Ultrasonic oxidation-extraction and deep desulfurization method for diesel oil

A technology for deep desulfurization and diesel oil, which is only applied in the direction of multi-stage series refining process, can solve the problems of difficult separation, long reaction time, poor oxidation performance, etc., and achieve the goal of short process route, short reaction time and improved oxidation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

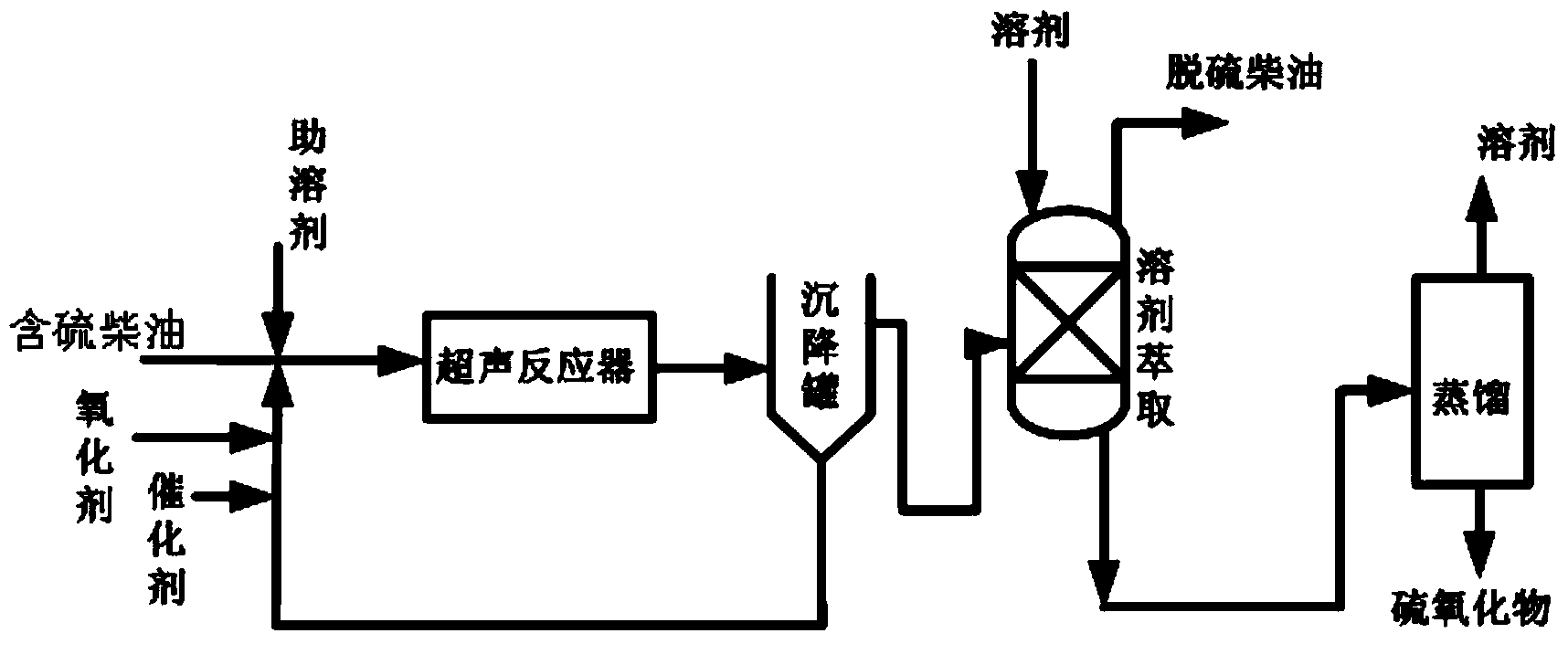

[0032] Diesel ultrasonic oxidation-extraction deep desulfurization method, such as figure 1 shown, including the following steps:

[0033] 1) Mix hydrogen peroxide, methanol, and phosphotungstic acid evenly, and then mix them online with sulfur-containing diesel, wherein the molar ratio of hydrogen peroxide to sulfur-containing diesel is 48:1, and the amount of methanol added is the volume of sulfur-containing diesel The amount of phosphotungstic acid added is 0.01% of the mass of sulfur-containing diesel;

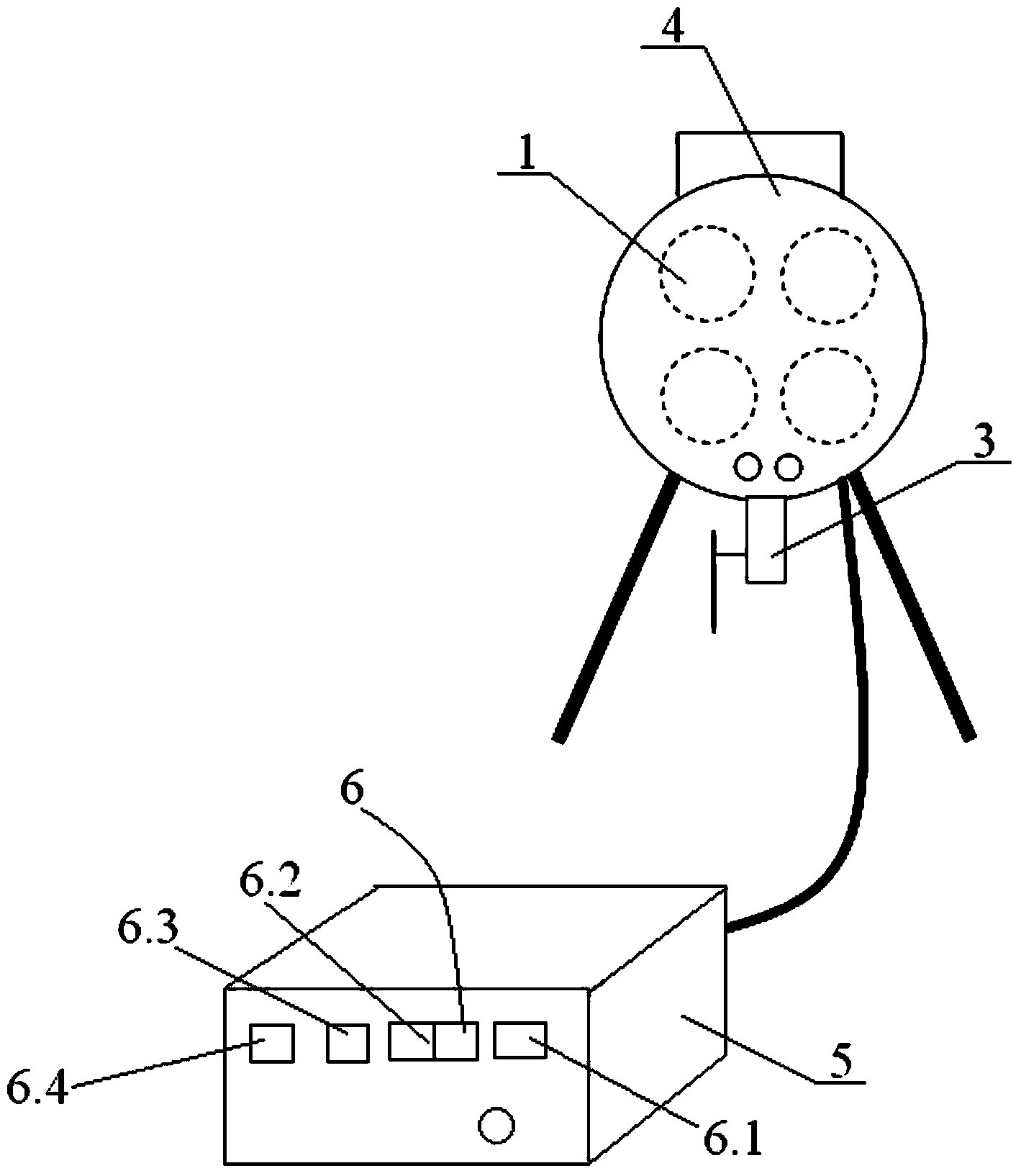

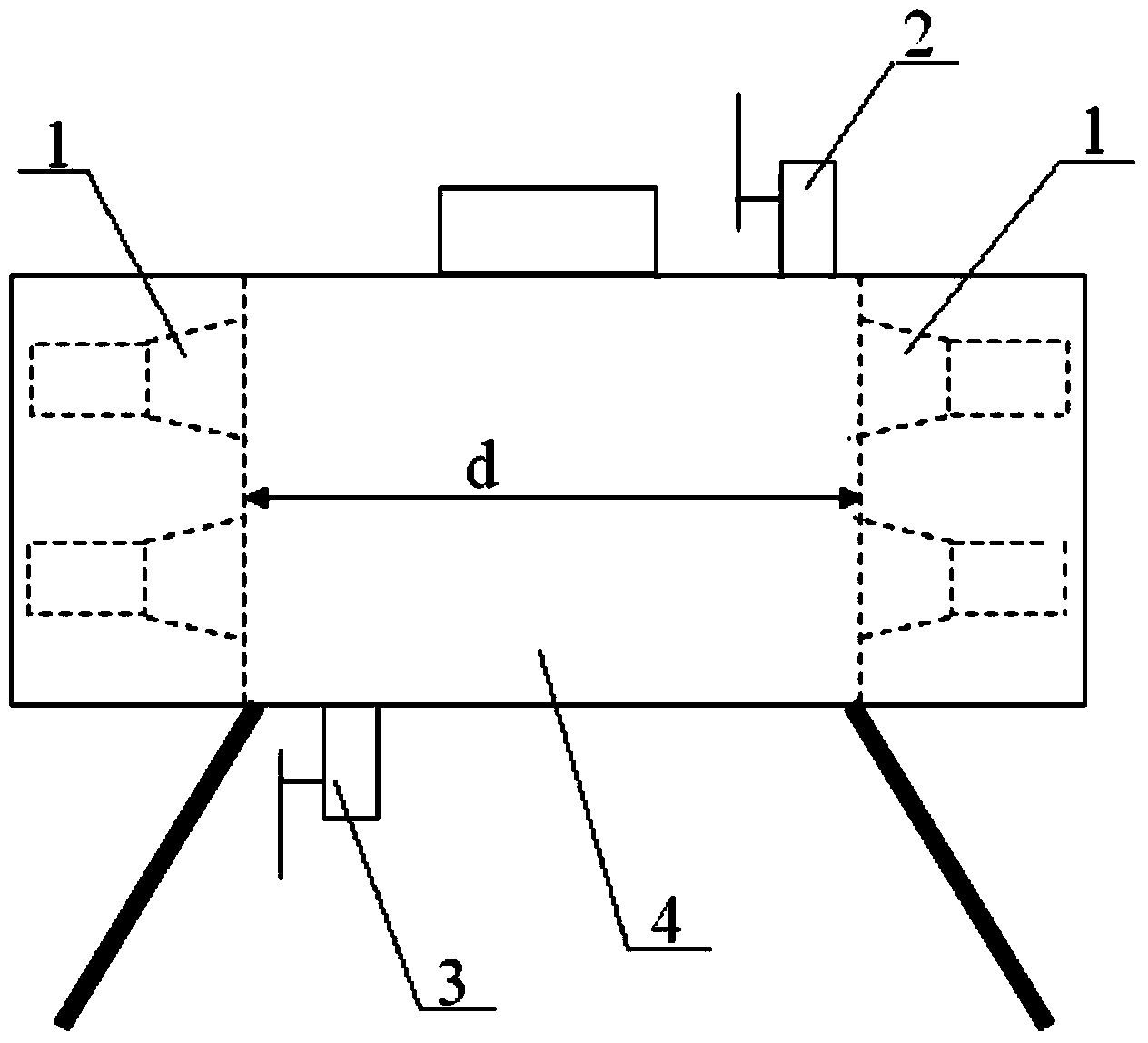

[0034] 2) The above mixture is subjected to ultrasonic oxidation desulfurization reaction in an ultrasonic reactor, the ultrasonic transducer 1 emits ultrasonic frequency into the cylinder 4 at a frequency of 10KHz, and the sound field intensity is 6000W / m 2 , the length d of the cylinder 4 is 15cm, the ultrasonic oxidation temperature is 85°C, and the ultrasonic oxidation time is 60min;

[0035] 3) The mixture after the ultrasonic oxidation desulfurization reaction is sen...

Embodiment 2

[0039] Diesel ultrasonic oxidation-extraction deep desulfurization method, such as figure 1 shown, including the following steps:

[0040] 1) Mix tert-butyl hydroperoxide, ethanol, and sodium phosphotungstate evenly, and then mix it with sulfur-containing diesel online, wherein, the molar ratio of tert-butyl hydroperoxide to sulfur-containing diesel is 24:1, and the molar ratio of ethanol The addition amount is 30% of the volume of sulfur-containing diesel oil, and the addition amount of sodium phosphotungstate is 0.1% of the mass of sulfur-containing diesel oil;

[0041] 2) The above mixture is subjected to ultrasonic oxidation desulfurization reaction in the ultrasonic reactor, the ultrasonic transducer 1 emits ultrasonic frequency into the cylinder 4 at a frequency of 10KHz, and the sound field intensity is 1000W / m 2 , the length d of the cylinder 4 is 50cm, the ultrasonic oxidation temperature is 105°C, and the ultrasonic oxidation time is 10min;

[0042] 3) The mixture ...

Embodiment 3

[0046] Diesel ultrasonic oxidation-extraction deep desulfurization method, such as figure 1 shown, including the following steps:

[0047] 1) Mix hydrogen peroxide, ethylene glycol, and phosphomolybdic acid evenly, and then mix them online with sulfur-containing diesel oil. The molar ratio of hydrogen peroxide to sulfur-containing diesel oil is 6:1, and the amount of ethylene glycol added is 20% of the volume of sulfur-containing diesel, the amount of phosphomolybdic acid added is 0.8% of the mass of sulfur-containing diesel;

[0048] 2) The above mixture is subjected to ultrasonic oxidation desulfurization reaction in the ultrasonic reactor, the ultrasonic transducer 1 emits ultrasonic frequency into the cylinder 4 at a frequency of 60KHz, and the sound field intensity is 6000W / m 2 , the length d of the cylinder 4 is 45cm, the ultrasonic oxidation temperature is 90°C, and the ultrasonic oxidation time is 15min;

[0049] 3) The mixture after the ultrasonic oxidation desulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com