Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Solve stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

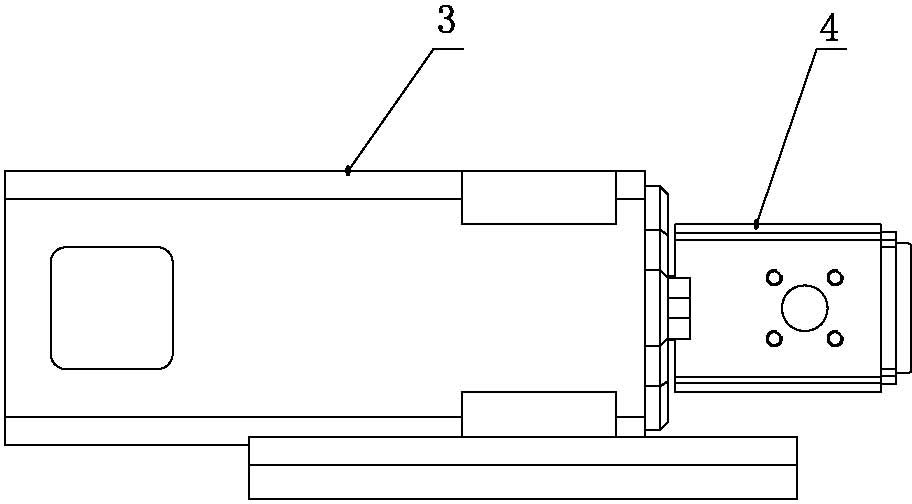

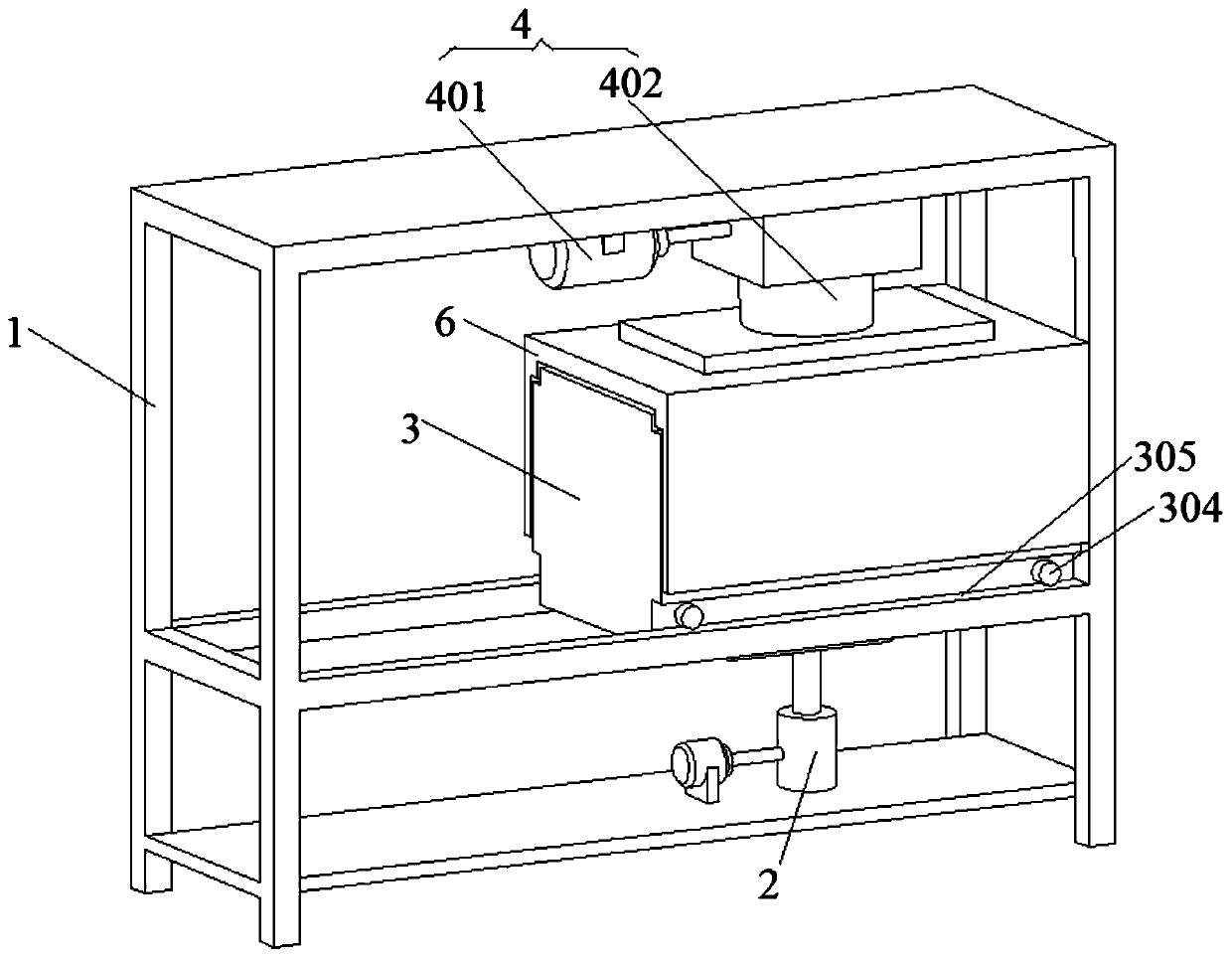

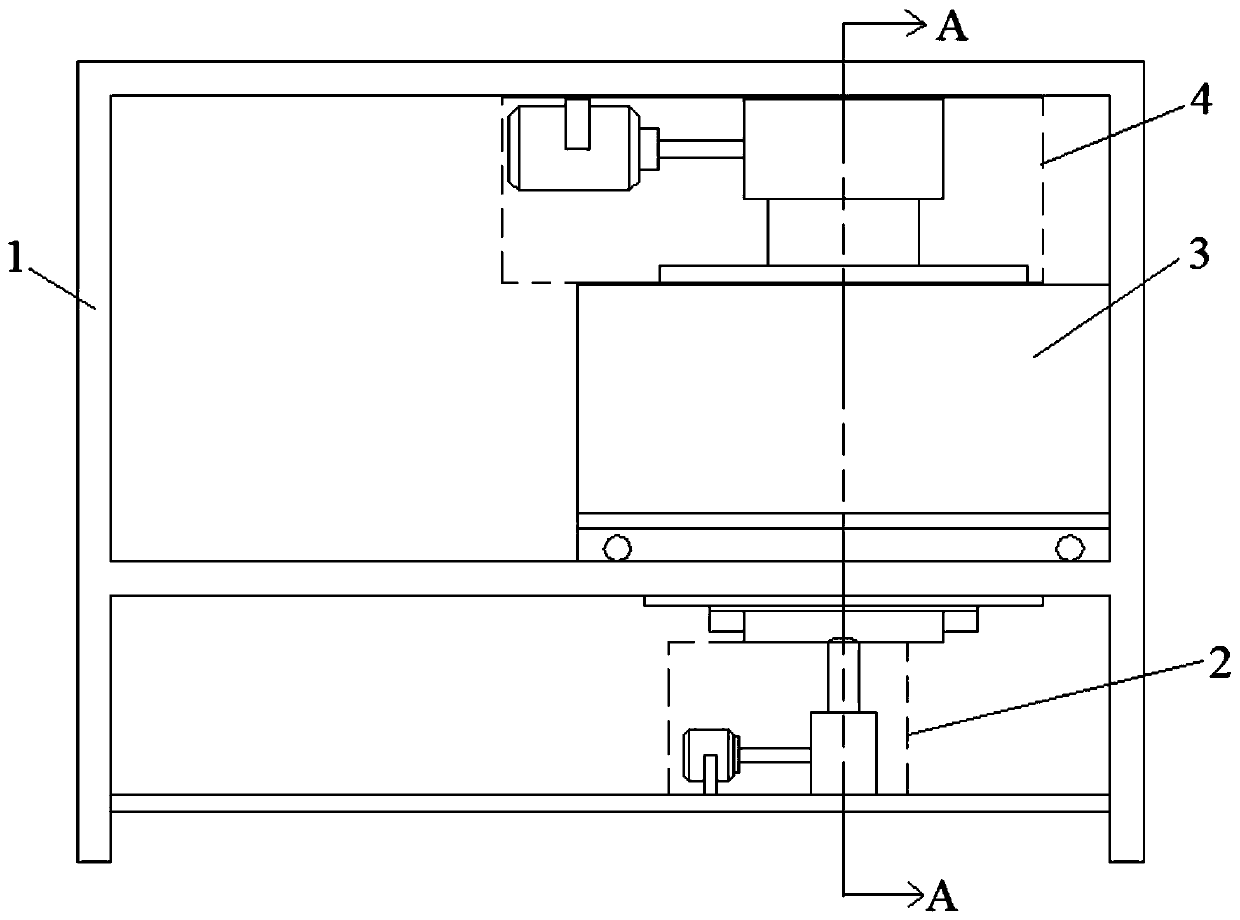

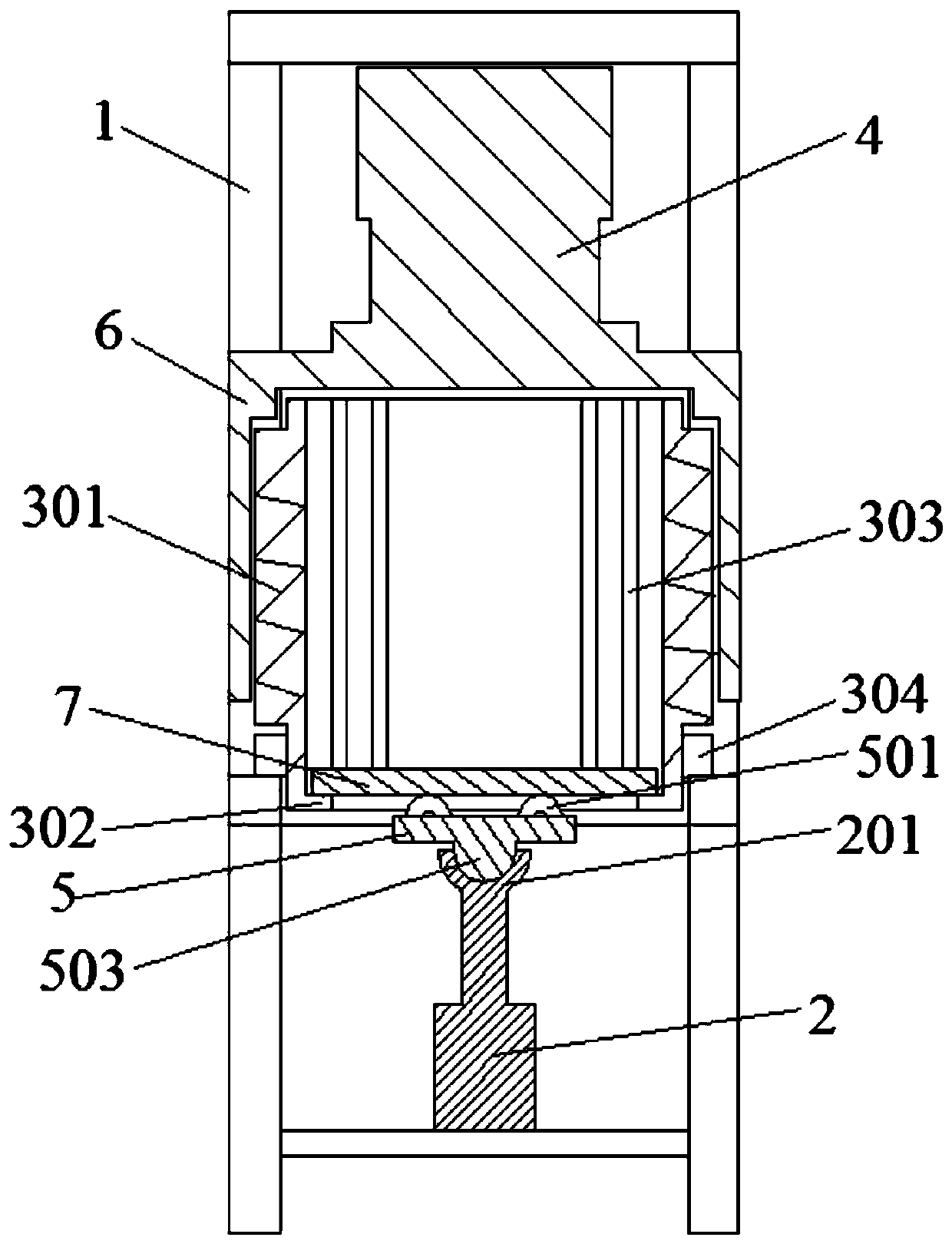

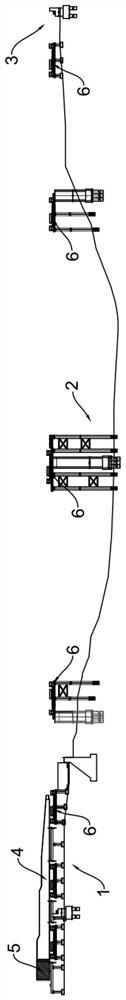

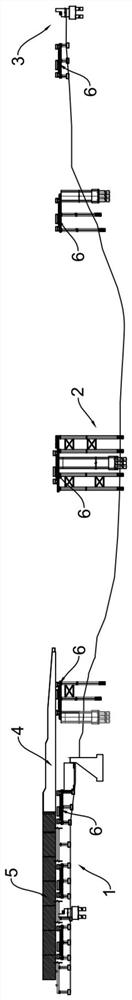

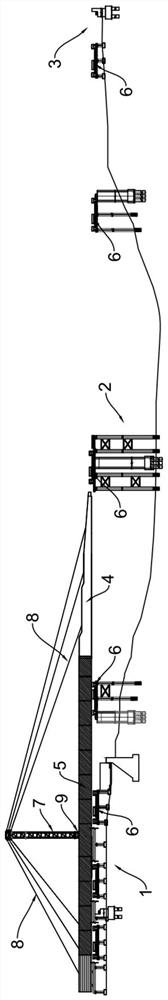

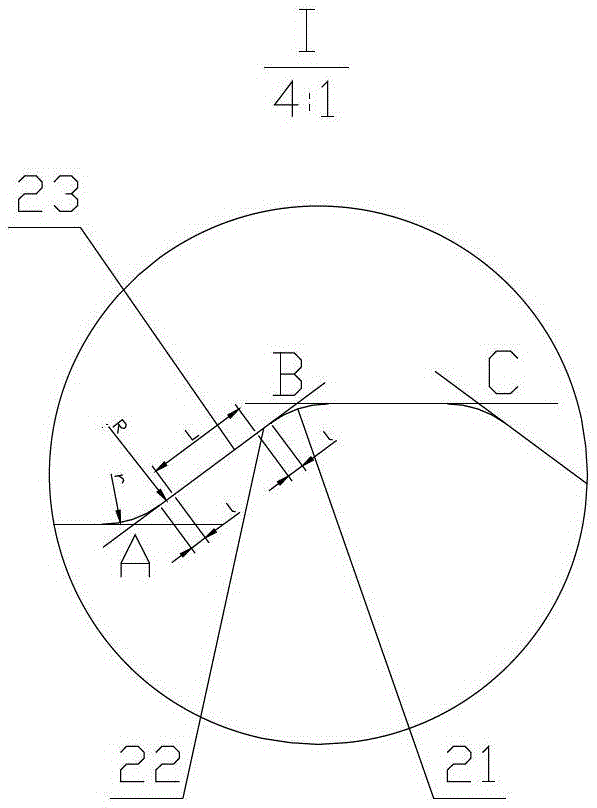

Nuclear power station pipeline weld inner wall grinding robot

InactiveCN107855859ASolve problems that cannot be polishedSolve the problem of weld stress concentrationEdge grinding machinesGrinding feed controlStress concentrationRound table

The invention discloses a nuclear power station pipeline weld inner wall grinding robot, which comprises a sealing unit, a grinding unit, a driving unit, and an electric element unit. The sealing unitcomprises a first round table and a rubber sealing plate arranged on the first round table; the grinding unit comprises a rotary holder and a grinding device arranged on the rotary holder; the driving unit is used for driving the grinding unit to enter and exit a pipeline; and the sealing unit, the grinding unit, the driving unit and the electric element unit are connected in a bending way. Compared with the prior art, the nuclear power station pipeline weld inner wall grinding robot provided by the invention has the following advantages that multiple functions of automatic grinding, polishing, cleaning and nondestructive testing of a steel-made pipeline weld inner wall are realized, the problem that the steel-made pipeline weld inner wall cannot be ground is solved, a turning and climbing problem of the robot on the pipeline inner wall is solved, the problem of weld stress concentration is solved, a heat fatigue effect is eliminated, the weld quality is ensured, and the weld potential quality hazard is eliminated.

Owner:中广核工程有限公司 +1

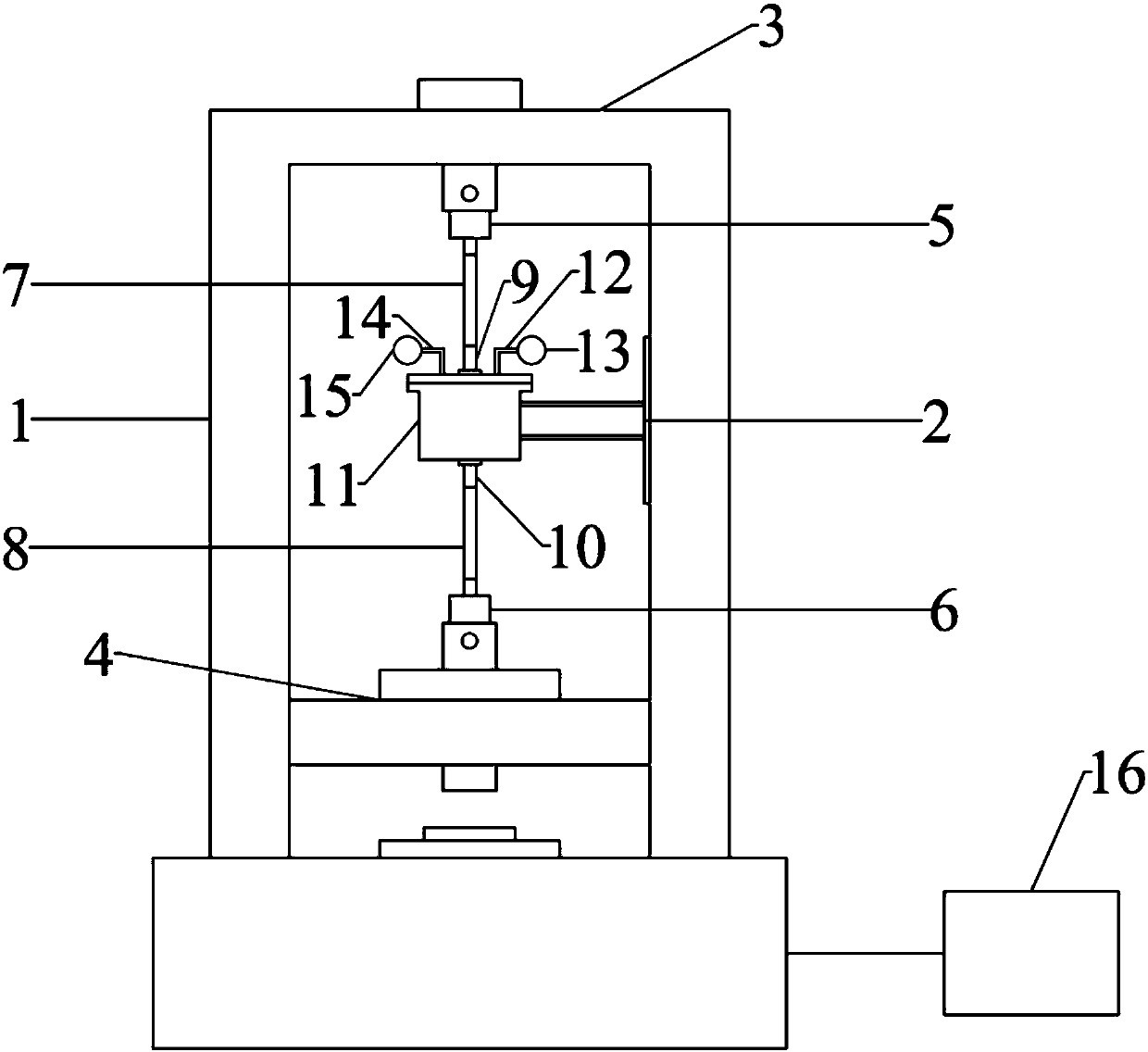

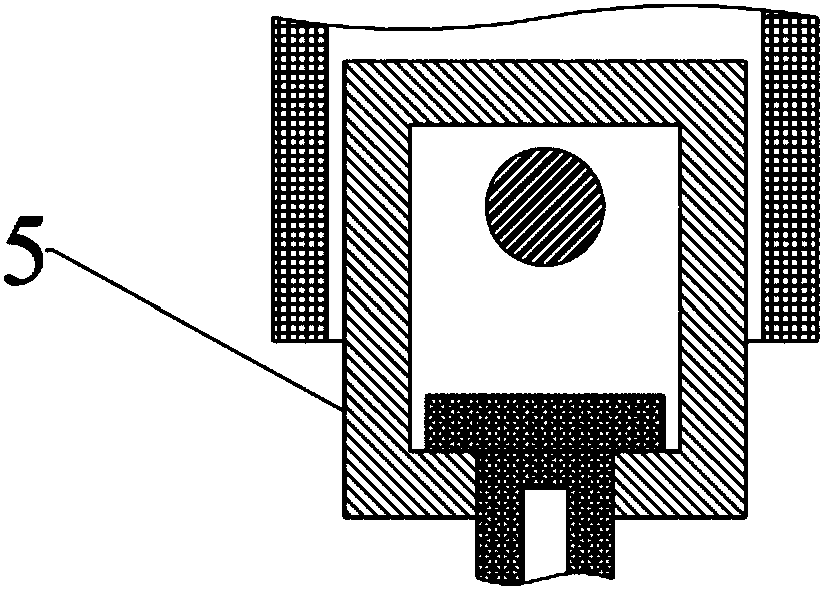

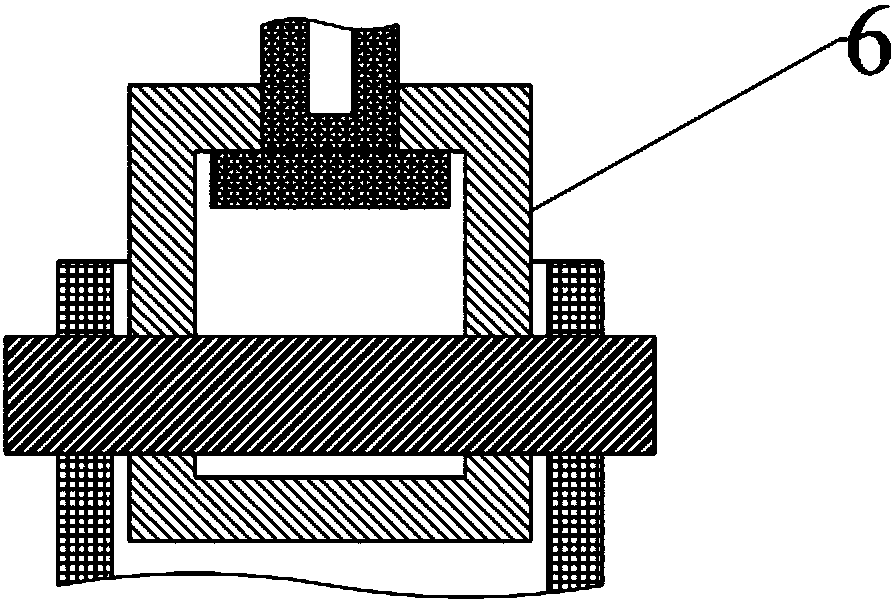

Simulation test device and method of evaluating stress corrosion cracking resistance of well logging steel wire

ActiveCN107687975AEasy to installOvercoming the limitations of constant loadsWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCrack resistanceWell logging

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

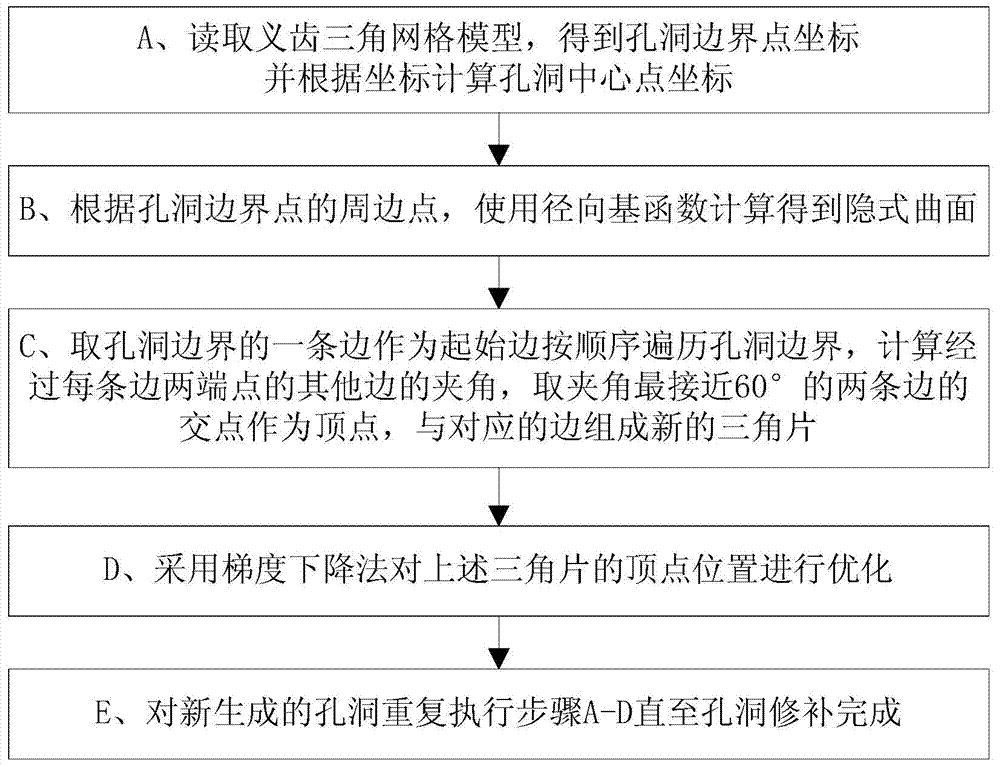

Iterative repair method for holes of false tooth triangular mesh model

ActiveCN104504663ASolve stress concentrationImprove smoothnessImage enhancement3D-image renderingStress concentrationIterative method

The invention discloses an iterative repair method for holes of a false tooth triangular mesh model. The method includes: preliminarily adding new triangular pieces for the holes through information of adjacent sides of hole borders according to reserved information of the hole borders of the false tooth triangular mesh model, adopting an iterative algorithm for generating new borders, and optimizing a vertex position each time iteration is carried out. By means of incremental repair for the holes, a hole repair surface is gradually faired from center to outside, and accordingly integral fairness is greatly improved, and the problem of stress concentration of repaired false teeth due to feature information loss caused by large curvature changes at positions of cervical margin lines, tooth fossea and the like is solved. The iterative repair method for the holes of the false tooth triangular mesh model is widely applicable to the field of repair of false teeth.

Owner:FOSHAN NUOWEI TECH

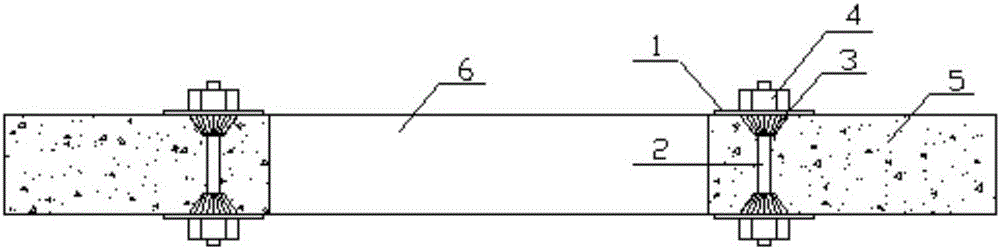

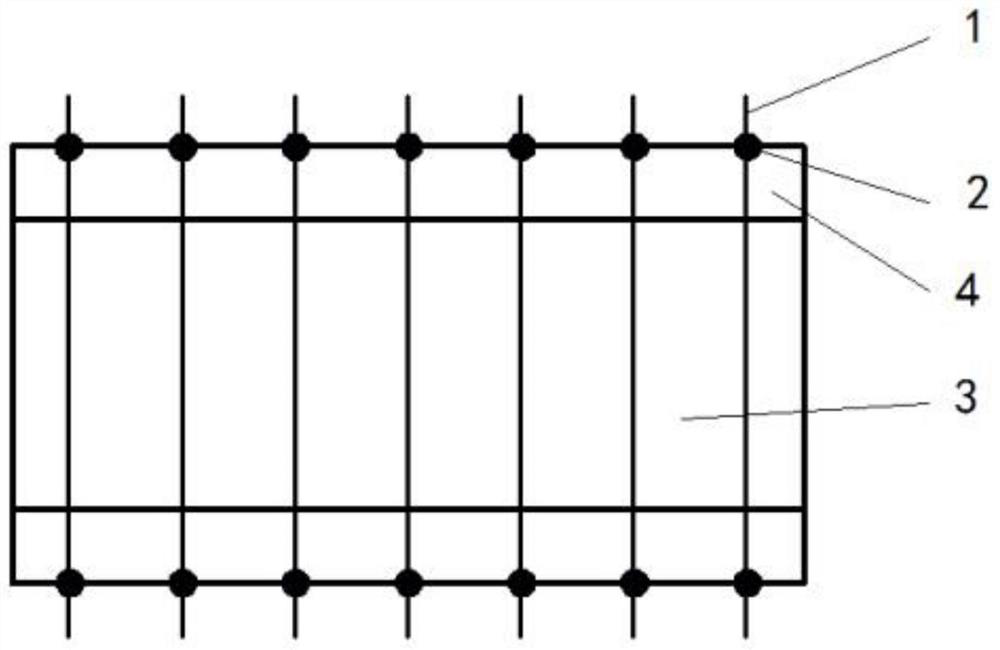

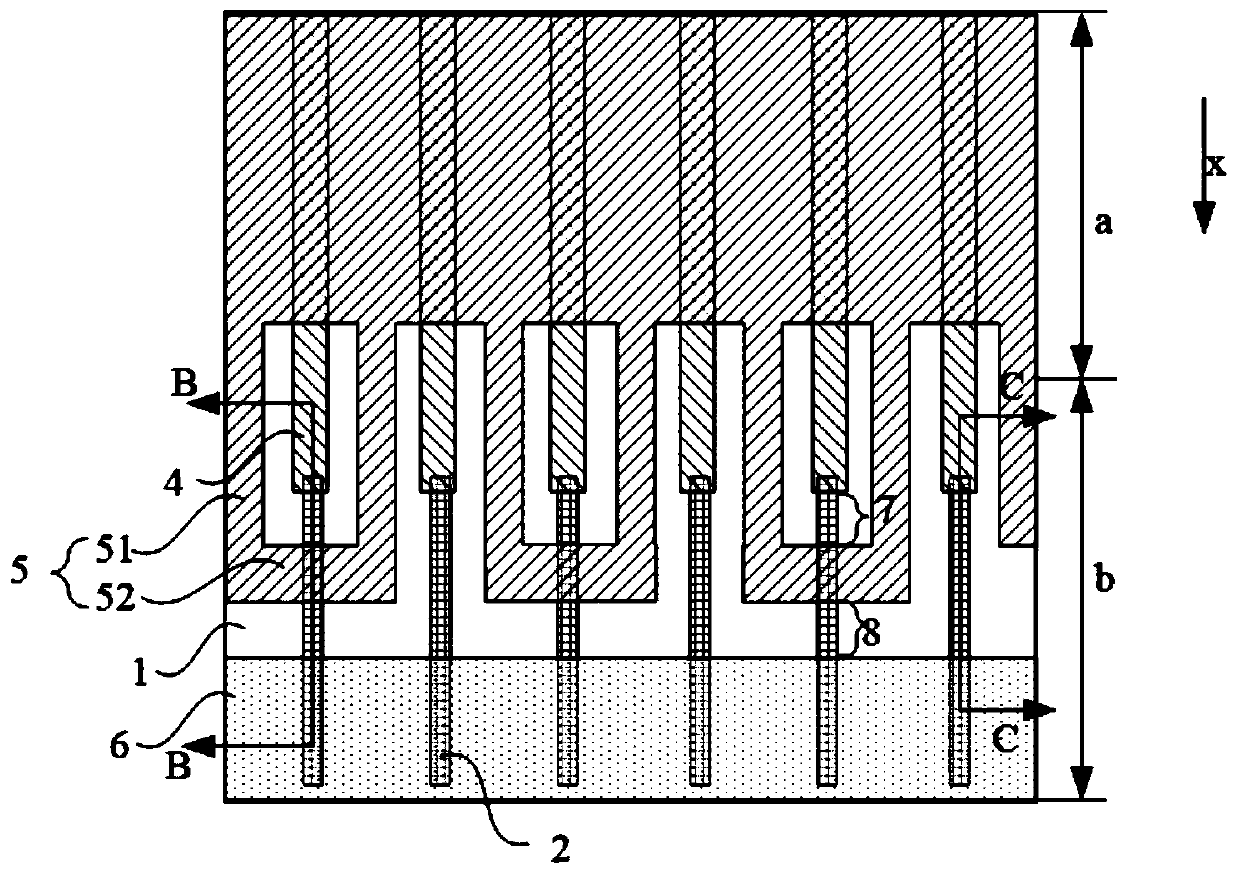

Steel structure spatial system for reinforcement and construction method thereof

InactiveCN105863289AGood anchoring effectIncreased bearing capacity and stiffnessBuilding repairsSpatial systemSteel plates

The invention discloses a steel structure spatial system for reinforcement and a construction method thereof. The steel structure spatial system for reinforcement and the construction method thereof are mainly applied to building structure reinforcement and reconstruction in the technical field of building science. The steel structure spatial system for reinforcement structurally comprises steel plates; the steel plates comprise the floorslab top steel plates and the floorslab bottom steel plates; the floorslab top steel plates are located on the top surface of a concrete floorslab; the floorslab bottom steel plates are located on the bottom surface of the concrete floorslab; the floorslab top steel plates and the floorslab bottom steels plates are aligned in the longitudinal direction; the floorslab top steel plates and the floorslab bottom steels plates are fixedly arranged at the edges of an open hole position in the concrete floorslab so as to achieve reinforcement of the concrete floorslab; and rigid connecting devices for connecting the floorslab top steel plates with the floorslab bottom steels plates are disposed between the floorslab top steel plates and the floorslab bottom steels plates. According to the steel structure spatial system for reinforcement and the construction method thereof, the steel structure spatial system is combined with the concrete floorslab, thus the anchoring effect is good, and the bearing capacity and rigidity can be improved to the great degree; construction and mounting are convenient, and anchoring of the steel plates is achieved; and using space is not occupied, the steel consumption is small, and the cost is low.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES +2

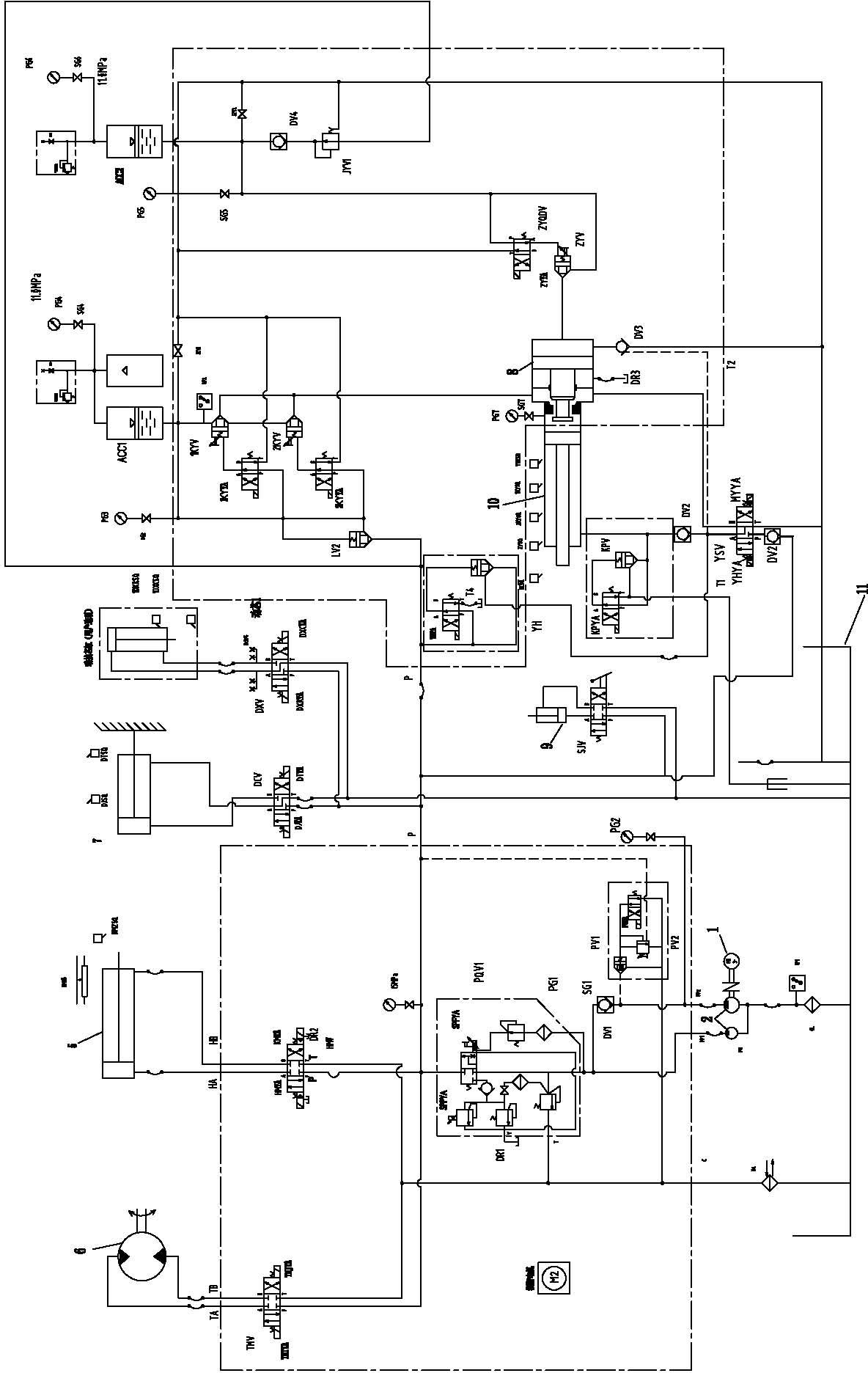

Control system and method for ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation

PendingCN110792482AAchieve a FMIncrease capacityBoiler controlEngine componentsUltra high pressureControl system

The invention discloses a control system and method for an ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation. The system comprises an ultrahigh-pressure cylinder regulation valve, a high-pressure cylinder regulation valve, a medium-pressure cylinder regulation valve, a first steam supplementing valve and a second steam supplementing valve; ultrahigh-pressure cylinder regulation valve, the high-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve of a secondary reheating unit can be controlled to simultaneouslyparticipate in power grid primary frequency modulation in a steam supplementing regulation mode. When the practical load of a power grid is higher or lower than a rated load, the frequency of the power grid deflects for 50 HZ; the deflection change of the frequency of the power grid is received by the control system; the opening amplitudes of the ultrahigh-pressure cylinder regulation valve, thehigh-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve are controlled, and the steam inlet flow of each cylinder is changed, so that the mechanical power output of asecondary reheating turbine is changed; and practical power output is matched with the load of the power grid, so that primary frequency modulation of the power grid is realized.

Owner:XI AN JIAOTONG UNIV

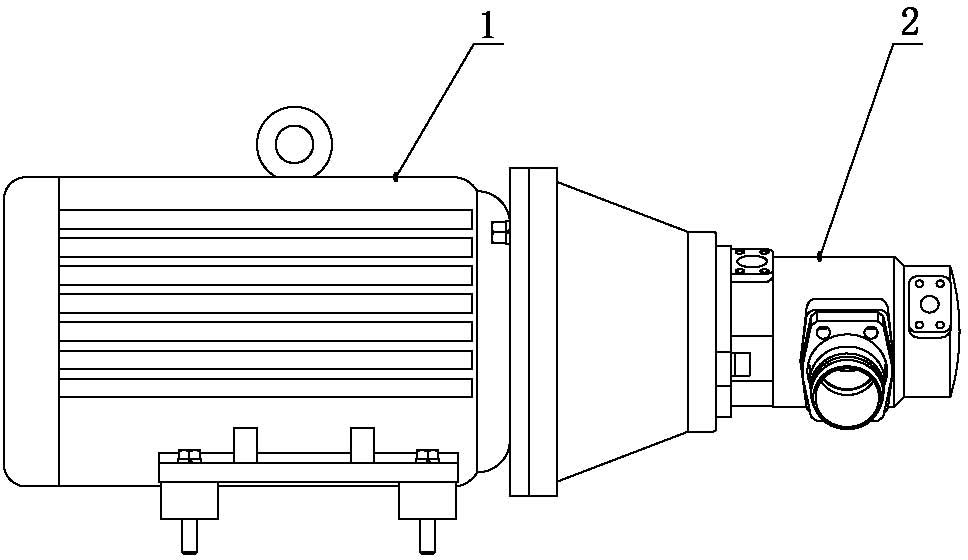

Servo driving type die-cast machine

The invention discloses a servo driving type die-cast machine, which is characterized by comprising a servo driving system, an injection pull rod (203), an ejection push plate (302) and a mold-adjusting big gear (403), wherein the servo driving system consists of a servo motor (3) and an oil pump (4); the output of the oil pump (4) is connected with the input end of a hydraulic actuating part; the hydraulic actuating part is internally provided with a pressure and flow sensor; the output of the pressure and flow sensor is connected with an electric control device; and the output of the electric control device is connected with the input end of the servo motor (3). The servo driving type die-cast machine has the advantages that due to adoption of the servo control, the control accuracy of a power system is improved, and the structure is simplified; and due to improvement on a key part, the service life is prolonged, the raw material is reduced, and meanwhile, the structure of the whole machine is simpler.

Owner:江苏新佳晨精密机械科技有限公司

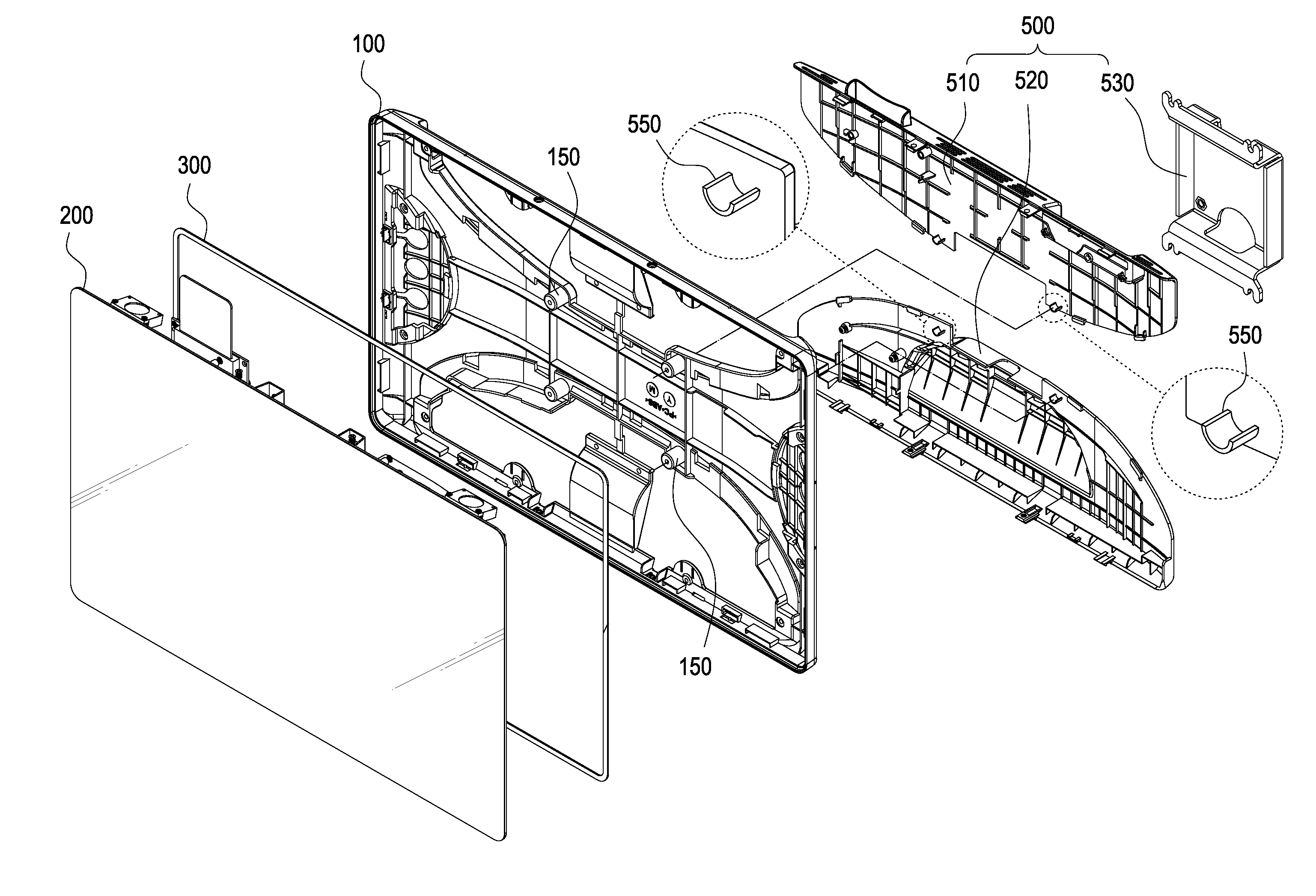

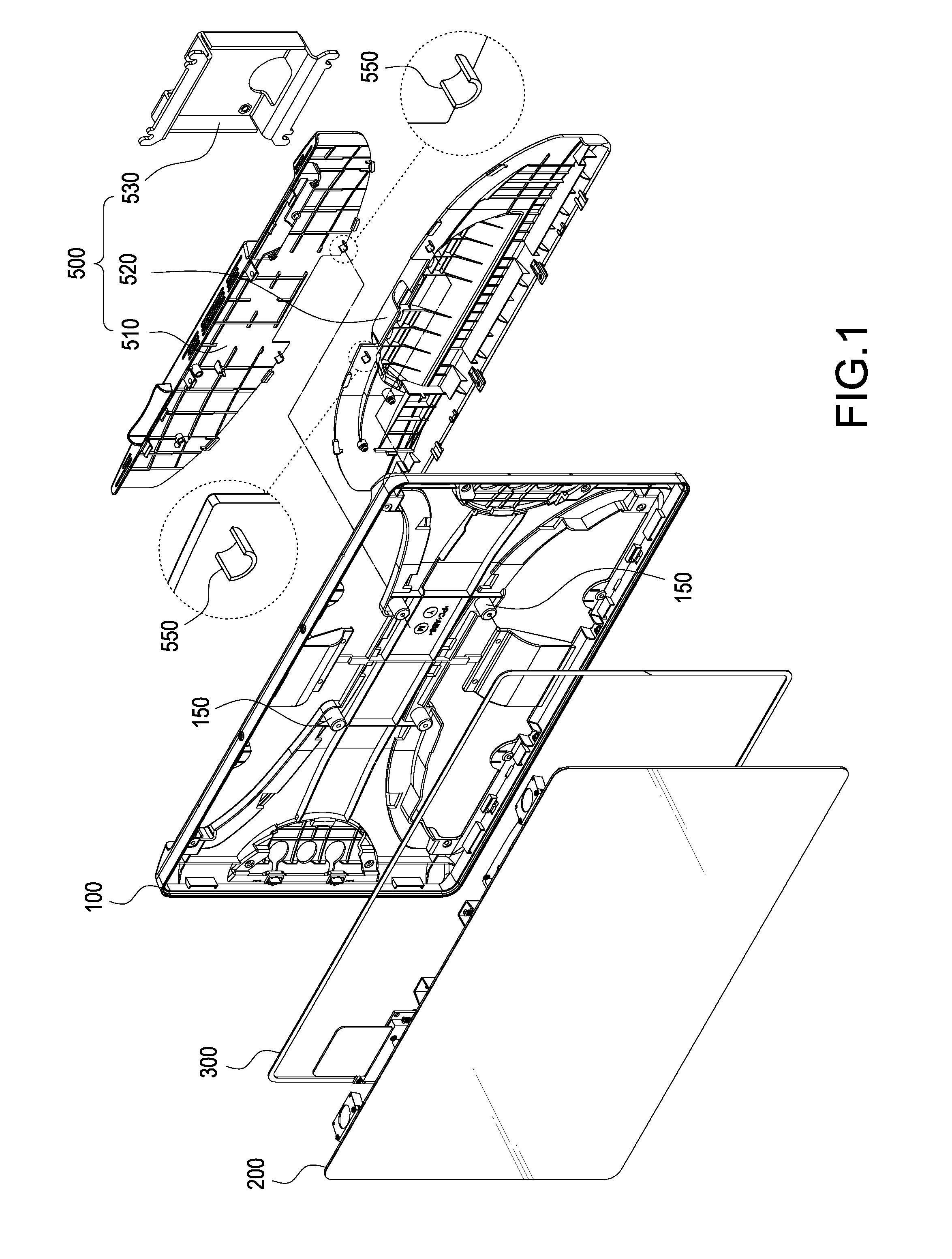

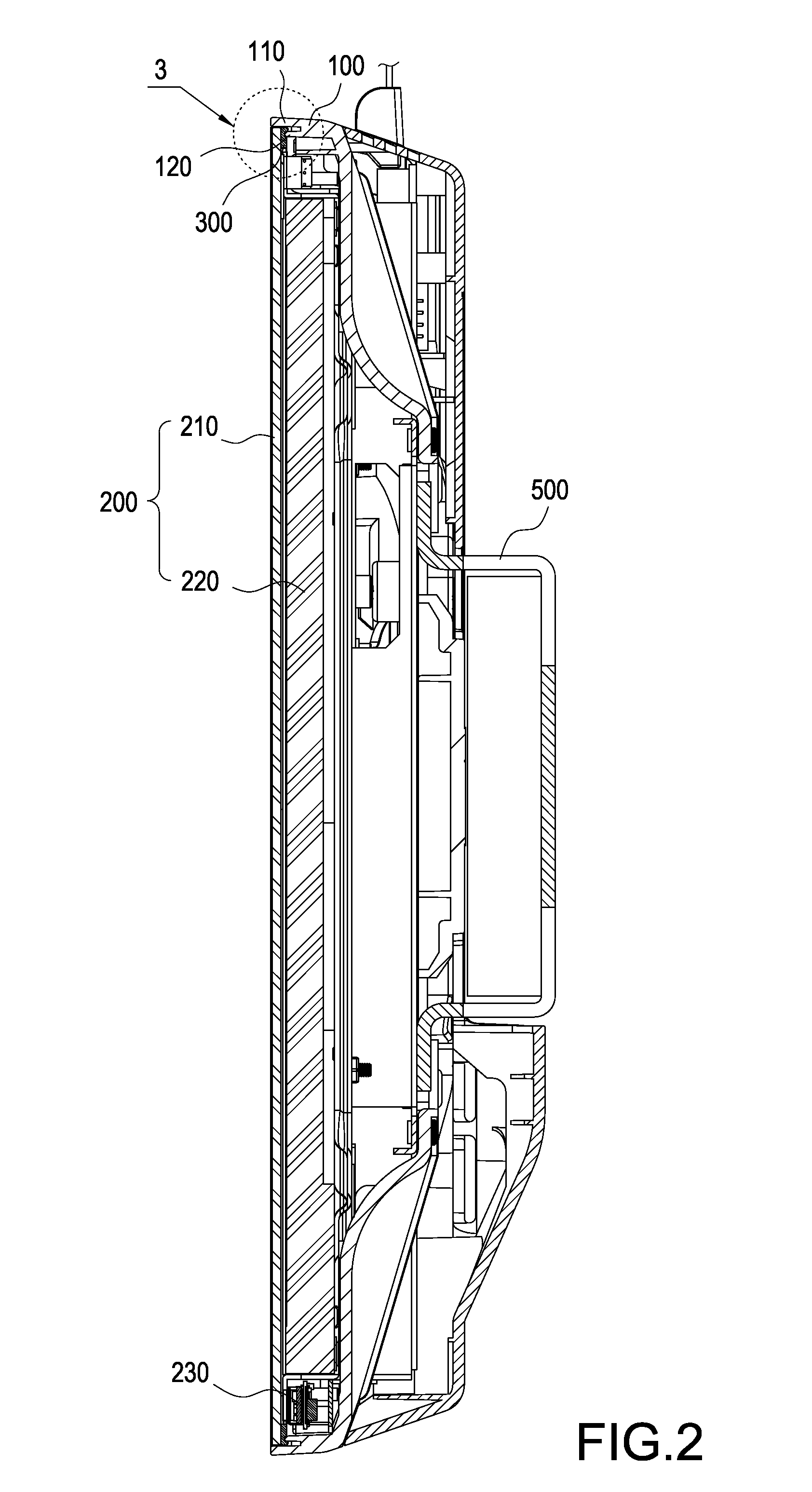

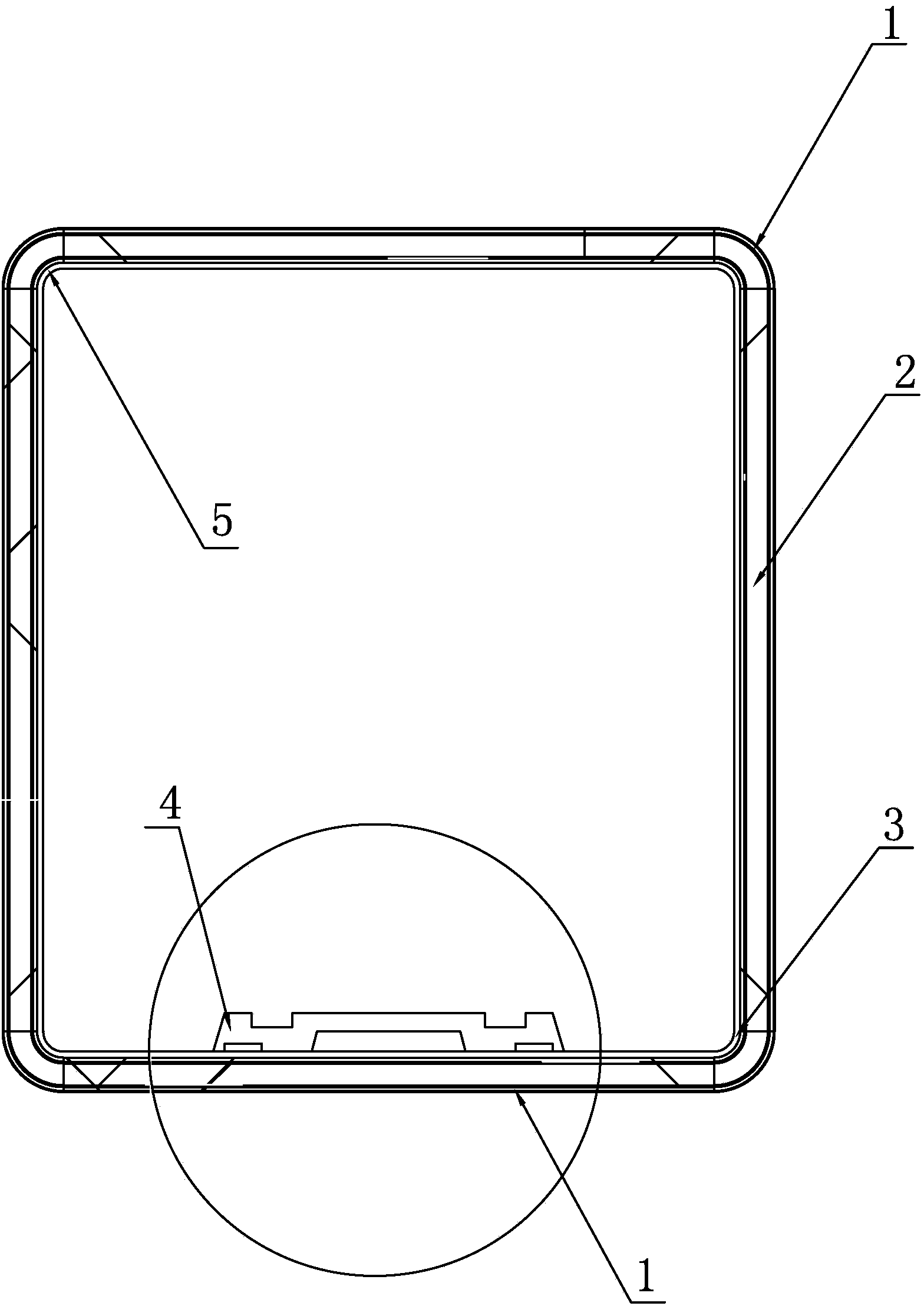

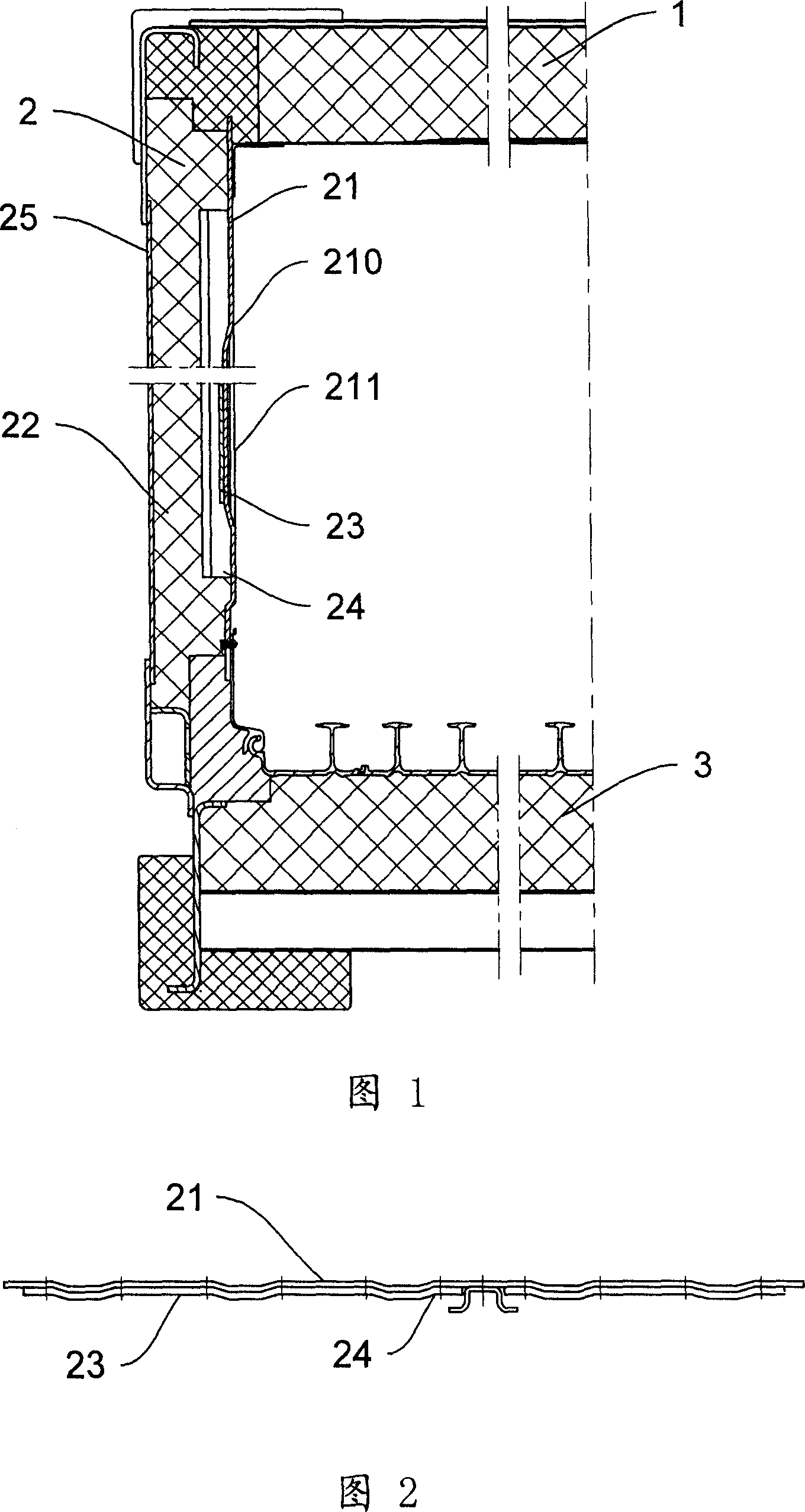

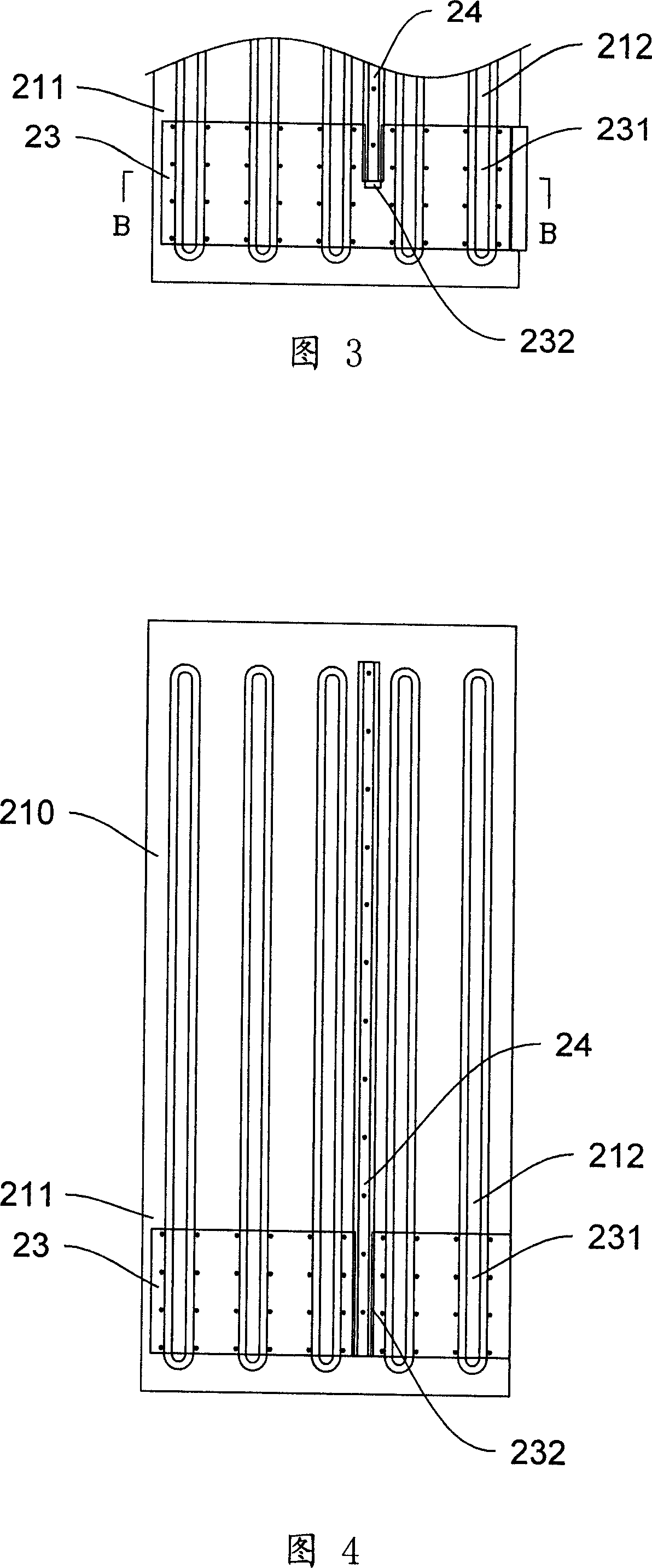

Waterproof structure for use in display device

ActiveUS20160192523A1Speed efficientExtended service lifeClosed casingsCasings with display/control unitsDisplay deviceEngineering

A waterproof structure for use in display device includes a back cover (100), a display module (200) and a waterproof member (300). The back cover (100) includes a peripheral part of back cover (110), a stop part (120) connected to the peripheral part of back cover (110), and a groove (130) defined between the peripheral part of back cover (110) and the stop part (120), wherein the height of the peripheral part of back cover (110) is greater than the height of the stop part (120). The display module (200) is disposed on the back cover (100). The waterproof member (300) is disposed between the display module (200) and the stop part (120). Accordingly, the speed of moisture permeating into the display device can be buffered so as to prolong the service life.

Owner:AVALUE TECH

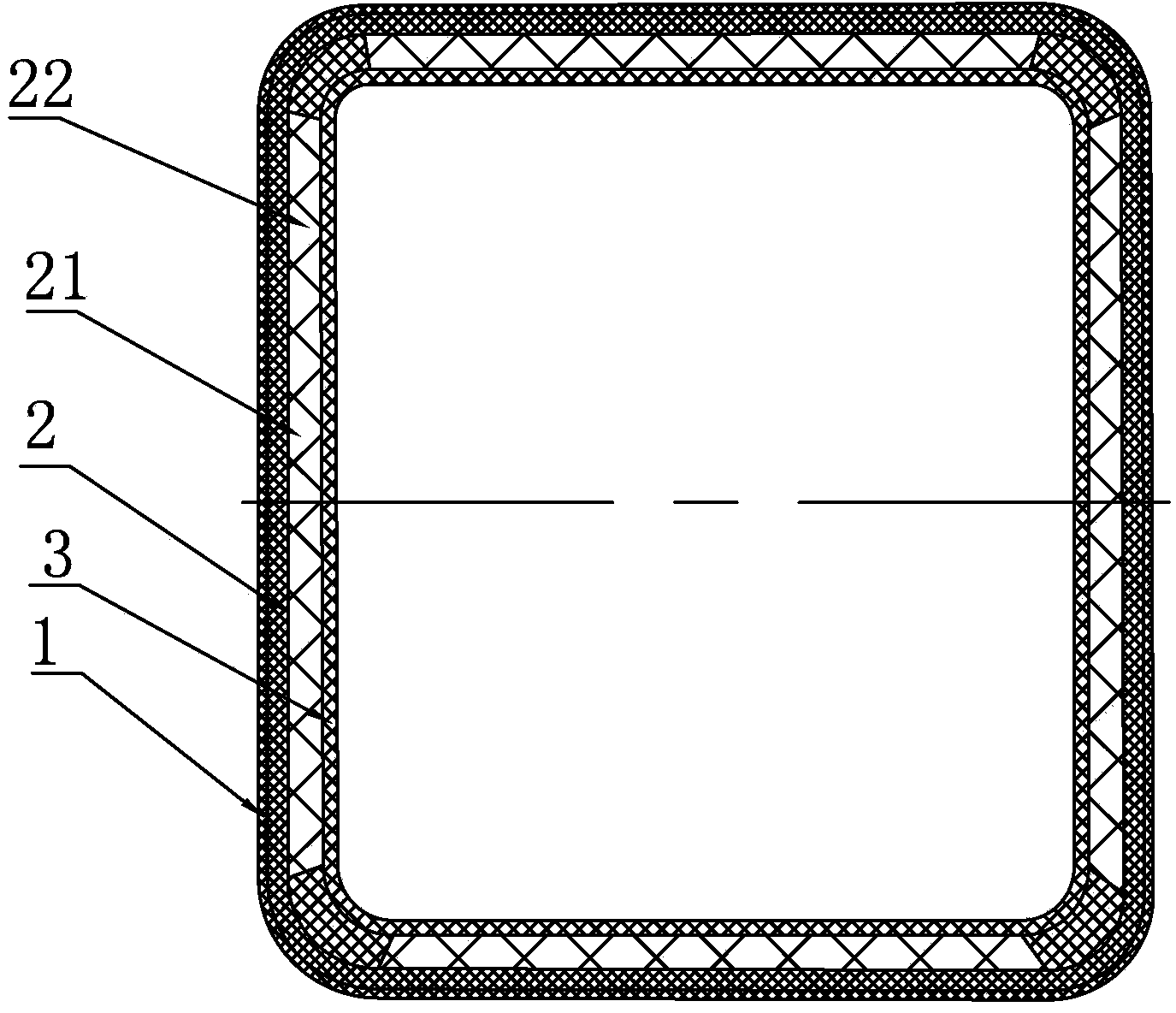

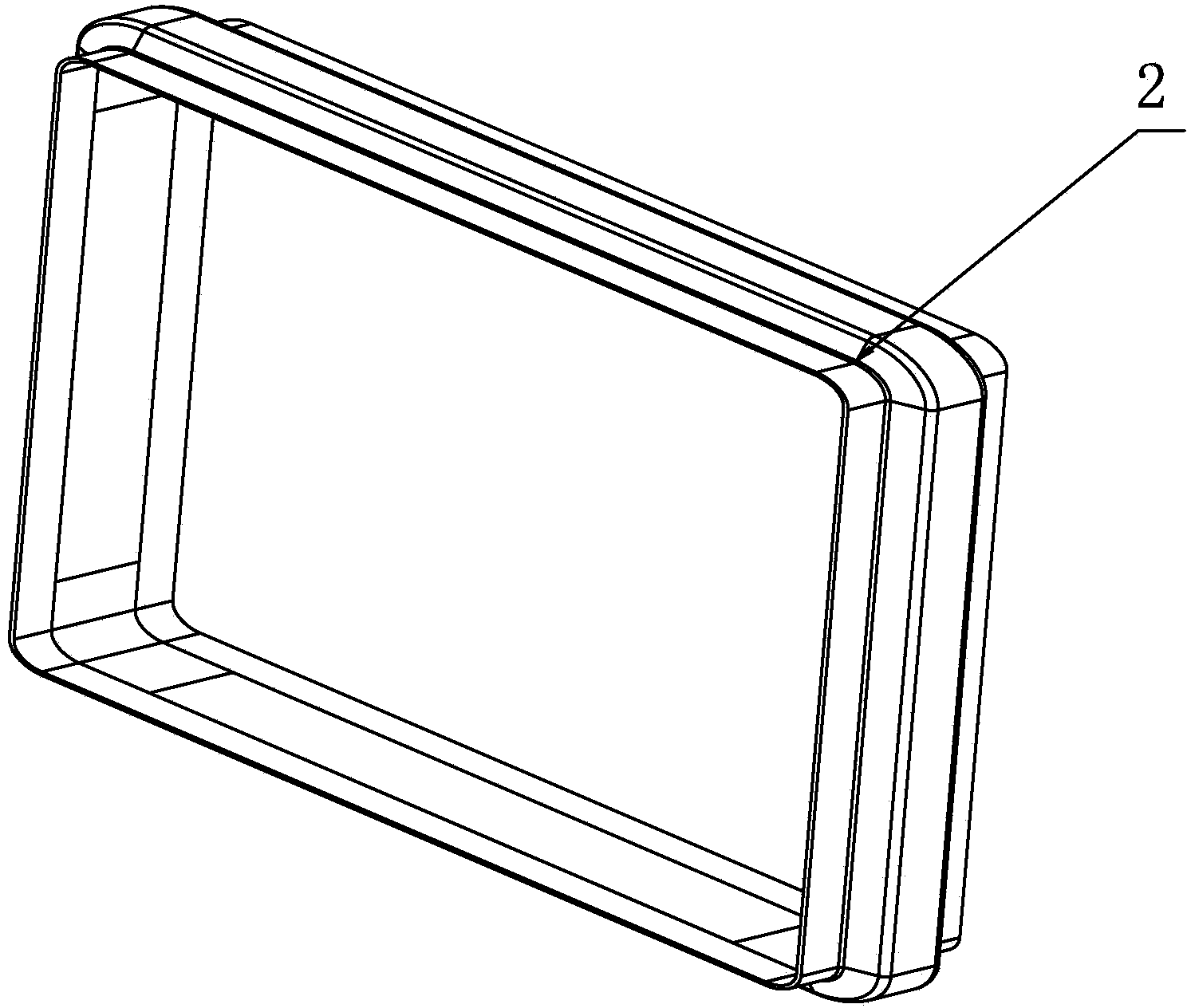

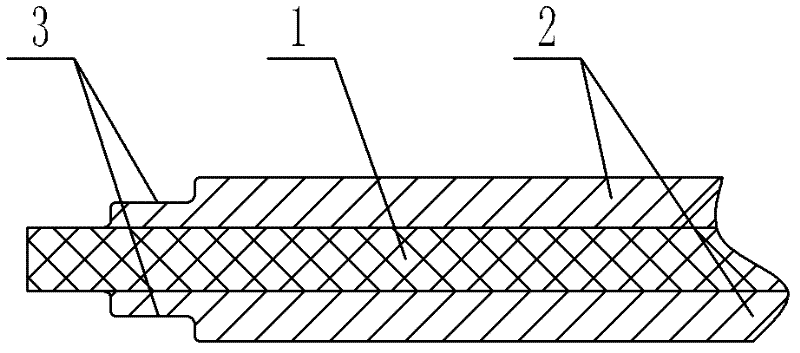

High-rigidity light launching box

The invention discloses a high-rigidity light launching box and relates to a launching box used for supporting, fixing, transporting and storing missiles. The high-rigidity light launching box is high in both circumferential rigidity and longitudinal rigidity and light and can provide large storage space for the missiles, and the stress on the corners of the launching box can be effectively diffused. The high-rigidity light launching box comprises an outer skin, an inner skin, longitudinal ribs and ring ribs evenly distributed between the outer skin and the inner skin. The ring ribs are connected with the outer skin and the inner skin through glue respectively, the ring ribs are installed on the inner skin in a sleeved mode, small rounded corners are adopted for the corners of the inner skin, the outer skin and the ring ribs, the space between the inner skin and the ring ribs is filled with a heat preserving layer, reinforcing blocks are arranged on the corners of the heat preserving layer, filling interfaces are arranged on the longitudinal ribs, a 35-degree laying layer is adopted for the inner skin, the longitudinal rib laying layers and the ring rib laying layers respectively comprise 0-degree laying layers and 90-degree laying layers, the proportion of the laying layers of the longitudinal ribs is as follows: n 0 degree: n 90 degrees= 2:1- 3:1, and the proportion of the laying layers of the ring ribs is as follows: n 90 degrees: n 0 degree= 2:1- 3:1.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

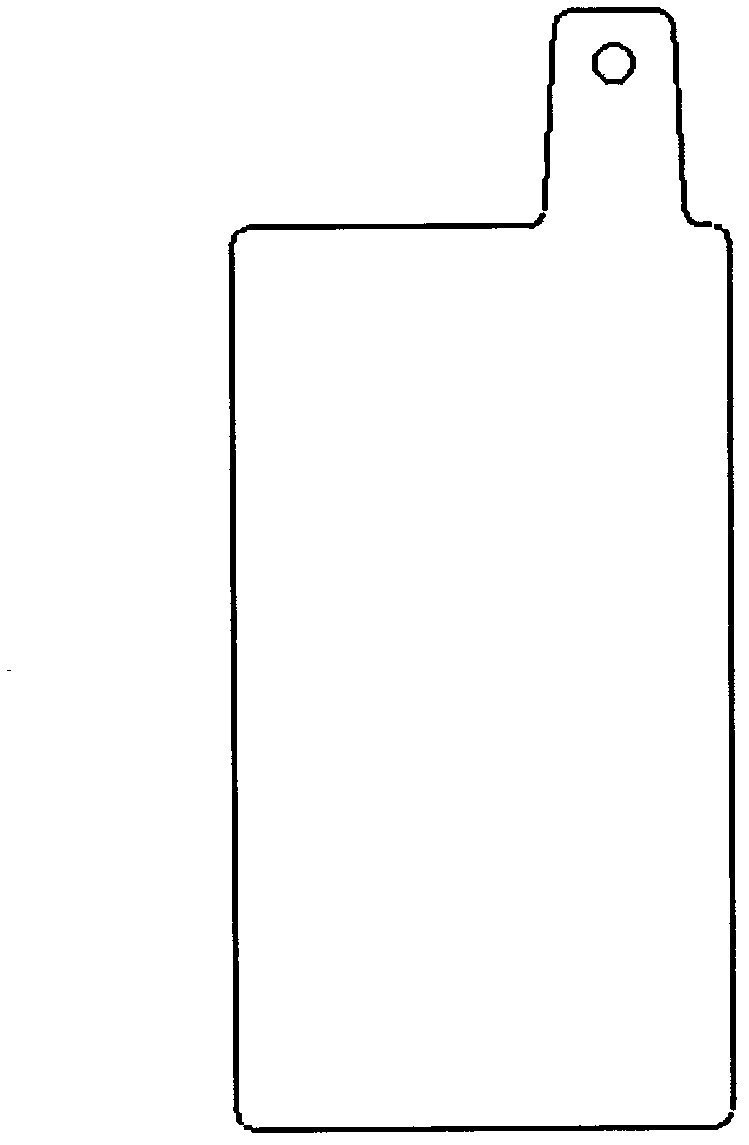

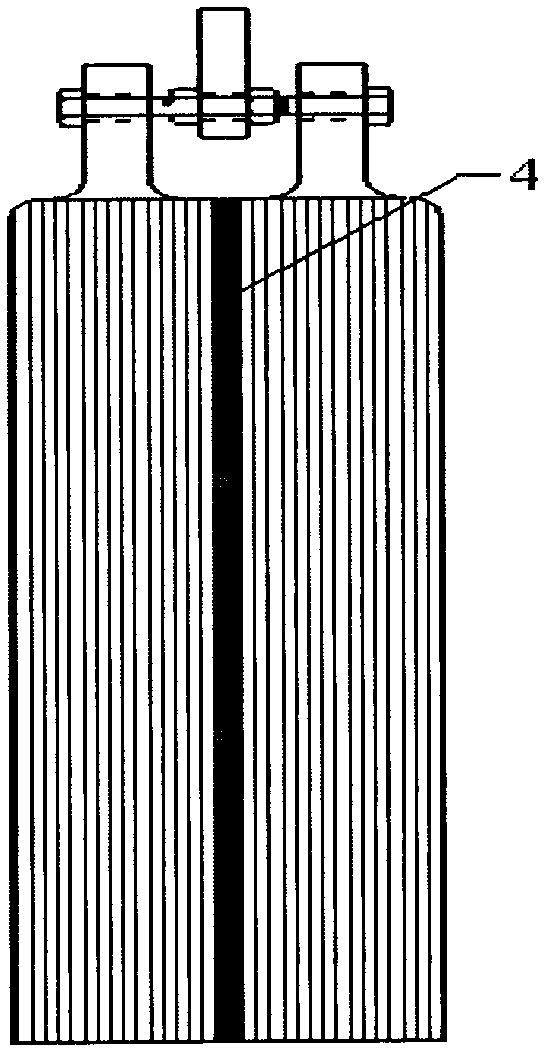

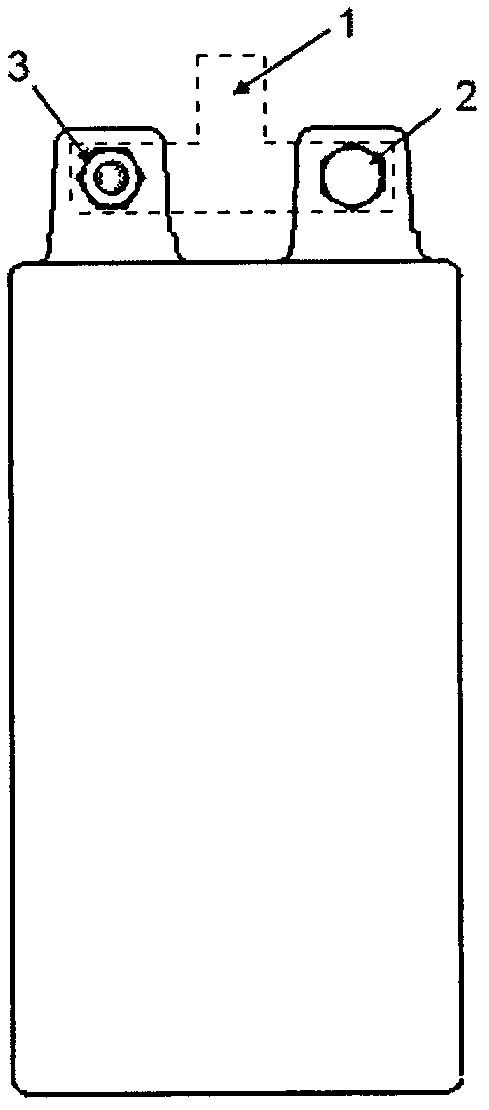

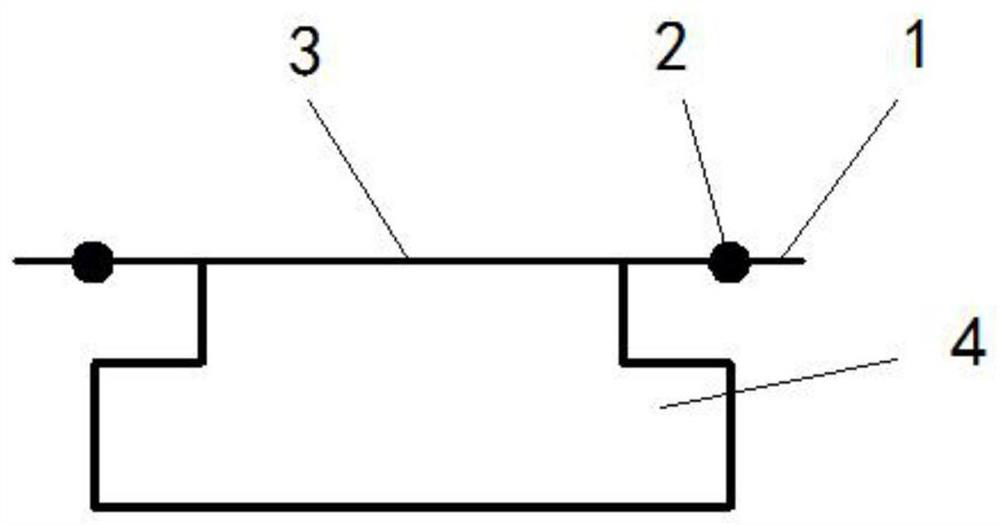

Lug bolted lithium ion battery

InactiveCN102306736AEasy to assembleExtended service lifeCell component detailsStress concentrationElectrical battery

The invention discloses a lug bolted lithium ion battery which comprises electrical cores and an outer housing; the electrical cores are arranged in an aluminum housing or a plastic outer housing; at least two electrical cores are stacked together, and a diaphragm is arranged between the two electrical cores; a bolting hole is arranged on a lug of each electrical core; a positive lug and a negative lug are respectively connected by a bolt and a nut, and a gasket penetrates through the bolt between the lugs; and a bus-bar electrode also penetrates through the gasket on the bolt between the lugs. The battery provided by the invention has the advantages that the electrical cores are simple to assemble, and problems of unstable welding and connecting way between the electrical cores and electrode of the existing high-capacity laminated lithium ion battery and complex technology are overcome, the problem of stress centralization of the lugs in the external layer caused by the excessive deflection of the lugs to one side when the lugs of the high-capacity laminated lithium ion battery are connected is solved, the production efficiency can be improved obviously through the connection way of the bolt, and the service life of the electrical cores is improved.

Owner:SHANDONG SACRED SUN POWER SOURCES

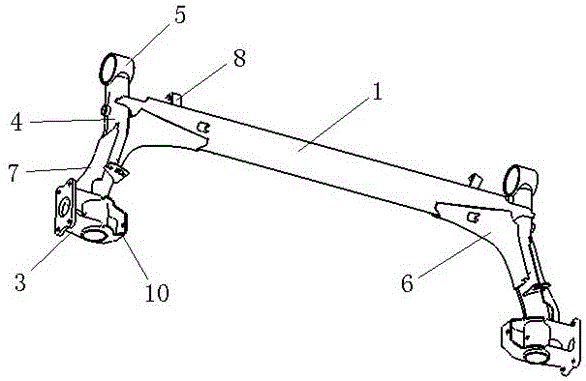

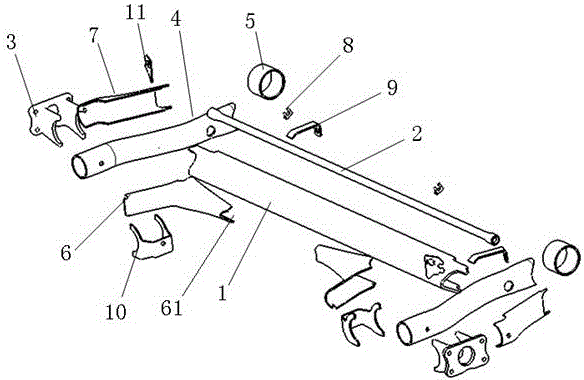

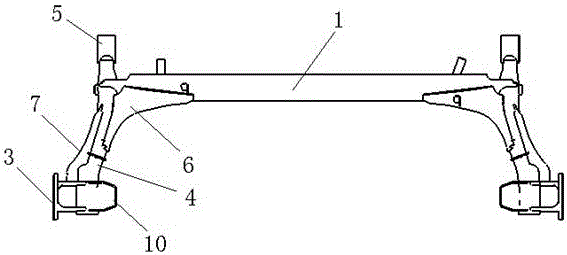

Rear torsion beam assembly of vehicle

InactiveCN105966187AReduce stress levelsAvoid breakingInterconnection systemsTrailing armStress level

The invention aims to provide a rear torsion beam assembly of a vehicle. The rear torsion beam assembly of the vehicle reduces structural stress level and is good in durability. The rear torsion beam assembly of the vehicle comprises a beam, a torsion rod, hub supports on the two sides and trailing arms. The front ends of the trailing arms are provided with bushing sleeves, and the rear ends of the trailing arms are fixedly welded to the hub supports on the corresponding sides. The two ends of both the beam and the torsion rod are fixedly welded to the trailing arms on the corresponding sides respectively. The key is that beam reinforcing plates with arc-shaped sections are welded to the lap joint parts of the beam and the trailing arms, the inner sides of the beam reinforcing plates adhere to the beam and the trailing arms respectively, the front ends of the beam reinforcing plates extend towards the middle of the beam along the beam, and the front ends of the beam reinforcing plates are provided with arc-shaped notches. The rear ends of the beam reinforcing plates extend in the front-end direction of the trailing arms along the trailing arms. The front ends of the beam reinforcing plates are provided with the arc-shaped notches. In the beam torsion process, the arc-shaped notches can effectively reduce the stress level at the position, and thus fracture and the like at the position can be avoided.

Owner:CHERY AUTOMOBILE CO LTD

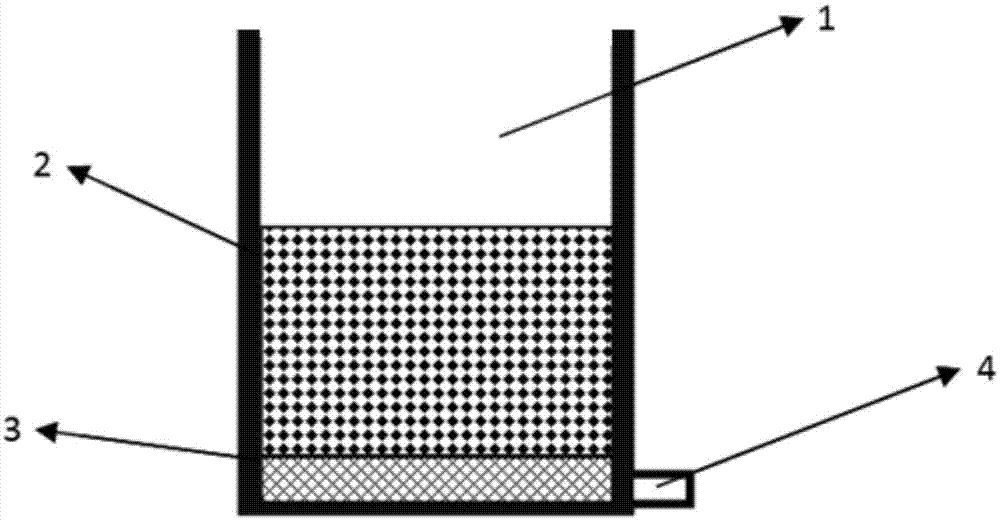

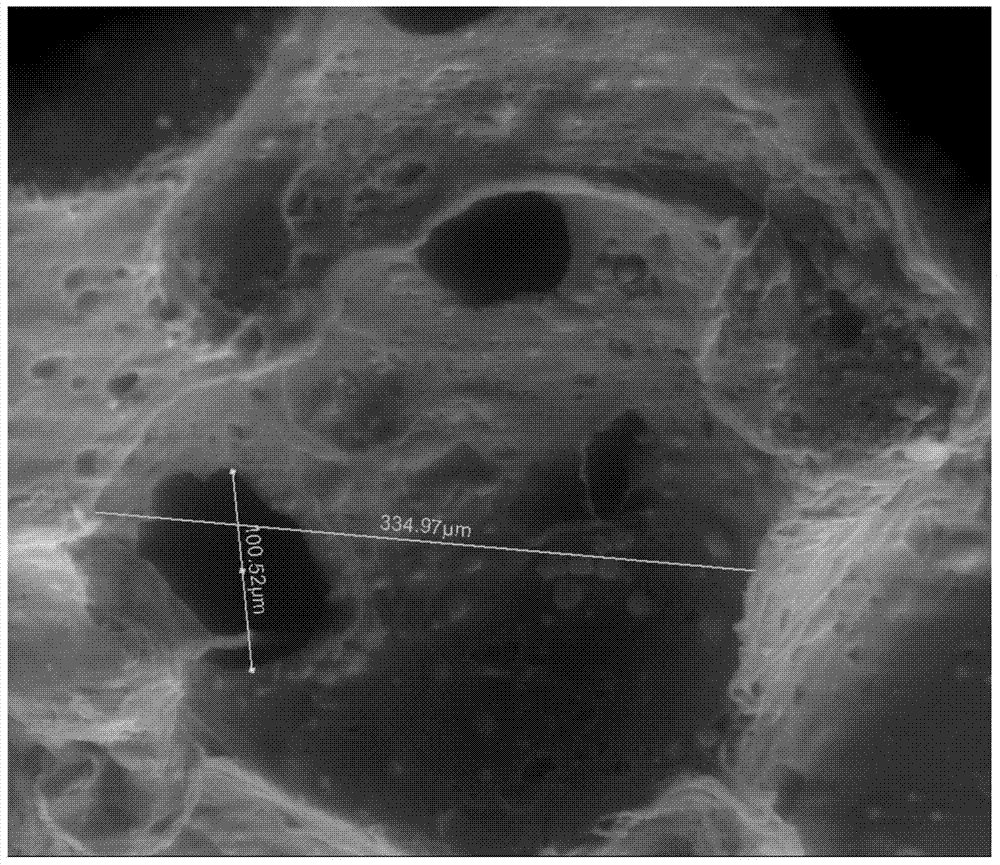

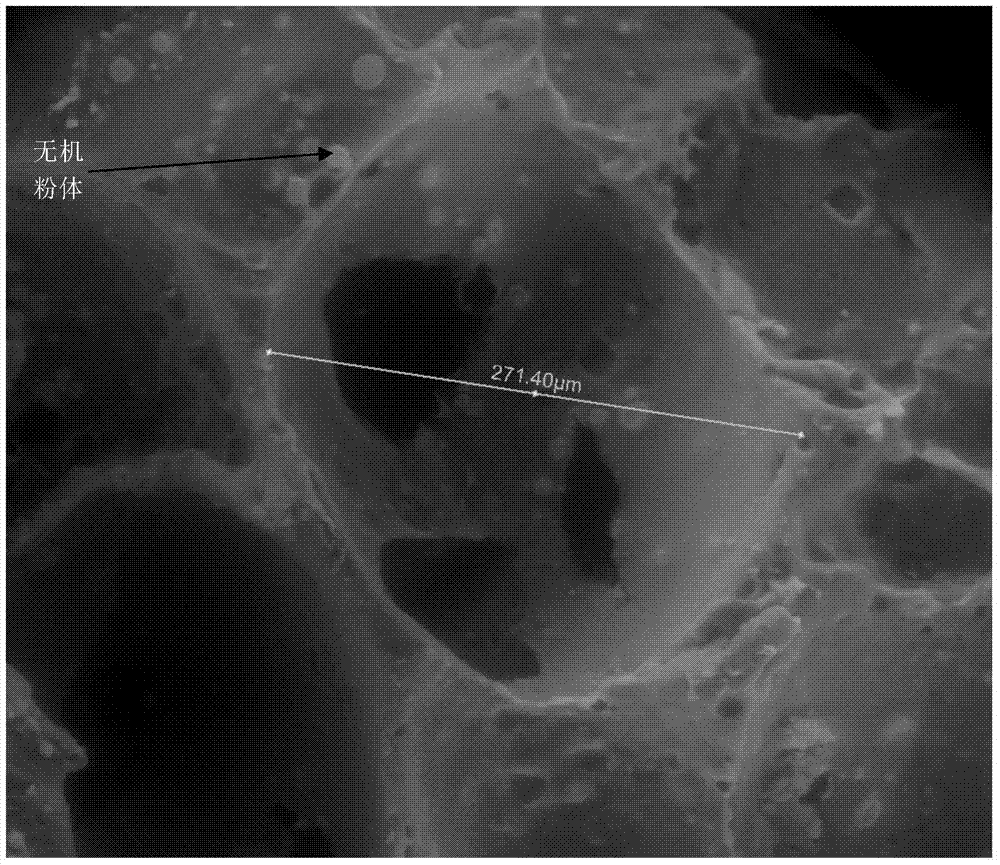

Modified polyvinyl alcohol hydrogel material, special die, preparation method and application

InactiveCN104708736AImprove biological activityImprove mechanical propertiesProsthesisStress concentrationEngineering plastic

The invention discloses a modified polyvinyl alcohol hydrogel material, a special die, a preparation method and application. The preparation method comprises the following steps: (1) preparing polyvinyl alcohol / bioactive calcium-phosphorus powder blended suspension I and polyvinyl alcohol / engineering plastic blended suspension II; (2) injecting the suspension I into the special die, vacuumizing at the gas outlet of the die until a pore-forming agent is right impregnated by the suspension I, adding the suspension II, and pressurizing the die to obtain a target material precursor I; (3) performing freezing treatment on the precursor I, performing unfreezing treatment at room temperature, and radiating with gamma rays to further form a target material precursor II; (4) dialyzing and washing the precursor II in de-ionized water for multiple times to obtain the target material. The obtained material has high biocompatibility and bioactivity, and can be applied to cartilage repair and replacement, the problem that an interface exists between a compacted layer and a porous layer is solved, and the problems of stress concentration and the like in a using process are solved.

Owner:SOUTH CHINA UNIV OF TECH

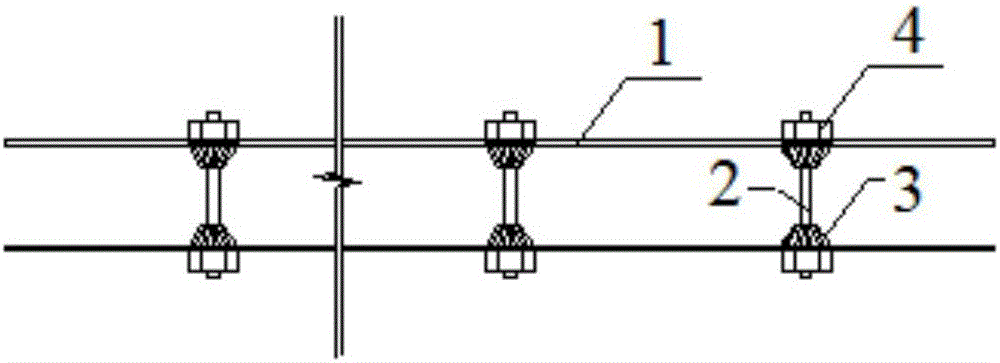

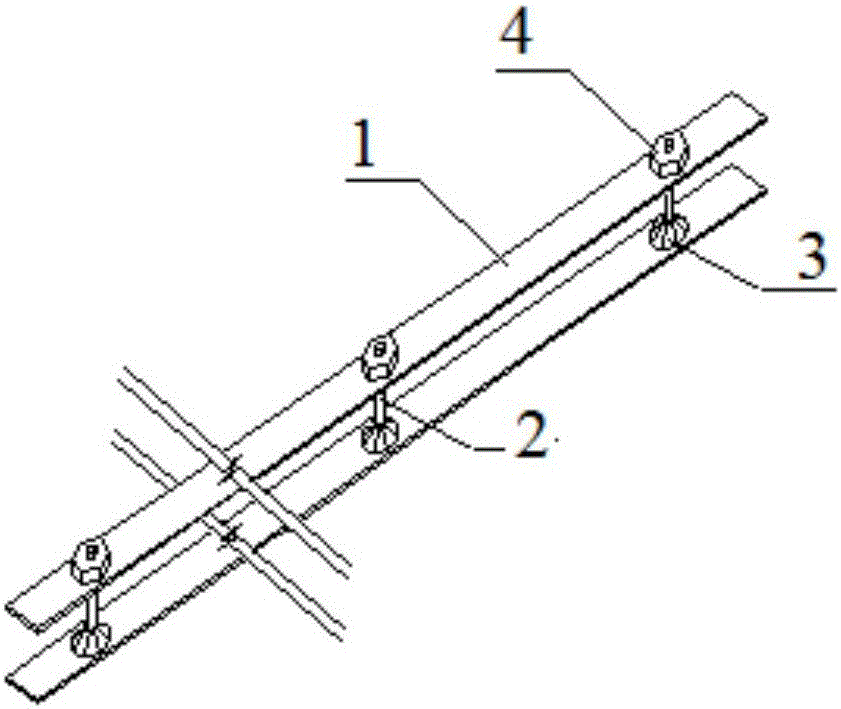

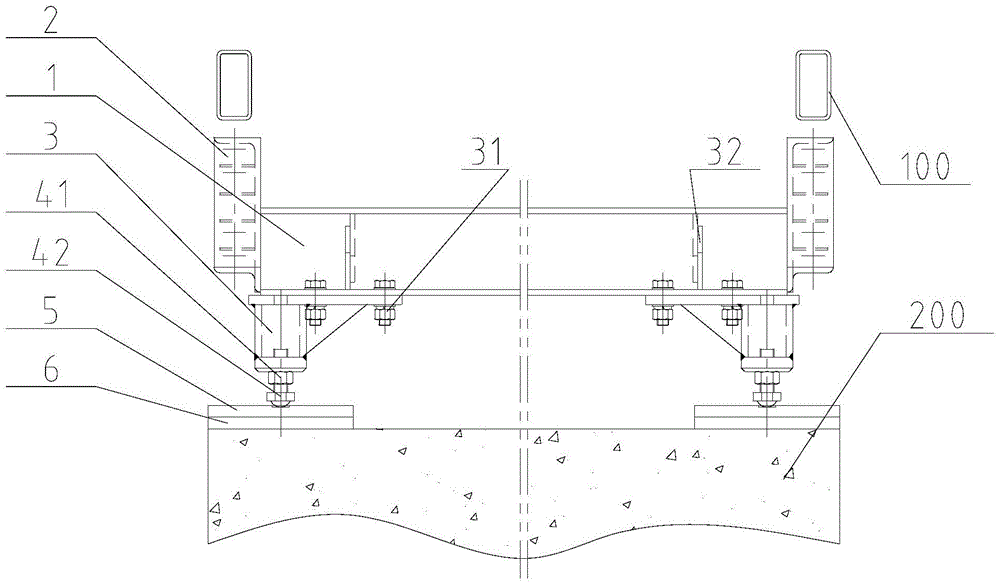

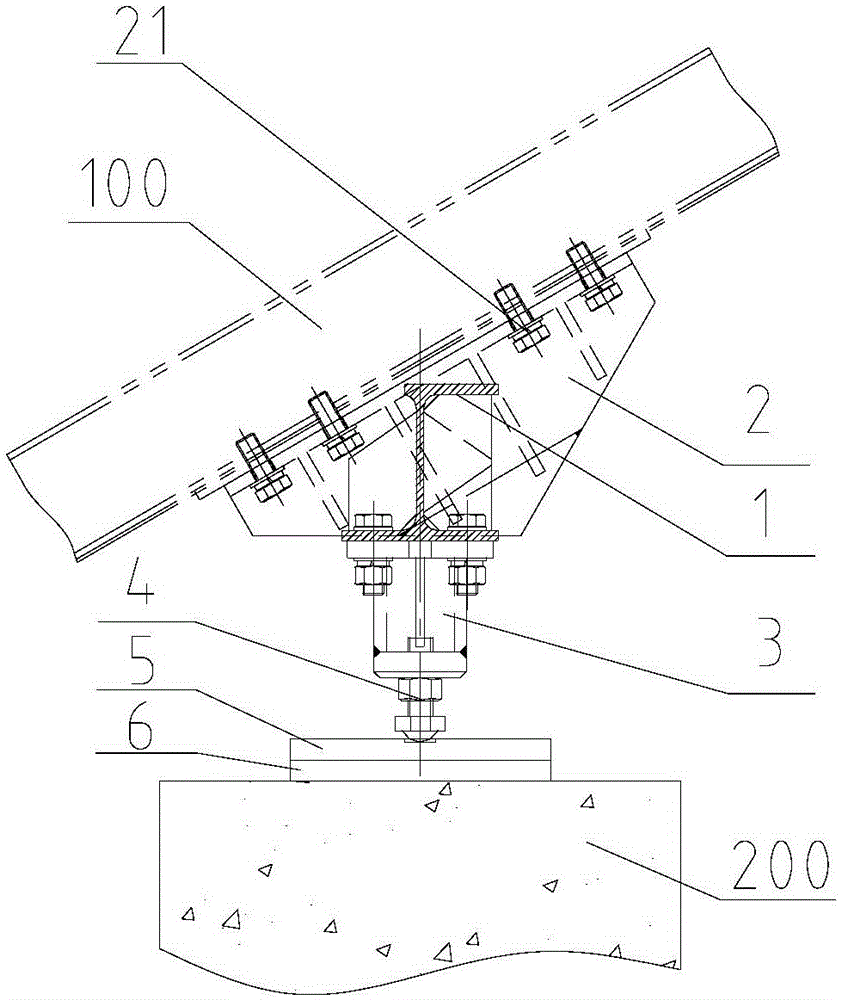

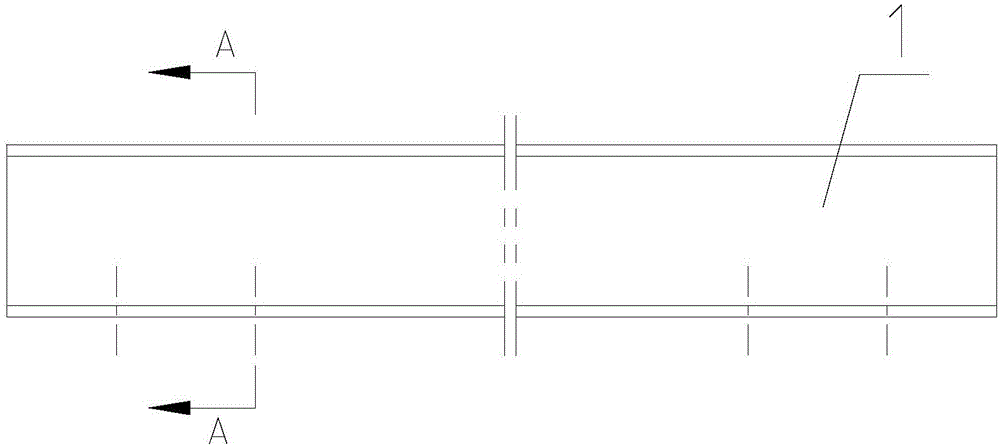

Intermediate support device of escalator truss

ActiveCN105110156ARealize position adjustmentSolve stress concentrationEscalatorsEngineeringRelative motion

The present invention discloses an intermediate support device of an escalator truss. The device comprises a cross beam of which the length extends along a width direction of the escalator truss, connection supports fixed on two ends of a length direction of the cross beam and used for supporting the escalator truss, a pair of support seats installed on a bottom face of the cross beam, and cushion blocks for placement of the support seats, wherein the connection supports are connected with the escalator truss through connection members, the support seats are arranged in a spaced manner along the length direction of the cross beam and can perform relative motion and adjustment so as to be connected onto the bottom face of the cross beam in an approaching or parting manner, and each support seat is connected and fixed with the bottom face of the cross beam through a fastening member. Width adjustment of the intermediate support device is realized, the problem of excessive concentration of stress is solved, and the device is applicable to an installation environment where civil engineering intermediate supports are small in width.

Owner:SJEC CORP

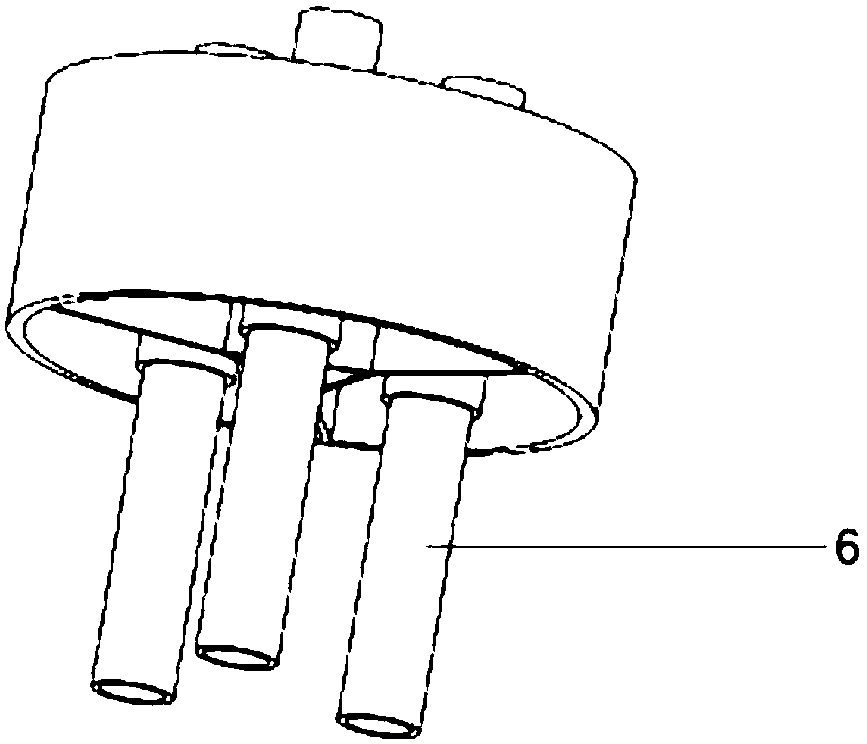

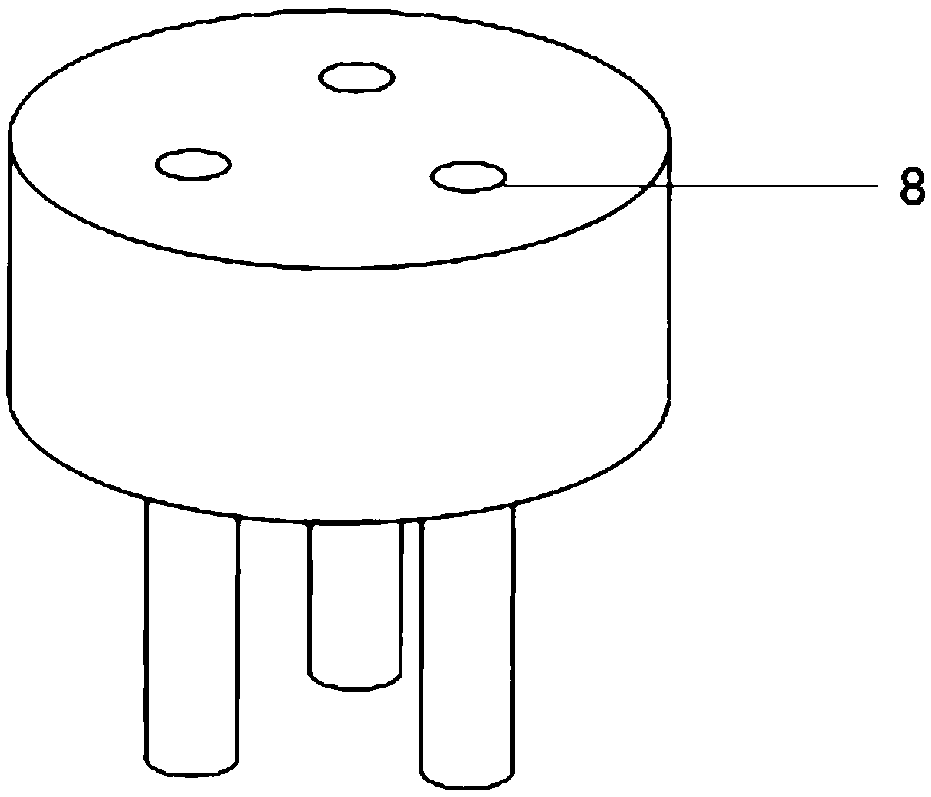

Long and short pile bucket foundation suitable for deep water complex sea areas and construction method of bucket foundation

PendingCN109440805AImprove bearing capacityImprove stabilityFoundation engineeringElectricityOffshore wind power

The invention belongs to the technical field of offshore wind power foundations, and discloses a long and short pile bucket foundation suitable for deep water complex sea areas and a construction method of the bucket foundation. The bucket foundation comprises a bucket structure composed of a bucket top cover and a bucket apron board. A plurality of side tanks are arranged in the bucket structure.A plurality of short piles are evenly and annularly distributed in the bucket structure, and the short piles are arranged in the side tanks. The top ends of the short piles are flush with the buckettop cover, holes are formed in the portions, corresponding to top openings of the short piles, of the bucket top cover, and the bottom ends of the short piles are basically flush with the bucket apronboard. A long pile is embedded in each short pipe, the tops of the long piles of the bucket foundation arranged in place are cut off to be flush with the bucket top cover, and the top ends of the long piles and the top ends of the short piles are subjected to cover sealing treatment together. According to the construction method, the long piles are driven into the earth and then the bucket structure is sunk or the bucket structure is sunk and then the long piles are driven into the earth. The bucket foundation has good anti-overturning performance, skid resistance and stability, high in bearing capacity and precise to construct and install, the installation stability and safety of the bucket foundation in the deep water complex sea areas are improved, and the application range of bucket foundation installation is expanded.

Owner:TIANJIN UNIV

Beam test piece forming device and forming method for asphalt mixture

PendingCN110987569AAccurate test verificationHeight adjustablePreparing sample for investigationStress concentrationRoad engineering

The invention, which belongs to the technical field of road engineering asphalt mixtures, discloses a beam test piece forming device and forming method for an asphalt mixture. According to the invention, the structural design is adopted and the forming device can form beam test pieces with different heights and different widths, and cutting is not needed, so that problems that in the forming and manufacturing process of the asphalt mixture small beam test piece in the existing experiment, stress concentration is caused by cutting a track plate, vibration rolling compaction of pavement construction cannot be completely simulated, and the test piece with the large thickness is difficult to form are solved and the accuracy of asphalt mixture low-temperature cracking performance evaluation and fatigue performance verification tests is improved; and meanwhile, the operation is convenient, and the accuracy and repeatability of a test result are improved.

Owner:CHANGAN UNIV

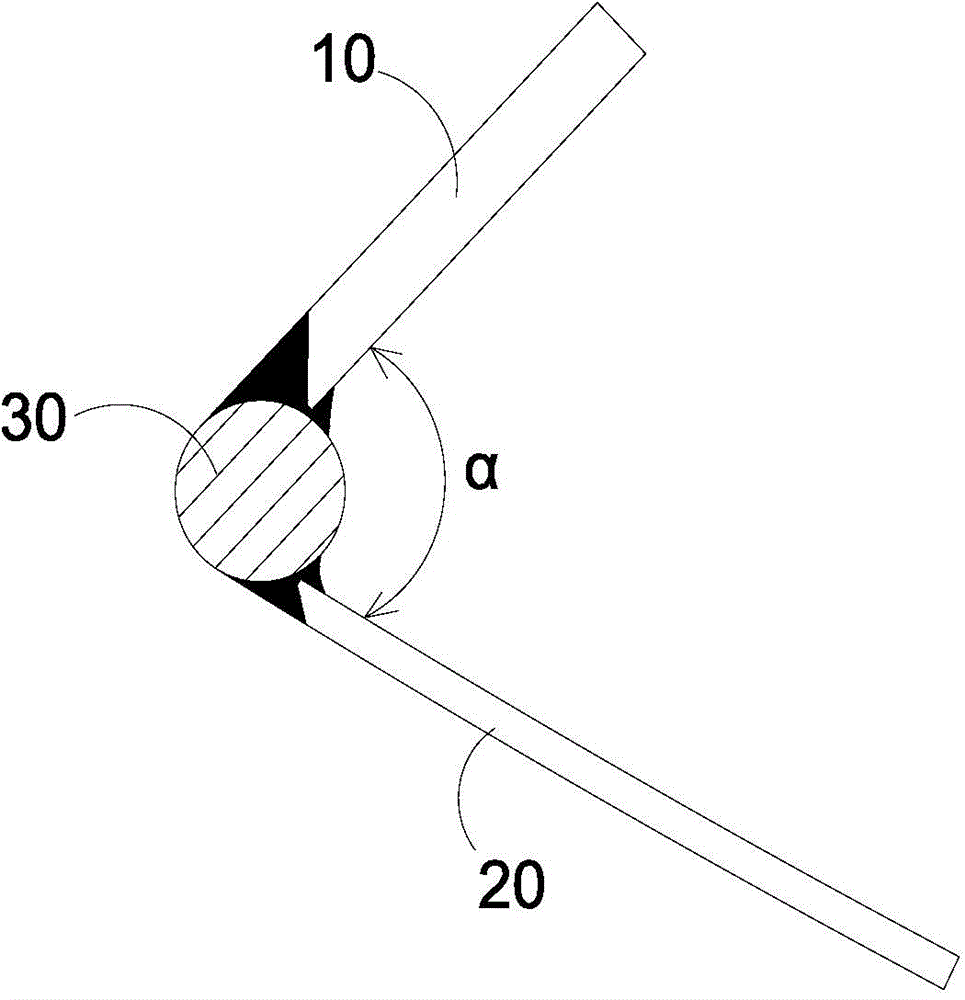

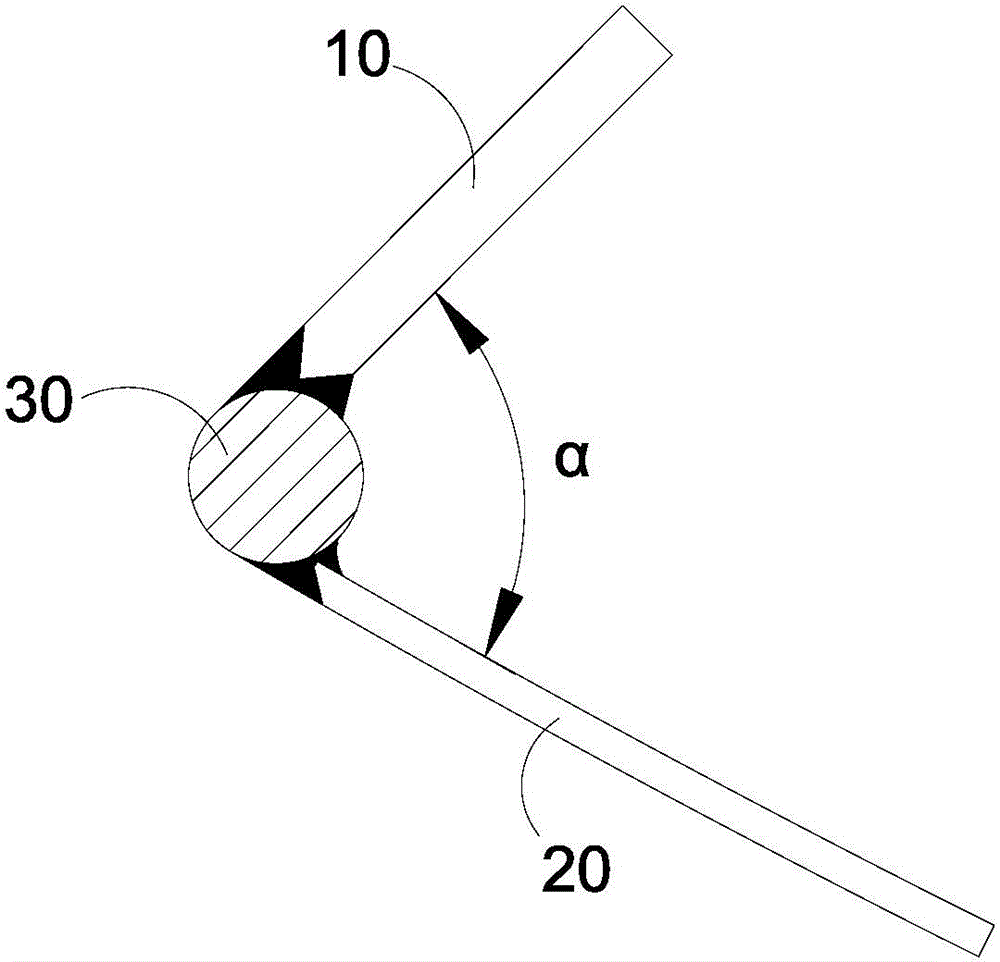

Steel plate butt welding method

ActiveCN104801821AConvenient welding operationReduce welding difficultyArc welding apparatusWelding/soldering/cutting articlesButt weldingSheet steel

The invention discloses a steel plate butt welding method for butt welding of a first steel plate with certain thickness and a second steel plate with certain thickness. The method comprises the steps of transition structure providing; chamfering: chamfering the ends of the first steel plate and the second steel plate to be welded to form slopes; location: locating the first steel plate, the second steel plate and the transition structure to enable a required angle to be formed between the first steel plate and the second steel plate and enable the transition structure to be located between the first steel plate and the second steel plate; first steel plate welding: welding the first steel plate and the transition structure; second steel plate welding: welding the second steel plate and the transition structure. According to the method, the welding is simple to perform, the quality is good, and the method is applicable to butt welding among small-angle steel plates.

Owner:YANTAI RAFFLES SHIPYARD +3

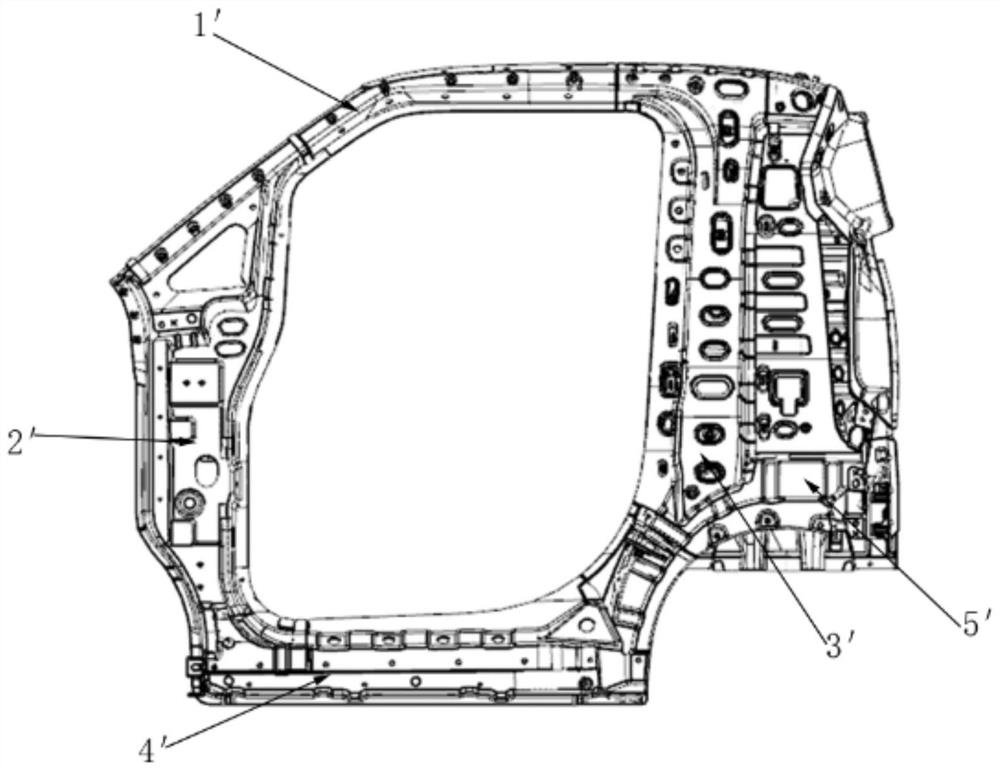

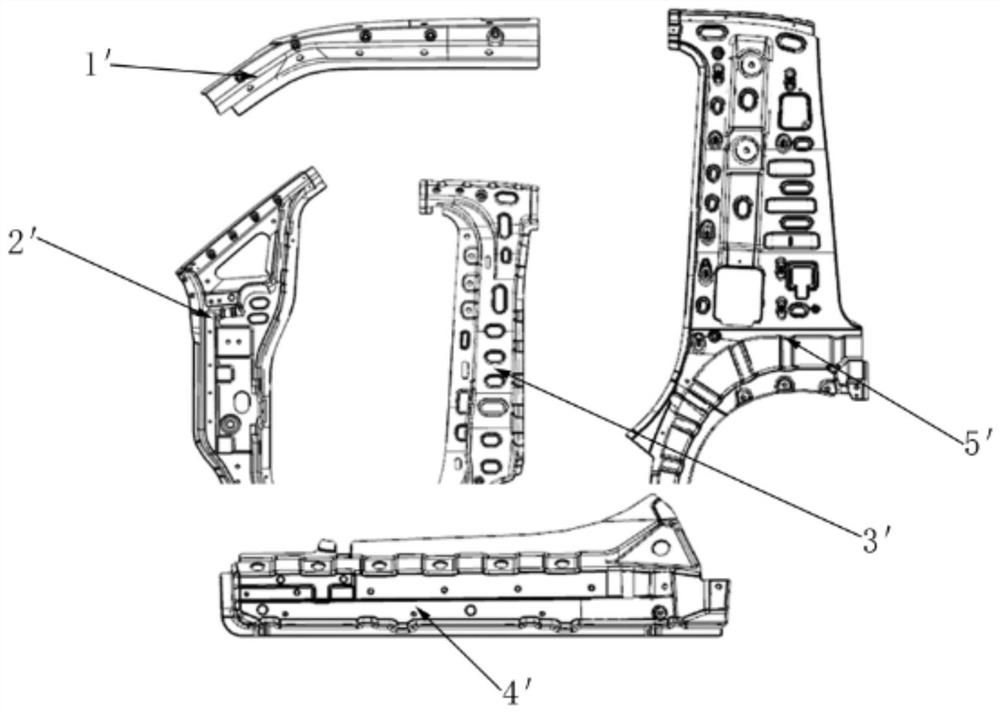

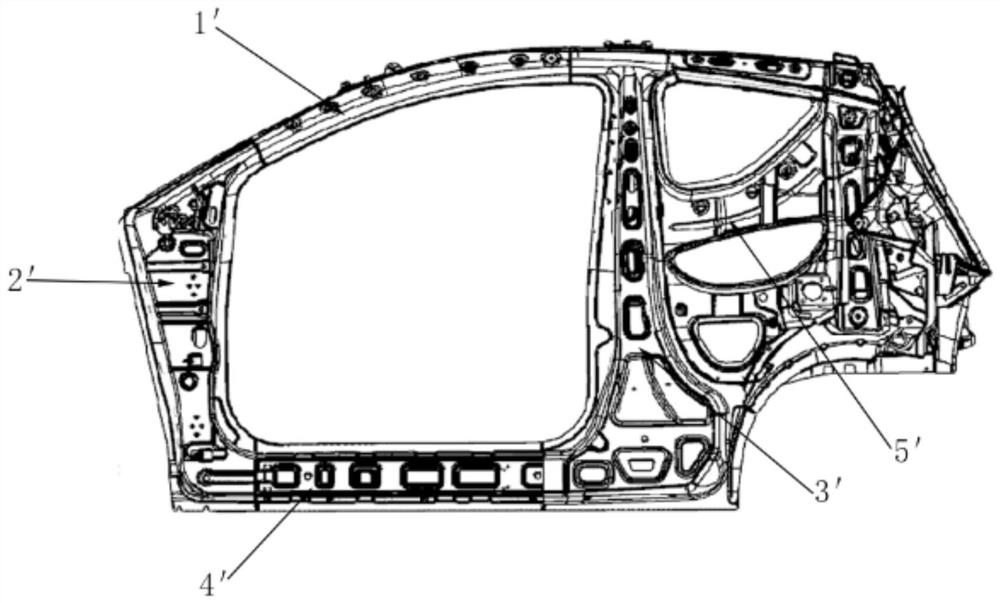

Door ring reinforcing frame assembly of two-door electric vehicle

ActiveCN113147904AIncrease stiffnessHigh strengthSuperstructure subunitsSuperstructure connectionsElectrical batteryElectric cars

The invention discloses a door ring reinforcing frame assembly of a two-door electric vehicle, which comprises an A column assembly, a rear side wall inner plate assembly, a doorsill assembly and a B column reinforcing plate, the rear end of the top of the A column assembly is fixed to the front end of the top of the rear side wall inner plate assembly, and the top of the B column reinforcing plate is fixed to the rear side wall inner plate assembly in a two-layer mode. The front side and the rear side of the B column reinforcing plate are fixed to the front portion of the rear side wall inner plate assembly in a two-layer mode, the lower end of the B column reinforcing plate is fixedly connected with the doorsill assembly, and the lower portion of the front end of the rear side wall inner plate assembly is detachably fixed to the upper portion of the rear end of the doorsill assembly. The front end of the doorsill assembly is fixedly connected with the bottom of the A column assembly. The door ring reinforcing frame assembly of the two-door electric vehicle is simple in structure, the B column is reinforced, the side collision and column collision performance is improved, the requirement for the mounting rigidity of the vehicle door is met, the problem of stress concentration of the door frame is solved, the risk of welding spot cracking is reduced, the cost is reduced, and the safety of passengers and batteries is protected.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Refrigerated container possessing anti collision board

InactiveCN101092204ASimple structureImprove performance against damaging external forcesLarge containersTank wagonsStress concentrationEngineering

The invention relates to refrigerated container with crash proof board. It includes inner side plate, reinforcing bar, and crash proof board. The port of the crash proof board is matched with the lower part of the reinforcing bar by which the reinforcing bar can be fixed on the inner side plate to increase its strength and rigidity, effectively offset stress concentration caused by setting crash proof board, which can increase destructive external force resistance for whole refrigerated container, make processing technology simple.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

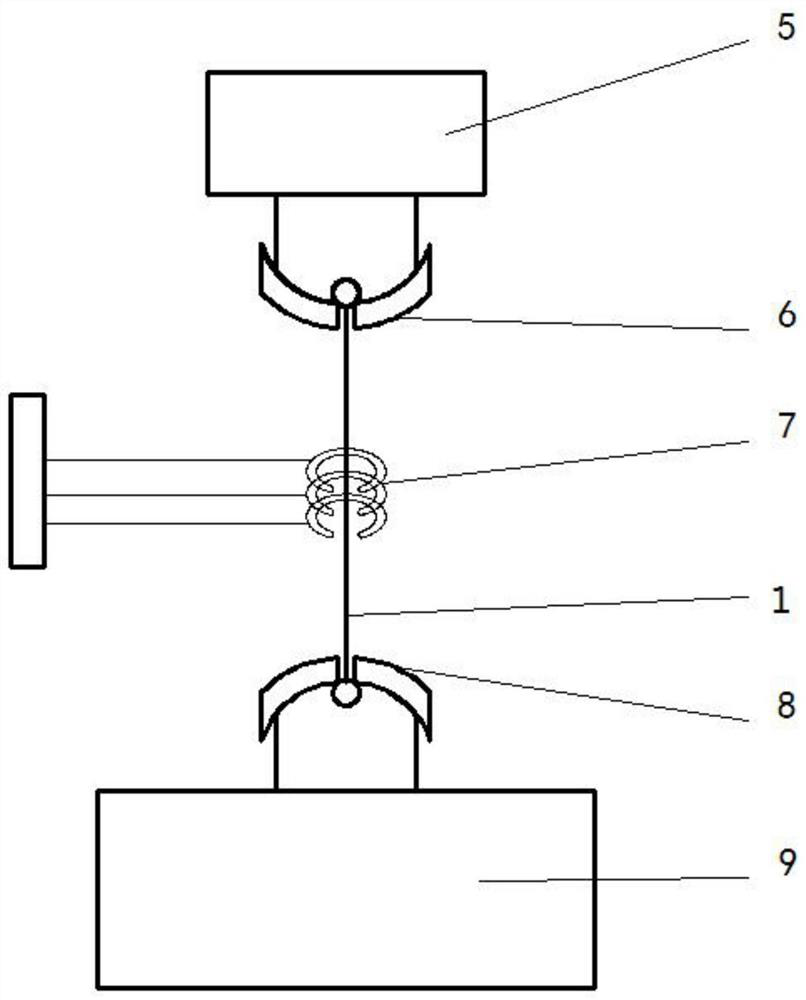

Fiber monofilament high-temperature tensile property testing method and device

ActiveCN112540007AHeating fastImprove temperature uniformityAuxillary controllers with auxillary heating devicesMaterial strength using tensile/compressive forcesStructural engineeringTensile testing

The invention discloses a method and a device for testing the high-temperature tensile property of a fiber monofilament, and solves the problem that the existing method cannot accurately measure the high-temperature tensile property of an alumina fiber monofilament. The fiber monofilament high-temperature tensile property testing device comprises a tensile testing machine testing device and a high-temperature heating device, wherein the tensile testing machine testing device comprises a sensor and a sample mounting device, the sample mounting device comprises an upper mounting end and a lowermounting end, and the mounting surfaces of the upper mounting end and the lower mounting end are both in a symmetrical circular arc shape. The method for testing the high-temperature tensile propertyof the fiber monofilament greatly improves the success rate and accuracy of testing.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Construction method for repairing reinforced concrete wall

ActiveCN108915292ASolve stress concentrationRaise early temperatureBuilding repairsCoatingsRebarRepair material

Provided is a construction method for repairing a reinforced concrete wall. An interface bonding agent is sprayed to a damaged concrete surface, and standing is carried out for 5-8 minutes after evenspraying. The interface bonding agent is composed of, by weight, 100 parts of ethyl acrylate, 5-10 parts of dodecyl alcohol ester, 2-6 parts of 2-(3, 4-cyclohexene oxide) ethyl trimethoxysilane, and 2-4 parts of polyether amine. According to the construction method for repairing the reinforced concrete wall, repairing materials added with antifreeze agents can increase the early temperature of concrete by accelerating the hydration process and heat releasing, the strength and durability of the concrete are improved, cracks and fractures are reduced, the repair materials can be operated at thelow temperature, the hardening can be quickly completed and hydration reaction is sufficient, and damaged concrete parts are effectively filled.

Owner:上海常浦建筑工程有限公司

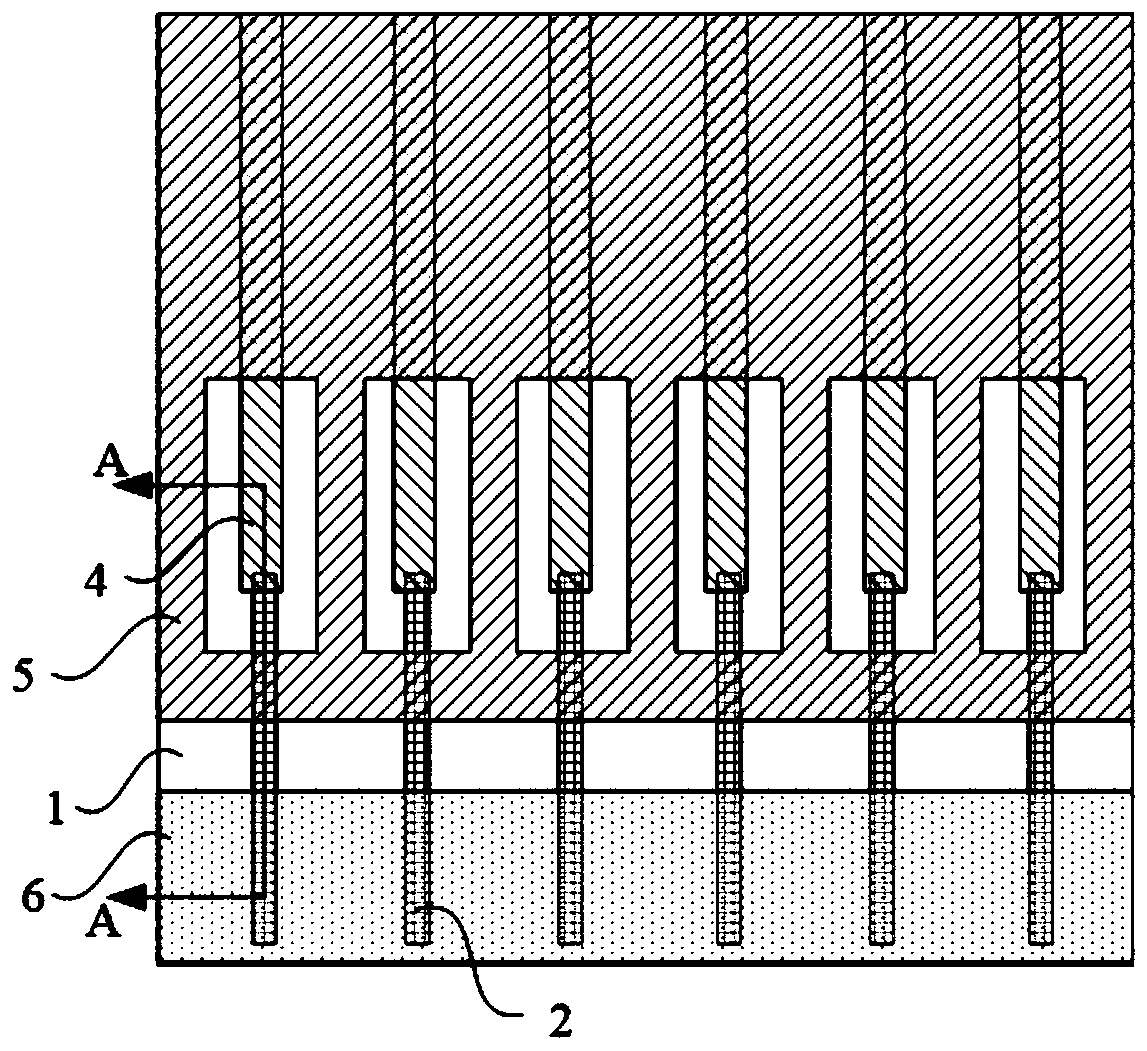

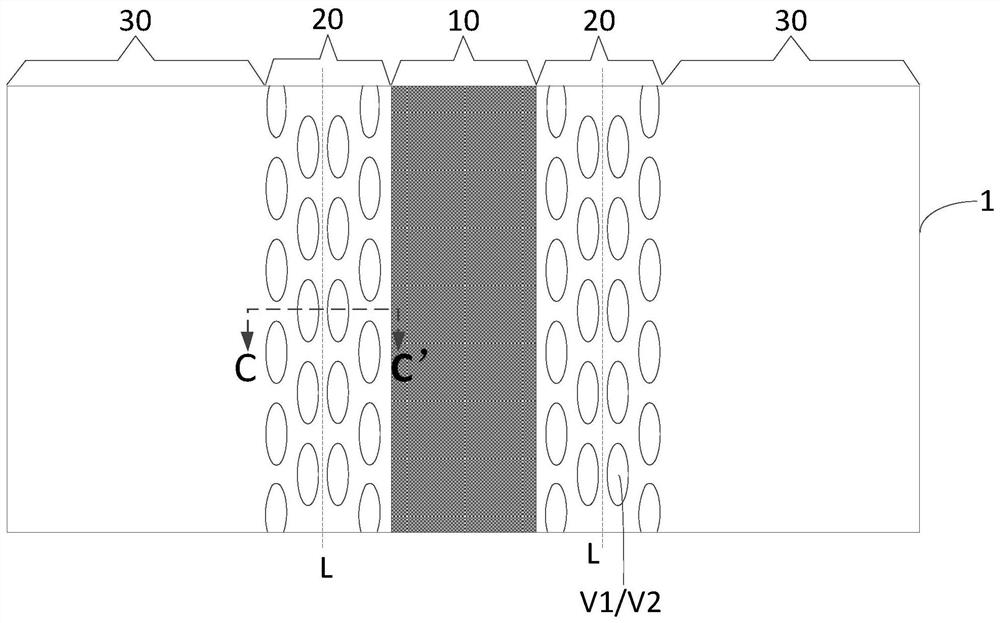

Flexible array substrate, preparation method thereof and flexible display panel

PendingCN111341824ASolve stress concentrationAvoid stress concentrationSolid-state devicesIdentification meansEngineeringFlexible display

The invention provides a flexible array substrate, a preparation method thereof and a flexible display panel, belongs to the technical field of display, and can at least partially solve the problem ofstress concentration caused by the fact that a long-strip-shaped groove is formed by over etching in the preparation process of an existing flexible array substrate. The flexible array substrate provided by the invention comprises a flexible substrate, a plurality of first wires located on the flexible substrate, a first insulating layer, a plurality of second wires and a second insulating layer.The second insulating layer comprises a plurality of first parts and second parts, each second part and the two adjacent first parts connected with the second part form a protection structure surrounding the corresponding second wire, and a first gap is formed between each second wire surrounded by the protection structure and the corresponding second part. One of every two adjacent second wiresis surrounded by one protection structure, or all the second wires are surrounded by the protection structures, and the positions of the first gaps corresponding to the adjacent second wires in a first direction are different.

Owner:BOE TECH GRP CO LTD +1

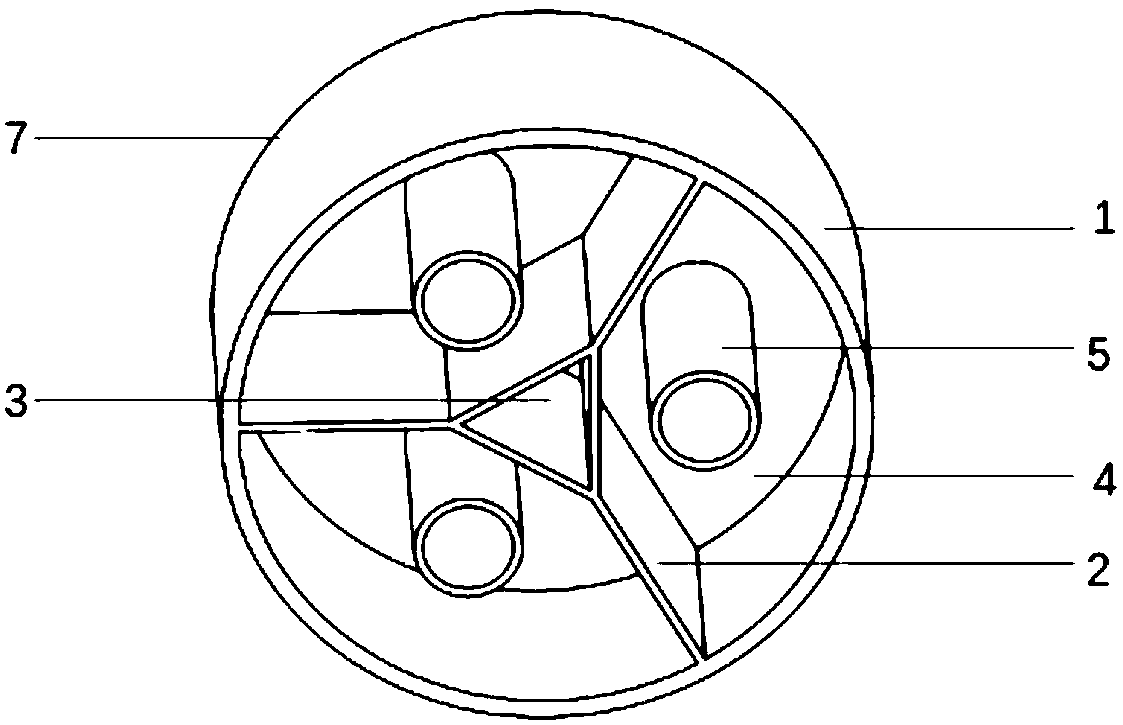

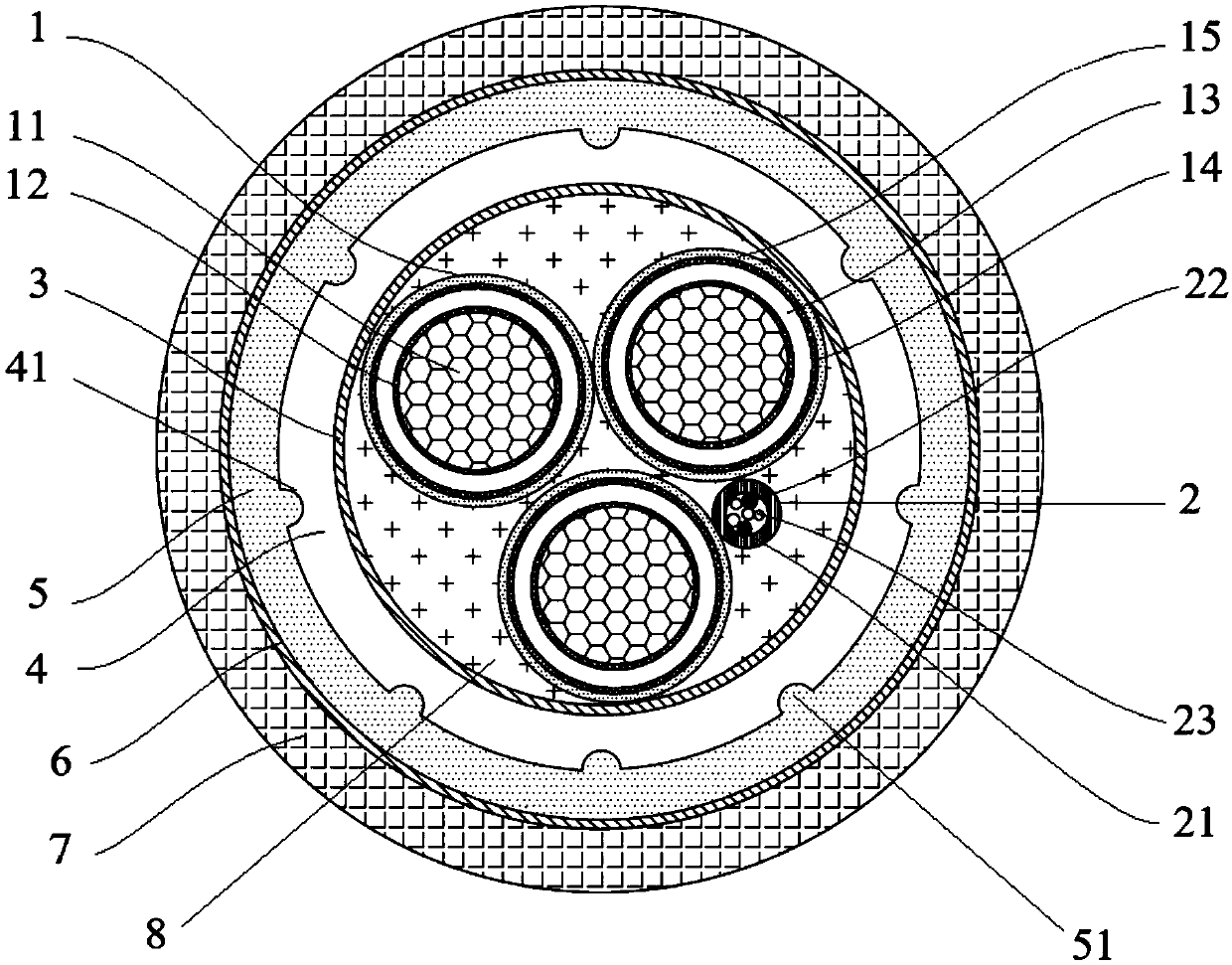

Manufacturing process of medium-voltage fireproof cable for intelligent early warning communication

InactiveCN109524172APlay a role in communicationEnsure normal communicationInsulating conductors/cablesCopper conductorElectric power transmission

The invention discloses a manufacturing process of a medium-voltage fireproof cable for intelligent early warning communication. The medium-voltage fireproof cable for intelligent early warning communication comprises a power transmission unit and an optical transmission unit, and the power transmission unit is formed by a copper conductor, a conductor shielding layer, an insulating layer and an insulating shielding layer which coats the outer surface of the copper conductor from inside to outside, and a metal shielding layer coating the outer surface of the insulating shielding layer. The power transmission unit and the optical transmission unit are wrapped by a wrapping tape to form a first winding layer, the outer surface of the first winding layer is coated with an oxygen barrier layer, and the outer surface of the oxygen barrier layer is coated with a refractory layer. The outer surface of the refractory layer is coated with a second winding layer, and an outer sheath is extrudedon the outer surface of the second winding layer. The prepared cable has good heat insulation and flame retardant performance and is used for a distributed optical fiber temperature measuring system to achieve the purpose of timely detecting a disaster and emitting an early warning in the early stage of fire, and a time guarantee is provided for escape and disaster relief.

Owner:JIANGSU HENGTONG POWER CABLE

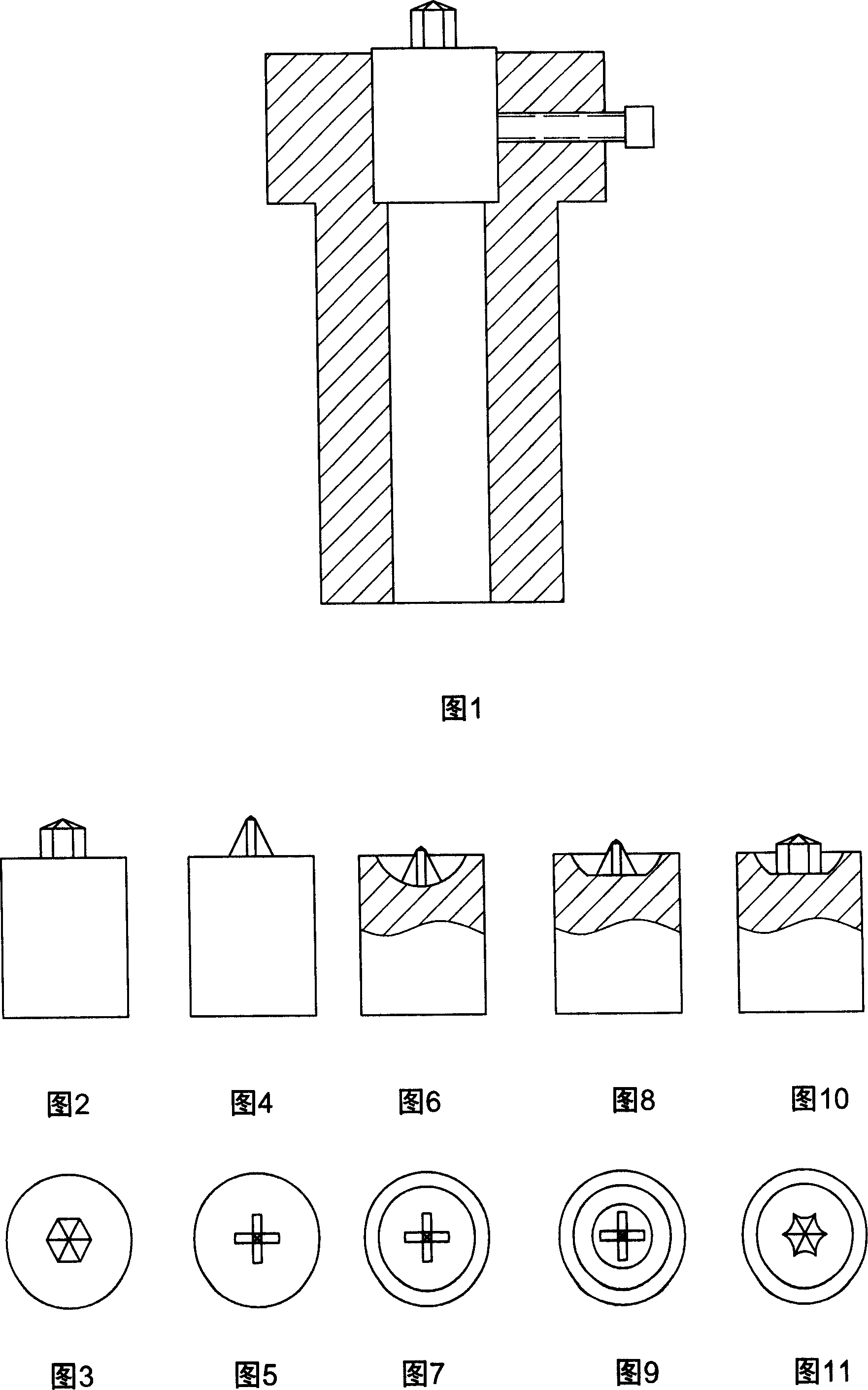

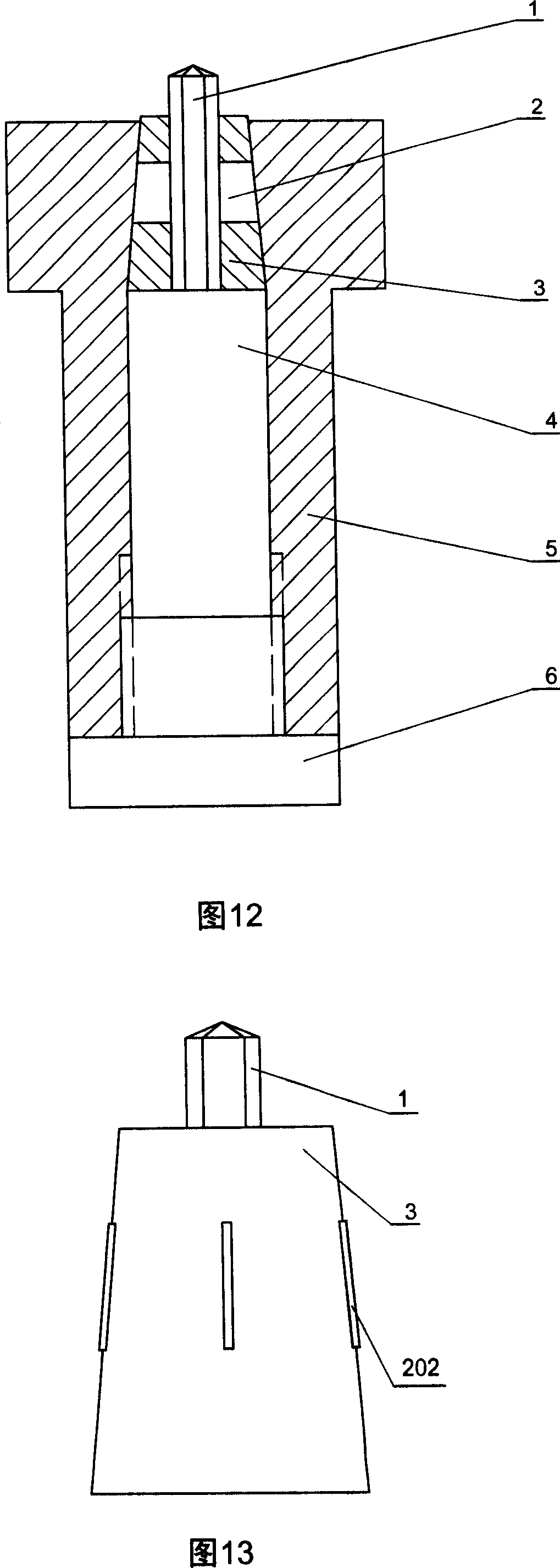

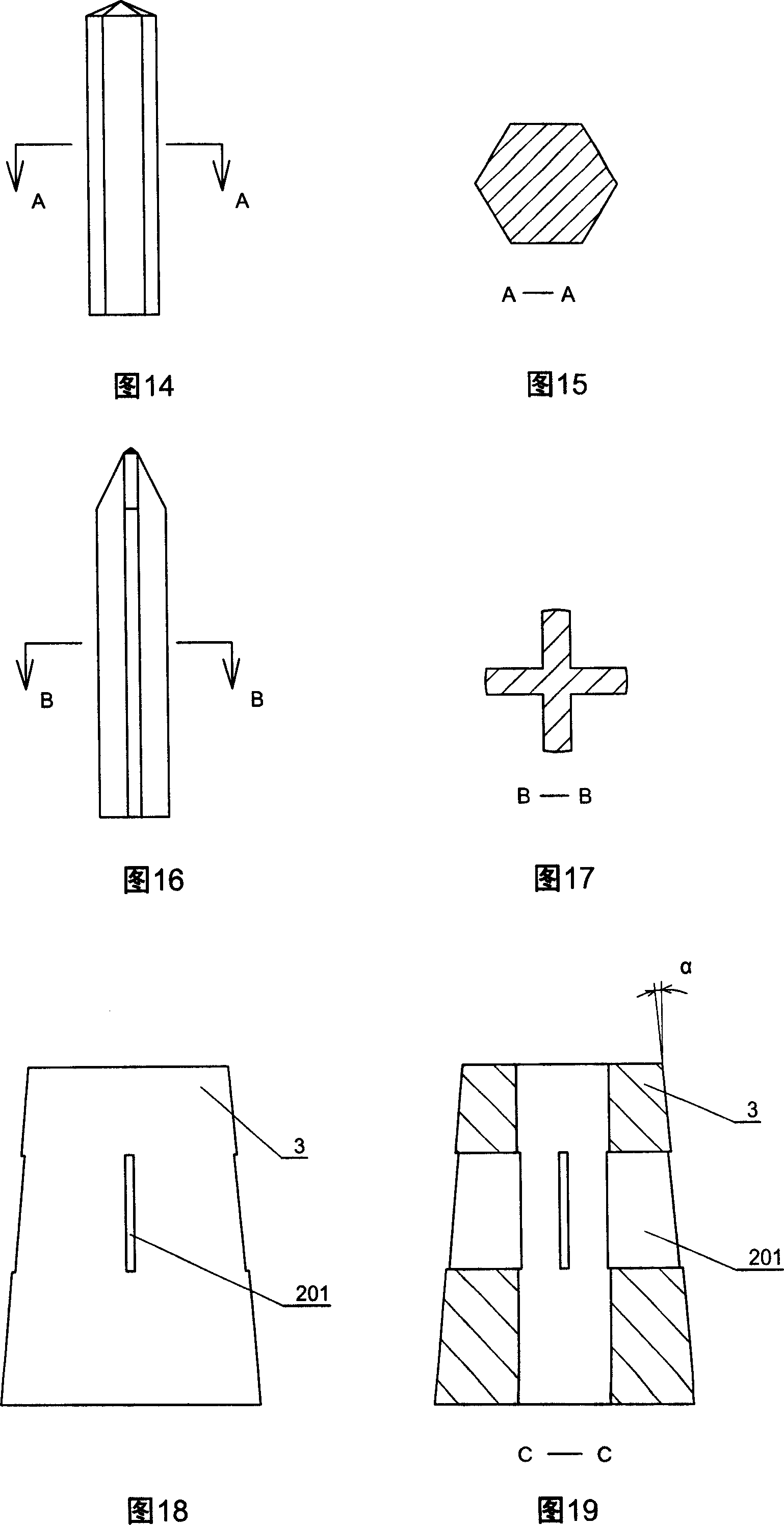

Screwhead punching pin locking method and screwhead punching die

InactiveCN101020265AEasy to disassembleExtended service lifeSecuring devicesChucksPunchingEngineering

The present invention discloses screwhead punching pin locking method and screwhead punching die, and relates to screwhead machining technology. The screwhead punching pin includes spacer block, sleeve seat, thread slot punching head, punching head jacket, punching head seat and punching pin locking device. The design with separable thread slot punching head and punching head seat makes it possible to reuse the punching head seat repeatedly and to repair the worn thread slot punching head for reuse, and this results in saving in expensive material, saving in setup time and raising in production efficiency.

Owner:陈显国

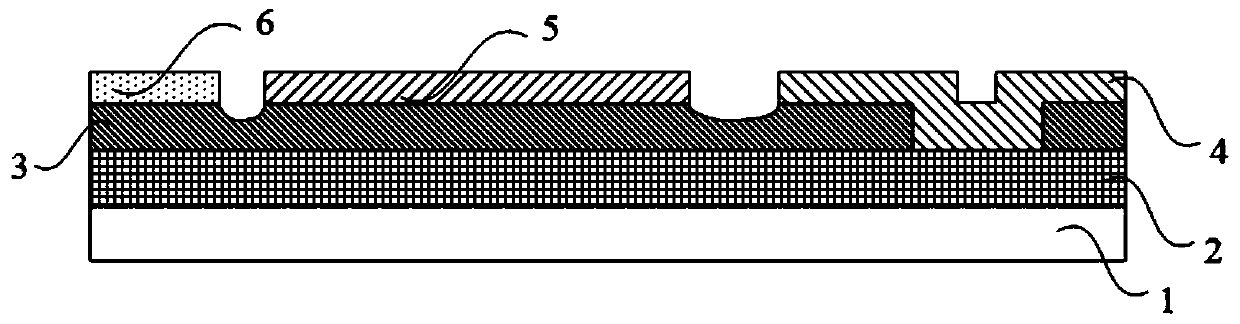

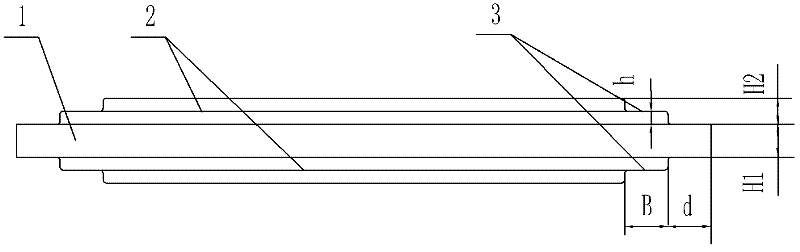

Metal-coated ceramic baseplate and manufacturing method thereof

InactiveCN102315179AReduces cyclic thermal stressSmall amount of deformationSemiconductor/solid-state device detailsSolid-state devicesTemperature cyclingPhotoresist

The invention relates to a manufacturing method of a metal-coated ceramic baseplate, which is carried out according to the following steps of: (1) cleanly washing the two surfaces of a ceramic baseplate; (2) directly welding metal layers on the upper surface and the lower surface of the ceramic baseplate, or brazing the metal layers on the upper surface and the lower surface of the ceramic baseplate, wherein the outer peripheral surface of each metal layer and the outer peripheral surface of the ceramic baseplate have a space d; and (3) brushing a photoresist along the outer peripheral surfaces of the two metal layers, forming at least one thinned and annular step surface at the peripheries of the two metal layers through illumination and corrosion, and manufacturing the metal-coated ceramic baseplate after washing. In the invention, by photoetching and thinning the thicknesses of the edges of the metal layers on the metal-coated ceramic baseplate, the heat stress on the two connecting edges of the step surface can be continuously released, so that not only is the metal-coated ceramic baseplate convenient to manufacture, but also the circulating heat stress among the ceramic baseplate and the metal layers is effectively reduced, the deformation quantity on the edges of a ceramic basal layer combined with the metal layers is greatly decreased, and the temperature-cycling reliability and the service of the metal ceramic baseplate can be greatly improved and prolonged.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

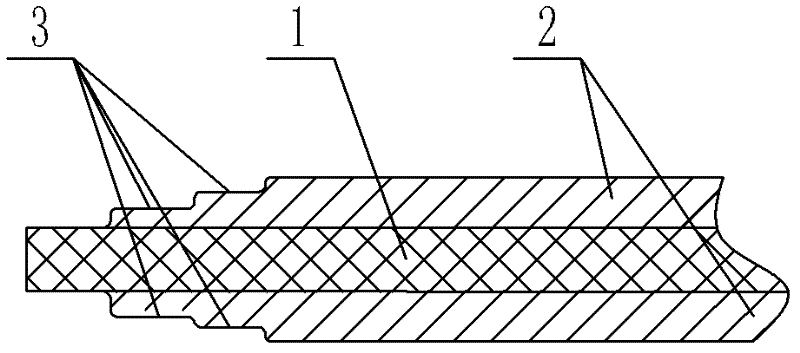

Rolling body of self-aligning roller bearing

InactiveCN103573822AImprove impact resistanceExtended service lifeBearing componentsSpherical roller bearingEngineering

The invention discloses a rolling body of a self-aligning roller bearing. A through hole penetrating through two ends is formed in the middle of the rolling body along the axial line direction, and inclined surfaces are formed between two ends of the through hole and two end faces of the rolling body, and are in arc transition with the end parts of the through hole and the end faces of the rolling body. The rolling body is simple in structure and reasonable in design, and the defect of the core part of the rolling body can be effectively overcome; the rolling body is capable of generating trace elastic deformation when the self-aligning roller bearing suffers from extreme load impaction, so that the impact resistance of the bearing is improved, and the service life of the bearing is further prolonged.

Owner:HENAN SANWEI HEAVY IND

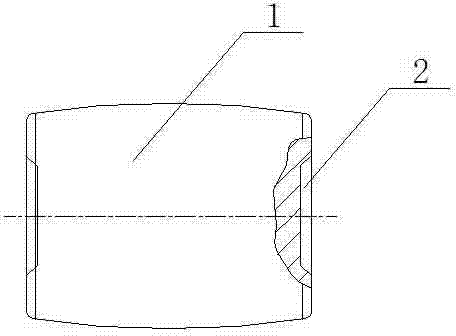

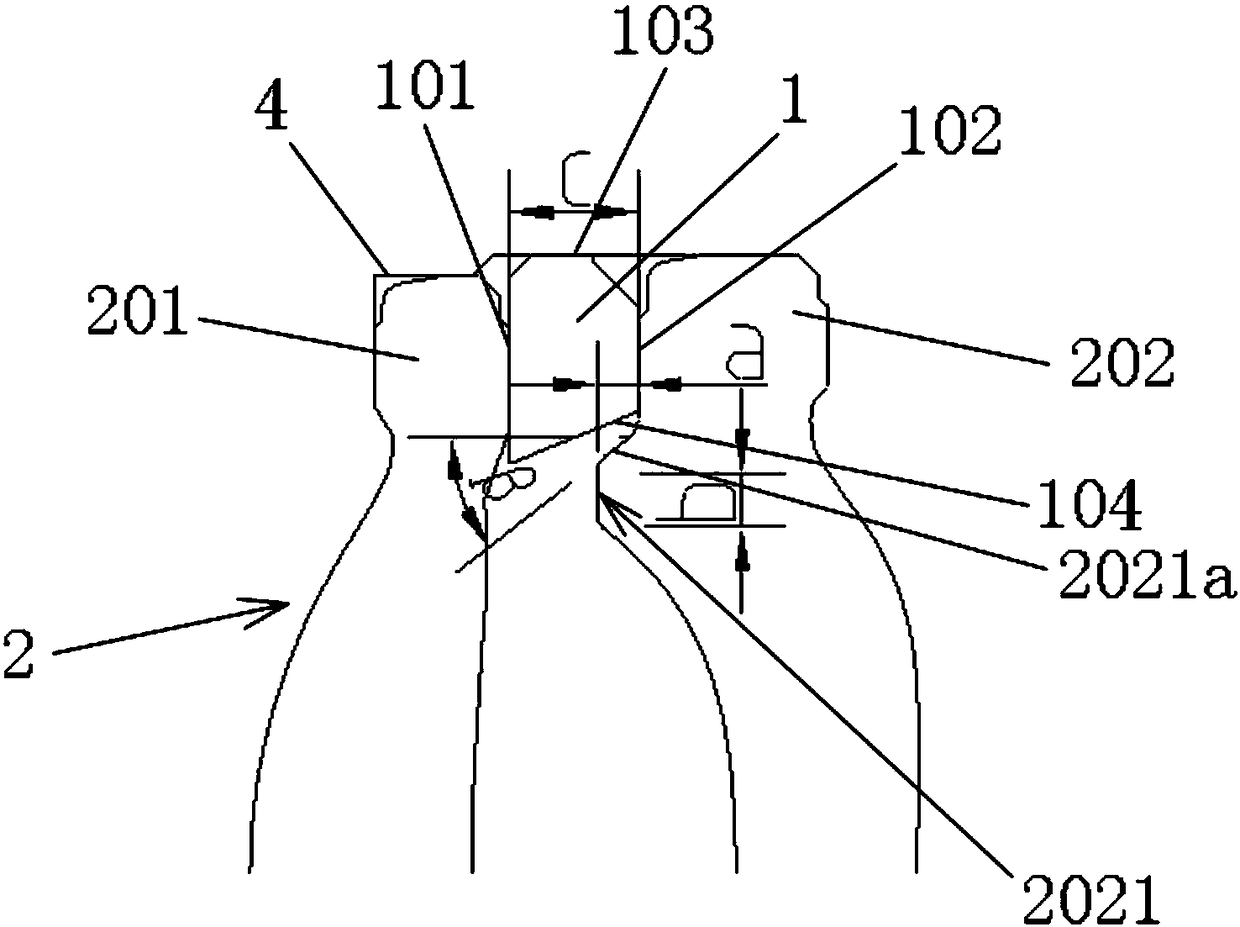

Spacing ring, optical lens and camera module

PendingCN108459389ADoes not affect image qualityImprove imaging effectMountingsCamera lensImaging quality

The invention relates to a spacing ring (1), an optical lens and a camera module. The spacing ring (1) is arranged in a lens cone of the camera module, and is used for spacing two adjacent lenses in the optical lens; the spacing ring (1) comprises a first surface (101) abutting against one of the lenses, a second surface (102) abutting against the other lens, as well as a third surface (103) connected with the inner wall of the lens cone; and the spacing ring (1) also comprises a fourth surface (104) which is far away from the third surface (103) and is used for avoiding the lenses in the optical lens. When the optical lens is assembled according to the spacing ring, the lenses can be avoided, each lens in the optical lens is provided with a boss, can provide a mounting space for the spacing ring and can avoid the spacing ring. Therefore, after the optical lens or the camera module is assembled, the stability is higher, the imaging quality is guaranteed, and the problem that the lens stress is concentrated is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

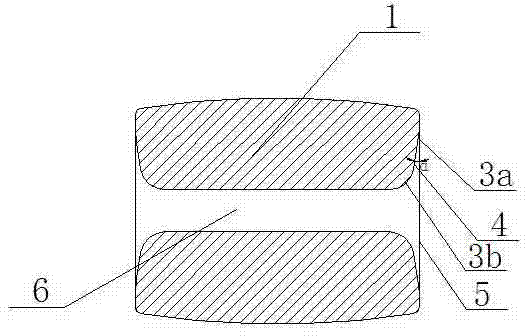

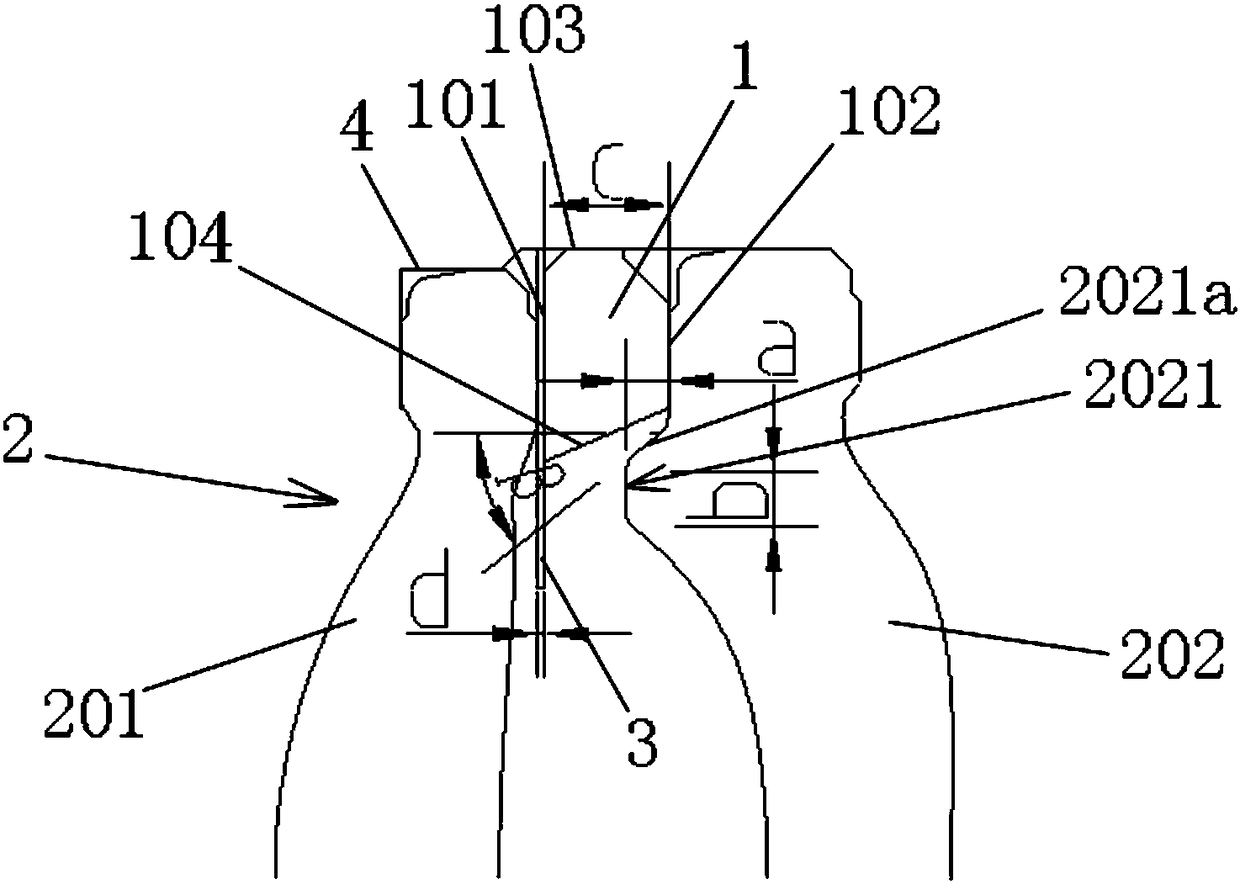

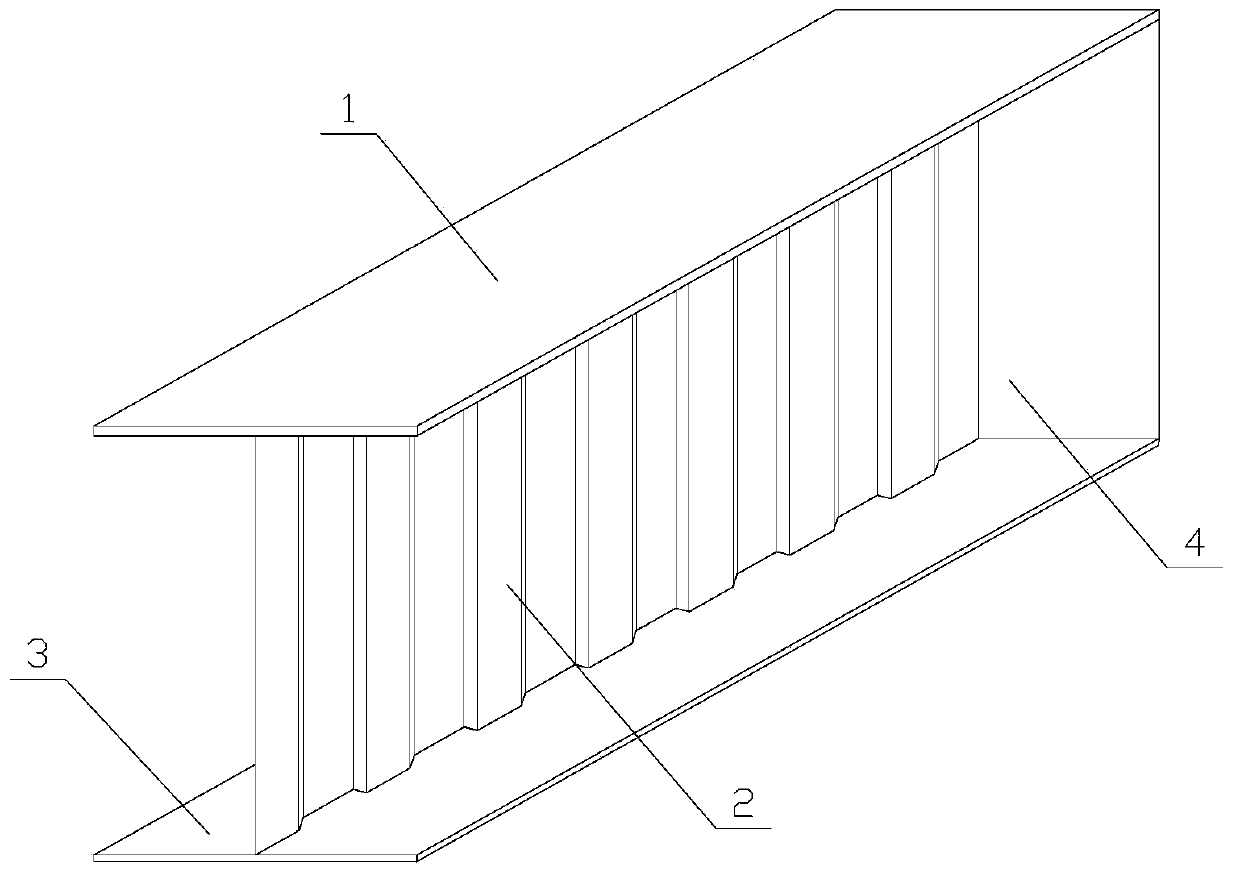

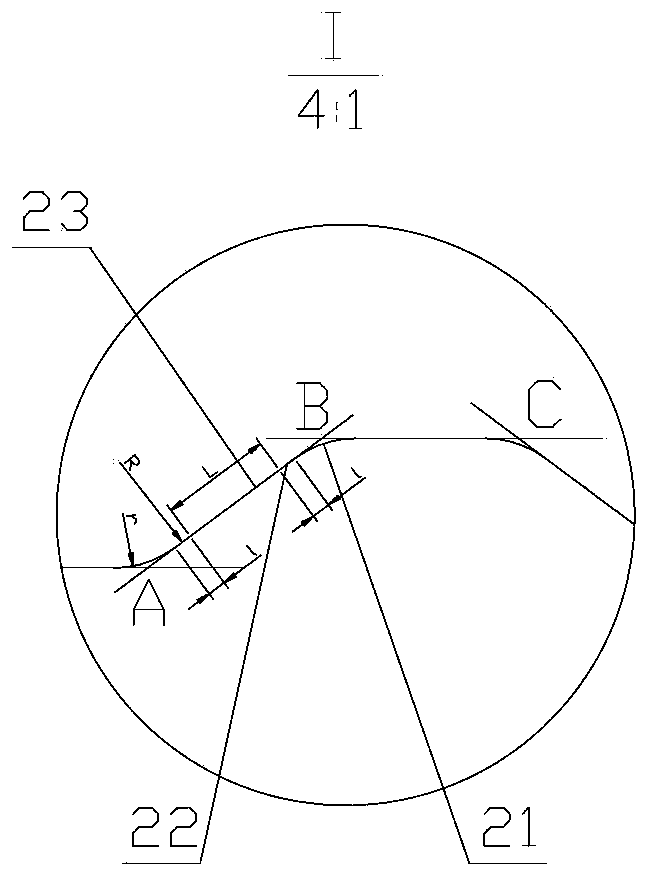

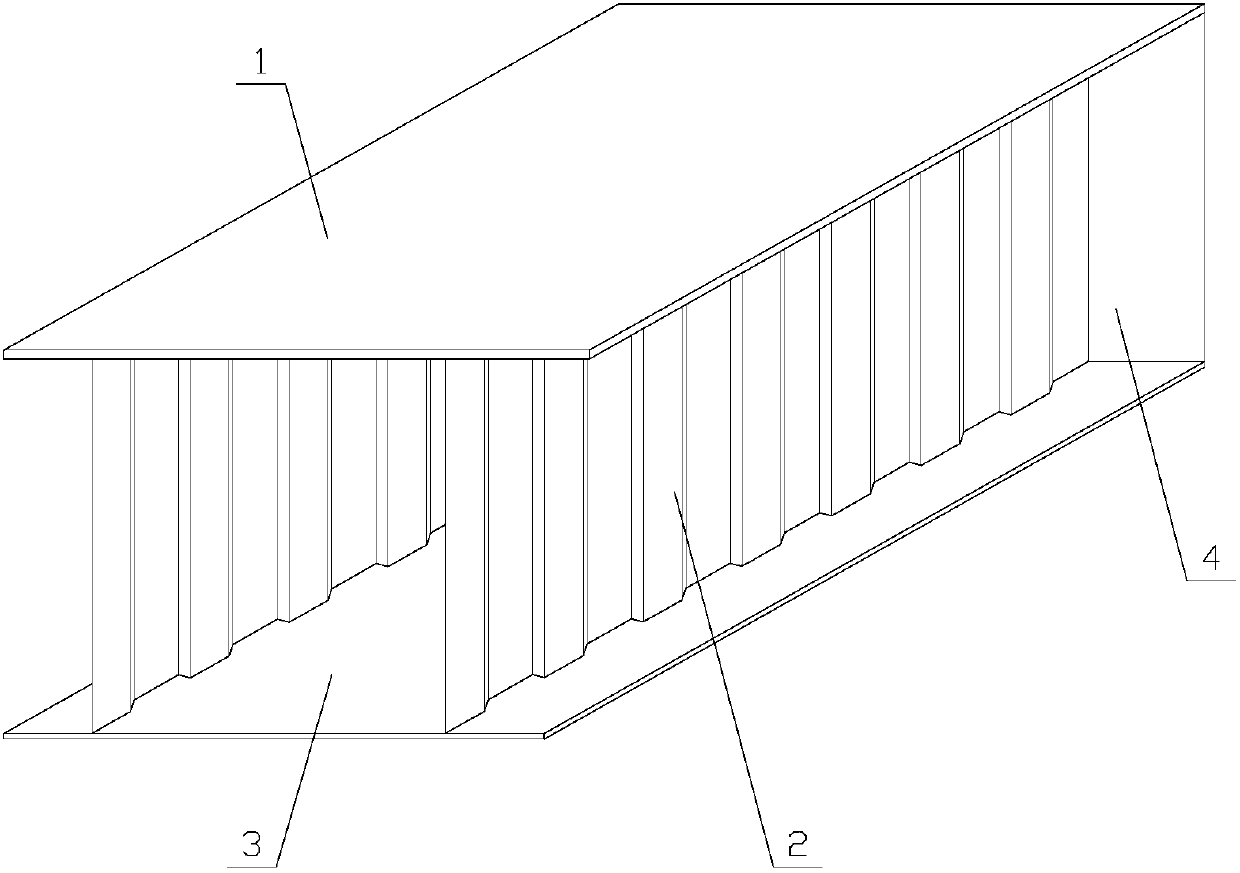

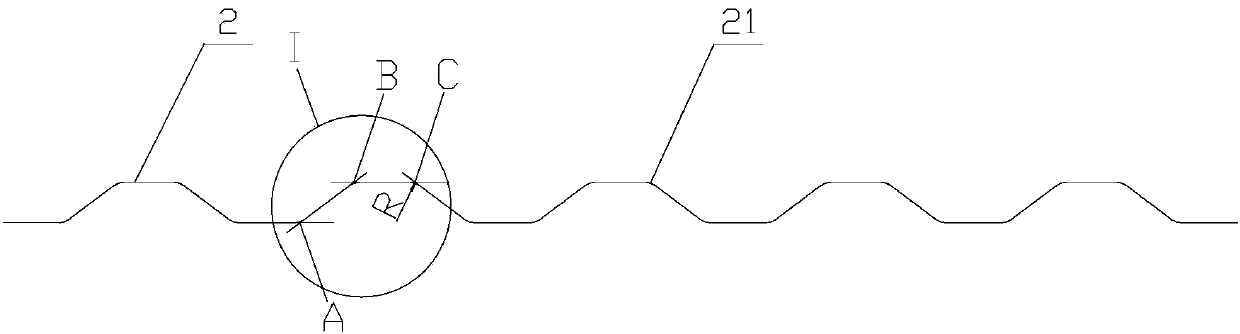

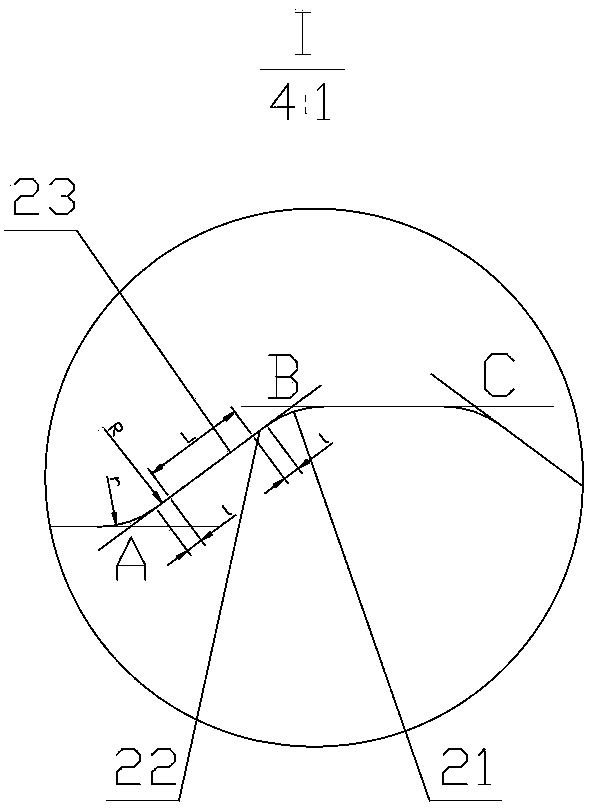

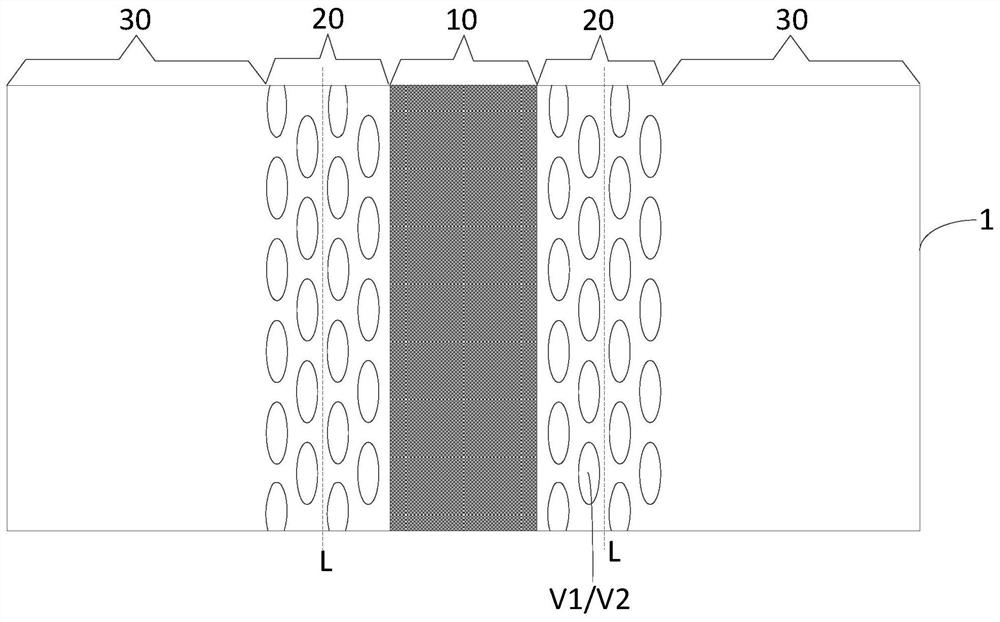

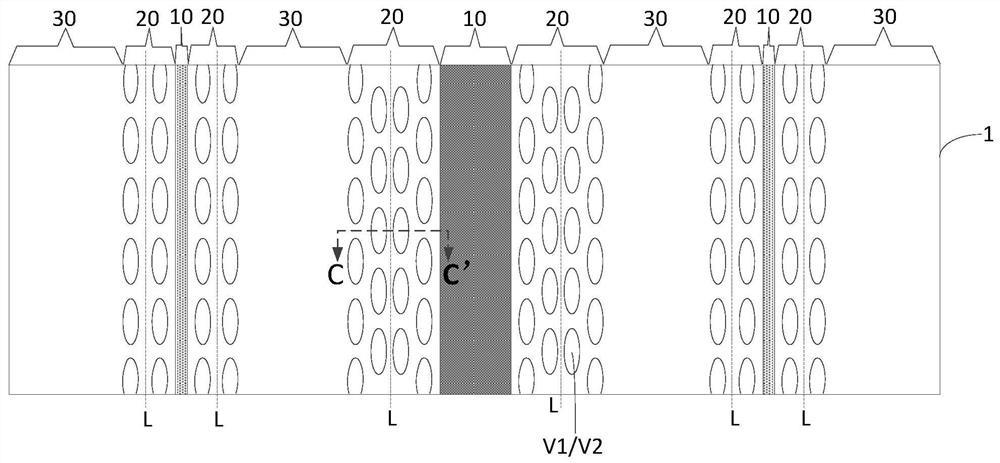

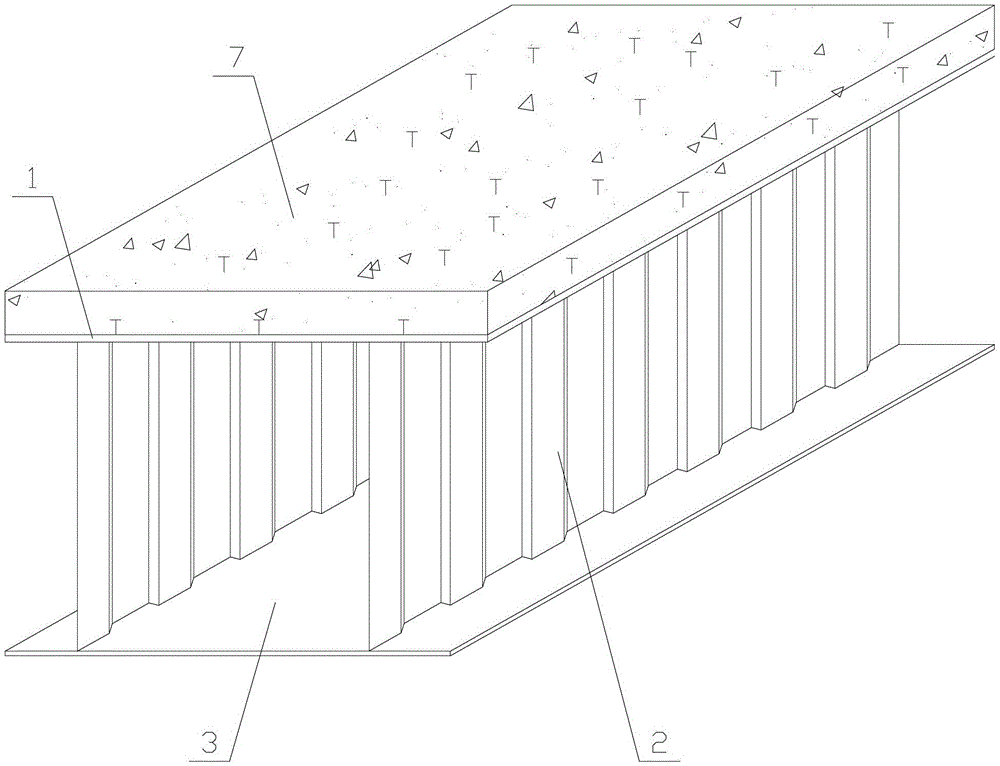

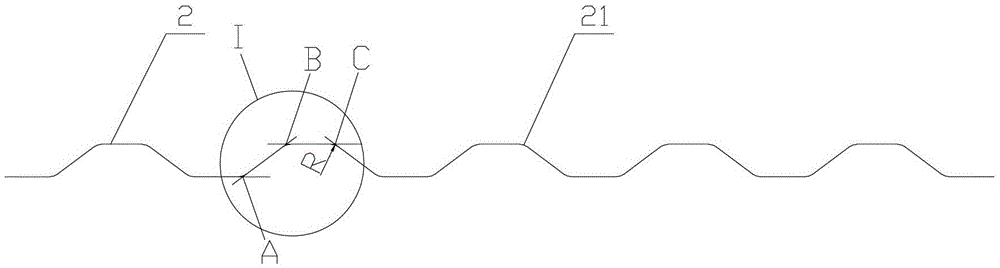

Simply supported I beam adopting corrugated steel web steel structure

ActiveCN103422613AIncrease cross section stiffnessPrevent falling phenomenonBridge structural detailsGirdersStress concentrationSheet steel

The invention relates to an I beam, and discloses a simply supported I beam adopting a corrugated steel web steel structure. A beam body includes a corrugated steel web (2), a top flange steel plate (1), a bottom flange steel plate (3), and a gland end plate (4), wherein the corrugated steel web (2) is arranged between the top flange steel plate (1) and the bottom flange steel plate (3); the top flange steel plate (1) is connected with the corrugated steel web (2) through welding; the corrugated steel web (2) is connected with the bottom flange steel plate (3) through welding. The arranged gland end plate improves the rigidity of a cross section and strength of a connecting end of the beam body, and wave forms of the web include three parts, namely the straight line section, the transitional section and the arc section, the transitional section can be used for effectively connecting the straight line section with the arc section, thereby solving the problem of stress concentration during the direct connection of the straight line section and the arc section; besides, the simply supported beams adopt a connected and discontinuous structure, thereby effectively preventing the beam body from falling off under the actions of overloaded vehicles and big loads or under the earthquake action.

Owner:HANGZHOU BOSHU CIVIL ENG TECH

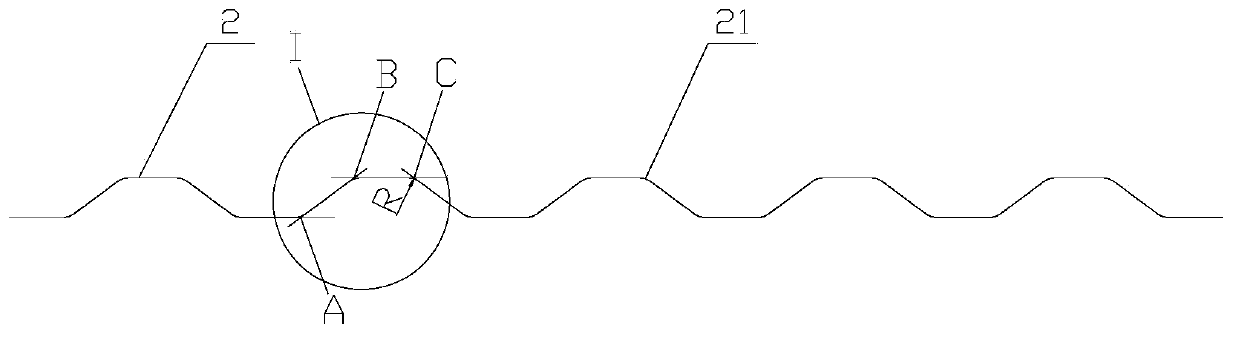

Continuous box girder adopting corrugated steel web steel structure

ActiveCN103422614AActive connectionFirmly connectedBridge structural detailsGirdersStress concentrationSheet steel

The invention relates to a box girder, particularly to a continuous box girder adopting a corrugated steel web steel structure, which includes two or more corrugated steel webs, a top steel plate, a bottom steel plate and a connecting end, wherein the corrugated steel webs are arranged between the top steel plate and the bottom steel plate; the top steel plate is connected with the corrugated steel webs through welding; and the bottom steel plate is connected with the corrugated steel webs through welding; the single girder body structure forms a continuous girder structure through the connecting end or steel nooses or the combined connection of the connecting end and the steel nooses. The wave forms of the webs in the continuous box girder include three parts, namely the straight line section, the transitional section and the arc section, the transitional sections can be used for effectively connecting the straight line sections with arc corners, thereby solving the problem of stress concentration during the direct connection of the straight line sections and the arc sections, an inserting-type pressure-bearing structure in a pressure-bearing zone enables the connection to be stable, is provided with a shrinking space in case of temperature variation, and is stable in the connection of a pulled zone, and the arranged cavity can be used for resisting thermal expansion when the temperature of the girder body varies.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Method for achieving synchronous pushing of large-span steel-concrete composite beams through cable-stayed tower

InactiveCN113322813ASolve stress concentrationEliminate bending momentBridge erection/assemblyStress concentrationTower

The invention discloses a method for achieving synchronous pushing of large-span steel-concrete composite beams through a cable-stayed tower. The method comprises the steps that: the tower is mounted on a steel box beam, a hinged support is arranged at the bottom of the tower, and the tower is connected with the top of the steel box beam through the hinged support; and a pushing device is used for pushing a guide beam and the steel box beam to a middle pier and a guide beam receiving platform successively from a splicing area, and in the pushing process, under the action of the hinged support, the tower can incline by a small angle. The hinged support is arranged at the bottom of the tower so that the tower can incline, the constraint of rotation in a bridge direction can be released, and the tower and the steel box beam can rotate freely; in the pushing process, when the hogging moment of a pushing cantilever is increased or the guide beam is mounted onto the piers, the change of the horizontal force of the top of the tower can be automatically eliminated in a tower inclination mode, the whole tower is only pressed and is not bent, and the root bending moment is eliminated, so that stress concentration is avoided, the structural safety is guaranteed, and the problem of root stress concentration of the temporary tower during synchronous pushing of the large-span steel-concrete composite beams is solved.

Owner:SHANGHAI CIVIL ENG GRP FIFTH +1

Supporting plate and display device

ActiveCN113793554AReduce weightReduce rigidityIdentification meansPhotovoltaic energy generationStress concentrationDisplay device

The embodiment of the invention discloses a supporting plate and a display device. The supporting plate is characterized in that a plurality of through holes are formed in a first region (namely a bending region), and a plurality of first grooves which are distributed in a first surface of a supporting plate body at intervals and a plurality of second grooves which are distributed in a second surface of the supporting plate body at intervals are formed in the transition region; and a stress difference between the first region and the second region(the supporting region) can be reduced so that stress generated during bending is distributed more uniformly, the problem of stress concentration at the junction of the bending region and the supporting region in the prior art can be effectively solved, cracks are prevented from being generated at the joint of the bendingregion and the supporting region, and the supporting piece is effectively prevented from being broken. According to the scheme, the weight of the supporting plate can be reduced, the rigidity of the supporting plate is reduced, the bending capacity of the supporting plate is improved, and therefore the reliability of the supporting plate is improved.

Owner:BOE TECH GRP CO LTD +1

Continuous box girder with corrugated steel web and steel-concrete composite structure

ActiveCN103422616BSolve stress concentrationSolve the problem of stress redistributionLoad-supporting elementsStress concentrationBox girder

The invention relates to a box girder, particularly to a continuous box girder adopting a corrugated steel web steel and concrete composite structure, which includes two or more corrugated steel webs, a top steel plate, a bottom steel plate, concrete and a connecting end, wherein the corrugated steel webs are arranged between the top steel plate and the bottom steel plate; the top steel plate, the bottom steel plate and the corrugated steel webs are all connected through welding; the single girder body structure forms a continuous girder structure through the connecting end; the top steel plate or the bottom steel plate is combined with concrete to form a concrete composite structure. The corrugated steel webs in the continuous box girder realize the smooth transition of a straight line section and an arc section through three transitional sections at corners, solve the problem of stress concentration at corners; besides, a pressure-bearing part adopts a steel and concrete composite structure with micro strain waves, so that the problem of stress concentration in the composite structure is solved, and excellent structural performance and economy can be obtained.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com