Multi-effect refining agent for ladle refining furnace

A ladle refining furnace and refining agent technology, which is applied in the field of refining agents, can solve the problems of large fluctuations in Al content, high foaming agent consumption, and short foam retention time, so as to reduce the consumption of synthetic slag, reduce consumption and cost, and save electrodes The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Refining agent of the present invention, the weight percent of its component is: CaC 2 --50%, SiC--15%, Al--15% and sustained release agent 20%; CaC 2的The block size or particle size is 1gmm, SiC is 2mm, Al is 4mm, and the slow-release agent is 4mm; each component processed according to the above block size or particle size is prepared, and then mixed according to the above ratio and double-woven with inner plastic and outer braid Layers of moisture-proof packaging, the weight is preferably 5-10kg / bag. During steelmaking, the molten steel for primary smelting in the converter is transported into the ladle refining furnace, and after a period of time after the refining station starts to be powered and heated and the slag is added, the ratio of 0.25 to 0.5 kg per ton of molten steel is added to the present invention. Or, during the refining process, adjust the slag according to the change of the slag; add 0.05-0.20kg per ton of molten steel each time to adjust the slag. ...

Embodiment 2

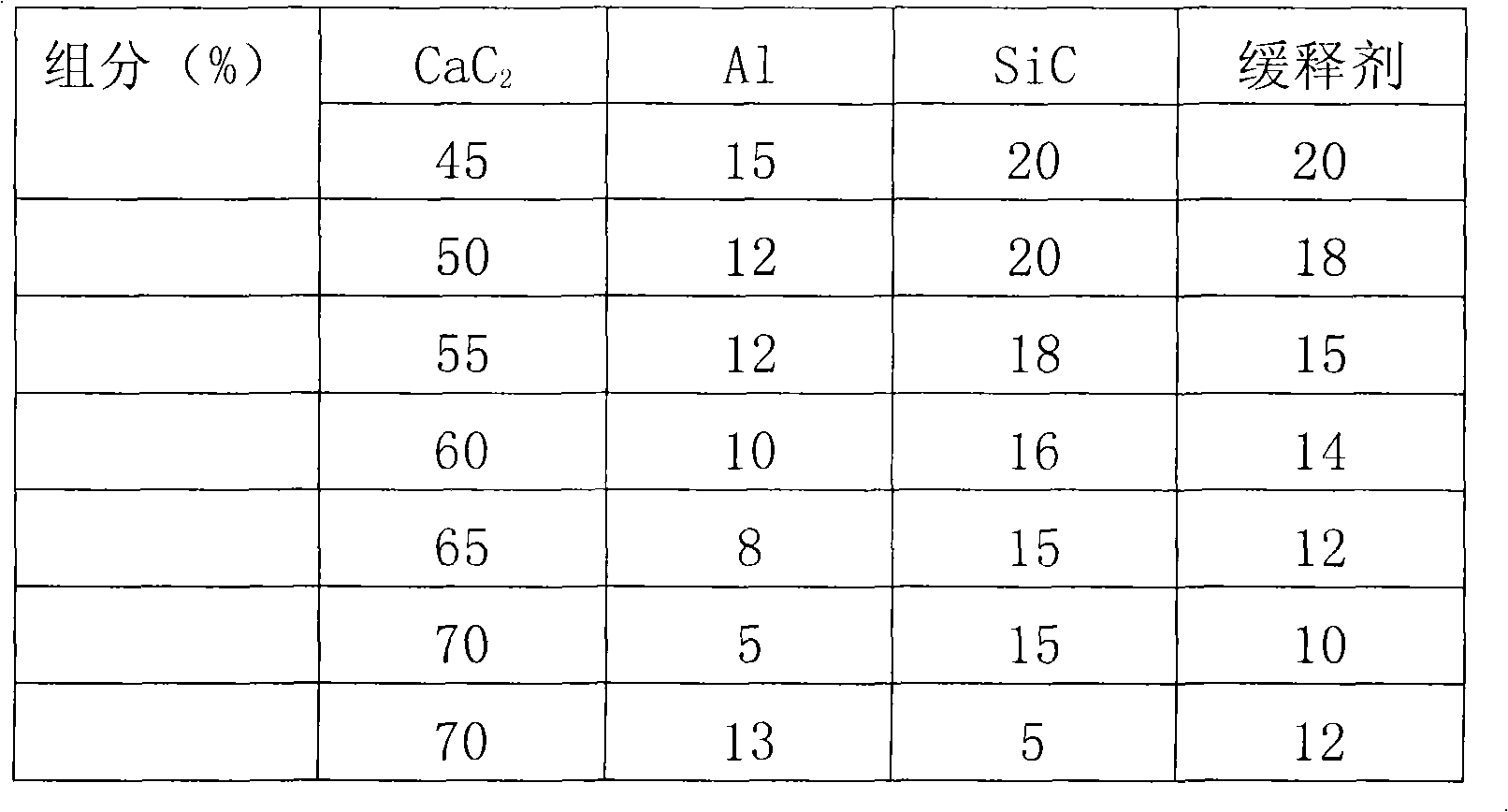

[0031] For the refining agent of the present invention, the weight percentage of each component can also be as shown in the table below, and the same refining effect can be obtained.

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com