Preparation method and application of Li-IIMs ion imprinted membrane

A technology of ion imprinting and dimethoxysilane membrane, applied in the direction of ion exchange, ion exchange regeneration, chemical instruments and methods, etc., can solve the problems of easy loss of ion imprinting membrane ligands, low reuse rate, low adsorption capacity, etc. Achieve the effect of facilitating subsequent separation, solving difficult recycling, and high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

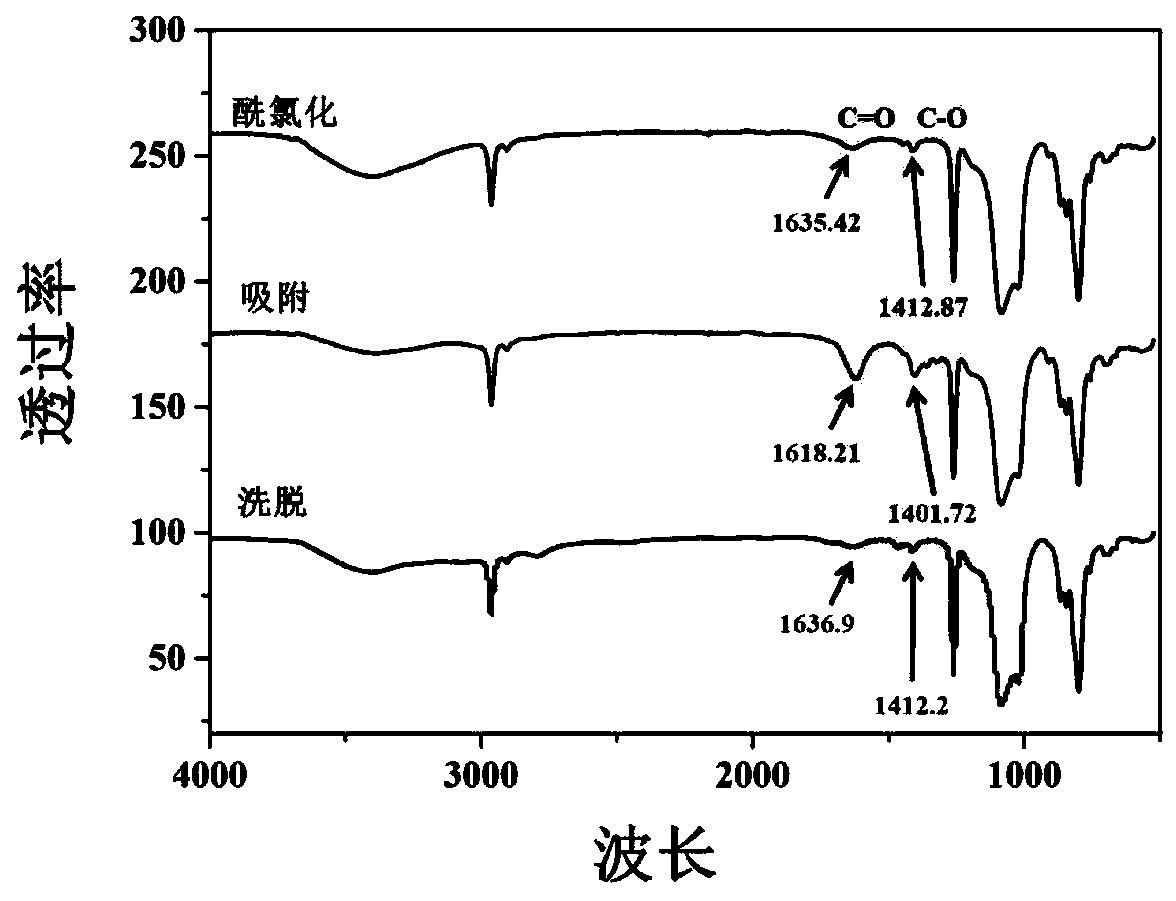

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of polydimethylsiloxane membrane:

[0041]Put 2 g of polydimethylsiloxane in a petri dish to coat evenly, add 0.2 g of curing agent B in 184 silicone rubber and stir to form a mixture, put edible sugar cubes on the surface of the mixture, and vacuum pump at room temperature Filtrate the mixture for 6 hours to filter the mixture into the cube sugar, and dry it in an oven at 65°C for 6 hours; immerse it in a water bath to solidify, change the water every 6 hours, and dry it at 40°C after three times to obtain a polydimethoxysilane film;

[0042] (2) Polydopamine modification of polydimethoxysilane membrane:

[0043] Dissolve 0.1211 g of Tris in 100 mL of deionized water, and quickly adjust the pH to 8.5 to obtain Tris solution; take another part of Tris solution and add 0.2 g of dopamine to Dopamine solution; The polydimethoxysilane membrane prepared in step (1) was pretreated by immersing in tris solution for 5 minutes, then soaked in dopamine solution, ...

Embodiment 2

[0054] (1) Preparation of polydimethylsiloxane membrane:

[0055] Put 2 g of polydimethylsiloxane in a petri dish to coat evenly, add 0.2 g of curing agent B in 184 silicone rubber and stir to form a mixture, put edible sugar cubes on the surface of the mixture, and vacuum pump at room temperature Filter for 8 hours, suction filter the mixture into the sugar cube, dry in an oven at 60°C for 10 hours, immerse in a water bath to solidify, change the water every 6 hours, dry at 45°C after 3 times of water to obtain a polydimethoxysilane film ;

[0056] (2) Polydopamine modification of polydimethoxysilane membrane:

[0057] The polydimethoxysilane membrane prepared in step (1) was pretreated by immersing in tris solution for 3 minutes, then immersed in dopamine solution, shaken at room temperature for 24 hours, washed with ethanol and water, and then dried at 40°C to obtain Polydimethoxysilane film modified by polydopamine;

[0058] (3) Carboxylation of polydimethoxysilane film...

Embodiment 3

[0065] (1) Preparation of polydimethylsiloxane membrane:

[0066] Put 2 g of polydimethylsiloxane in a petri dish to coat evenly, add 0.5 g of curing agent B in 184 silicone rubber and stir to form a mixture, put edible sugar cubes on the surface of the mixture, and vacuum it at room temperature Filter for 10 hours, suction filter the mixture into the sugar cube, dry in an oven at 55°C for 12 hours, immerse in a water bath to solidify, change the water every 6 hours, and dry at 35°C after 3 times to obtain a polydimethoxysilane film;

[0067] (2) Polydopamine modification of polydimethoxysilane membrane:

[0068] The polydimethoxysilane membrane prepared in step (1) was pretreated by immersing in tris solution for 6 minutes, then immersed in dopamine solution, shaken at room temperature for 36 hours, washed with ethanol and water, and then dried at 40°C to obtain Polydimethoxysilane film modified by polydopamine;

[0069] (3) Carboxylation of polydimethoxysilane film:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com