Separation system and method for preparing acetaldehyde product from ethanol

A separation system and separation method technology, applied in the field of separation of acetaldehyde products from ethanol, can solve the problems of difficult separation of acetaldehyde and hydrogen, increase of chilled water system, large consumption of cooling capacity, etc., and achieve high utilization efficiency of raw materials and separation accuracy. High and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

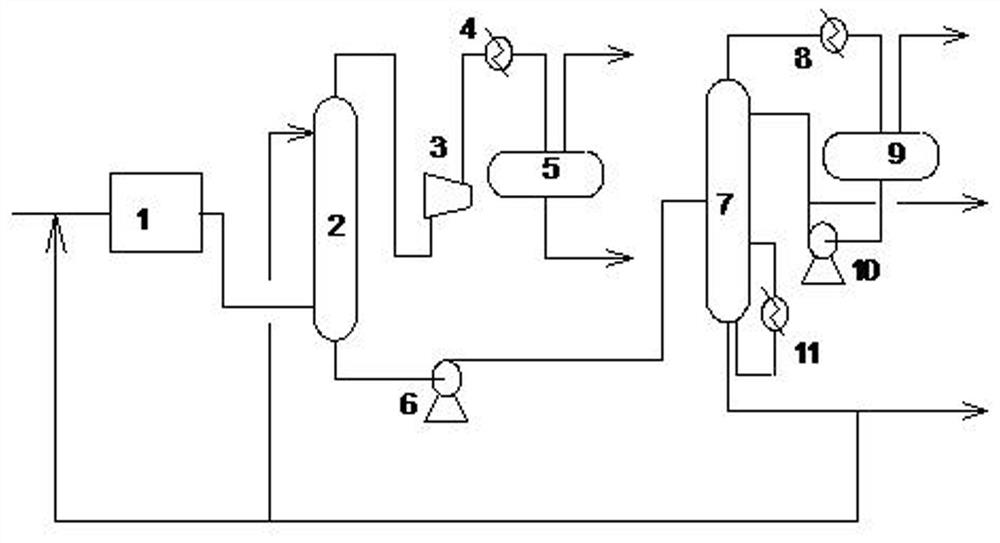

[0032] A separation system for producing acetaldehyde products from ethanol, comprising a reactor 1 and an ethanol absorption tower 2, the reactor 1 is connected with the bottom side wall of the ethanol absorption tower 2, and the top of the ethanol absorption tower 2 is connected in turn There are a compressor 3, a first cooler 4, and a first gas-liquid separation tank 5;

[0033] The bottom outlet of the ethanol absorption tower 2 is connected with an acetaldehyde rectification tower 7 through a booster pump 6, and the top of the acetaldehyde rectification tower 7 is connected with a second cooler 8 and a second gas-liquid separation tank in turn. 9. The reflux pump 10 is also connected with the top side wall of the acetaldehyde rectifying tower 7; the second gas-liquid separation tank 9 is provided with a gas outlet, and the reflux pump 10 is connected to the The pipeline that distillation tower 7 is connected is also provided with acetaldehyde outlet;

[0034] The bottom ...

Embodiment 2

[0037] On the basis of Example 1, the ethanol absorption tower 2 is provided with 10-20 trays. The acetaldehyde rectifying tower 7 is provided with 10-20 trays.

Embodiment 3

[0039] A method for separating acetaldehyde products from ethanol, using the above-mentioned separation system for acetaldehyde products from ethanol to separate, comprising the following steps:

[0040] (1) Ethanol enters the reactor 1 for dehydrogenation reaction, the temperature in the reactor 1 is 220-300°C, the pressure is 0.05-0.15MPa, and the catalyst used is a Cu-based catalyst;

[0041] The product of ethanol dehydrogenation, according to the mole percentage of 100%, the mole percentage of each substance is as follows:

[0042] Acetaldehyde 15-25%,

[0043] Ether 0.1-0.5%,

[0044] Butyraldehyde 0.1-1%,

[0045] Ethyl acetate 0.1-0.5%,

[0046] Butanol 0.001-0.1%,

[0047] Hydrogen 15-25%,

[0048] The rest are unreacted ethanol;

[0049]Among them, acetaldehyde is used as the main product, and hydrogen is used as a by-product;

[0050] (2) The gaseous product of the dehydrogenation reaction is cooled to 30-50 °C, and enters the bottom of the ethanol absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com