Microalloying wear resisting ball and preparation method and preparation system thereof

A technology of microalloying and preparation system, which is applied in the field of metallurgy, can solve the problems of poor production process and unstable hardness of grinding balls, and achieve the effects of good and stable product quality, enhanced wear resistance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment discloses a microalloyed wear-resistant ball, and its main chemical composition (mass fraction %) is shown in Table 1.

[0048] Table 1 Chemical composition of microalloyed wear-resistant balls

[0049] C

Si

mn

Cr

B

N

Mg

Ca

P

S

Fe

0.8

0.2

0.68

0.43

0.08

0.02

0.12

0.1

≤0.010

≤0.010

margin

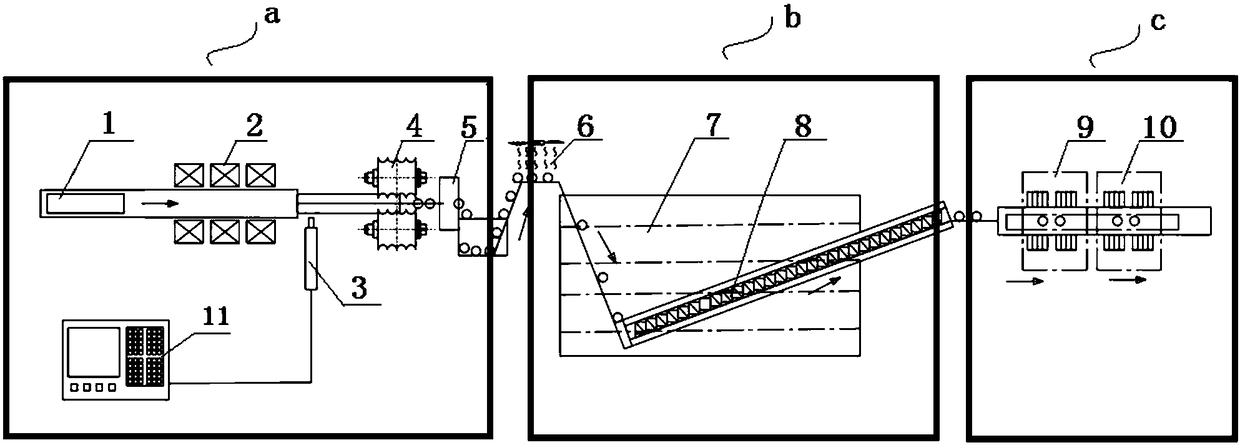

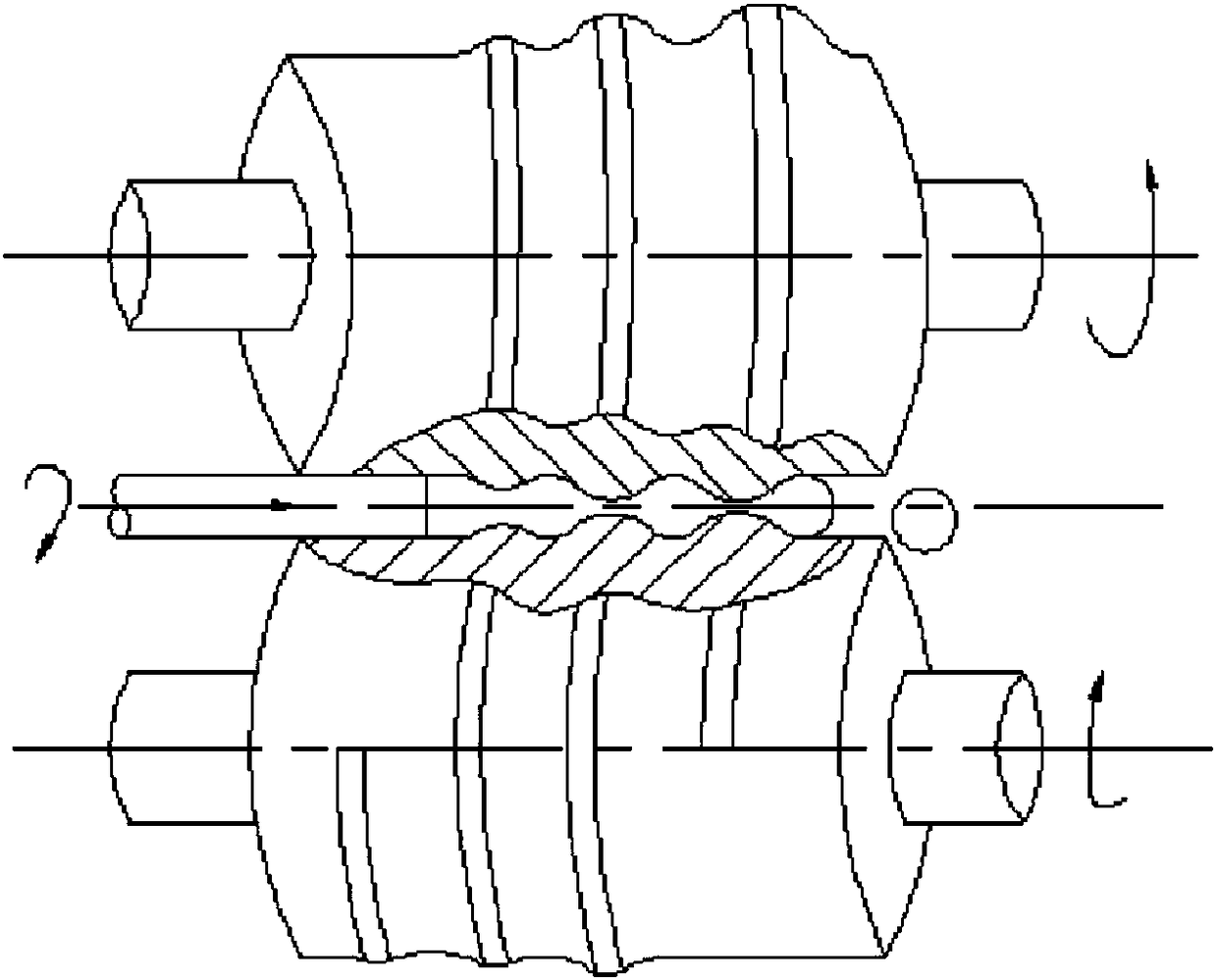

[0050] This embodiment discloses a microalloyed wear-resistant ball preparation system, its structure is as follows Figure 1-2 The shown includes: sequentially connected smelting device, continuous casting and rolling device, induction heating device 2 (intermediate frequency induction heating device), steel ball rolling mill 4, ball sieving device 5 and heat treatment device. The end of the reaction heating section of the induction heating device 2 is provided with an infrared temperature measuring device 3, and the preparation system of the micro-alloyed wear-resistant ball also incl...

Embodiment 2

[0059] This embodiment discloses a microalloyed wear-resistant ball, and its main chemical composition (mass fraction %) is shown in Table 2.

[0060] Table 2 Chemical composition of microalloyed wear-resistant balls

[0061] C

Si

mn

Cr

B

N

Mg

Ca

P

S

Fe

0.75

0.3

0.7

0.45

0.1

0.02

0.12

0.1

≤0.010

≤0.010

margin

[0062] This embodiment discloses a microalloyed wear-resistant ball preparation system, its structure is as follows Figure 1-2 The shown includes: sequentially connected smelting device, continuous casting and rolling device, induction heating device 2 (intermediate frequency induction heating device), steel ball rolling mill 4, ball sieving device 5 and heat treatment device. The end of the reaction heating section of the induction heating device 2 is provided with an infrared temperature measuring device 3, and the preparation system of the micro-alloyed wear-resistant ball also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com