelerating reaction rate, few reaction steps, simple subsequent separation, high conversion rate, high yield, low production cost, high product quality and easy industrial production, reduction of the steps of organic solvent recovery, distillation and the like due to no use of other solvents in the reaction and environmental friendliness.

Owner:ZHEJIANG UNIV

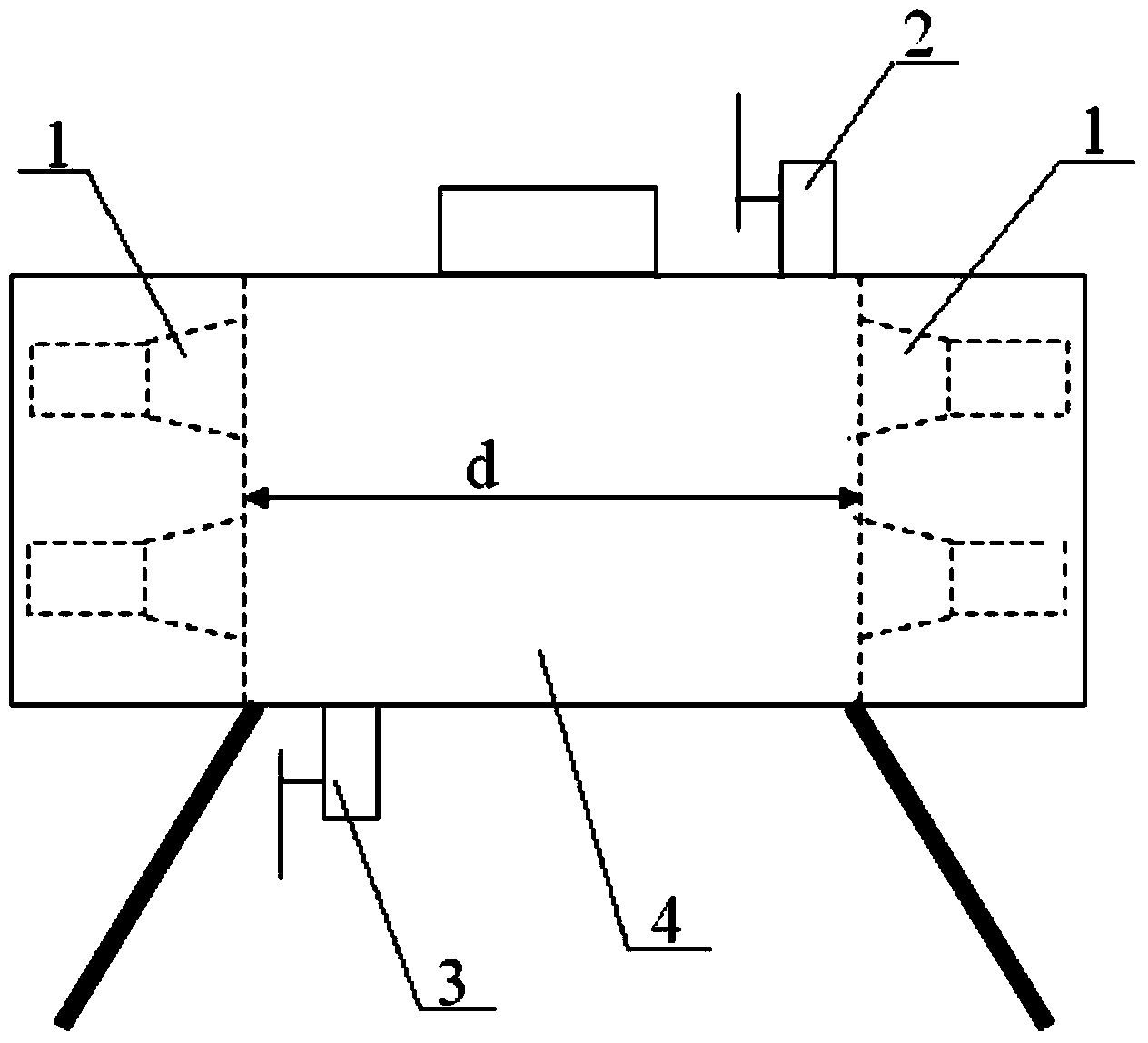

A method for synchronously extracting vanadium chromium by electrochemically decomposing vanadium slag in potassium hydroxide solution

ActiveCN103060843BSubsequent separation is simpleLow reaction temperaturePhotography auxillary processesProcess efficiency improvementSlagPotassium hydroxide

The invention relates to a method for synchronously extracting vanadium and chromium by electrochemically decomposing vanadium slag in a potassium hydroxide solution. The method comprises the steps as follows: introducing oxidizing gas into mixed slurry containing the vanadium slag, potassium hydroxide and water; carrying out electrochemical oxidization reaction; and after the reaction, carrying out solid-liquid separation on the mixed slurry to obtain tailings and a vanadium and chromium alkali solution. The method is low in cost, high in extraction efficiency, pollution-free and moderate in process conditions, and can be used for efficiently and synchronously extracting vanadium and chromium; the vanadium extraction rate can reach 85-99%; and the chromium extraction rate can reach 80-95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

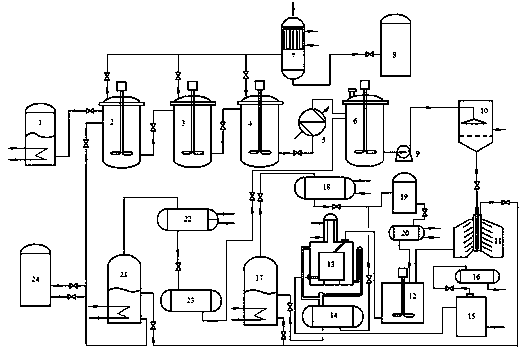

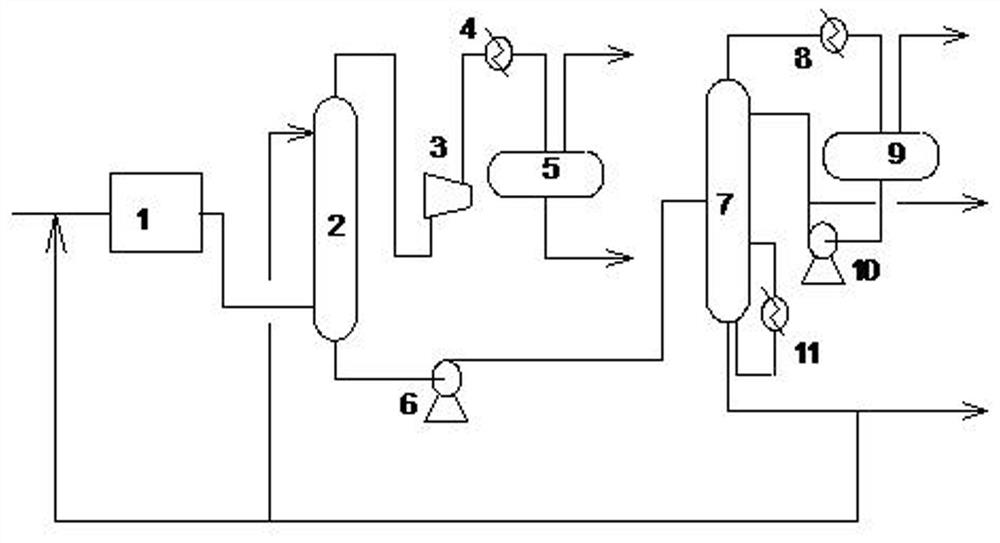

Separation system and method for preparing acetaldehyde product from ethanol

PendingCN114702375ASubsequent separation is simpleEfficient separationOrganic compound preparationPreparation by dehydrogenationEthanol absorptionAlcohol ethyl

The invention discloses a separation system for preparing acetaldehyde products from ethanol, which comprises a reactor and an ethanol absorption tower, the reactor is connected with the bottom side wall of the ethanol absorption tower, and the tower top of the ethanol absorption tower is sequentially connected with a compressor, a first cooler and a first gas-liquid separation tank; a tower bottom outlet of the ethanol absorption tower is connected with an acetaldehyde rectifying tower through a booster pump, the tower top of the acetaldehyde rectifying tower is sequentially connected with a second cooler, a second gas-liquid separation tank and a reflux pump, and the reflux pump is further connected with the side wall of the top of the acetaldehyde rectifying tower; the tower bottom of the acetaldehyde rectifying tower is respectively connected with the top side wall of the ethanol absorption tower and the inlet of the reactor; and the tower bottom of the acetaldehyde rectifying tower is also provided with an ethanol outlet. Meanwhile, the invention also discloses a method for preparing an acetaldehyde product by separating ethanol by using the system. By adding the ethanol absorption tower, the main product acetaldehyde, the by-product hydrogen and the unreacted ethanol can be efficiently separated, the separation precision is high, and the utilization efficiency of raw materials is high.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

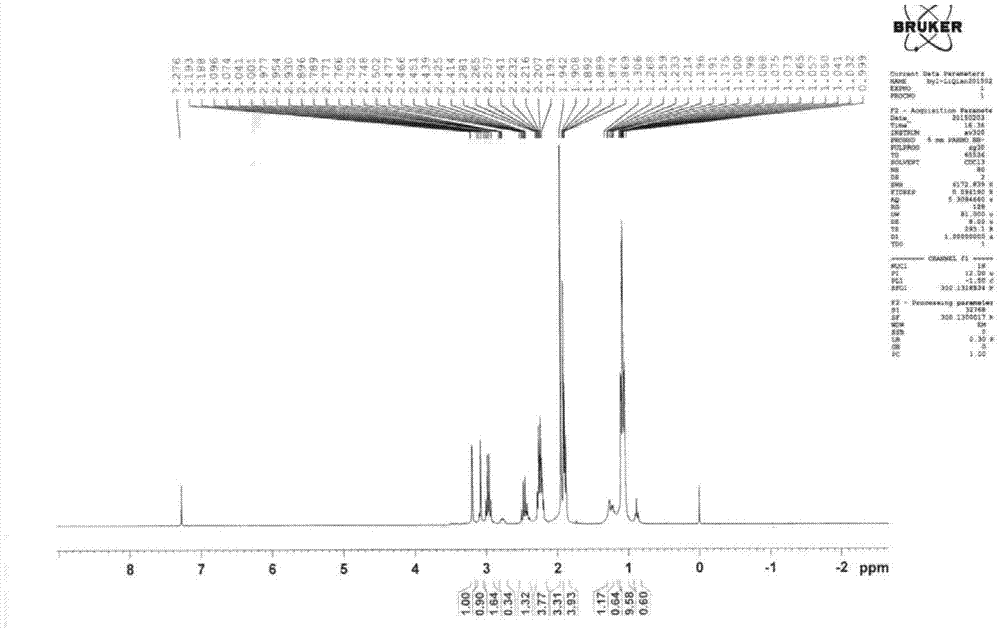

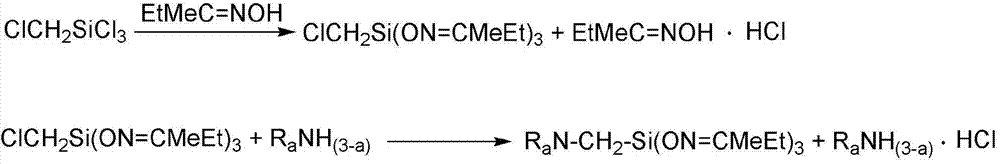

A kind of preparation method of α-aminotributanone oxime base silane

ActiveCN104650128BIncrease profitReduce generationGroup 4/14 element organic compoundsOrganic solventDistillation

The invention relates to a preparation method of α-aminotributanone oxime silane, comprising the following steps: (1) uniformly mixing butanone oxime with an organic solvent, then evenly adding chloromethyltrichlorosilane dropwise, after the dropwise addition is completed , and reacted at 0-60°C for 1-6 hours; after the reaction, stand and separate layers, neutralize the upper liquid with an organic base, filter off the insoluble matter, and distill under reduced pressure to remove impurities to obtain chloromethyl tributylketoxime Silane; (2) Mix the organic amine and the organic solvent evenly, then evenly drop chloromethyl tributylketoxime silane, after the dropwise addition is completed, react for 2-10 hours at 10-70°C; filter off the insoluble matter, Reduced pressure distillation to remove impurities, that is, too. The invention does not need to add additional acid absorbent, the subsequent separation is simple, and the generation of by-products such as multi-substituted organic amines is less, the utilization rate of the amine is high, and the side reactions of the reaction system are easy to control; the product purity can reach more than 85%, The yield is above 85%.

Owner:山东时代新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com