Steelmaking method of ladle refining furnace

A technology of ladle refining furnace and refining agent, which is applied in the field of refining outside the molten steel furnace, can solve the problems of high consumption of foaming agent, large fluctuation of Al content, high labor intensity, etc., so as to reduce consumption and cost, reduce consumption of synthetic slag, and avoid The effect of carbonization of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An 80-ton ladle refining furnace in a factory adopts this technology to produce 4 furnaces of anti-H 2 S Submarine Line Pipe X65 Steel (for subsea oil transportation)

[0036] 1. Seamless steel pipe production process

[0037] 1300 t Mixed iron furnace → desulfurization, slag removal → 80 t Converter→LF Ladle Refining Furnace→(VD)→Continuous Casting Machine

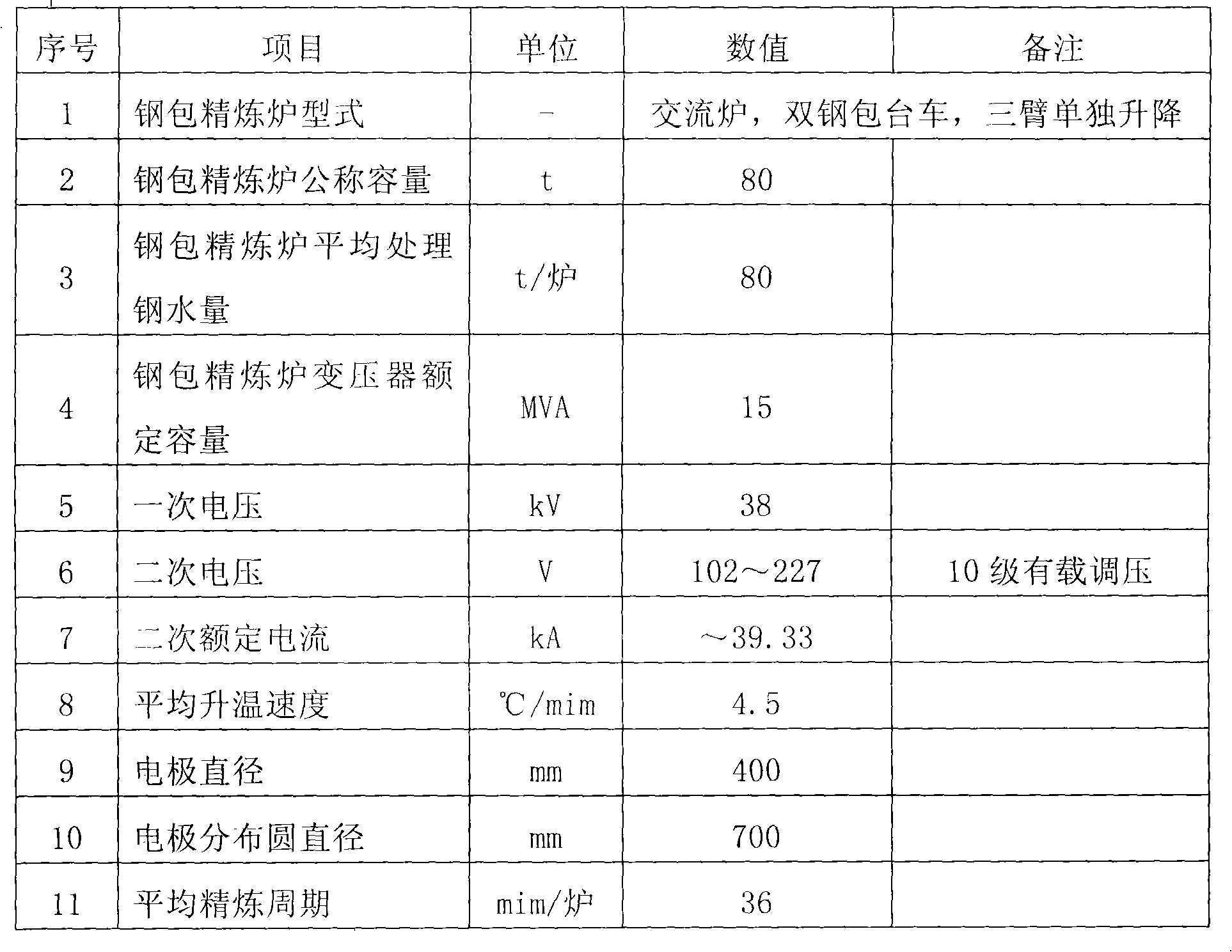

[0038] 2.80 t Main parameters of ladle refining furnace equipment

[0039] Form 180 t Main parameters of ladle refining furnace equipment

[0040]

[0041] 3. Technical conditions of main raw and auxiliary materials

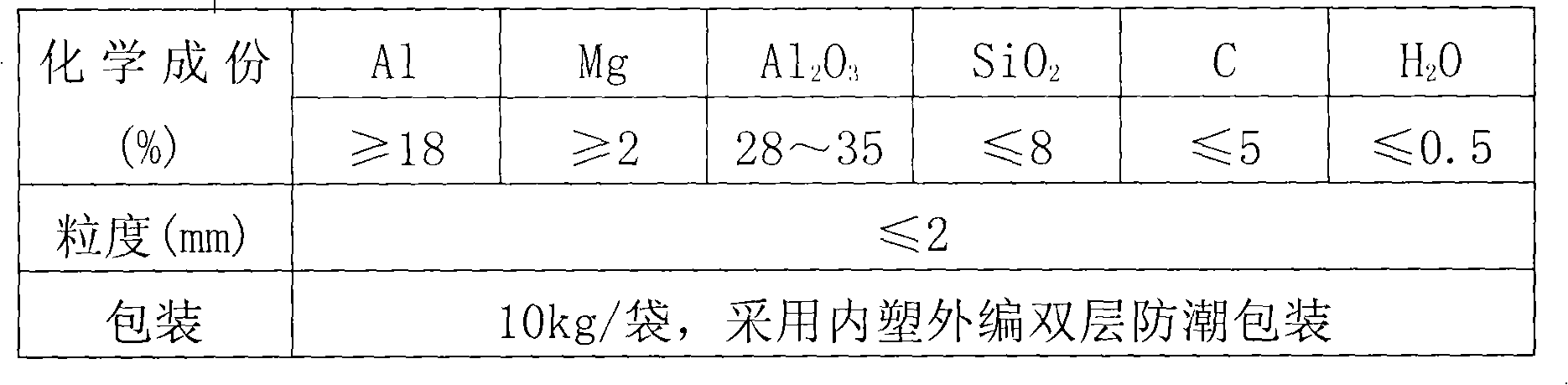

[0042] 3.1 Reducing agent for slag washing (used in the original process)

[0043] Table 2 Physicochemical properties of slag washing reducing agent

[0044]

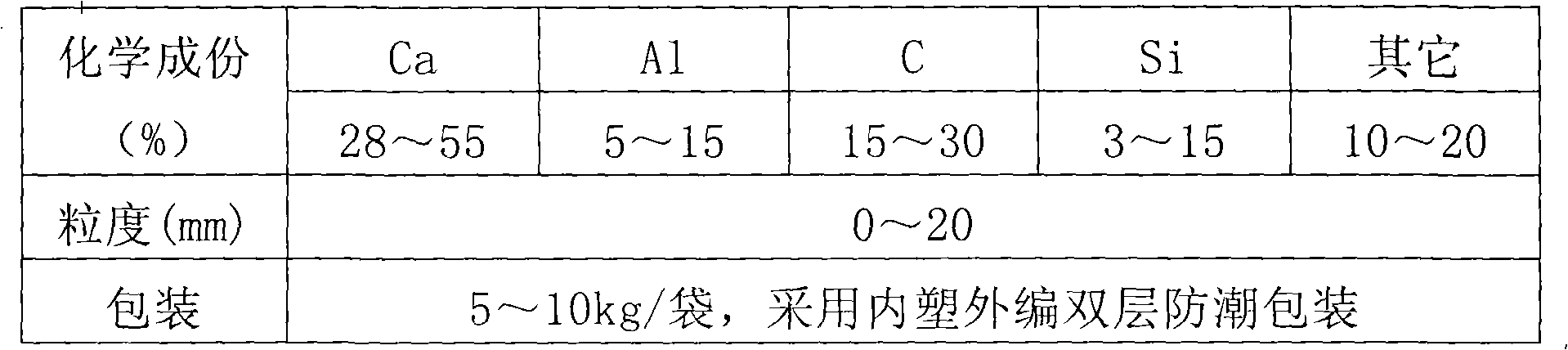

[0045] 3.2 Ladle refining furnace multi-effect refining agent (for new technology)

[0046] Table 3 Physical and chemical indicators of multi-effect refining agent in ladle refining furnace

[0047]

[0048] Prepare the vari...

Embodiment 2

[0087] For the multi-effect refining agent of the present invention, the weight percentage of each component can also be shown in the following table, which can achieve the same technical effect and realize the purpose of the present invention.

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com