A kind of method for electrochemically decomposing chromite in potassium hydroxide solution to extract chromium

A kind of potassium hydroxide and electrochemical technology, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problem of high equipment requirements, reduce the reaction temperature, facilitate the promotion of industrialization, and reduce the amount of slag discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

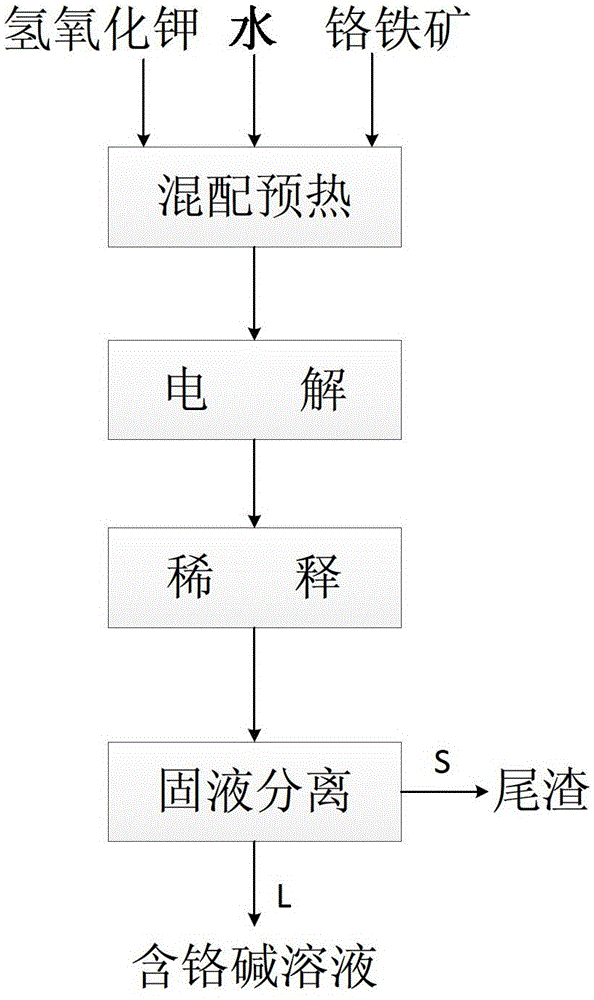

[0056] As a kind of embodiment of the present invention, the method for extracting chromium by electrochemical decomposition of chromite in a kind of potassium hydroxide solution described in the present invention, comprises the steps:

[0057] (1) Preheating of ingredients: Mix and heat chromite sieved to -200 mesh with potassium hydroxide aqueous solution to obtain raw material slurry, and preheat to 150-200°C, wherein the mass ratio of potassium hydroxide to chromite ≥3:1, the mass concentration of potassium hydroxide aqueous solution is 50-75%;

[0058] (2) Electrolysis: Add the raw material slurry obtained in step (1) into an atmospheric pressure electrolytic cell, pass oxidizing gas into the solution and apply mechanical stirring, control the gas flow rate to 0.7-1.4L / min, and the stirring rate to 700 -1000rpm, use stainless steel plate as anode, stainless steel rod as cathode, control anode current density ≥ 500A / m 2 , electrolysis for more than 4 hours, the reaction s...

Embodiment 1

[0063] A method for electrochemically decomposing chromite in potassium hydroxide solution to extract chromium, comprising the steps:

[0064] (1) Preheating of ingredients: Mix and heat chromite sieved to -200 mesh with potassium hydroxide aqueous solution to prepare mixed slurry, and preheat to 150°C, wherein the mass ratio of potassium hydroxide to chromite is 6: 1. The mass concentration of potassium hydroxide aqueous solution is 70%, that is, weigh 35g of chromite, 247.00g of KOH (containing 15% water), and 52.95g of pure water;

[0065] (2) Electrolysis: Add the raw material slurry obtained in step (1) into an atmospheric pressure electrolyzer, pass oxygen into the solution and apply mechanical stirring, control the gas flow rate to 1.0L / min, and the stirring rate to 850rpm, with an iron plate As the anode, the stainless steel rod is used as the cathode, and the anode current density is controlled to 1000A / m 2 , electrolysis 6h;

[0066] (3) Dilution: Dilute the reacti...

Embodiment 2

[0069]A method for electrochemically decomposing chromite in potassium hydroxide solution to extract chromium, comprising the steps:

[0070] (1) Preheating of ingredients: Mix and heat chromite sieved to -200 mesh with potassium hydroxide aqueous solution to prepare mixed slurry, and preheat to 180°C, wherein the mass ratio of potassium hydroxide to chromite is 6: 1. The mass concentration of potassium hydroxide aqueous solution is 70%, that is, weigh 35g of chromite, 247.06g of KOH (containing 15% water), and 52.95g of pure water;

[0071] (2) Electrolysis: Add the raw material slurry obtained in step (1) into an atmospheric pressure electrolytic cell, pass oxidizing gas into the solution and apply mechanical stirring, control the gas flow rate to 1.0L / min, and the stirring rate to 800rpm, to The iron plate is used as the anode, the stainless steel rod is used as the cathode, and the anode current density is controlled to 1200A / m 2 , electrolysis 8h;

[0072] (3) Dilution:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com