Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Strong deoxygenation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blackening method for lithium tantalite crystal substrate

ActiveCN105463581AEasy to control resistivityUniform colorPolycrystalline material growthAfter-treatment detailsNon oxidativeReducing atmosphere

The invention discloses a blackening method for a lithium tantalite crystal substrate. According to the method, a fluoride material and the to-be-treated lithium tantalite crystal substrate are contacted sufficiently, and the lithium tantalite crystal substrate is subjected to reductive heat treatment at the temperature of 450-600 DEG C in non-oxidative reducing atmosphere for 5-24 h. The volume resistivity of the lithium tantalite crystal substrate after blackening is 10<9>-10<12> omega cm. The method has the advantages that the method is simple, reliable and easy to operate, and the obtained lithium tantalite crystal substrate has good resistivity repeatability and low cost and is applicable to batch production.

Owner:上海召业申凯电子材料有限公司

Efficient composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systems or desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to 6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfur substance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4. the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

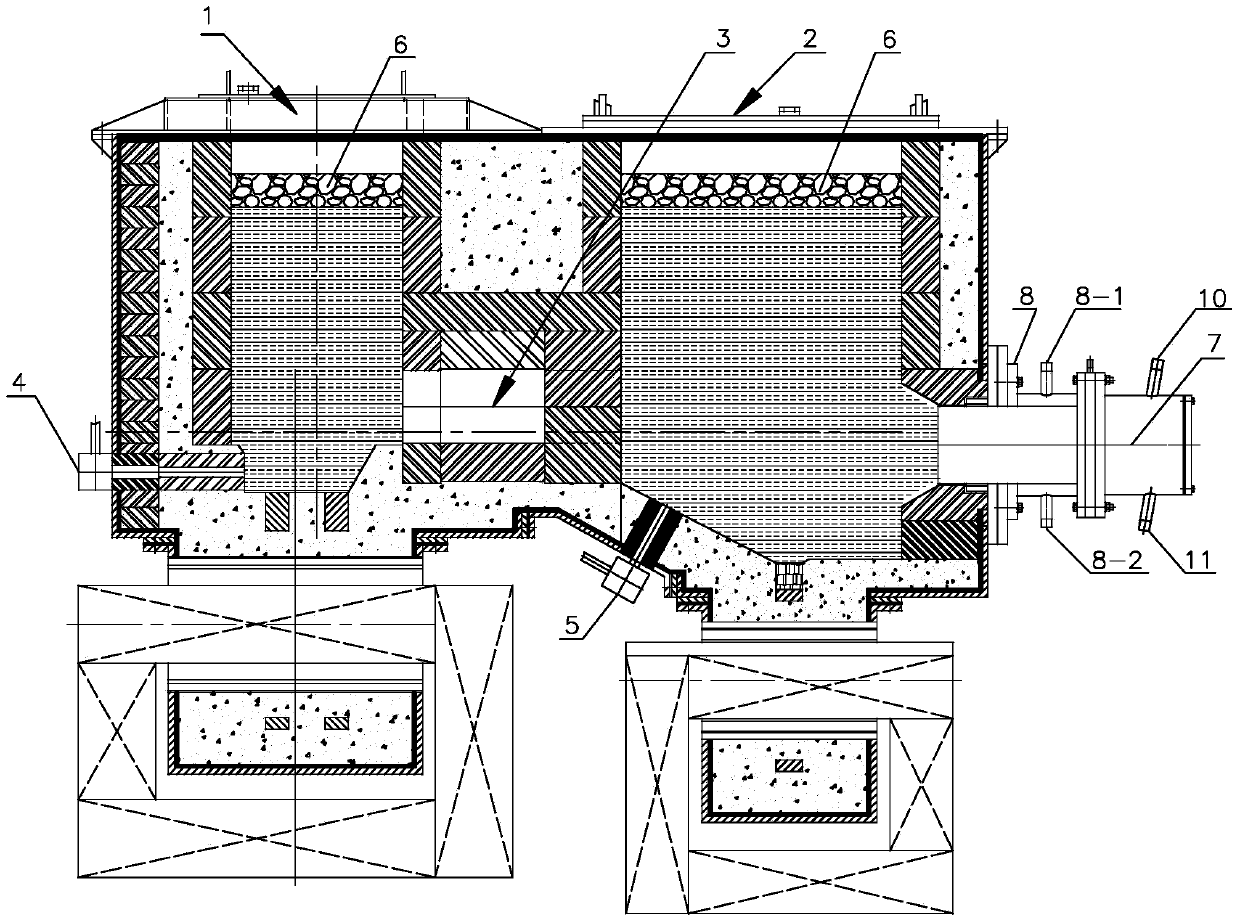

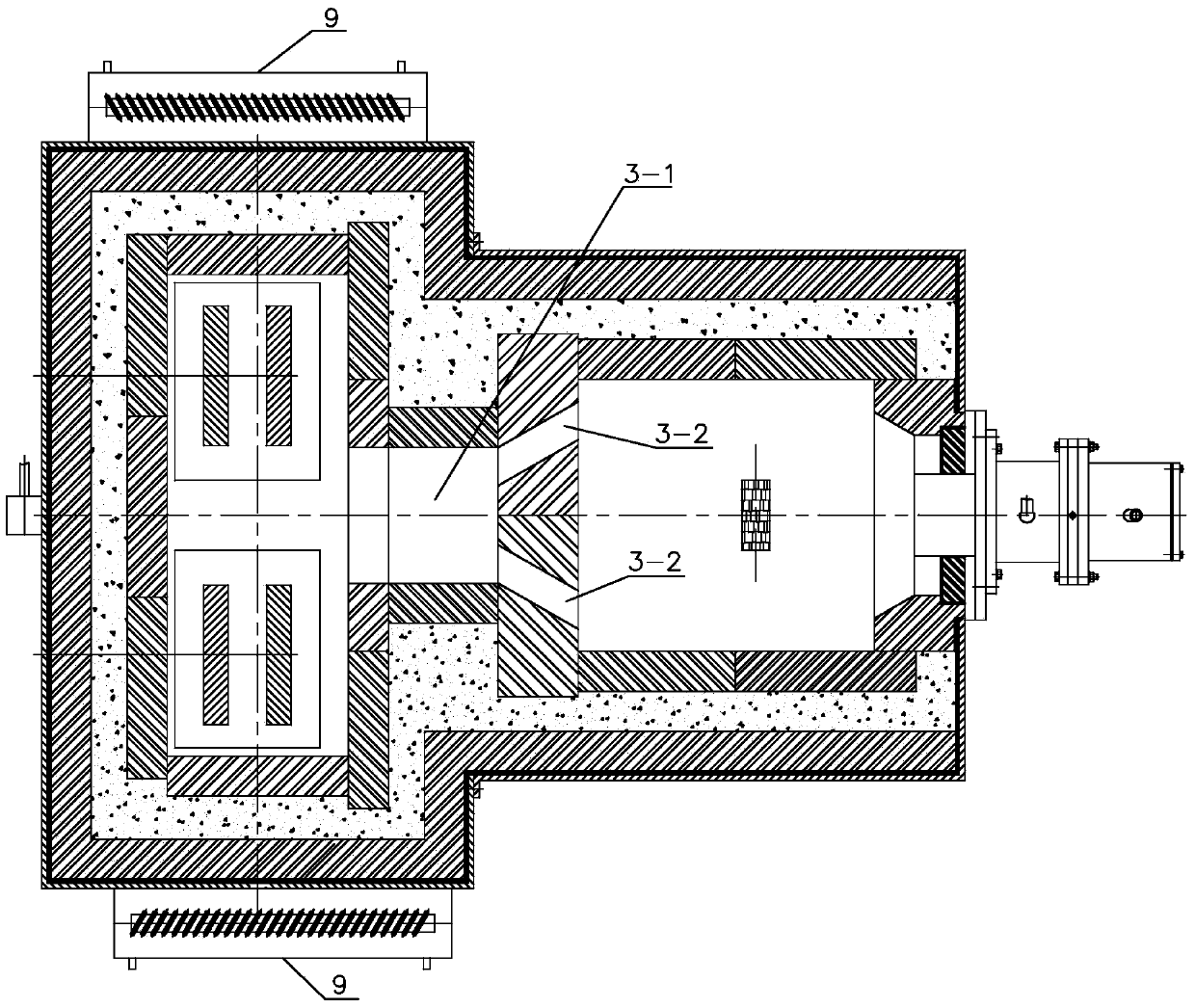

Large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process and connected furnace

The invention relates to a large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process. An oxide layer and particles are removed from the standby cathode copper surface, in addition, preheating treatment is carried out, and the preheating temperature is controlled to be 280 DEG C to 300 DEG C; pretreated cathode copper is placed into a smelting furnace to be smelted, the smelting temperature is controlled to be 1180 to 1230 DEG C, inert gas is introduced into the bottom of the smelting furnace, a calcined charcoal layer floats above molten copper to be used as the coverage, and the molten copper is stirred through electromagnetic stirring; then, the smelted molten copper flows into a heat insulation furnace, inert gas is introduced into the bottom of the heat insulation furnace, the calcined charcoal layer floats above molten copper to be used as the coverage, and the temperature inside the heat insulation furnace is controlled to be 1180 to 1230 DEG C; the molten copper in the heat insulation furnace is guided out, a graphite crystallizer is subjected to water cooling, and high-purity oxygen-free copper cast blanks are obtained. The process has the advantages that the oxygen content of the cast blanks can be effectively controlled, the production cost is reduced, products can completely reach TU1 standards, and the yield can reach more than 90 percent.

Owner:JIANGSU XINGRONG MEILE COPPER IND

Sintered flux for submerged-arc welding for nickel-based alloy

ActiveCN103394822AMeet the growing needsWeld firmlyWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention discloses sintered flux for submerged-arc welding for nickel-based alloy, and belongs to the technical field of welding materials. The sintered flux comprises, by weight, 25-35% of CaF<2>, 10-20% of MgO, 30-40% of Al<2>O<3>, 5-10% of CaCO<3>, 3-8% of Ti and 3-8% of Mn. The sintered flux has the advantages of stable electric arcs, easiness in removing slag, attractive formed welding seams, smooth transition and capability of overcoming shortcomings such as welding cracks and the like in a welding procedure.

Owner:HOHAI UNIV CHANGZHOU

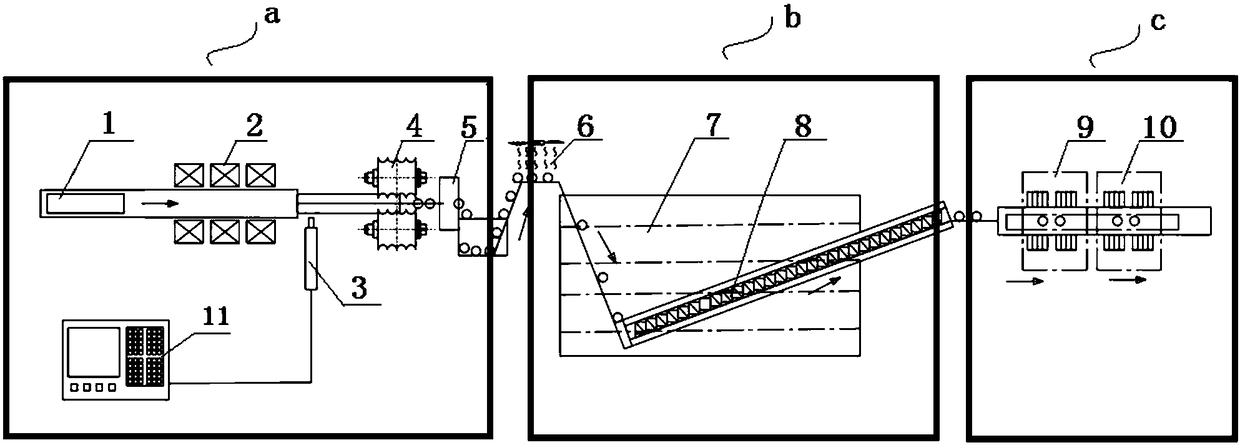

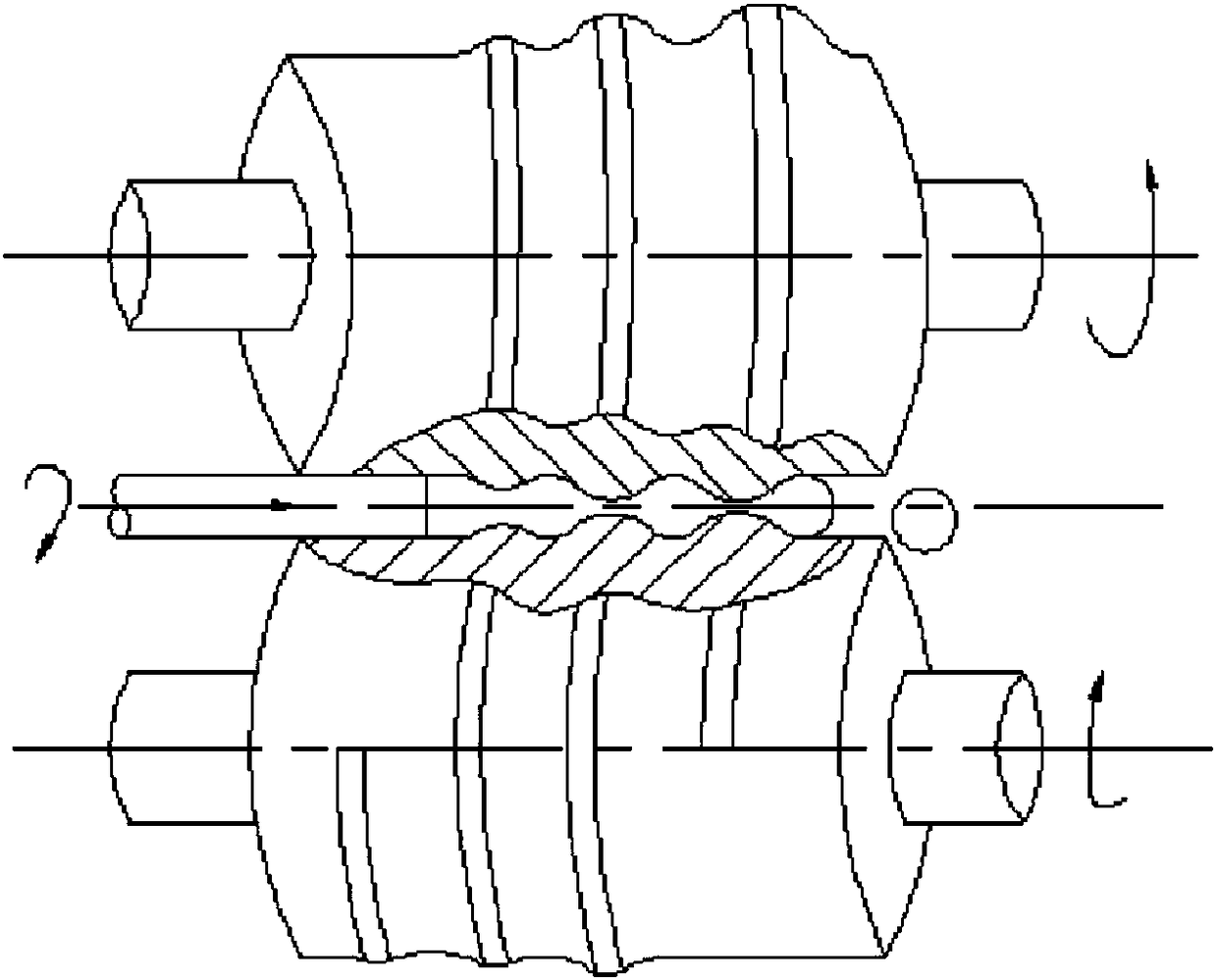

Microalloying wear resisting ball and preparation method and preparation system thereof

ActiveCN108588551APurifyStrong deoxygenation abilityBearing componentsFurnace typesToughnessQuenching

The invention provides a microalloying wear resisting ball and a preparation method and a preparation system thereof. The microalloying wear resisting ball comprises the following components in percentage by weight: 0.75-0.85% of C, 0.15-0.35% of Si, 0.65-0.75% of Mn, 0.4-0.5% of Cr, 0.05-0.1% of B, 0.01-0.05% of N, 0.01-0.015% of Mg, 0.05-0.15% of Ca, S not more than 0.010%, P not more than 0.015%, and the balance of Fe. The invention further discloses the preparation method of the microalloying wear resisting ball; and the preparation method comprises the steps of induction smelting-continuous casting and rolling of rods-medium-frequency induction heating-inclined rolling and rotary cutting of balls-heat treatment process (quenching+tempering). The microalloying wear resisting ball has the advantages of high strength, high toughness, simple production process and low cost.

Owner:ZHONGBEI UNIV

Aluminium killed steel deoxidizer - alfer

InactiveCN1605646AStrong chalking resistanceStrong deoxygenation abilityChemical compositionShock resistance

The present invention present invention belongs to the field of steel-smelting technology. The Al-Fe alloy as deoxidizer is suitable for use in producing low-silicon degasified steel, converter No. 45 steel and pipe steel. The Al-Fe alloy as deoxidizer has the chemical components of Al 40-60 wt%, Fe 37-57 wt%, Mn 0.1-10 wt%, Si 0.1-8 wt%, Ti 0.1-10 wt%, C 0.1-1.0 wt%, P 0.001-0.1 wt% and S 0.001-0.1 wt%. It has high chalking resistance, high deoxidizing capacity, low cost, less ablation, high yield and high aluminum utilization, and can reduce bubble generated at most, fine steel structure crystal grain, raise the shock resistance of steel and lower cold brittleness and age tendency.

Owner:北京科大中冶技术发展有限公司

Austenite ductile iron with low nickle content and high manganses and chromium content and technology thereof

The invention relates to a cheap and excellent low-nickel, high-manganese and high-chromium austenitic ductile cast iron and a preparation process thereof. The ductile iron comprises the following components by weight percentages: 0.7-1.5% of C, 1-2.3% of Si, 9-15% of Mn, 2-5% of Ni, 14-17% of Cr, 1-3% of Cu and Fe. The preparation process is as follows: furnace charges adopted comprise common iron, scrap steel (steel scraps), return scraps, low-carbon ferromanganese, electrolytic nickel, ferrochromium, electrolytic copper and 75 ferrosilicon; the charges are melted by an electrical furnace or an intermediate frequency furnace, the tapping temperature is over 1650 DEG C, the ferrosilicon and calcium silicon are added to a casting ladle for modification, wherein, the quantity of the calcium silicon added is 0.5-0.8%. The non-magnetic austenitic ductile iron is applicable to the production of impellers of submersible pumps in the petroleum industry, casing, chemical fittings, water pump bodies, wearable valve gears, seawater corrosion resistant parts, etc.

Owner:金仕善

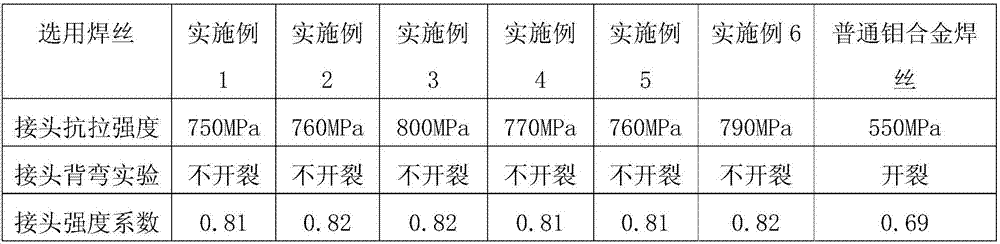

Method for welding molybdenum alloy

ActiveCN106862732AInhibition of sensitization tendencySmall mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentDirect current

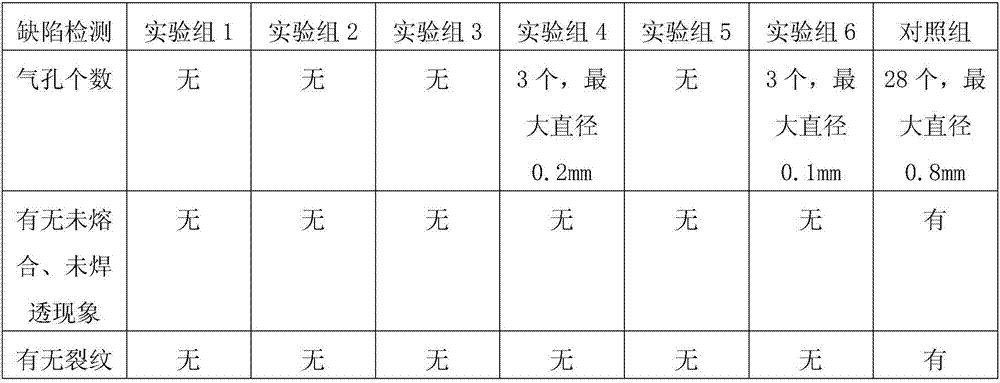

The invention discloses a method for welding molybdenum alloy, belonging to the technical field of metal welding. The method comprises the steps: (1) after cleaning, drying the welding area of molybdenum alloy; (2) manufacturing a special welding wire for the molybdenum alloy; (3) degassing at high temperature; (4) taking out a molybdenum alloy workpiece, spraying an active agent until the thickness is 0.2-0.8mm on the he welding area of molybdenum alloy, heating the special welding wire for the molybdenum alloy to dry, and then welding the molybdenum alloy workpiece, wherein the welding method adopts TIG wire filling welding, adopts a direct-current straight polarity power supply and determines welding process parameters; (5) cooling; (6) inspection. The method can reduce the quantity of joint holes, improve weldability, reduce cracks, refine parent crystalline grains so as to improve the tensile property of welded joints, and obtain good welding quality.

Owner:宝鸡市蕴杰金属制品有限公司

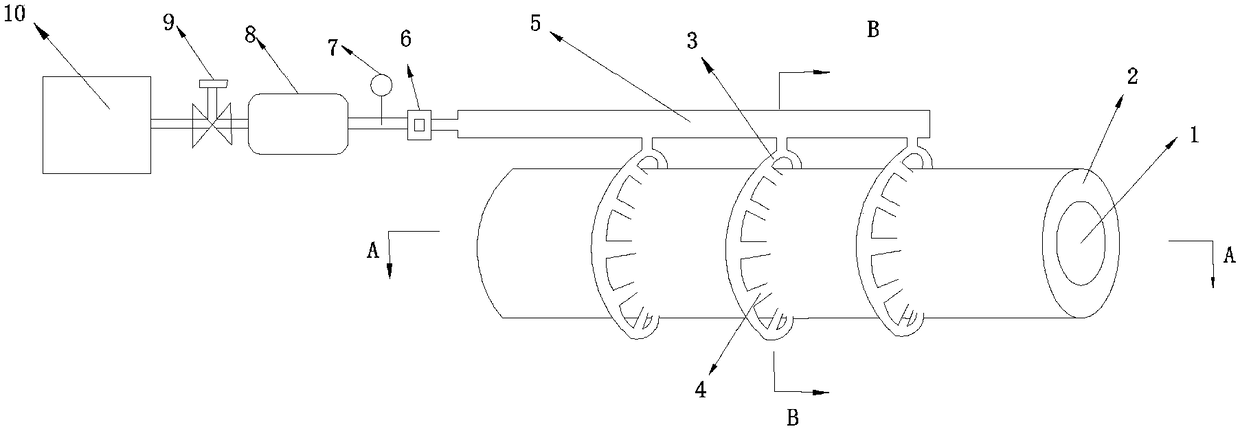

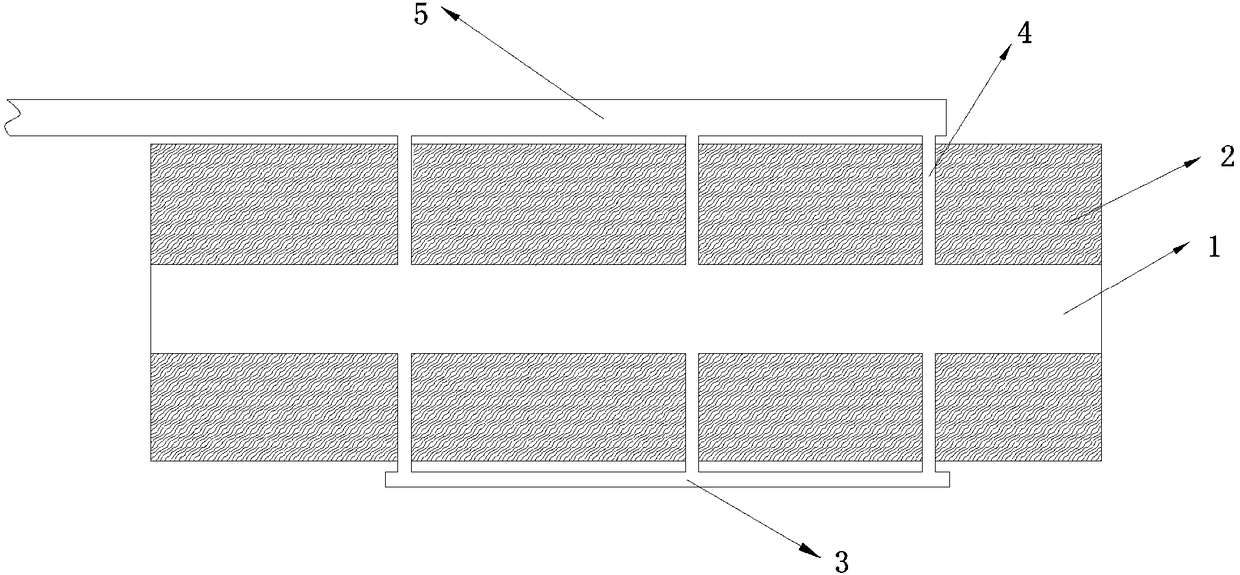

Pre-deoxygenation method and device for spraying blowing of carbon powder in tapping hole of converter

The invention belongs to the technical field of steel and iron metallurgy, in particular to a pre-deoxygenation method and device for spraying blowing of carbon powder in a tapping hole of a converter. A plurality of carbon powder spraying pipes are installed in a tubular refractory material of the tapping hole of the converter, in the tapping process of the converter, the carbon powder is blow into tapping steel stream in a spraying manner, the carbon powder and dissolved oxygen [O] in molten steel have a reaction, and CO is generated. By means of the carbon powder spraying pipes in the tapping hole, the carbon powder is blown into the tapping steel stream in the spraying manner for deoxygenation, a deoxygenation product is CO, the gas state CO can escape from the tapping steel stream andis discharged into the atmosphere, no inclusion is left in the molten steel, and no harm is caused to the steel material quality. The carbon powder has large deoxygenation space and has very high deoxygenation capacity, and more than 40% of dissolved oxygen in the molten steel can be removed. Compared with deoxygenation performed through aluminum, about 90% of the deoxygenation cost can be savedby adopting the carbon powder; and compared with deoxygenation performed through silicon, about 80% of the deoxygenation cost can be saved by adopting the carbon powder.

Owner:SHANDONG IRON & STEEL CO LTD

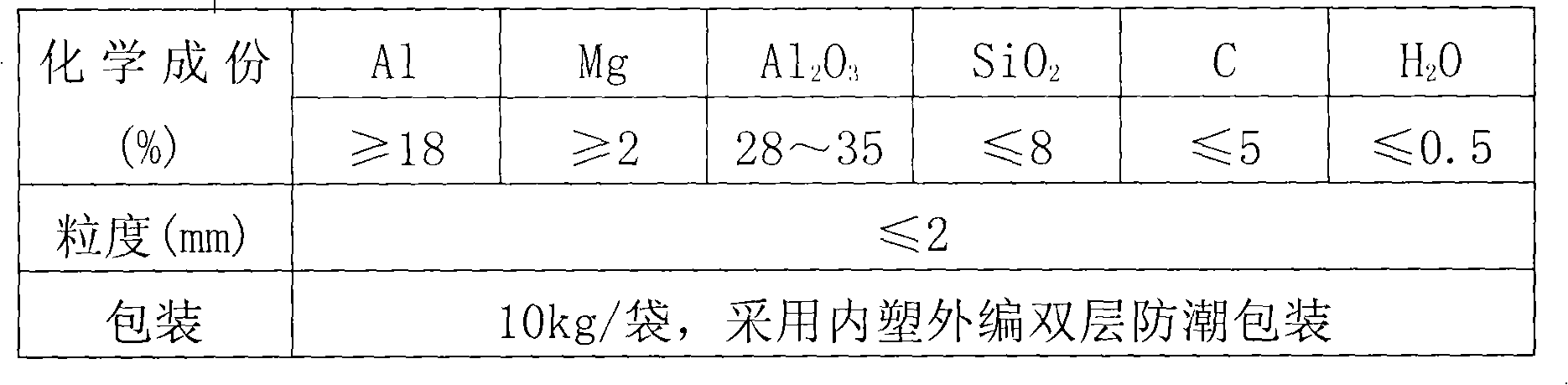

Aluminum -magnesium-ferrum multicomponent alloy steel melting deoxidizing agent

InactiveCN101435008AQuality improvementPromoting denaturation of crystalline tissueAlkaline earth metalCerium

An Al-Mg-Fe series complex alloy deoxidizing agent for steel making is characterized in that the deoxidizing agent also comprises lanthanon cerium and has the following chemical compositions by weight percentage: 30-35 percent of aluminum, 10-15 percent of magnesium, 1-5 percent of silicon, 5-10 percent of calcium, 5-10 percent of strontium, 0.1-2percent of cerium, and the balance of Fe. The deoxidizing agent conducts deep deoxidation by using the activity of alkaline earth metallic elements, not only has better deoxidizing capacity, but also has stronger penetrating power on molten steel due to low melting point and large proportion, effectively removes gas and changes sonims, has refining function on molten steel, nodularization function on devulcanized inclusion and grain refinement function, contributes to further improvement of steel quality. Simultaneously, lanthanon is added to promote crystalline structure degeneration of steel, thus increasing plastic nature and toughness of the steel.

Steel-making aluminum-calcium-iron deoxidizer and preparation method

The invention belongs to the technical field of metallurgy, and particularly relates to a steel-making aluminum-calcium-iron deoxidizer. The deoxidizer is a ball-shaped composition comprising powder, such as aluminum metal powder, calcium metal powder, iron metal powder and the like. Due to the components, the shapes and sizes of the components, and the shape of the composition formed after balling, the deoxidizer has the characteristics that: the aluminum metal powder, the calcium metal powder and the iron metal powder are pressed into balls, so a preparation method is simple and convenient; the finished products have strong strength, and are directly fed into a head bunker of a steel mill for use; the deoxidizer has high rate of finished products, high reducing capacity, high molten steel deoxidizing capacity, and molten steel total oxygen content lower than that obtained by like deoxidizers; deoxidizing products grow up in a mutual coalescence way, and fast float upwards; the impurity content of the steel is reduced, and simultaneously impurities can be denatured; and the molten steel has high flowability in casting.

Owner:上海盛宝冶金科技有限公司

Refining process for producing spring steel through electric furnace

InactiveCN110592313ASmooth changeAvoid enteringProcess efficiency improvementElectric furnaceElectric arc furnaceSlag

The invention discloses a refining process for producing spring steel through an electric furnace, and belongs to the technical field of steel smelting. The refining process comprises the steps of firstly, electric furnace smelting, wherein (a) steel scraps and molten iron are adopted as raw materials, (b) eccentric bottom tapping is adopted for preventing slag discharging, the refining rephosphorization quantity is smaller than or equal to 0.005%, the tapping temperature is 1620 DEG C or above, and (c) argon bottom blowing and stirring are carried out in the whole electric furnace tapping process; secondly, LF furnace smelting, wherein (a) lime, calcium carbide and silicon calcium barium are used for deoxidization and slagging in the early stage, and silicon carbide and calcium carbide are used for slag maintaining in the later stage, (b) components of refining slag are required to comprise 48%-55% of CaO, 23%-28% of SiO, smaller than 15% of Al2O3, 5%-8% of MgO and not larger than 0.8% of TFe+MnO; and thirdly, RH smelting. By means of the refining process, the components of the refining slag can be precisely controlled, and quartz sand does not need to be added for slag adjusting;meanwhile, stable control over the molten steel temperature and the components of the refining slag can be guaranteed through the manners of slag quantity control, stirring control, process slag maintaining and the like, and secondary oxidation of molten steel is reduced; and the deoxidization capacity of the refining slag is high, and the aims of deep deoxidization and deep desulfuration are achieved effectively.

Owner:MAANSHAN IRON & STEEL CO LTD

Slag modifier for converter refining

InactiveCN102002550AReduce oxidationStrong deoxygenation abilityManufacturing convertersProcess efficiency improvementSlagWhite line

The invention relates to a slag modifier for converter refining, which comprises the following components by mass percentage: 0-6.0 of CaO, 48-58 of Al2O3, 0-12 of SiO2, 20-25 of Al, and the balance of inevitable impurities. By adding the slag modifier in the processes of tapping, refining and slagging of a converter, the deoxidation cost in the steel making process can be reduced, the desulfurization degree of steel water in the tapping process of the converter can be increased, the slagging time of white line slag refined by a ladle furnace can be shortened, the refining effect can be improved, the oxidizability of refined early slag can be reduced, and the purity of the steel water can be enhanced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Manganese-base vanadium-containing MnAlV alloy smelted by high-phosphorus manganese ores and smelting method thereof

The invention relates to a manganese-base vanadium-containing MnAlV alloy smelted by high-phosphorus manganese ores and a smelting method thereof. The MnAlV alloy comprises the following chemical components by mass percentage: 30%-50% of Mn, 20%-40% of Al, 10%-20% of Si, 1%-10% of V, not more than 0.08% of P and the balance of Fe and other impurity elements. The needed main raw materials for smelting the alloy comprise the high-phosphorus manganese ores, manganese-enriched residues, coke, blue coke, silica, ferrovanadium, pure aluminum as well as a corresponding dephosphorizing agent and a slag forming constituent. The smelting method comprises the following steps: according to the design requirements for alloy components, firstly weighing the needed raw materials based on per unit weightof alloy; smelting the raw materials into a silicon-manganese alloy mother liquid; dephosphorizing, alloying and casting; and finally cooling to obtain the MnAlV alloy. The manganese-base vanadium-containing MnAlV alloy smelted by the method has high aluminum content, high vanadium content and low phosphorus content; the alloy can be stored under various weather conditions and has a stale structure without chalking; and a crystal structure and a carbide shape of the alloy are improved so as to enhance steel performances such as yield strength, tensile strength, heat resistance and cold workability.

Owner:重庆中盛裕康冶金有限公司

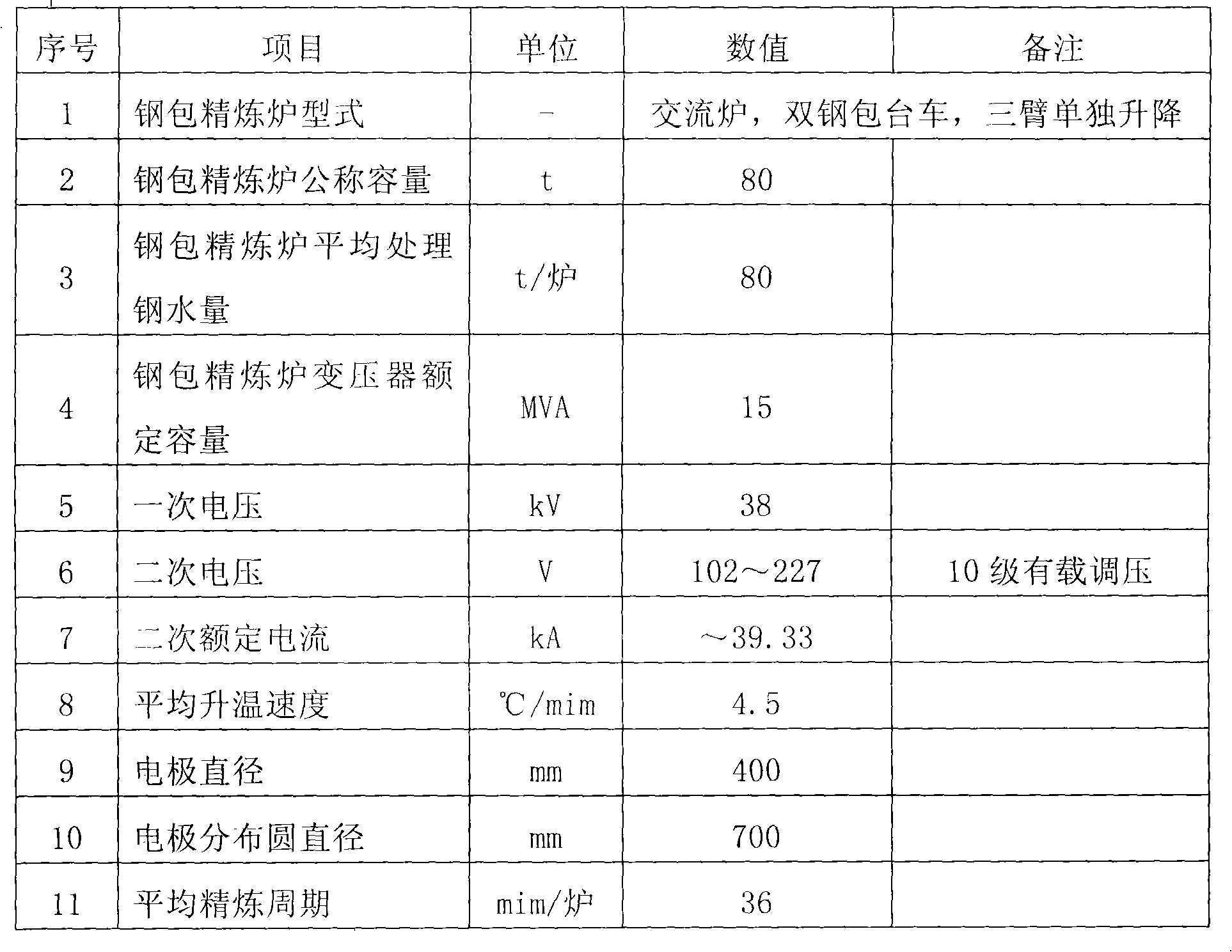

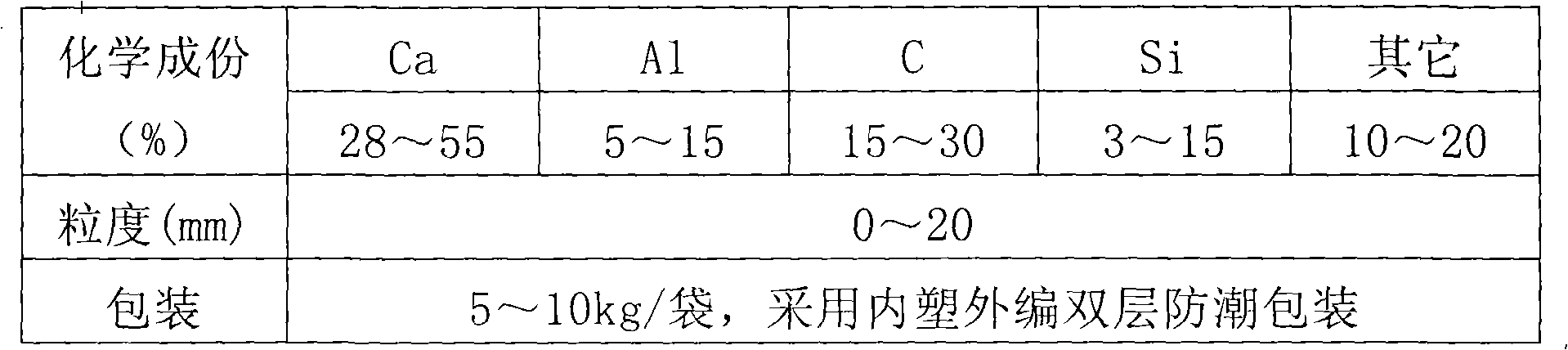

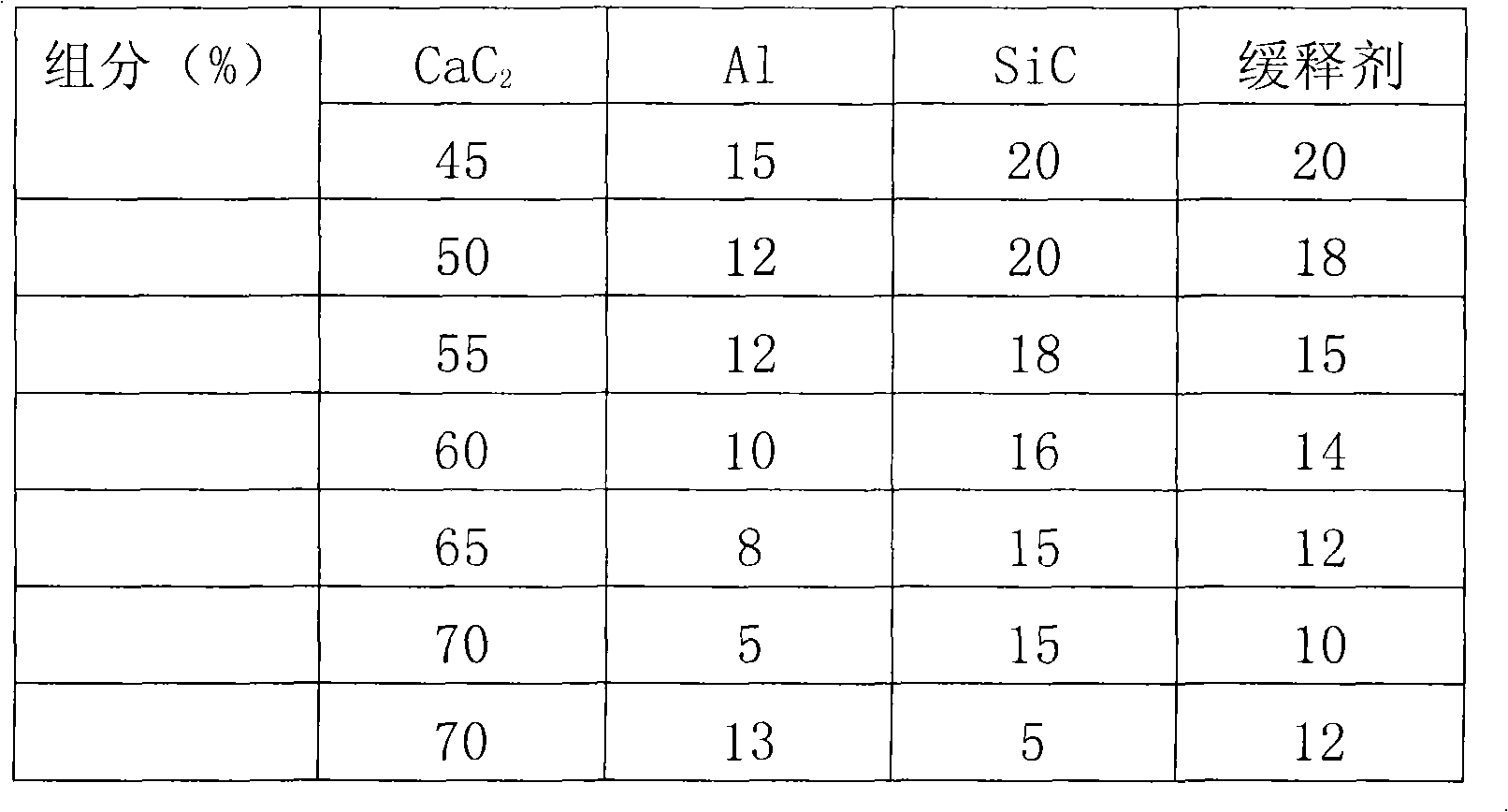

Steelmaking method of ladle refining furnace

The invention discloses a steelmaking method of a ladle refining furnace. The method comprises the following steps of: (1) conveying primarily-refined molten steel of a converter into a ladle refining furnace, after a period of time for powering to heat and adding synthetic slag at a refining station, adding 0.25 to 0.5kg of multiple effect refining agents per ton of molten steel once only, wherein the multiple effect refining agent is prepared from the constituents having the following percentages by weight: 45-70% of CaC2, 5-20% of SiC, 5-15% of Al and 10-20% of sustained release agents; (2) performing slag modification according to the change of the slag and adding 0.05-0.20kg of slag per ton of molten steel each time; and (3) adding 4-15kg powdered slag of bauxite or CaSi per furnace 5-10 minutes before finishing refining in the ladle refining furnace. In the method, the elements of Ca, Al, Si and C in the constituents all have strong deoxidizing capacity, which meets the requirements of fast and deep deoxidization for slag and diffusive deoxidization to molten steel; the product of deoxidizing elements can form a white slag mineral phase with the synthetic slag, which is beneficial to desulfurization and inclusion removal of molten steel; and the content of N and H is reduced in the process of refining molten steel, thereby the consumption and the cost are reduced.

Owner:重庆科健冶金材料有限公司

Steel-covered aluminum-calcium alloy for steelmaking and preparation method thereof

The invention relates to steel-covered aluminum-calcium alloy for steelmaking and a preparation method thereof. Aluminum and calcium are used to produce an aluminum-calcium alloy. The aluminum-calcium alloy contains 10 to 90 mass percent of aluminum and the balance of calcium and inevitable impurities. In addition, the aluminum-calcium alloy also contains 1 to 10 percent of one or two of magnesium and rare earth. The aluminum-calcium alloy is covered by a steel plate to form the steel-covered aluminum-calcium alloy. The steel-covered aluminum-calcium alloy has the advantages of high steelmaking deoxidizing capacity, small calcium melting loss, low production cost and better economic and social benefits.

Owner:谢应凯 +1

Silicon-calcium-magnesium-ferrous alloy used as steel-making deoxidizer

The invention provides a Si-Ca-Mg-Fe alloy for deoxidizing molten steel, which comprises Si 40-60%, Ca 10-15%, Mg 1-10% and Fe is more than or equal to 40%, the remainders are unavoidable foreign matters. As the alloy contains more Fe, the specific weight is high, so the utilization rate of deoxidizing element is improved; and as the alloy contains Mg, the desulfurizing and deoxidizing capability is improved. The alloy can finally deoxidize molten steel so that the T[O] of molten steel can be steadily less than 20 ppm.

Owner:NINGBO HELANSHAN METALLURGY

High-strength and high-conductivity refining agent for smelting chromium-zirconium-copper alloy and application method for refining agent

The invention discloses a high-strength and high-conductivity refining agent for smelting a chromium-zirconium-copper alloy. The refining agent comprises a covering component and a purifying component, wherein the purifying component comprises calcium hexaboride, fluorotitanate, fluoborate, chlorine metal salt and rare earth. The invention further discloses an application method for the high-strength and high-conductivity refining agent for smelting the chromium-zirconium-copper alloy. According to the refining agent and the application method thereof, the cooperation function of the covering component and the purifying component is adopted so that the good impurity removal and purification effect on chromium-zirconium-copper alloy melt can be achieved, in addition, the oxidation burning loss in the smelting process can be effectively avoided, and therefore the strength and the conductivity of the material can be improved, and no pollution can be caused to the copper alloy melt.

Anti-corrosion and low-abrasion wear-resistant ball and preparation method thereof

InactiveCN107747031AStrong mechanical propertiesAccelerated corrosionFurnace typesGrain treatmentsWear resistantManganese

The invention provides an anti-corrosion and low-abrasion wear-resistant ball and a preparation method thereof. The anti-corrosion and low-abrasion wear-resistant ball comprises the following alloyingelements of 2.1-2.8% of carbon, 0.5-0.8% of silicon, 1.8-2.2% of manganese, 16-22% of chromium, 1.8-2.1% of nickel, 0.5-2% of molybdenum, 0.1-0.35% of vanadium, 1.3-2.6% of tantalum and the balance iron and unavoidable impurities. According to the anti-corrosion and low-abrasion wear-resistant ball and the preparation method thereof, through reasonable element matching and process optimization, the comprehensive mechanical properties of the prepared wear-resistant ball are high, excellent corrosion resistance and abrasion assistance are achieved, and the service life is prolonged by more than6 times compared with a traditional high-chromium wear-resistant ball.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

Low silicon aluminum-iron alloy

A low silicon Fe-Al series alloy is characterized in that the alloy has the following chemical compositions by weight percentage: 30-40 percent of aluminum, 5-10 percent of magnesium, 5-10 percent of calcium, 1-3 percent of strontium, 0.05-0.85 percent of silicon, 0.1-2 percent of cerium, and the balance of Fe. The alloy conducts deep deoxidation by using the activity of alkaline earth metallic elements, not only has better deoxidizing capacity, but also has stronger penetrating power on molten steel due to low melting point and large proportion, effectively removes gas and changes sonims, has refining function on molten steel, nodularization function on devulcanized inclusion and grain refinement function, and contributes to further improvement of steel quality. Simultaneously, lanthanon is added to promote crystalline structure degeneration of steel, thus increasing plastic nature and toughness of the steel.

Owner:杨军

Seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding

ActiveCN112404795AFast solidificationEasily ionizedWelding/cutting media/materialsSoldering mediaSilica fumeNitriding

The invention relates to a seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding. According to the technical scheme, the seamless self-protection flux-coredwire is composed of 70 wt%-80 wt% of a stainless steel strip and 20 wt%-30 wt% of flux-cored powder, and the stainless steel strip is filled with the flux-cored powder. The stainless steel strip comprises the following chemical components of, in percentage by weight, 0.03-0.08 wt% of C, less than or equal to 1wt% of Si, less than or equal to 2 wt% of Mn, 18-20 wt% of Cr, 8-11 wt% of Ni, less thanor equal to 0.03 wt% of S, less than or equal to 0.03 wt% of P and the balance Fe and inevitable impurities. The flux-cored powder comprises the following chemical components of, in percentage by weight, 40-43 wt% of barium fluoride, 5-8 wt% of marble, 8-10 wt% of aluminum powder, 2-4 wt% of silicon powder, 7-10 wt% of manganese powder, 2-5 wt% of manganese nitride, 10-13 wt% of nickel powder, 5-7 wt% of chromium powder and the balance iron powder. According to the seamless self-protection flux-cored wire, weld metal formed by welding the low-nitrogen non-magnetic naval vessel steel is high in strength, good in ductility and toughness, non-magnetic and excellent in seawater corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

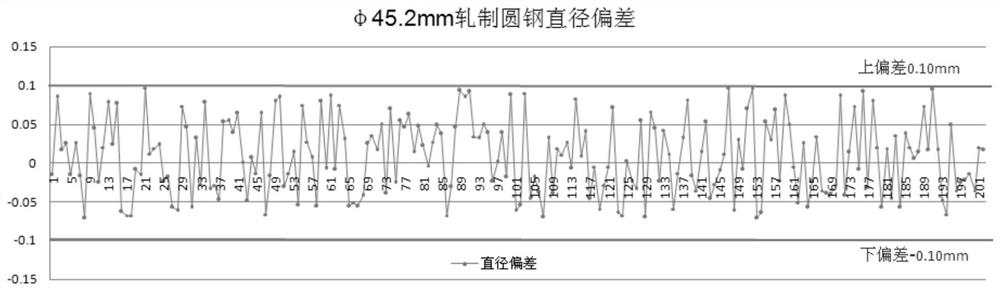

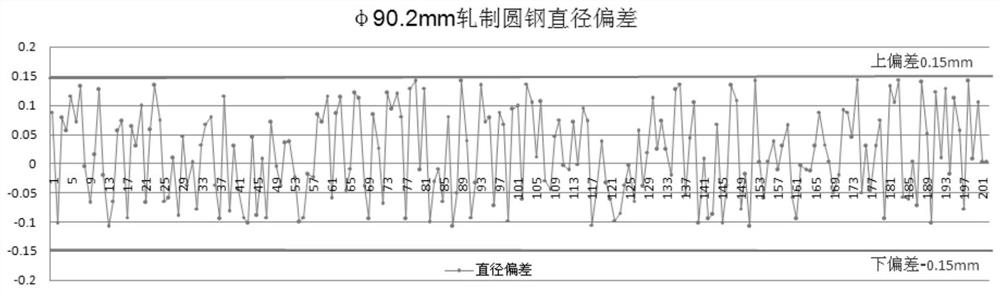

Low-silicon medium-carbon gear steel suitable for cold forging machining and manufacturing method thereof

ActiveCN112981233AInhibits the tendency to work hardeningStrong deoxygenation abilityFurnace typesHeat treatment furnacesGear wheelPearlite

The invention relates to low-silicon medium-carbon gear steel suitable for cold forging machining and a manufacturing method thereof. The steel comprises, by mass percent, 0.35-0.45% of C, smaller than or equal to 0.08% of Si, 0.30%-0.60% of Mn, 0.20-0.50% of Cr, smaller than or equal to 0.020% of P, 0.010-0.040% of S, smaller than or equal to 0.10% of Cu, smaller than or equal to 0.05% of Ni, smaller than or equal to 0.05% of Mo, smaller than or equal to 0.050% of Al, larger than or equal to 0.005% of N, 0.0005-0.0035% of B, smaller than or equal to 0.010% of Ti, smaller than or equal to 0.0020% of [O], smaller than or equal to 0.15% of (Cu+Ni+Mo) and the balance Fe and inevitable impurity elements Round steel with the specification being phi 45 mm to phi 90 mm is formed, and the size precision is smaller than or equal to + / -0.15 mm. According to GB / T 4162-2008, ultrasonic flaw detection on the interior of the round steel meets the A-level requirement. The outer layer of the section of the round steel is a partial decarburized layer, the depth of the partial decarburized layer is smaller than or equal to 0.5% d of the nominal diameter of the round steel, the core part is a matrix structure, the matrix structure is ferrite and spheroidized pearlite, and the spheroidization rate reaches 90% or above.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Steel making deoxidant-Si-Ba-Sr-Ca-Fe alloy

The present invention relates to a steel-smelting deoxidant Si-Ba-Sr-Ca-Fe alloy, belonging to the field of steel-smelting technology. The composition of said alloy comprises (wt%) 30-60% of Si, 8-28% of Ba, 1-20% of Sr, 1-20% of Ca and the rest is Fe. As compared with existent technology it is strong in deoxidation, can thin crystal grains and raise steel quality.

Owner:本溪冶炼厂

Silicon-magnesium-calcium-strontium-barium-ferrum alloy

A Si-Mg-Ca-Sr-Ba-Fe series alloy is characterized in that the alloy also comprises lanthanon cerium and has the following chemical compositions by weight percentage: 48-52% of silicon, 4-10 percent of magnesium, 10-12 percent of calcium, 1-3 percent of strontium, 8-12 percent of barium, 0.1-2 percent of cerium, and the balance of Fe. The alloy conducts deep deoxidation by using the activity of alkaline earth metallic elements, not only has better deoxidizing capacity, but also has stronger penetrating power on molten steel due to low melting point and large proportion, effectively removes gas and changes sonims, has refining function on molten steel, nodularization function on devulcanized inclusion and grain refinement function, contributes to further improvement of steel quality. Meanwhile, lanthanon is added to promote crystalline structure degeneration of steel, thus increasing plastic nature and toughness of the steel.

Owner:张雪柏

High-manganese low-carbon composite alloy and method for preparing same

The invention discloses a kind of high manganese and low carbon composition alloy and the preparation method of it, the composition alloy contain the percentage by weight component as follow: Mn 70~75, Si 11~17, Al 7~14, P<0.2, C<0.3, S<0.03,surplus is Fe. The invention of composition alloy component proportioning science and rational, specific weight controlling strict, the method can deoxidize efficient for liquid steel, remove the foreign substance in liquid steel and deoxidize rapidly, make the steel slag easily floated upward and removed to obtain high degree of purity liquid steel, the composition alloy can be used as deoxidant in smelting kinds of steel, especially suitable for smelting conduit wiring steel, bridge and canal steel and high-strength ship plate steel that need strength deoxidation capacity, the composition alloy can reach high deoxidation effect.

Owner:危松林

Low-carbon steel molten-steel modifier

InactiveCN1605633AImproved chalking resistanceProportionally largeChemical compositionSmelting process

The present invention belongs to the field of steel-smelting technology, and is especially one kind of molten low carbon steel modifier. The molten low carbon steel modifier consists of Al 35-60 wt%, Mn 8-30 wt%, Ti 0.1-8 wt%, C 0.1-2 wt%, Si 0.1-5 wt%, S 0.001-0.03 wt% and P 0.001-0.03 wt% except Fe. The molten low carbon steel modifier has high specific weight, high aluminum content, deoxygenation capacity higher than pure aluminum and Si-Al-Ca, and lower use cost, and can lower the oxygen content in molten steel, make billet structure compact and make the steel possess e mechanical performance. During smelting low alloy steel and micro alloyed steel, the molten low carbon steel modifier provides main element Ti to raise the wear and corrosion resistance of steel, simplify steel smelting process and raise molten steel quality.

Owner:北京科大中冶技术发展有限公司

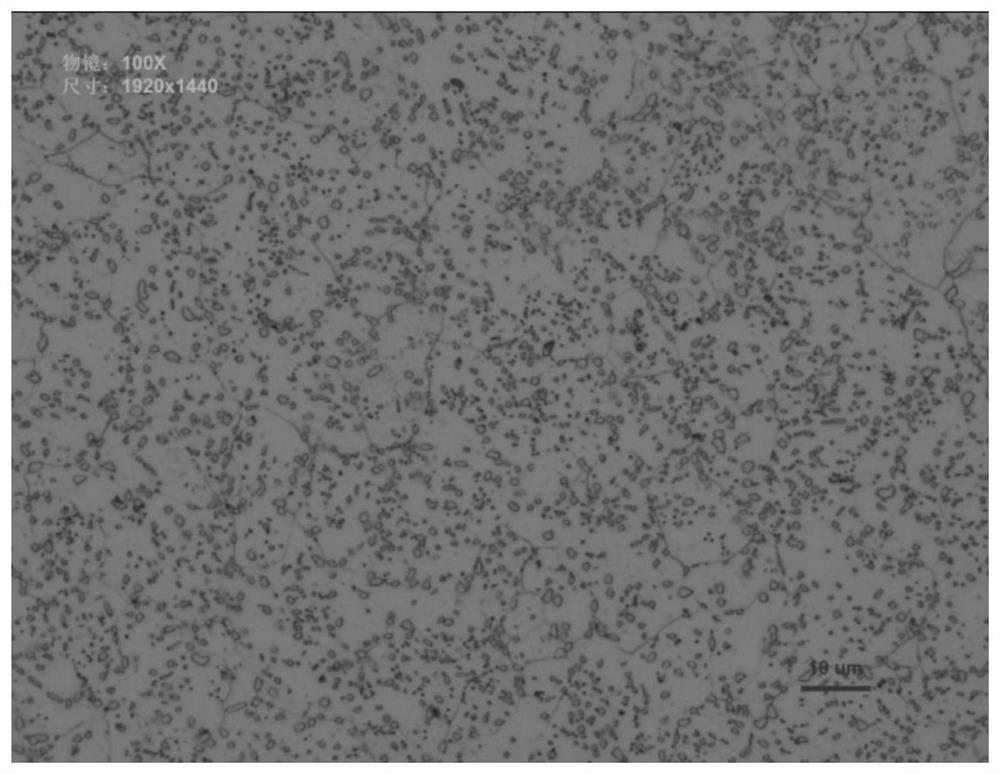

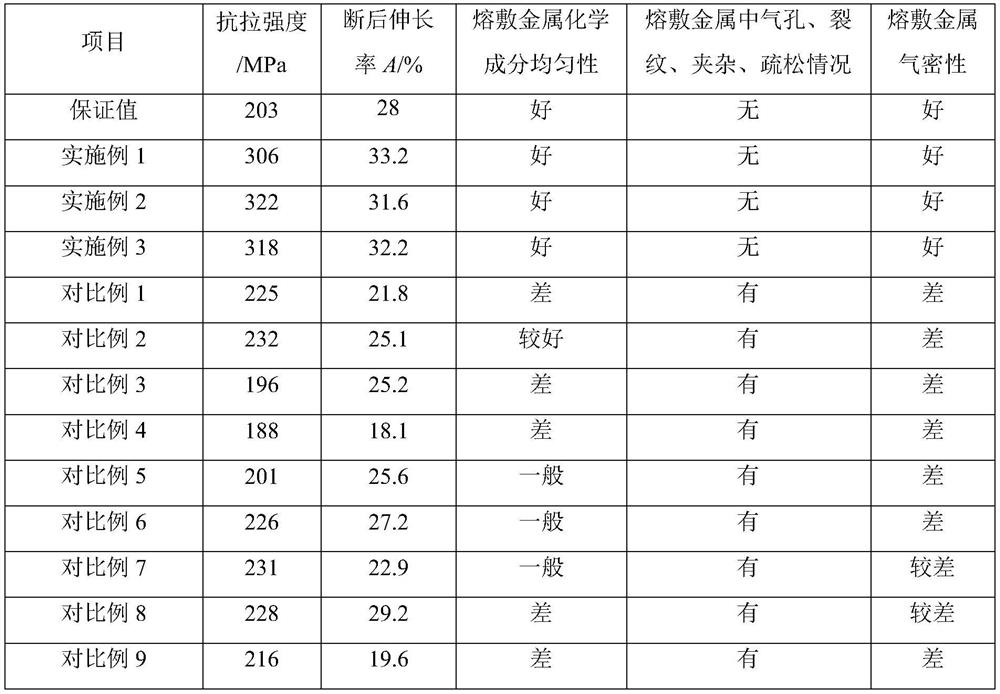

Matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding

ActiveCN112077476AUniform chemical compositionHigh droplet temperatureWelding/cutting media/materialsSoldering mediaPipeFusion welding

The invention belongs to the field of welding materials, and particularly relates to a matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding. The matched flux-cored wire comprises a TU1 semi-hard copper alloy sheath and a flux core; the flux core comprises 2.1%-3.2% of CuSi16 powder, 2.2%-3.0% of CuMn30 powder, 1.5%-2.2% of CuP12 powder, 3.0%-3.8% of AlSr40 powder,2.8%-3.6% of nanometer F3Ti powder, 3.2%-4.5% of nanometer NdF3 powder, and the balance FTD1 electrolytic copper powder; and the filling rate of the flux core is 32%-38%. Chemical components of deposited metal are uniform, inclusion, cracks and air hole defects are avoided, the air tightness is good, the minimum value of the tensile strength of the deposited metal is 306 MPa, the minimum value ofthe percentage elongation after fracture is 31.6%, and a component formed by fusion welding the seamless copper pipe completely meets the medical gas and vacuum requirements.

Owner:ZHENGZHOU UNIV

Metal rod for refining and purifying RH (Rockwell Hardness) molten steel

The invention belongs to a refining technology outside a steel refining furnace and relates to a metal rod for refining and purifying for desulfurizing, deoxidizing and removing impurities for RH (Rockwell Hardness) refining. The metal rod comprises an inner core and an outer cladding layer, wherein the outer cladding layer is coated on the outer surface of the inner core; the inner core is a pure metal calcium rod; the inner rod is in the form of a cylinder or a similar cylinder; the metal rod adopts a pure metal calcium rod outer-cladding steel outer layer so as to have certain specific gravity; and when being thrown to the molten steel, the metal rod can quickly enter the deep part of the molten steel without spilling, thus avoiding a spilling and nitriding problem of the molten steel during wire injection. Besides, the metal rod has high desulfurizing and deoxidizing ability, and can stably control the dimension and quantity distribution of impurities in the molten steel, and optimizes the site operation is optimized while ensuring the quality of the molten steel is ensured.

Owner:上海盛宝冶金科技有限公司

High-toughness wear-resistant flux-cored wire

InactiveCN107262964AStrong deoxygenation abilityAvoid infringementWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a high-toughness wear-resistant flux-cored wire which consists of a flux core and stainless steel skin covering the flux core. The flux core comprises the following raw materials: graphite powder, silicon powder, magnesium powder, nickel powder, titanium powder, titanium dioxide powder, titanium boride powder, iron oxide powder, zirconium oxide powder, aluminum-strontium alloy powder, electrolytic manganese powder, ferromolybdenum powder, ferroniobium powder, ferrovanadium powder, rare earth ferroalloy powder, carbonate, metal fluoride, and the balance reduced iron powder and unavoidable impurities. The high-toughness wear-resistant flux-cored wire has the advantages that splashes are small, smoke is little, the forming is good, deslagging is easy, deposited metal is compact in structure, no pores or flaws appear, the high-toughness wear-resistant flux-cored wire is combined with parent metal well and is stable in performance, the deposited metal has good wear resistance, corrosion resistance and high toughness, and the high-toughness wear-resistant flux-cored wire has good economic benefits.

Owner:天长市通联焊业有限公司

Multi-effect refining agent for ladle refining furnace

The invention discloses a multi-effect refining agent for a ladle refining furnace, which is prepared from following components in percent by weight: 45-70% of CaC2, 5-20% of SiC, 5-15% of Al and 10-20% of controlled release formulation. The lumpiness or granularity of the CaC2, the SiC, the Al and the controlled release formulation are respectively 5-20 mm, not more than 3 mm, 1-5 mm and not more than 5 mm. The elements Ca, Al, Si and C in the components of the refining agent all have relatively strong deoxidizing capacity and can meet the requirements of quickly and deeply deoxidizing the furnace slag and diffusing and deoxidizing the molten steel. The deoxidized element products can form white slag mineralogical phase together with synthetic slag components. The molten steel desulfurization and impurity removal are favorable. The contents of [N] and [H] in the refining process of the molten steel are reduced, and the energy consumption and the cost are decreased.

Owner:重庆科健冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com