A kind of recycling method of fumei slag

A technology of fumei slag and slag, which is applied in the improvement of process efficiency, organic chemistry, etc., to achieve the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

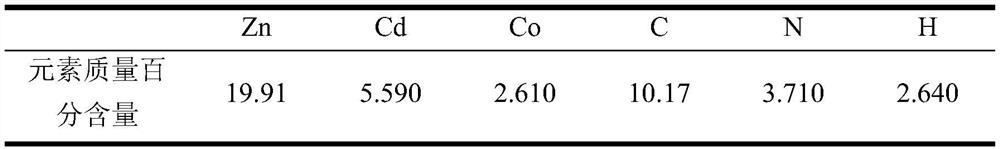

[0031] In the present embodiment, the chemical composition analysis (unit: %) of Fumei slag sees the following table:

[0032]

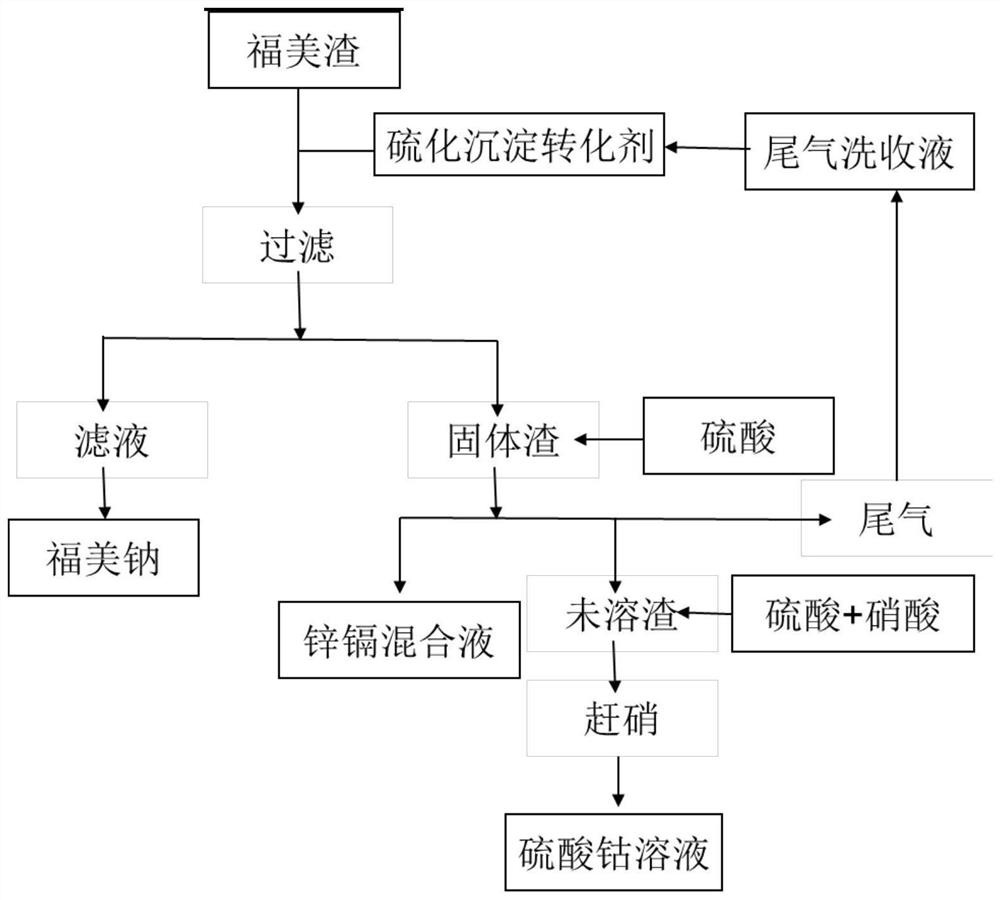

[0033] For the Fumei slag whose chemical composition and content are shown in the above table, the following procedures are carried out. figure 1 Processing shown:

[0034] (1) Take 31.70 g of fume slag (the fome root contained is 15 g in terms of sodium fomelic acid dihydrate), beat with 100 mL of water, add 30.00 g of sodium sulfide nonahydrate, react at 85° C. for 2 hours, and filter. The filtrate is distilled under reduced pressure to dryness to obtain 7.1 g of sodium formate dihydrate, and the yield of organic matter formate is 47.3%, which can be reused in the purification and decobalt removal process of electrolytically producing metallic zinc. The filtered solid slag is processed in the following step (2).

[0035] (2) The solid residue was first leached with 150 mL of 100 g / L sulfuric acid to obtain a solution containing zinc, and the y...

Embodiment 2

[0038] In this embodiment, the Fumei slag is the Fumei slag in Example 1, that is, its chemical composition content is the same as that in Example 1.

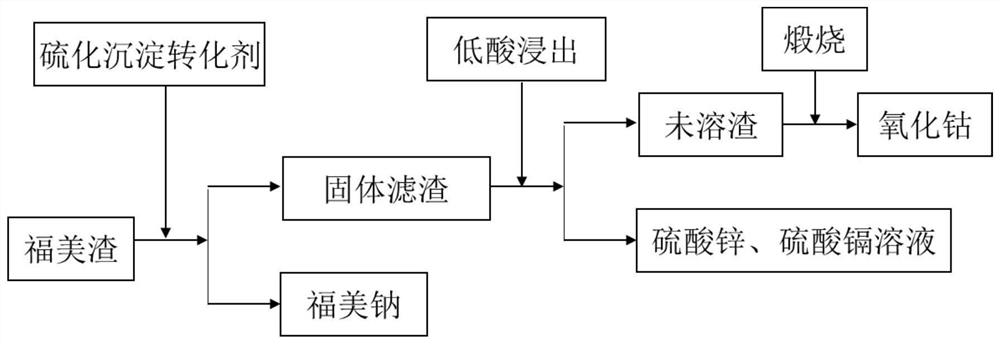

[0039] The Fumei slag is carried out as follows figure 2 Processing shown:

[0040] (1) Take 31.70 g of fume slag (the fome root contained is 15 g in terms of sodium fomelic dihydrate), beat with 300 mL of water, add 24.00 g of sodium sulfide nonahydrate, react at 70° C. for 2 hours, and filter. The filtrate is distilled to dryness under reduced pressure to obtain 6.9 g of sodium formate dihydrate, and the yield of organic compound formate is 46%, which can be reused in the purification and removal of cobalt in the electrolytic production of metallic zinc. The filtered solid slag is processed in the following step (2).

[0041] (2) The solid slag was first beaten with 30mL water, and then 13.00g MnO 2 and 25mL of 6.00mol / L sulfuric acid at 70°C for 6 hours under normal pressure oxidative leaching to obtain a solution contai...

Embodiment 3

[0044] In this embodiment, the Fumei slag is the Fumei slag in Example 1, that is, its chemical composition content is the same as that in Example 1.

[0045] The treatment method of this Fumei slag is basically the same as Example 2, and the difference is:

[0046] In the step (1), the reaction temperature was 10° C. and the reaction time was 5 hours, to obtain 6.1 g of sodium formate dihydrate, and the yield of the organic compound formate was 40.67%.

[0047] In step (2), the solid slag used 35.00g Na 2 S 2 O 8 and 40.00 mL of 6.00 mol / L concentrated sulfuric acid at 70 °C for 6 h under normal pressure oxidative leaching to obtain a solution containing zinc and cadmium. The yields of zinc and cadmium are 89.1% and 88.7%, respectively.

[0048] In the step (3), the undissolved residue was subjected to suction filtration at 130° C. to obtain 1.6 g of sulfur. The residual slag was calcined in a muffle furnace at 600°C for 2 hours to obtain 0.91 g of cobalt tetroxide as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com