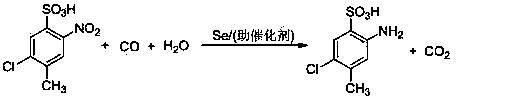

Method for synthesizing CLT acid

A technology of chlorobenzenesulfonic acid and carbon monoxide, which is applied in the fields of sulfonic acid preparation, chemical recovery, organic chemistry, etc., can solve the problems of serious pollution, complicated operation, and many steps, and achieve high reaction selectivity, simple raw materials, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 2-nitro-4-methyl-5-chlorobenzenesulfonic acid (50mmol), selenium powder (0.3g) into a 1000ml autoclave equipped with a stirring bar, H 2 O (400ml), Na 2 CO 3 (22g), add carbon monoxide to 4MPa, then heat to 130°C, stir and react for 6 hours, after cooling to room temperature, add hydrochloric acid to acidify and precipitate precipitate, vacuum-dry after suction filtration, and the target product can be obtained.

[0019] According to the national standard GB / T23670-2009, the yield of CLT acid was 99.8%.

Embodiment 2

[0021] The reaction temperature was 140° C., and the time was 6 hours. Other experimental methods and conditions were the same as in Example 1, and the measured yield was 90.1%.

Embodiment 3

[0023] The reaction time was 4 hours, and other experimental methods and conditions were the same as in Example 1, and the yield was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com