Tantalum ring and preparation method thereof, sputtering device comprising tantalum ring and application thereof

A sputtering device and tantalum ring technology, which is applied in the field of semiconductor manufacturing, can solve the problems of less sputtering sources and small attachment areas, etc., and achieve the effects of improving service life, avoiding tip discharge, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below through specific embodiments. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

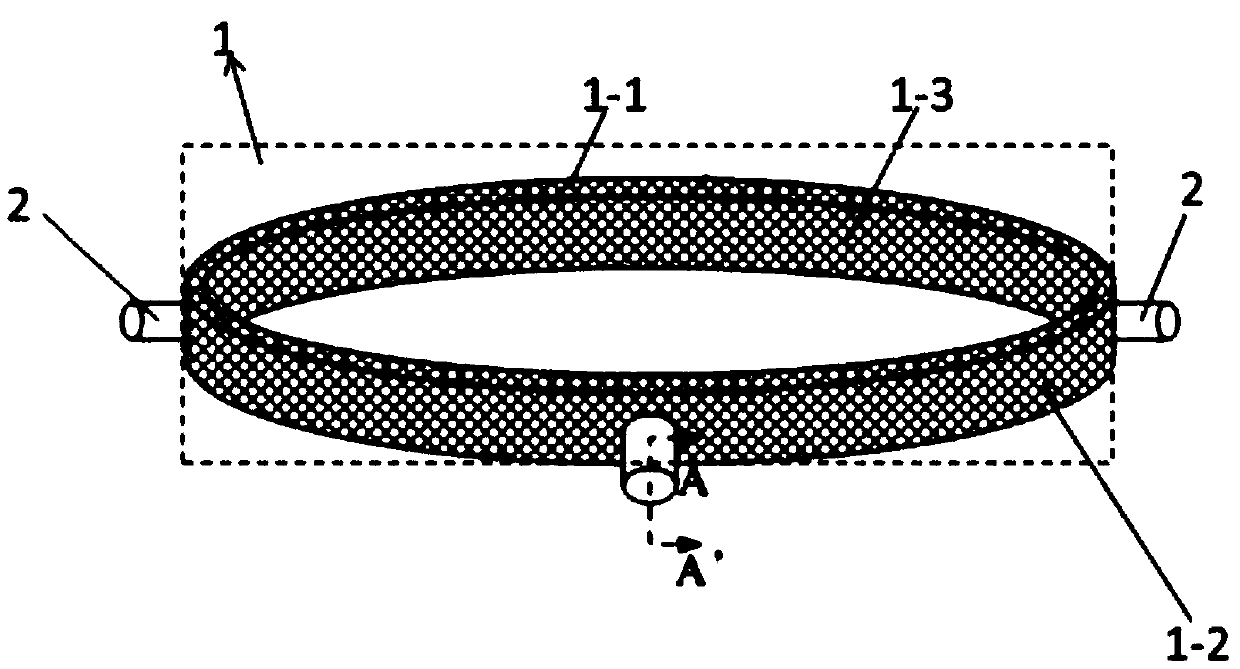

[0051] This embodiment is to provide a tantalum ring, such as figure 1 As shown, it includes a ring and the patterns arranged on the ring, wherein the ring includes a ring body 1 and a boss 2 located on the outer peripheral surface of the ring, wherein the ring body includes two circular end faces 1 facing away from each other in the axial direction -1 and an outer peripheral surface 1-2 and an inner peripheral surface 1-3 arranged between the two annular end faces 1-1 and diametrically opposite, the outer peripheral surface 1-2 and the inner peripheral surface 1-3 1 is perpendicular to the two circular end faces 1-1.

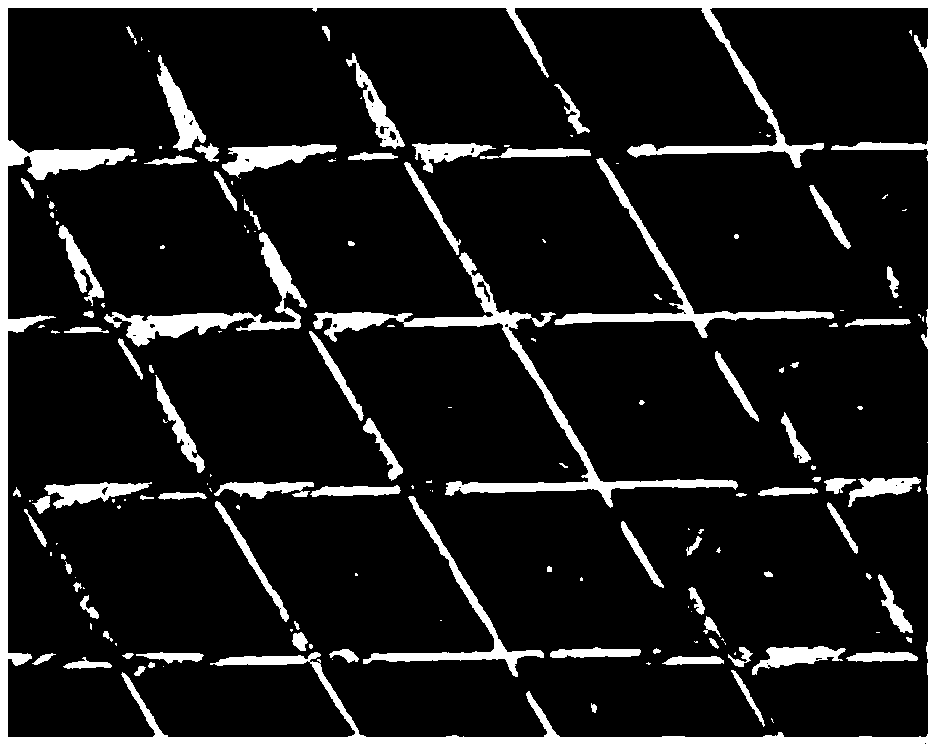

[0052] In this embodiment, the shape o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com