Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Solve anchoring problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

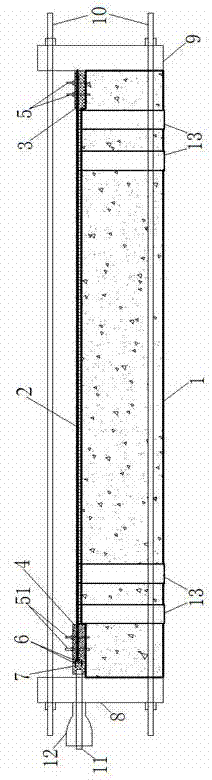

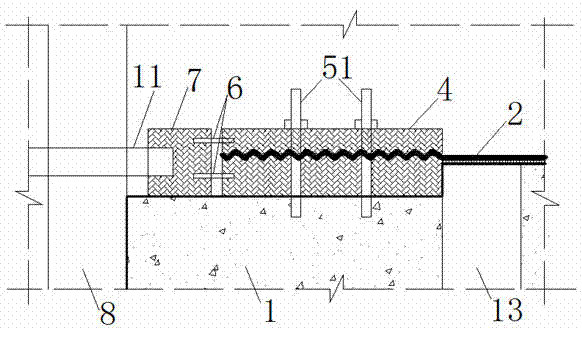

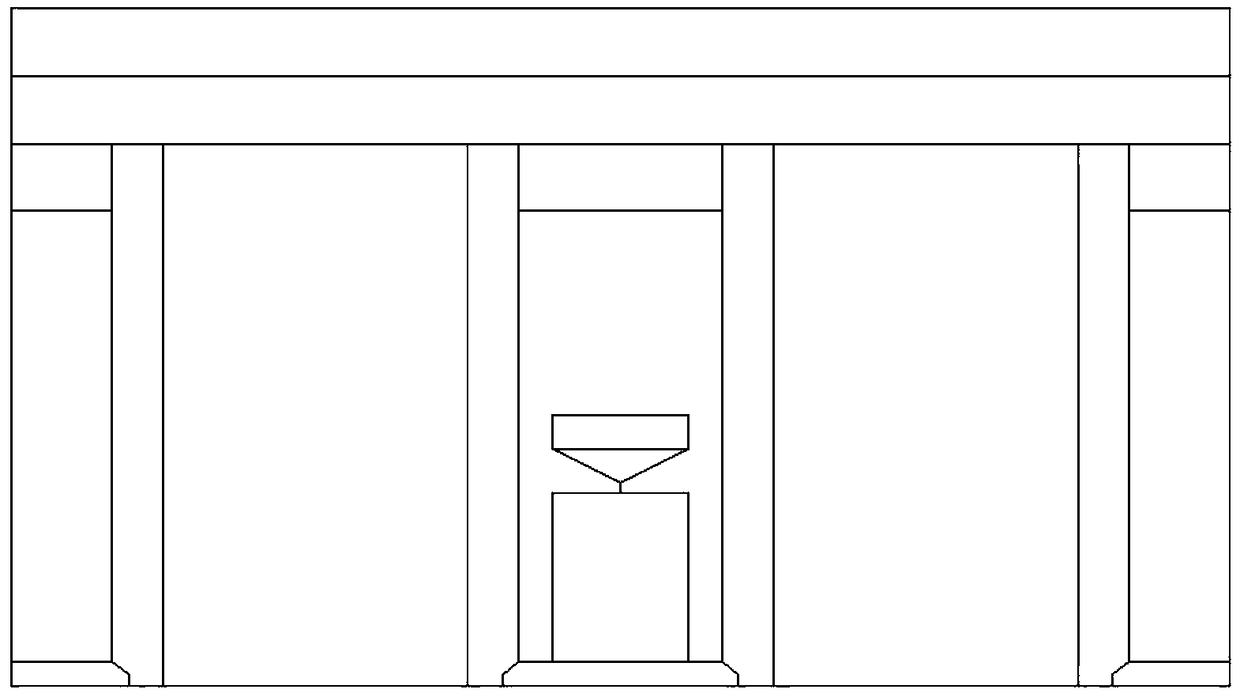

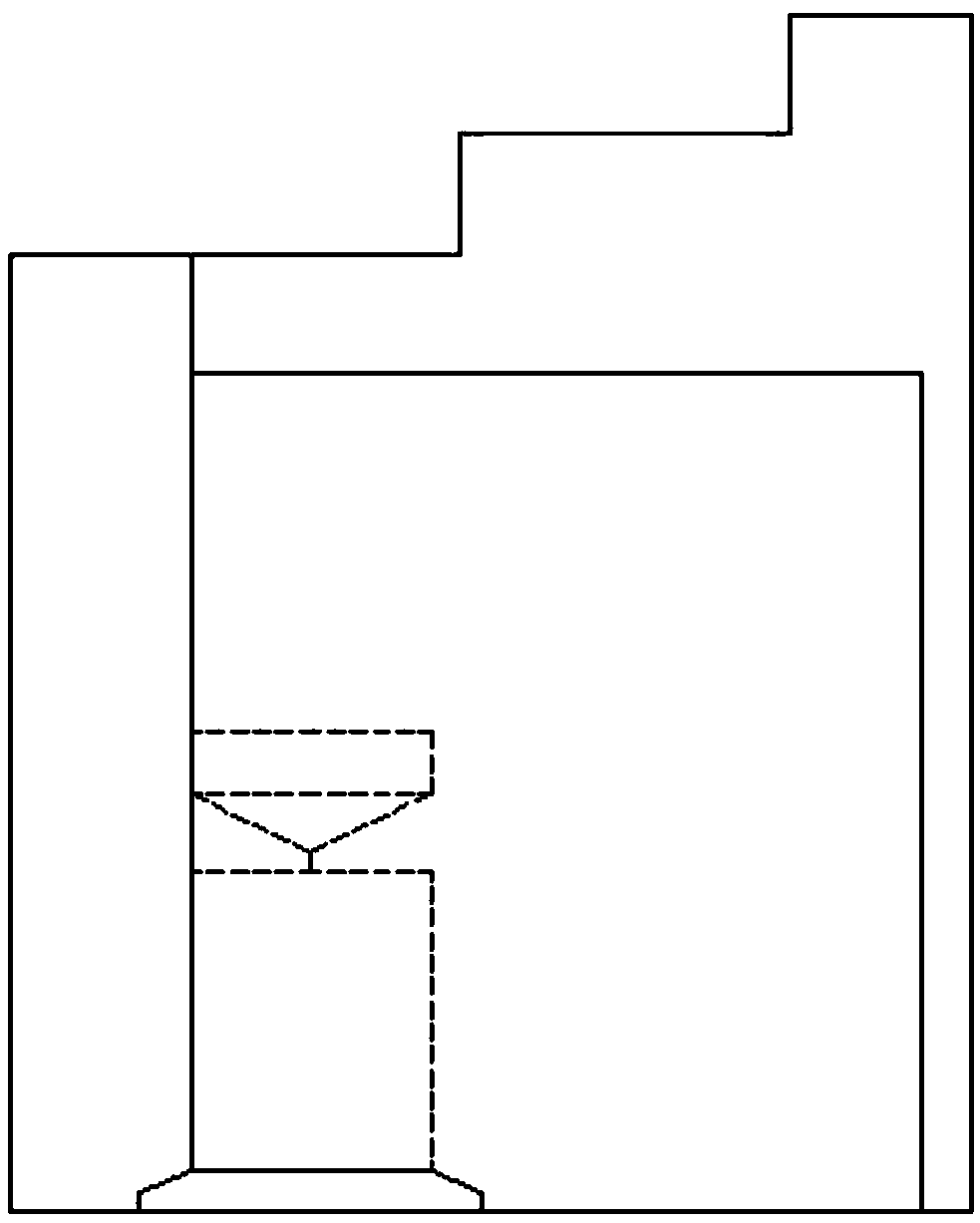

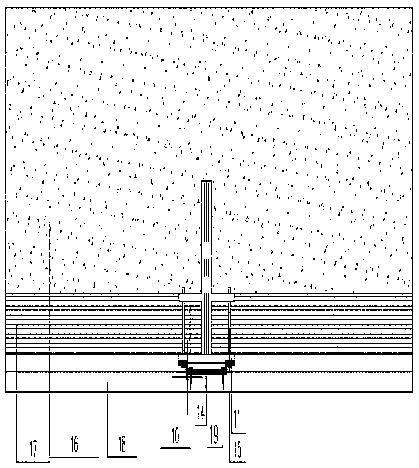

Pre-tensioning prestressed composite beam structural system and construction method thereof

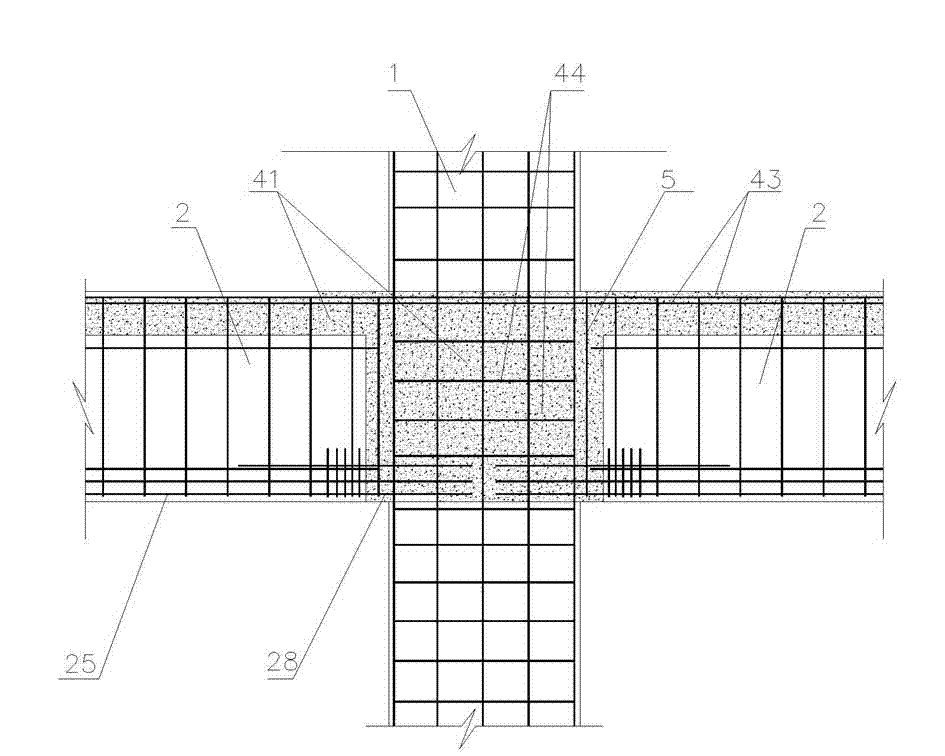

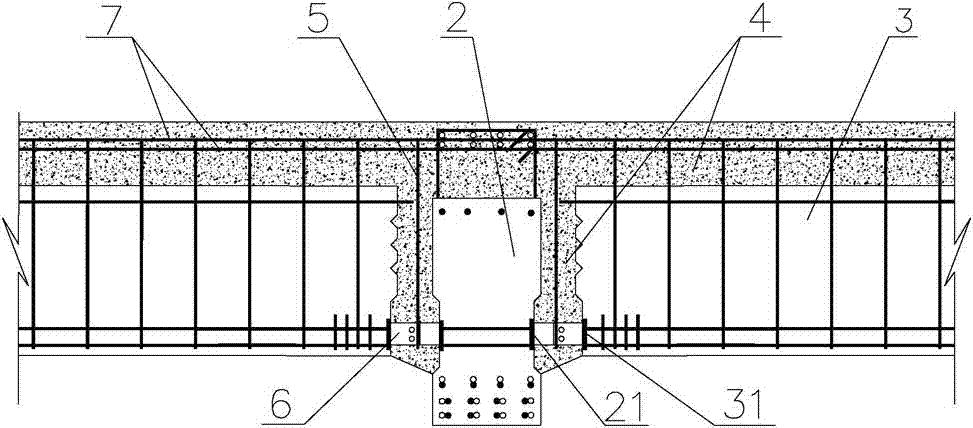

The invention relates to a pre-tensioning prestressed composite beam structural system and a construction method of the pre-tensioning prestressed composite beam structural system. Lower longitudinal reinforcements are bound and lapped on lower longitudinal prestress wires in composite frame beam prefabricated components; the lower longitudinal reinforcements are inserted into frame pillars; second pre-buried steel plates are buried in the lower end portions of the composite frame beam prefabricated components; lower portion longitudinal prestress wires are buried in the composite frame beam prefabricated components; secondary beam longitudinal reinforcements are lapped and bound on the lower portion longitudinal prestress wires; the second pre-buried steel plates are welded with the secondary beam longitudinal reinforcements; first pre-buried steel plates opposite to the second pre-buried steel plates are arranged on the composite frame beam prefabricated components; pitch point steel plates are respectively welded on the first pre-buried steel plates and the second pre-buried steel plates; and the pitch point steel plates are connected through bolts, which enables the composite frame beam prefabricated components to connect with composite secondary beam prefabricated components. Wires and longitudinal reinforcements are lapped to use in the pre-tensioning prestressed composite beam structural system, and therefore the connecting mode of the pre-tensioning prestressed composite beam structural system is scientific and reasonable, and quality is safe and reliable.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

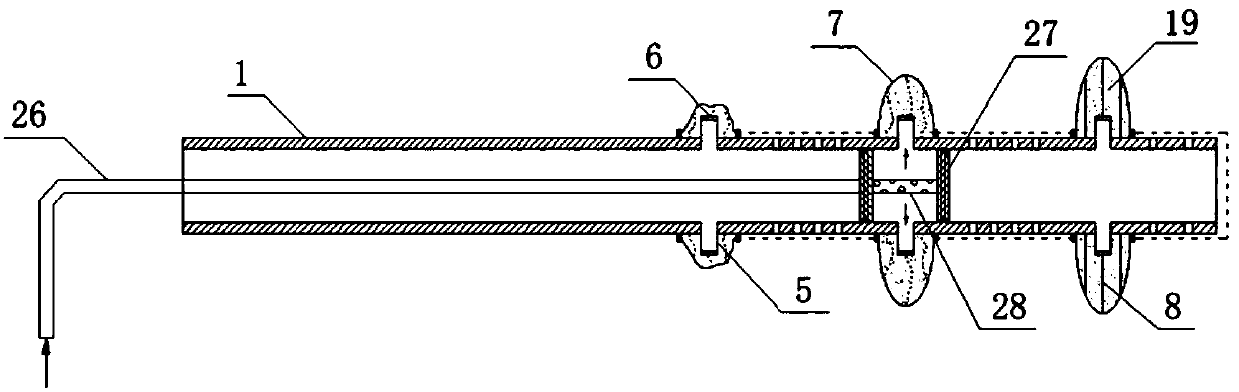

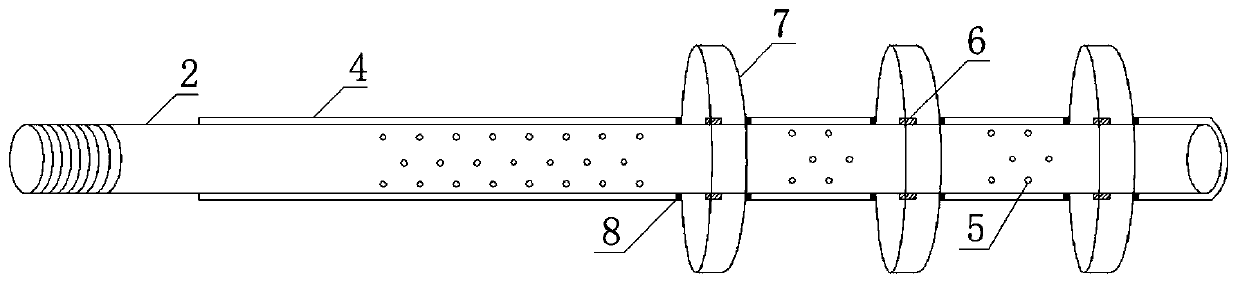

Vacuum drainage anchor rod and construction method thereof

ActiveCN109629566AIncrease anchoring forceGood governanceExcavationsBulkheads/pilesSleeve valveSlurry

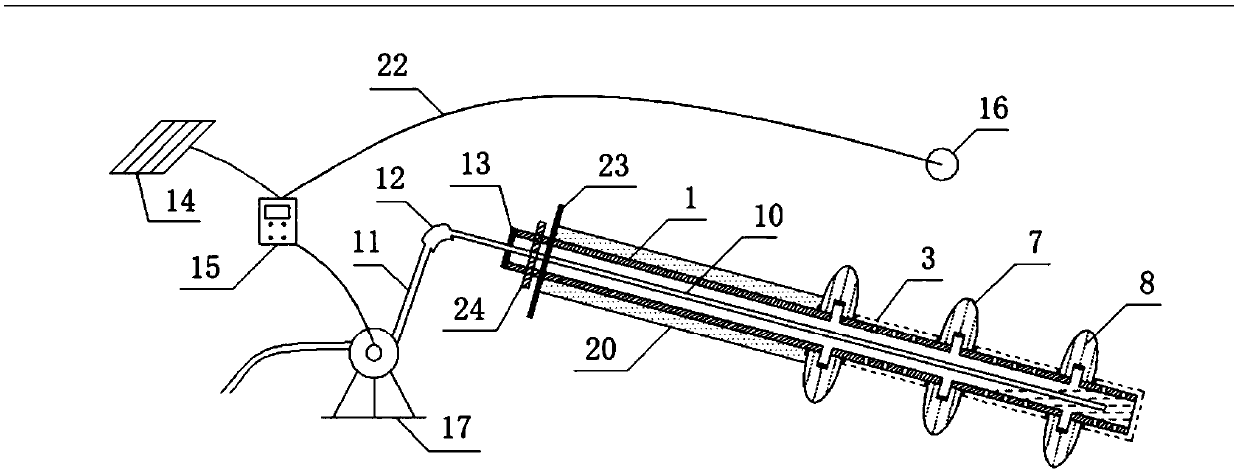

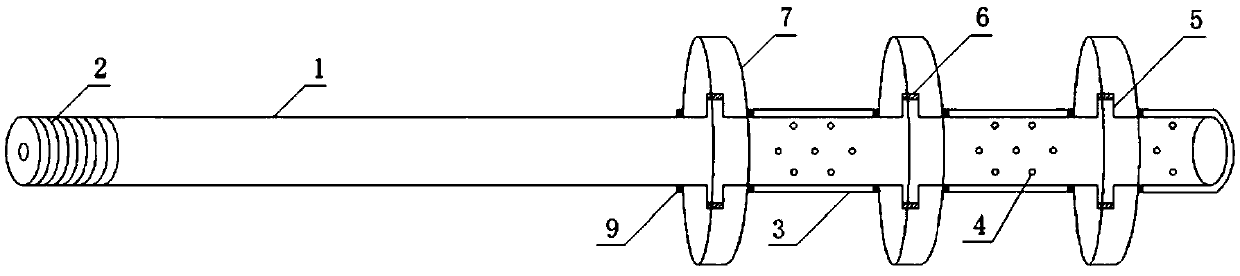

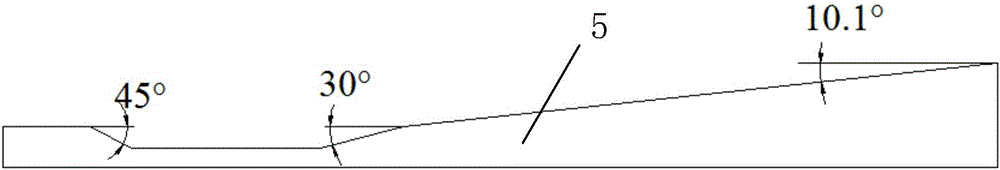

The invention provides a vacuum drainage anchor rod and a construction method thereof. The anchor rod is composed of an anchoring system and a vacuum drainage system; a thread is arranged at the frontend of each hollow anchor pipe, the middle rear part of each hollow anchor pipe is connected with a slurry outlet pipe, water permeable holes are formed in each hollow anchor pipe which is wrapped bya filter screen, a rubber sleeve valve and a geotextile bag sleeve an opening of each slurry outlet pipe, and each geotextile bag is clamped in the corresponding hollow anchor pipe through a hoop; the hollow anchor pipes are obliquely arranged in a slope, pressure grouting is conducted on the interior and the periphery of the front end of each hollow anchor pipe, and the hollow anchor pipes are anchored on backing plates through anchorage devices; a controller and a vacuum pump are installed outside the slope; moisture meters are embedded in the slope and connected with the controller; waterabsorbing pipes penetrate through sealing covers and are inserted into the hollow anchor pipes, connected with a drain pipe through sealing joints and connected with the vacuum pump; the controller and the vacuum pump are switched on, pumping starts to be conducted, a negative pressure zone is formed in each hollow anchor pipe, and the water in the slope enters a water suction pipe and then is discharged out of the slope. Accordingly, the structure is simple, anchorage and drainage can be achieved simultaneously, a good effect is achieved, construction is easy, and the manufacturing cost is low.

Owner:NINGXIA UNIVERSITY

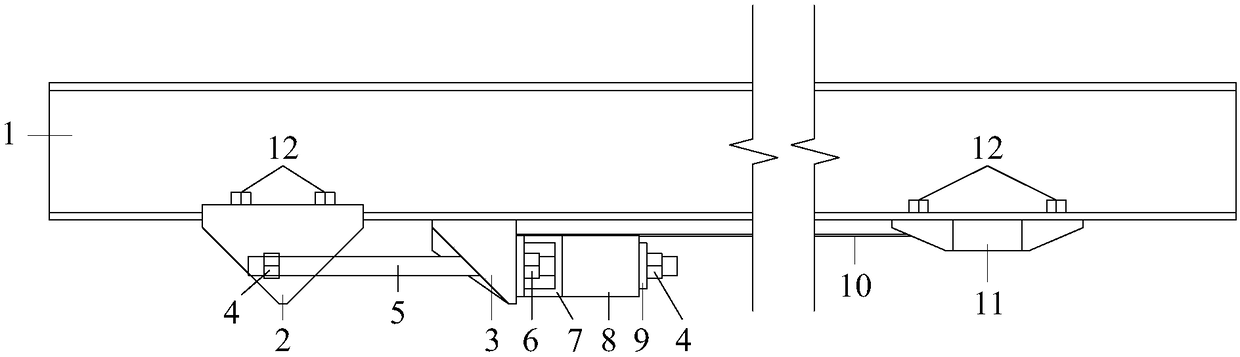

Construction method of main beam of steel-concrete composite beam cable-stayed bridge

ActiveCN109972517ASolve the lifting installationSolve walkingBridge erection/assemblyCable stayedEngineering

The invention discloses a construction method of a main beam of a steel-concrete composite beam cable-stayed bridge. The construction method comprises the steps: a wall-attached crane is mounted on acable tower, and initial section steel beams are hoisted by the wall-attached crane and fixed; the wall-attached crane hoists a first deck crane onto the initial section steel beams, unit splicing section steel beams are hoisted by the first deck crane and fixed to the two ends of the initial section steel beams, the first deck crane moves forwards onto the unit splicing section steel beams at oneends of the initial section steel beams, and the wall-attached crane hoists a second deck crane onto the unit splicing section steel beams at the other ends of the initial section steel beams; and the first deck crane and the second deck crane move forwards to splice the steel beams extending towards bridge side-span sections and the steel beams extending towards bridge mid-span sections and close the steel beams on the side-span sections and the steel beams on the mid-span sections. The construction method has the advantages of being high in operability, safe, reliable, controllable in quality, economical, efficient, capable of saving energy and protecting the environment and the like.

Owner:CCCC SECOND HARBOR ENG +1

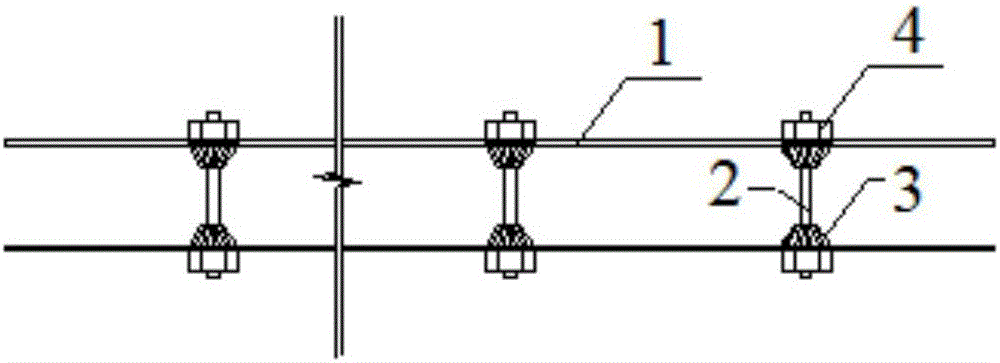

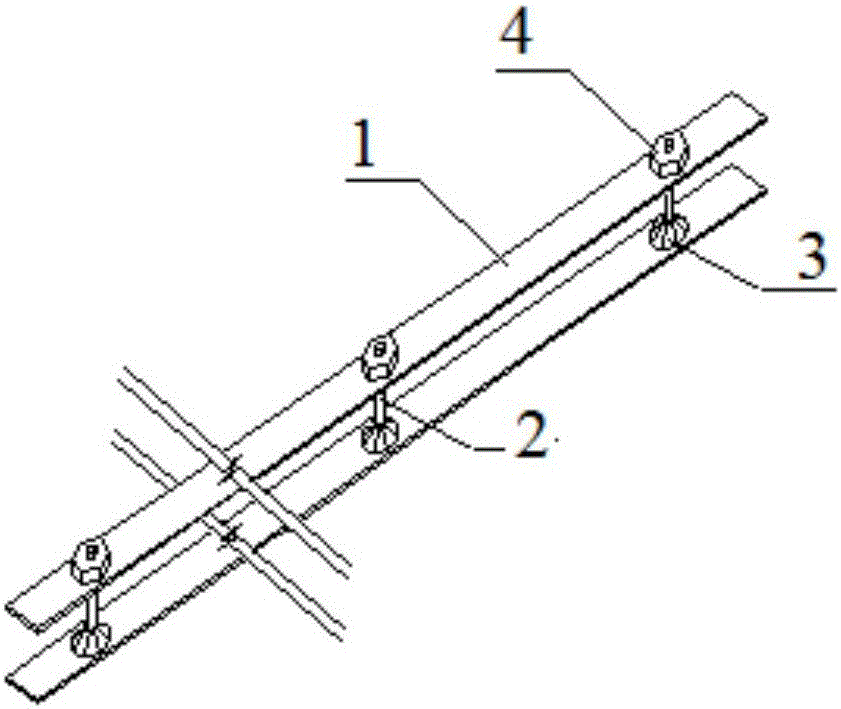

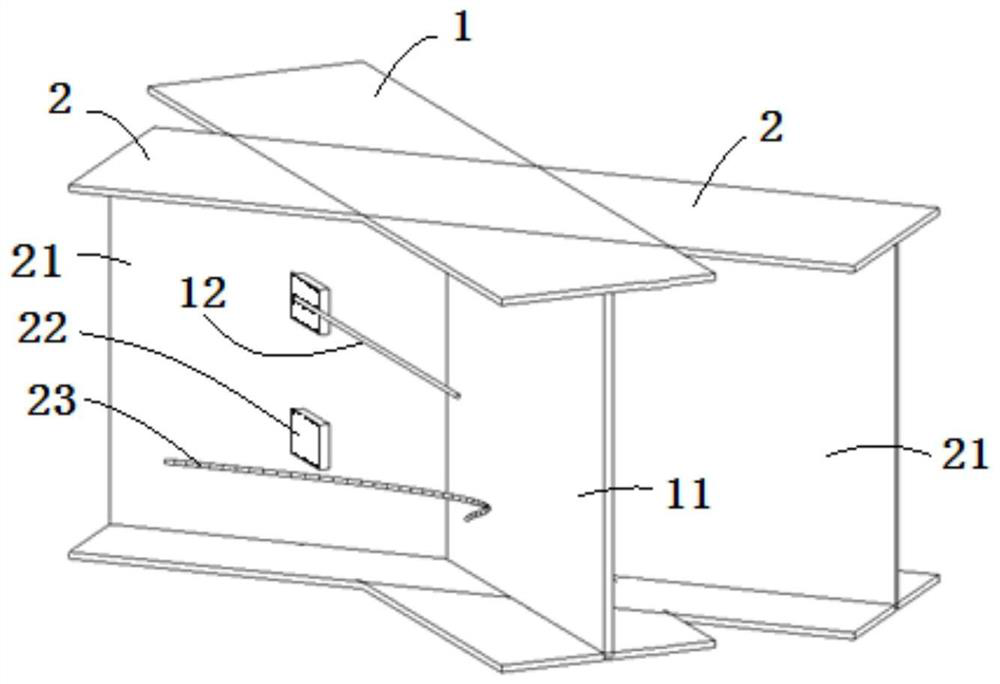

Steel structure spatial system for reinforcement and construction method thereof

InactiveCN105863289AGood anchoring effectIncreased bearing capacity and stiffnessBuilding repairsSpatial systemSteel plates

The invention discloses a steel structure spatial system for reinforcement and a construction method thereof. The steel structure spatial system for reinforcement and the construction method thereof are mainly applied to building structure reinforcement and reconstruction in the technical field of building science. The steel structure spatial system for reinforcement structurally comprises steel plates; the steel plates comprise the floorslab top steel plates and the floorslab bottom steel plates; the floorslab top steel plates are located on the top surface of a concrete floorslab; the floorslab bottom steel plates are located on the bottom surface of the concrete floorslab; the floorslab top steel plates and the floorslab bottom steels plates are aligned in the longitudinal direction; the floorslab top steel plates and the floorslab bottom steels plates are fixedly arranged at the edges of an open hole position in the concrete floorslab so as to achieve reinforcement of the concrete floorslab; and rigid connecting devices for connecting the floorslab top steel plates with the floorslab bottom steels plates are disposed between the floorslab top steel plates and the floorslab bottom steels plates. According to the steel structure spatial system for reinforcement and the construction method thereof, the steel structure spatial system is combined with the concrete floorslab, thus the anchoring effect is good, and the bearing capacity and rigidity can be improved to the great degree; construction and mounting are convenient, and anchoring of the steel plates is achieved; and using space is not occupied, the steel consumption is small, and the cost is low.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES +2

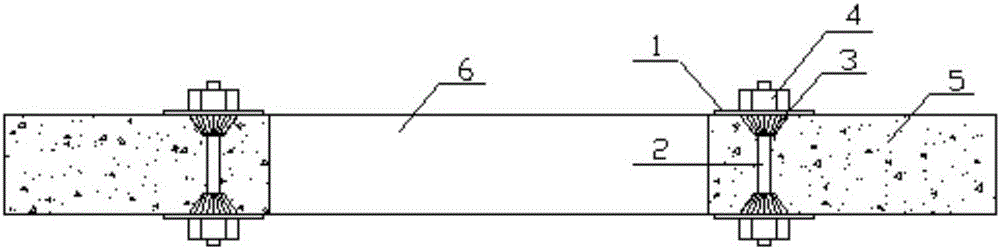

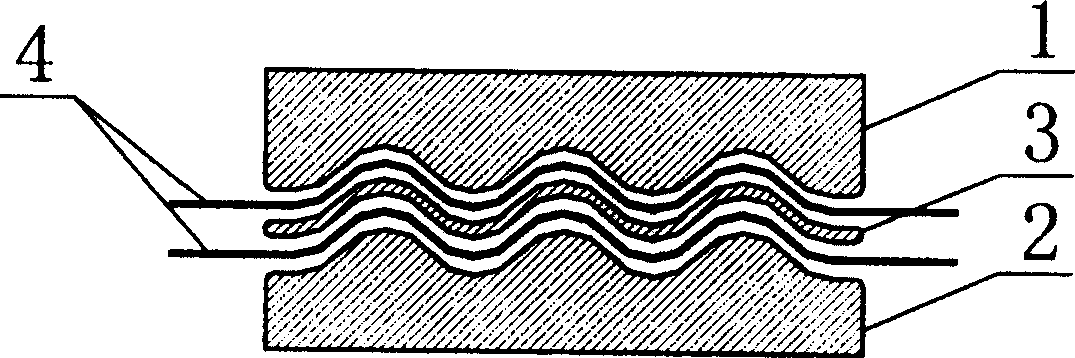

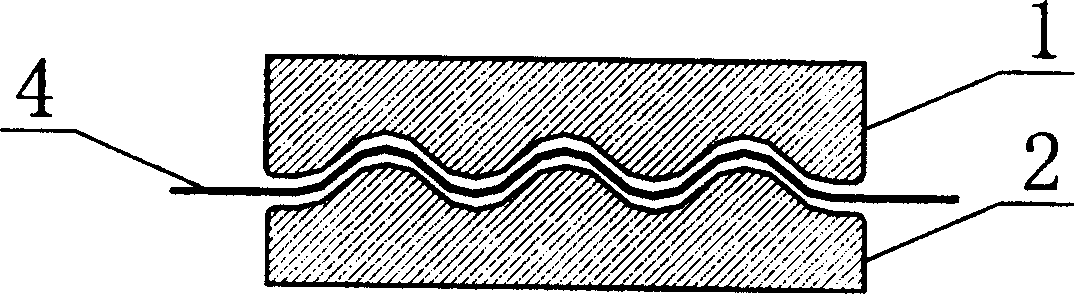

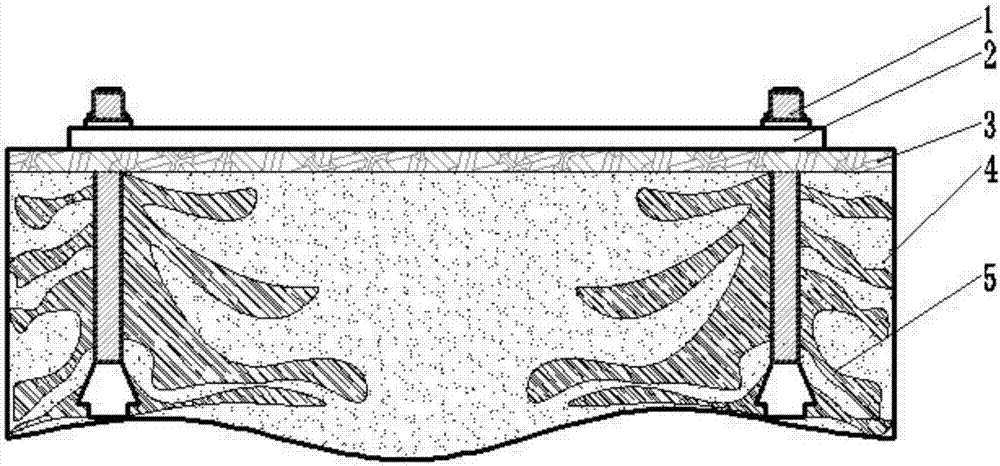

Device and method for reinforcing flexural concrete member

ActiveCN102926551ASolve anchoring problemsReinforcement is convenient and practicalBuilding repairsSteel platesReinforced concrete

The invention discloses a device and a method for reinforcing a flexural concrete member. The method comprises the following steps of: forming grooves in two ends of a tensile surface of a reinforced concrete member, respectively pressing steel plates with reserved holes at two ends of the member, and tensioning steel strands, so that a counter-force table is formed between the steel plates and the concrete member; embedding steel clamps for adhering and clamping the ends of a fiber reinforced composite material into the grooves, anchoring the clamp at one end into concrete through anchor bolts, and connecting the clamp at the other end by utilizing bolts and an overlap steel block; taking a high-strength bolt which penetrates through the steel plates and is connected with the overlap steel block as a tensioning rod, and tensioning the fiber reinforced composite material by utilizing a lifting jack; and finally, adhering the fiber reinforced composite material, anchoring the clamp at the tensile end into concrete, adhering U-shaped hoops at two ends of the reinforced concrete member, and gradually releasing the prestress in a graded mode after the adhesives are cured. The reinforced concrete member serves as a tensile counter-force table, a complex tensioning device is prevented from being manufactured, and the problem that the prestressed fiber reinforced composite material cannot be anchored is solved.

Owner:GUANGDONG DIANBAI CONSTR GRP

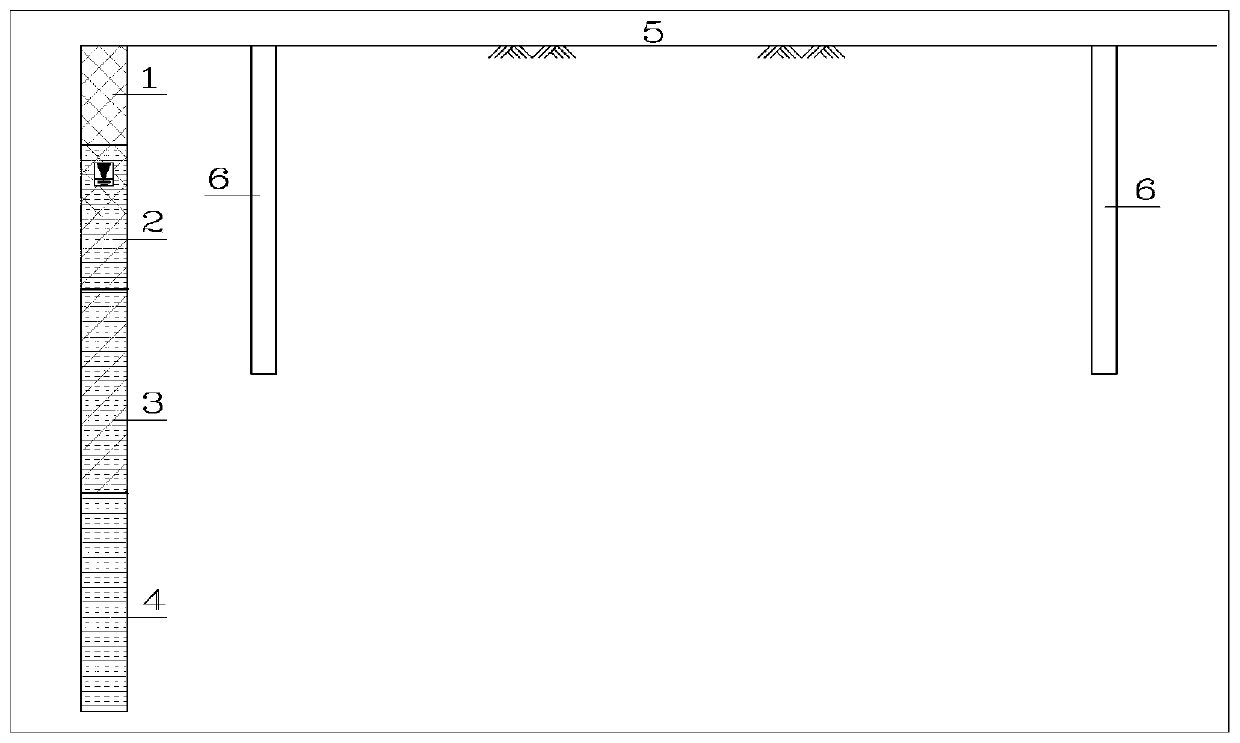

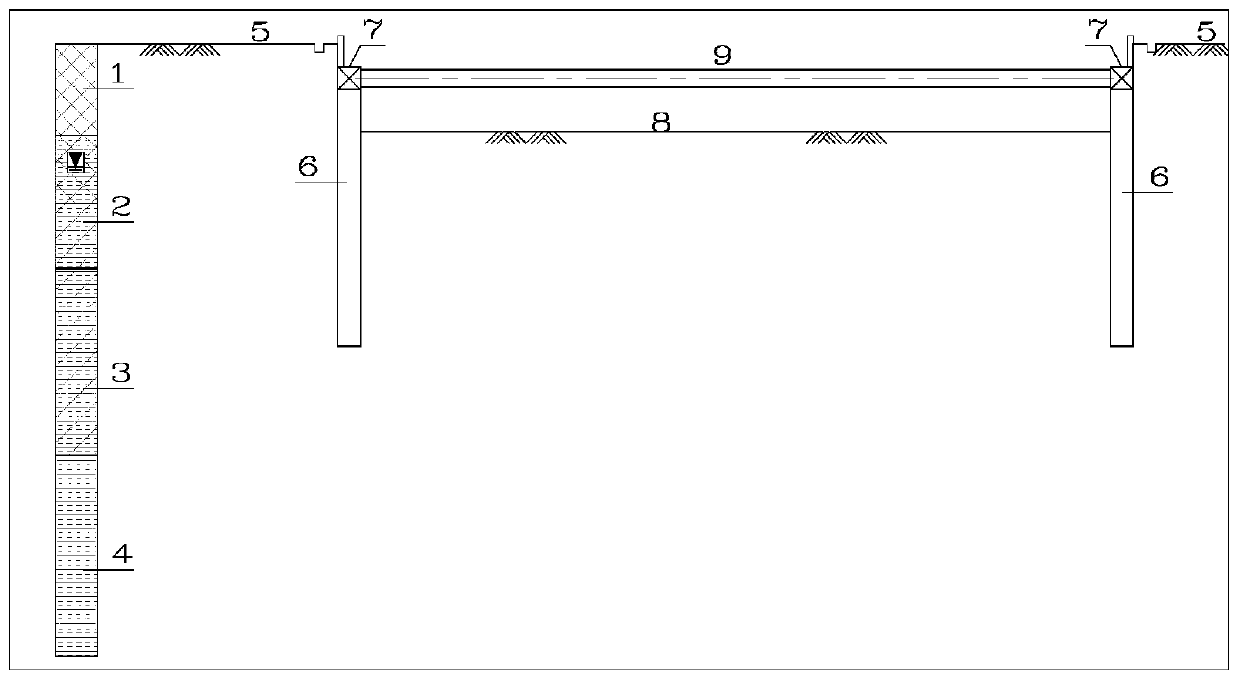

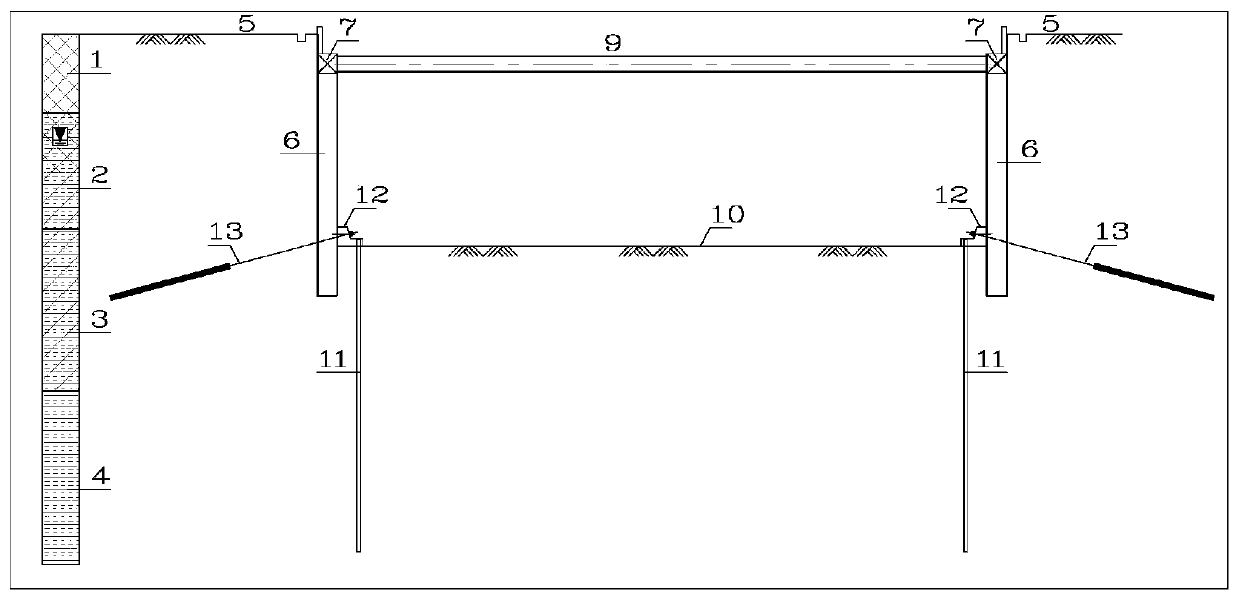

Design method of subway foundation pit end-suspended pile enclosing structure in rock stratum with soft upper portion and hard lower portion

InactiveCN110924433ASolving Envelope Design ProblemsResolve connectivityArtificial islandsExcavationsSubway stationPipe

The invention provides a design method of a subway foundation pit end-suspended pile enclosing structure in rock stratum with a soft upper portion and a hard lower portion, and relates to the technical field of underground building engineering construction, in particular to a method for designing a foundation enclosing structure when an underground subway station is excavated and built in the decayed rock stratum with the soft upper portion and the hard lower portion. Large-rigidity and large-diameter cast-in-situ bored piles are adopted in the soft upper portion of the rock stratum for enclosing, as the weakly-decayed flow liner rock stratum which is hard and large in strength on the lower portion is small in deformation and large-diameter drill holes are difficult to construct, small-diameter steel pipe piles easy to construct are adopted, and the two kinds of piles are effectively connected. The problem that enclosing piles in the decayed rock stratum with the soft upper portion andthe hard lower portion are difficult to construct is solved; the problem about effective connection of the two kinds of up-and-down discontinuous piles of a foundation pit is solved; and the purposesthat the upper cast-in-situ bored piles and the lower steel pipe piles are connected, spuds are locked by anchor cables, and the upper cast-in-situ bored piles are prevented from toppling and stability lose are achieved.

Owner:中交铁道设计研究总院有限公司

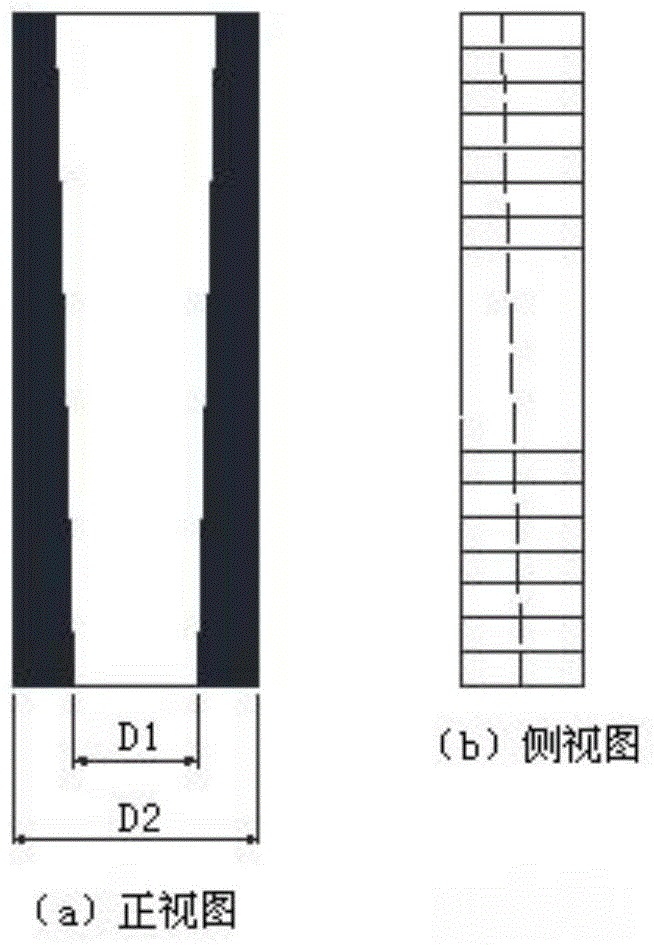

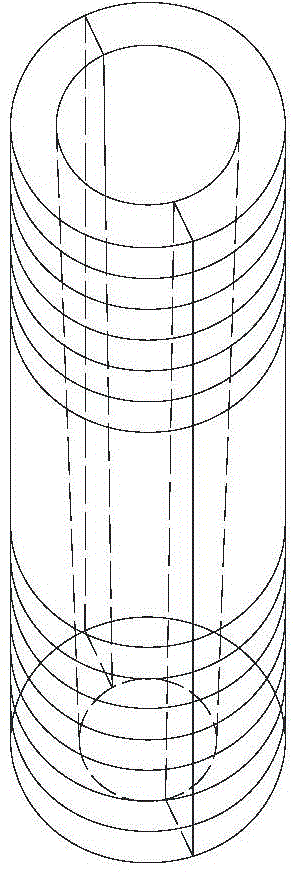

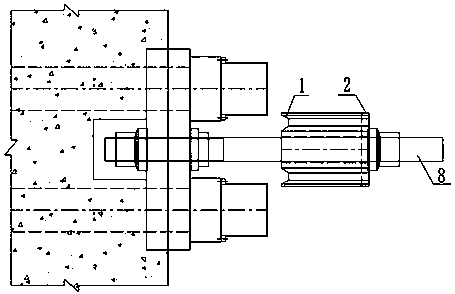

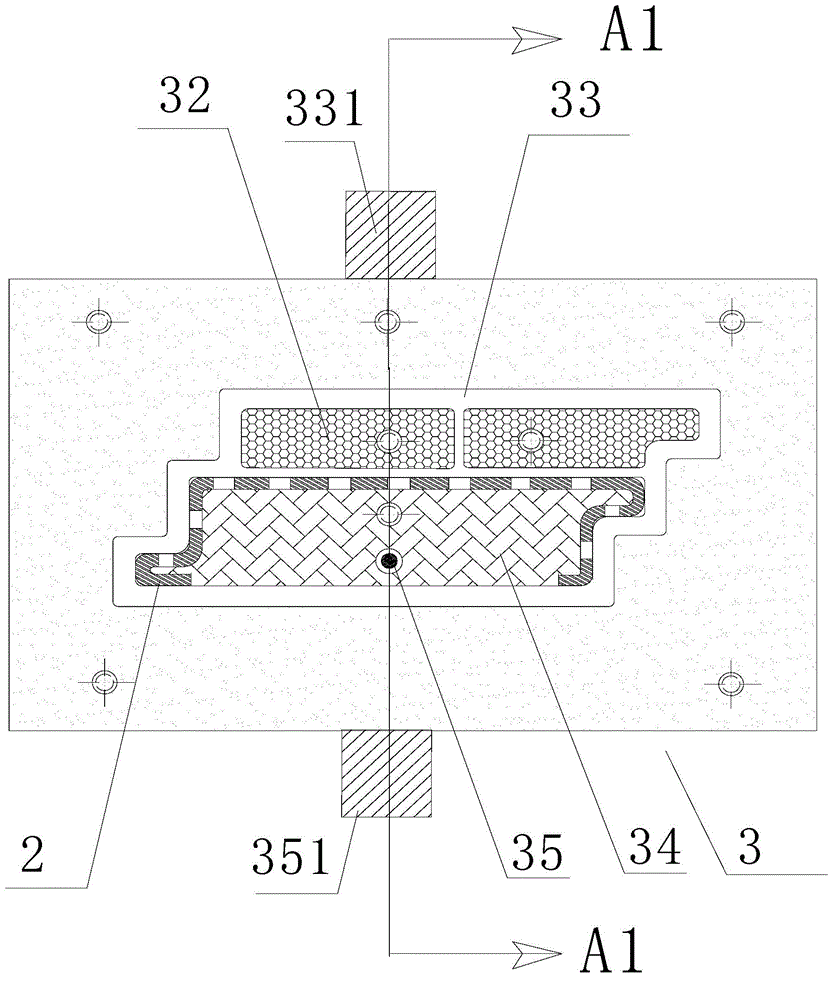

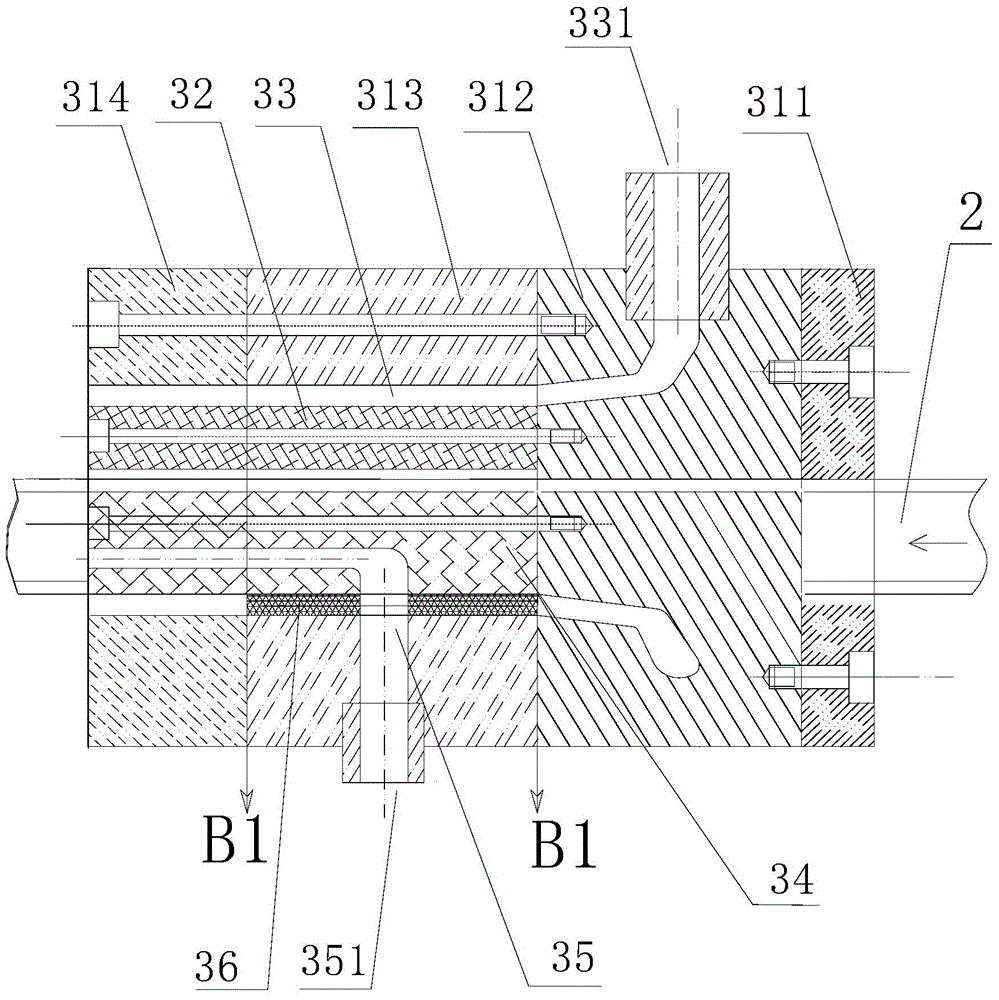

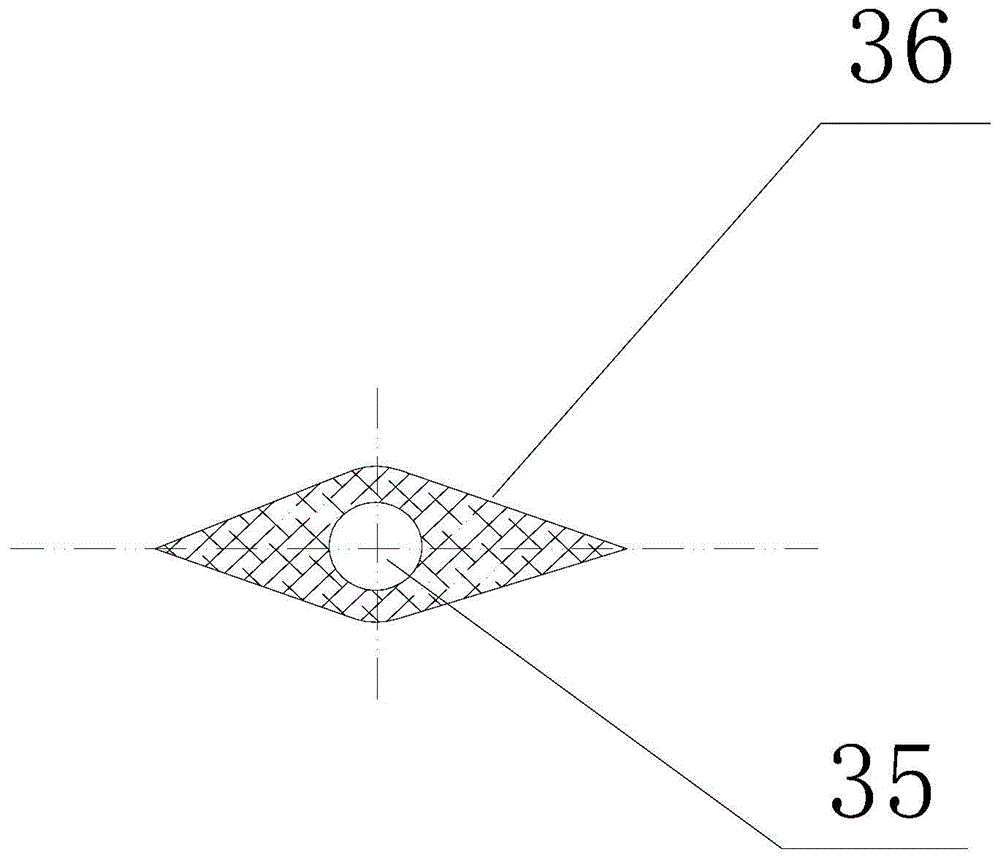

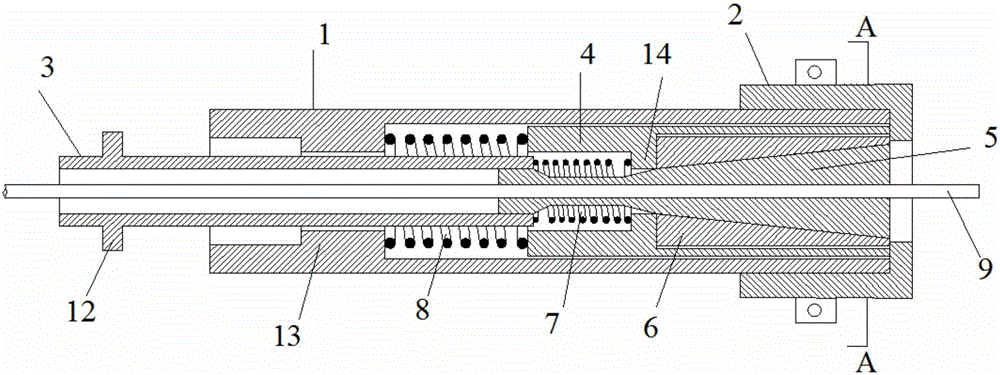

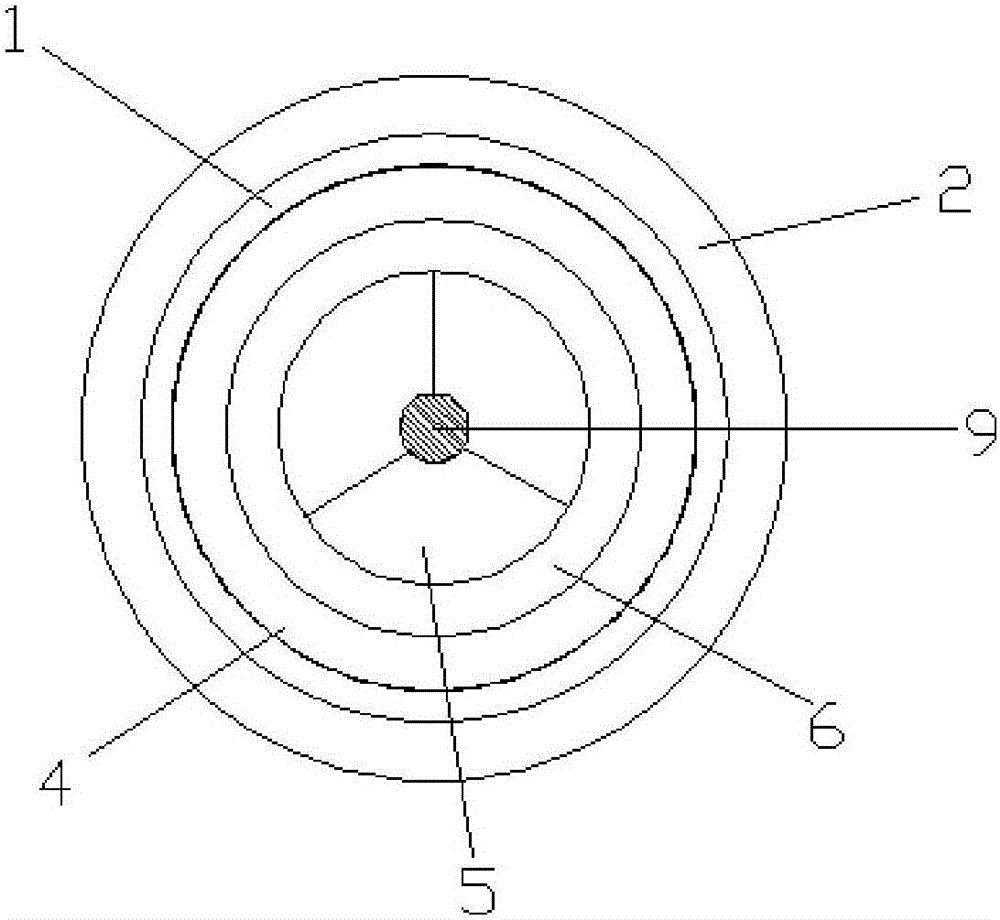

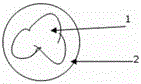

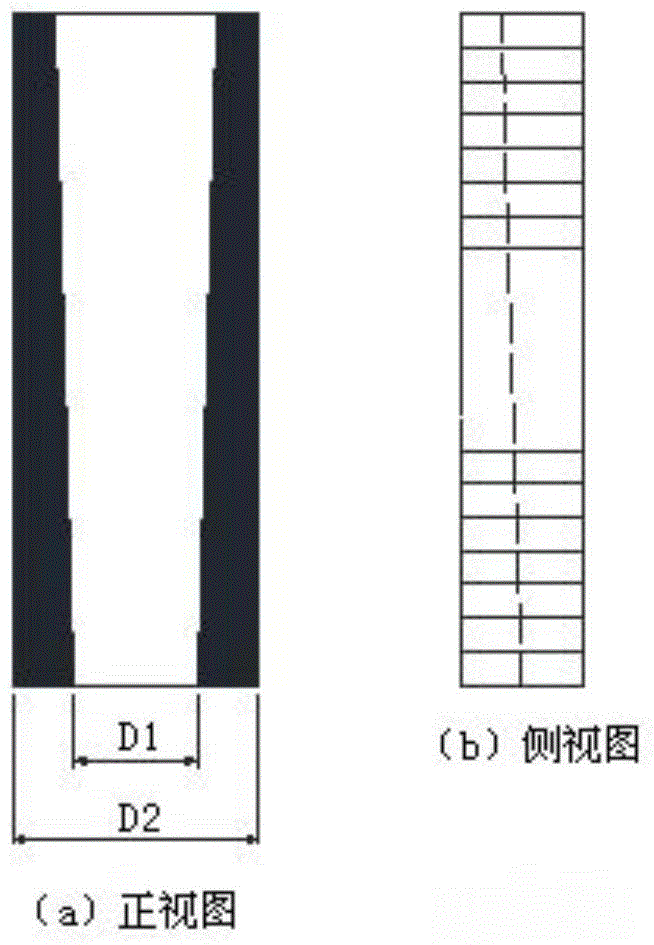

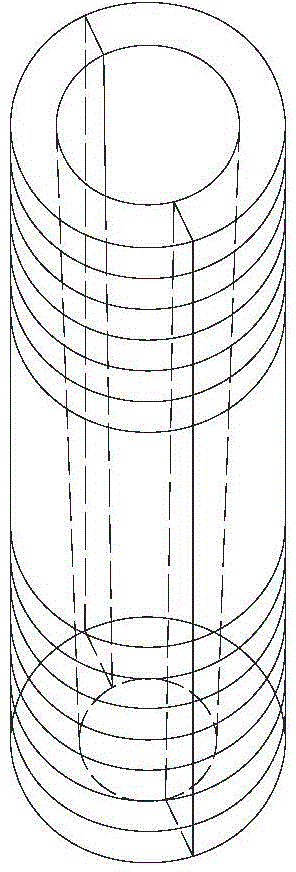

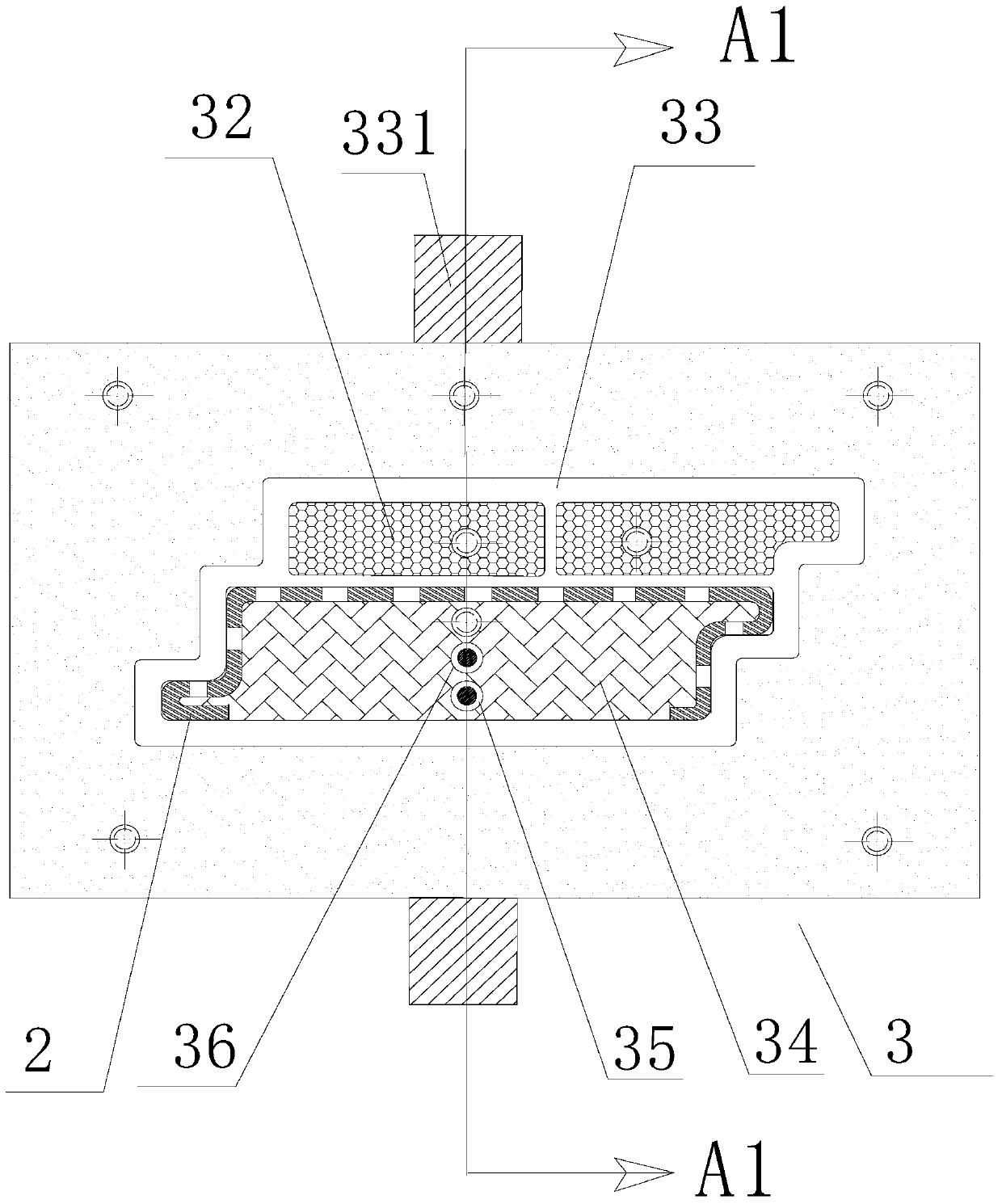

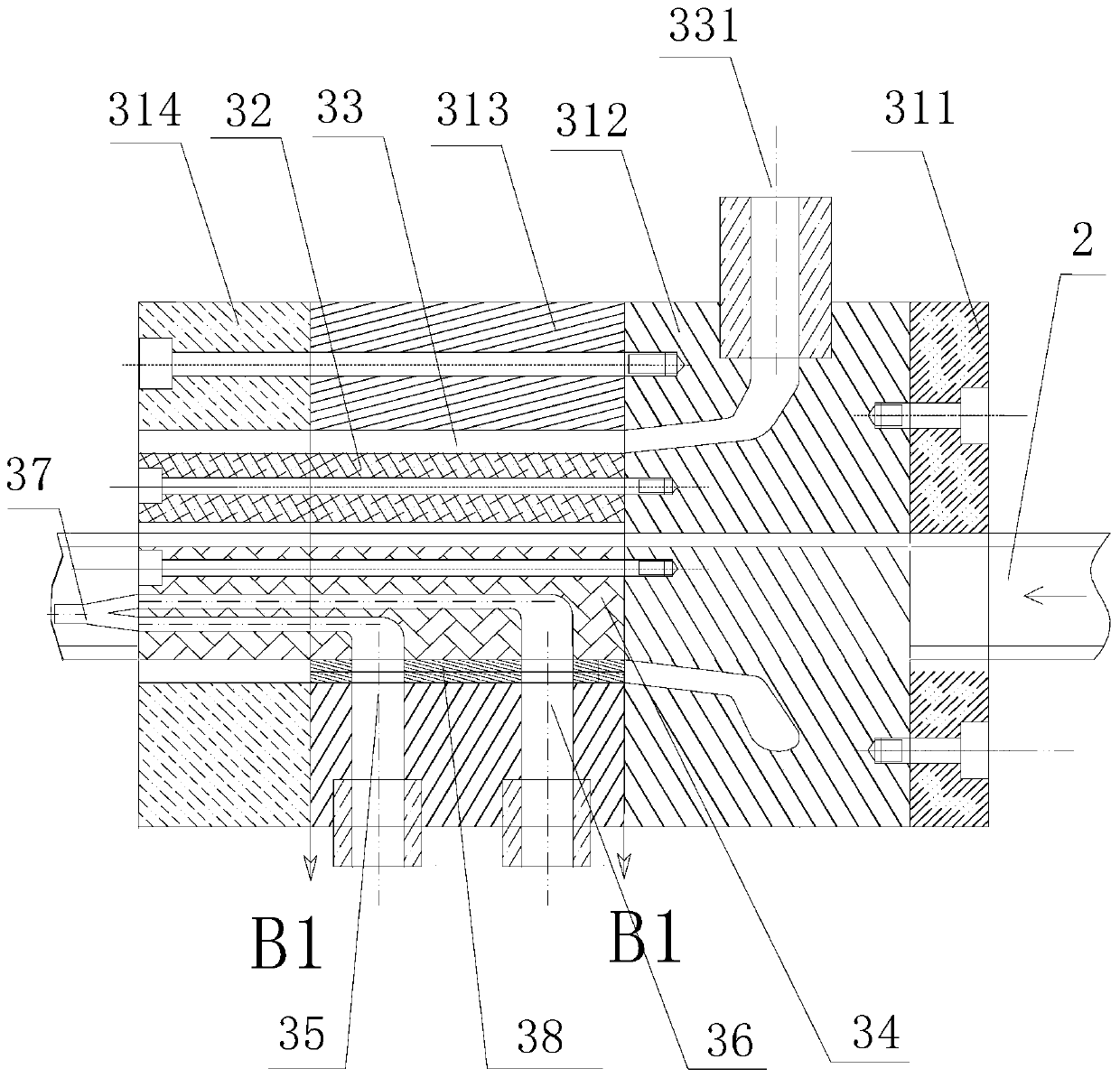

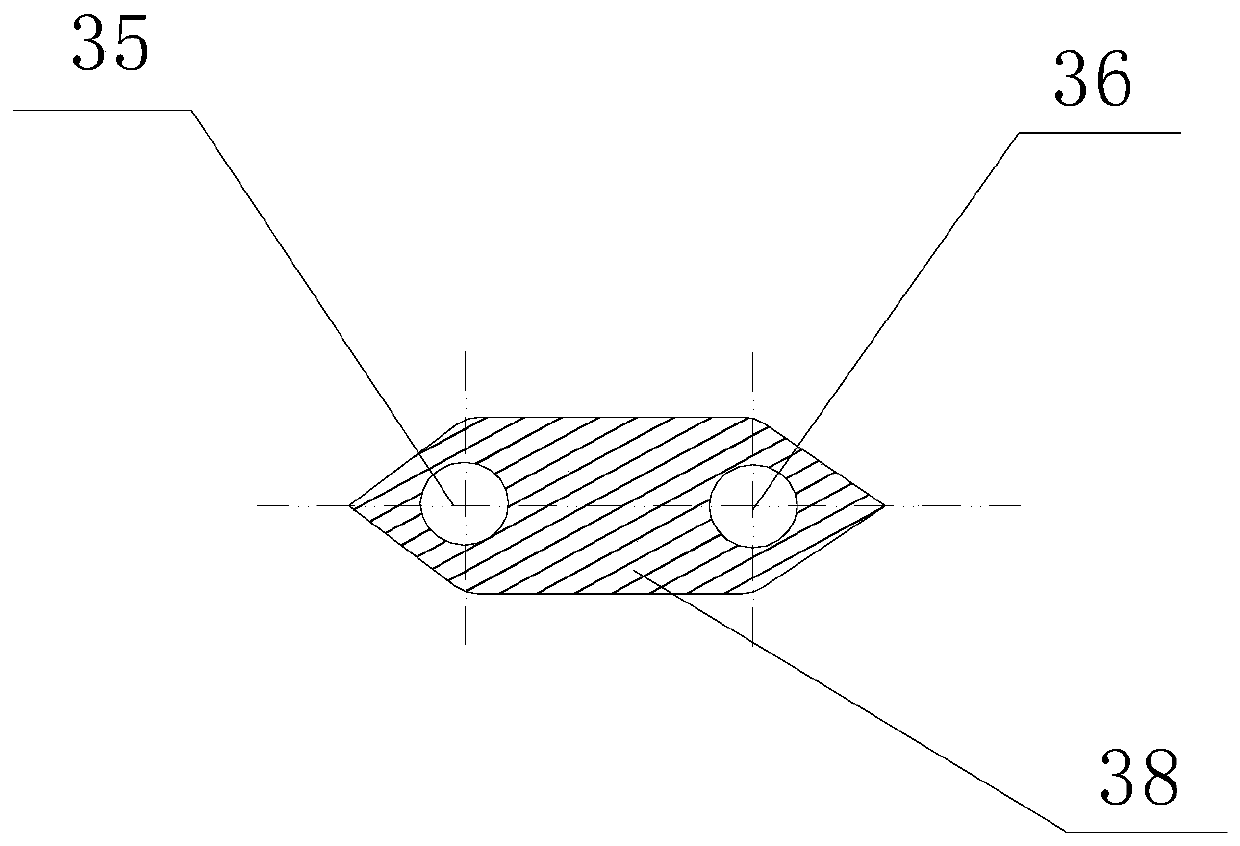

Device and method for tensile test of fragile rib material

ActiveCN103604689AIncrease squeezeEasy to removeMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention provides a device and a method for a tensile test of a fragile rib material. The device comprises a sleeve 1, a binding screw cap 2, a ball socket type screw cap 3 and a ball head pull rod 4, wherein the inner part of the sleeve 1 is a circular-platform-shaped cavity and the inner diameters of the two ends of the sleeve 1 are different; the binding screw cap 2 is screwed down on the outer part of one end with the smaller inner diameter of the sleeve 1; after the ball head pull rod 4 penetrates through the ball socket type screw cap 3, the ball socket type screw cap 3 is screwed down on the outer part of one end with the larger inner diameter of the sleeve 1. When the device and the corresponding method are used for carrying out the tensile test on the fragile rib material, a test sample does not need to be directly clamped so as to protecting end parts of the test sample from being damaged by a too large transverse concentrated force; the test sample is anchored firmly and cannot be unstuck in the testing process; and the device can be used conveniently and repeatedly.

Owner:JINLING INST OF TECH

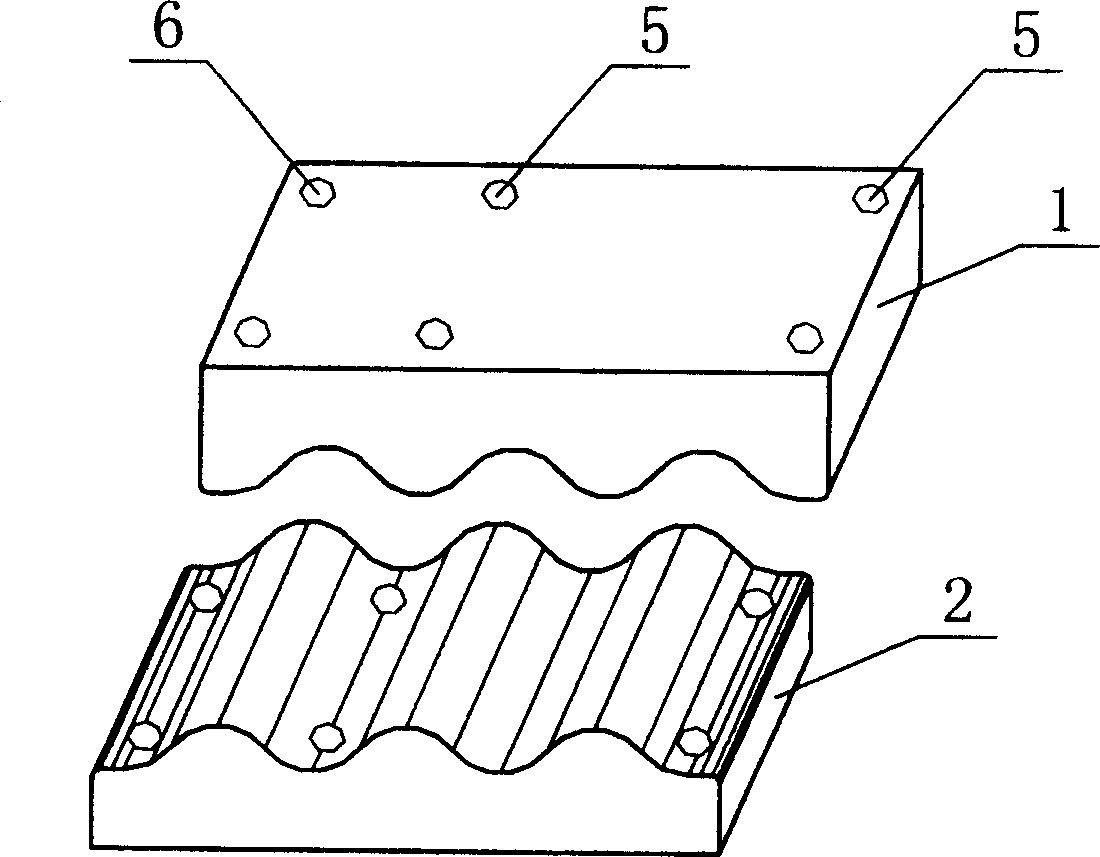

Metal sectional material and wood-plastic co-extrusion moulded composite plate as well as preparation method thereof

ActiveCN105484423AGuaranteed basic strengthReduce steel consumptionBuilding componentsCo extrusionPlastic materials

The application provides a metal sectional material and wood-plastic co-extrusion moulded composite plate. The metal sectional material and wood-plastic co-extrusion moulded composite plate comprises a wood-plastic frame and a metal sectional material, wherein the wood-plastic frame is provided with a first chamber; the metal sectional material is located in the first chamber; the wall surface of the first chamber is bonded with the surface of the metal sectional material; the metal sectional material is provided with a plurality of prefabricated holes; the first chamber of the wood-plastic frame is provided with projections embedding into or penetrating through the prefabricated holes; the projections are integrally moulded with the wood-plastic frame, wherein the wood-plastic frame is made from a foamed wood-plastic material, and the metal sectional material is an open metal sectional material. According to the co-extrusion moulded composite plate provided by the embodiment of the invention, the open metal sectional material is used, and a closed shape is not used, thus ensuring the basic strength of the composite plate, saving the consumption of steel, and creating conditions for realizing compressed air inner-cooling for an extrusion mould.

Owner:BEIJING NEW BUILDING MATERIAL

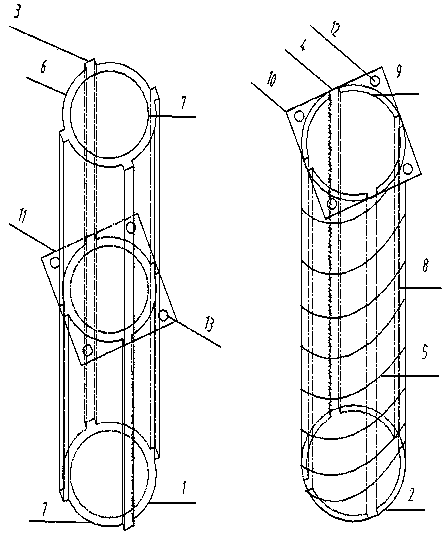

Main cable strand anchoring device of suspension bridge

PendingCN109440643ASolve anchoring problemsThe power transmission path is clearBridge structural detailsEngineeringBuilding construction

The invention relates to a main cable strand anchoring device of a suspension bridge, which comprises a strand boot, a pull rod and a pull rod anchoring assembly; the strand boot is a semi-cylindricalblock structure, which comprises a circular arc surface, semicircular surfaces on both sides and a rectangular surface on the opposite side of the circular arc surface; a plurality of strand boot grooves for locating and winding steel wires are formed in the circular arc surface of the strand boot, and the track of the strand boot grooves is parallel to the outer arc of the strand boot; the strand boot is provided with a pull rod opening perpendicular to the rectangular surface; the pull rod passes through the pull rod opening, wherein one end of the pull rod is anchored to the front anchor surface by the pull rod anchoring assembly, and the other end is fixed to the rectangular surface of the strand boot by the pull rod anchoring assembly. According to the main cable strand anchoring device of the suspension bridge, the anchoring problem of the main cable strand of an AS-method suspension bridge can be solved, and has the advantages of clear route of transmission force, simple and reliable force, in line with the construction process of the main cable strand of the AS-method suspension bridge, and the construction technology is simple and convenient.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Co-extrusion molding composite board and preparation method thereof

The present invention provides a co-extrusion molding composite board. The co-extrusion molding composite board comprises a wood plastic frame, a foaming layer and a metal profile; the wood plastic frame is provided with a first cavity; the metal profile has an opening; the metal profile is positioned in the first cavity; the wall surface of the first cavity is bonded to the surface of the metal profile; the foaming layer is put in a space enclosed by the first cavity and the metal profile; the foaming layer is bonded to the wall surface of the first cavity and the surface of the metal profile; and the foaming layer is prepared by foaming materials. According to the composite board, the internal metal profile effectively provides mechanical strength, the metal profile, the foaming layer and the wood plastic frame are composited and integrated, so that the requirement for strength of the wood plastic part is reduced, the foaming technology can be adopted for materials of the wood plastic frame, wood plastic materials are saved, and heat and sound insulation performance of the composite board applied as a wall board is largely improved.

Owner:BEIJING NEW BUILDING MATERIAL

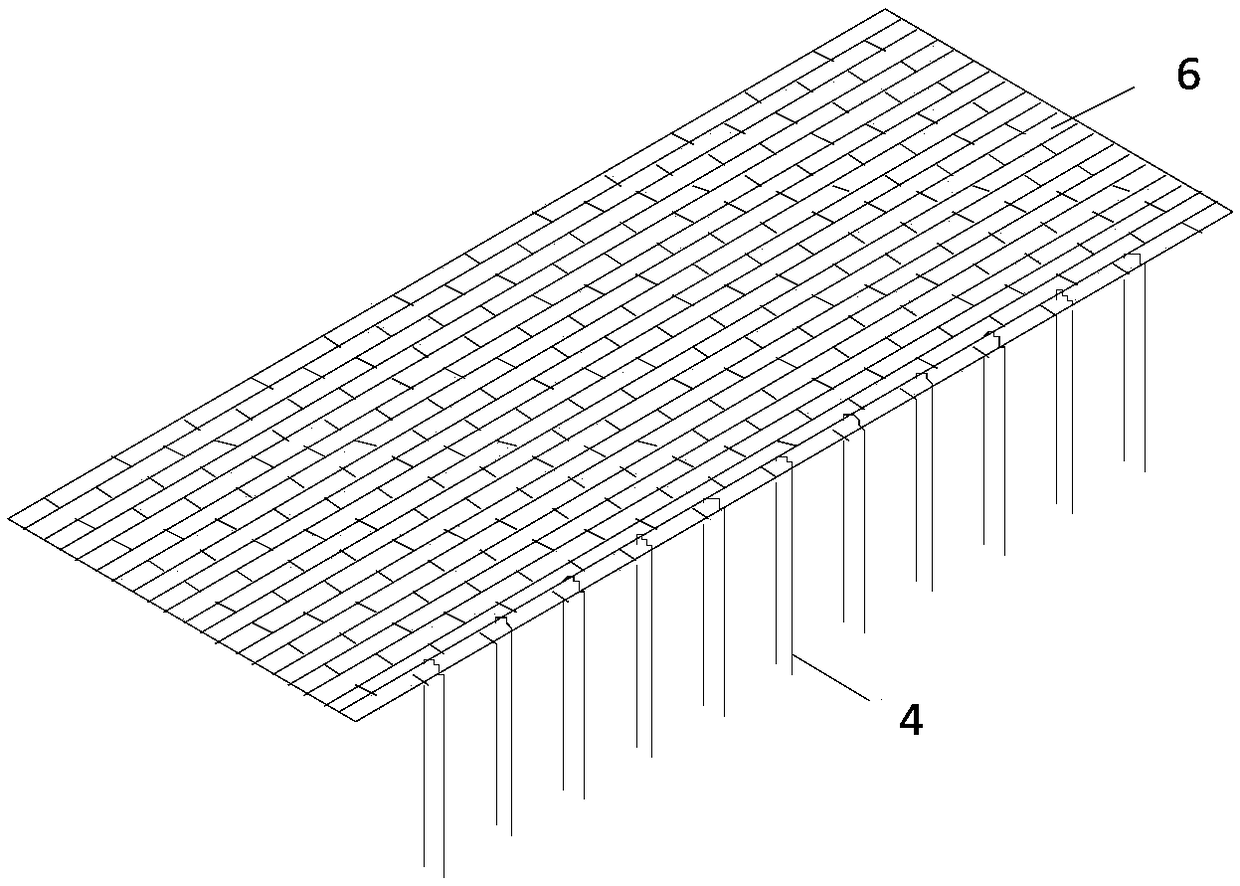

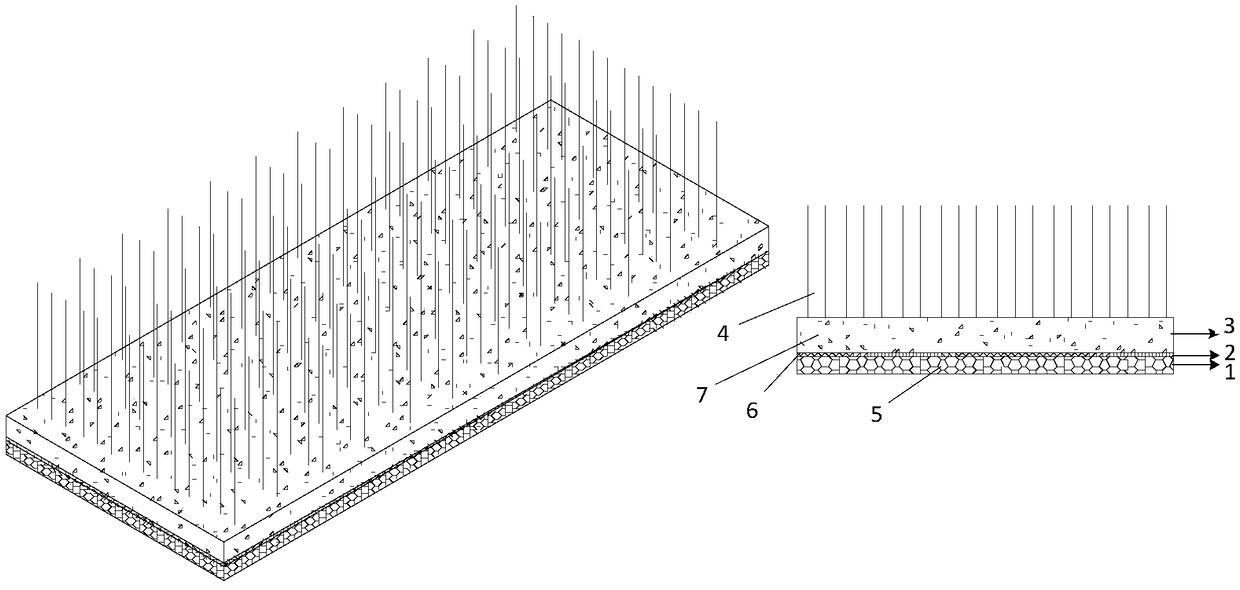

Prefabricated fiberboard and method for connecting prefabricated fiberboard with composite material profile

The invention discloses a prefabricated fiberboard and a method for connecting the prefabricated fiberboard with a composite material profile. The fiberboard comprises an epoxy resin adhesive layer provided with a carbon fiber cloth impregnating adhesive, a carbon fiber cloth layer connected with the epoxy resin adhesive layer, an adhesive sand mixed layer connected with the carbon fiber cloth layer and a plurality of steel fibers perpendicularly disposed on the carbon fiber cloth layer, wherein the carbon fiber cloth layer is provided with a carbon fiber cloth; and the adhesive sand mixed layer is provided with sand particles. An anchoring performance enhancement technology based on the prefabricated fiberboard and the method for connecting the prefabricated fiberboard with the compositematerial profile can significantly improve the anchoring performance between the composite material profile and concrete, the construction is convenient, and the application prospects in a composite material-concrete composite structure are broad.

Owner:TSINGHUA UNIV

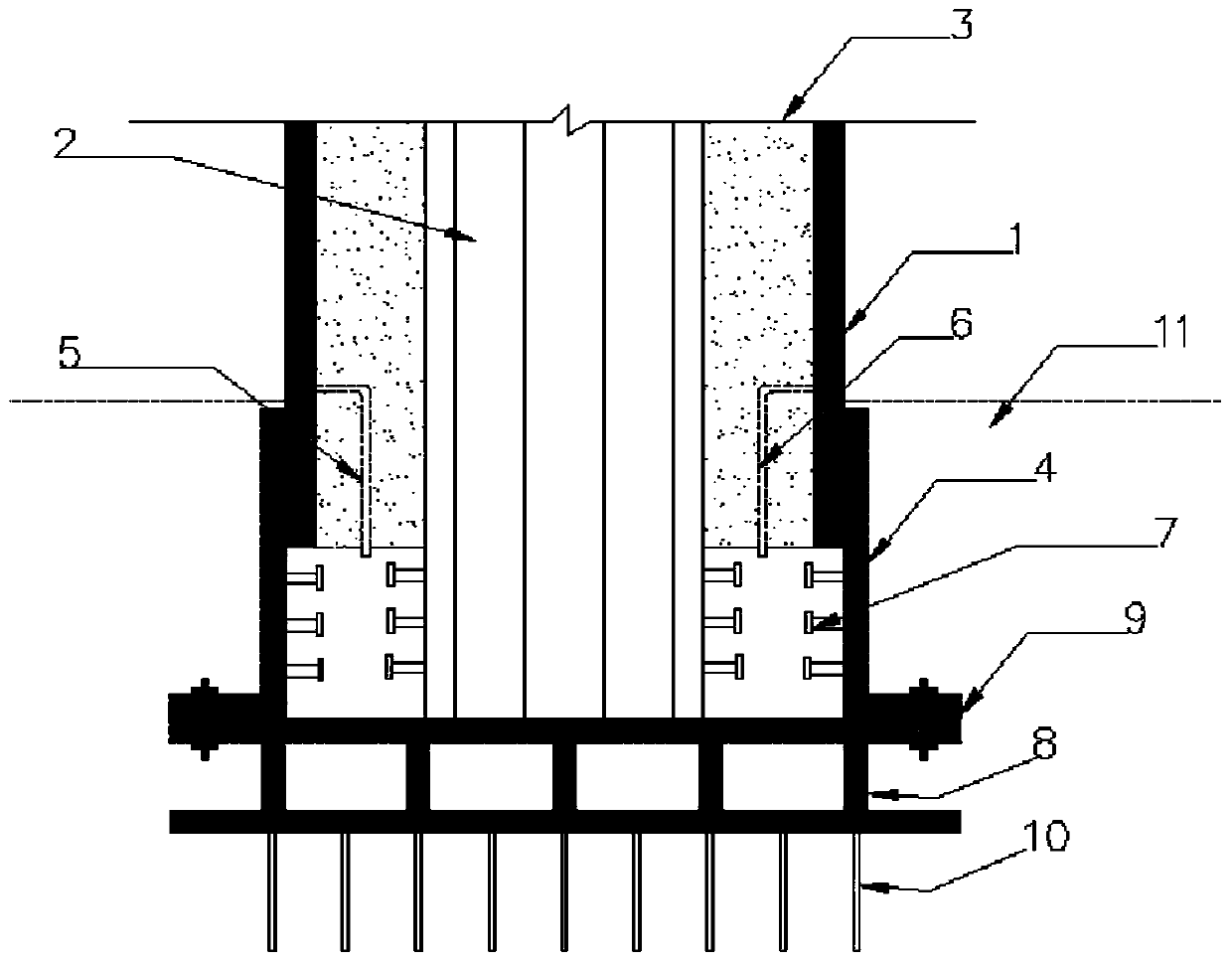

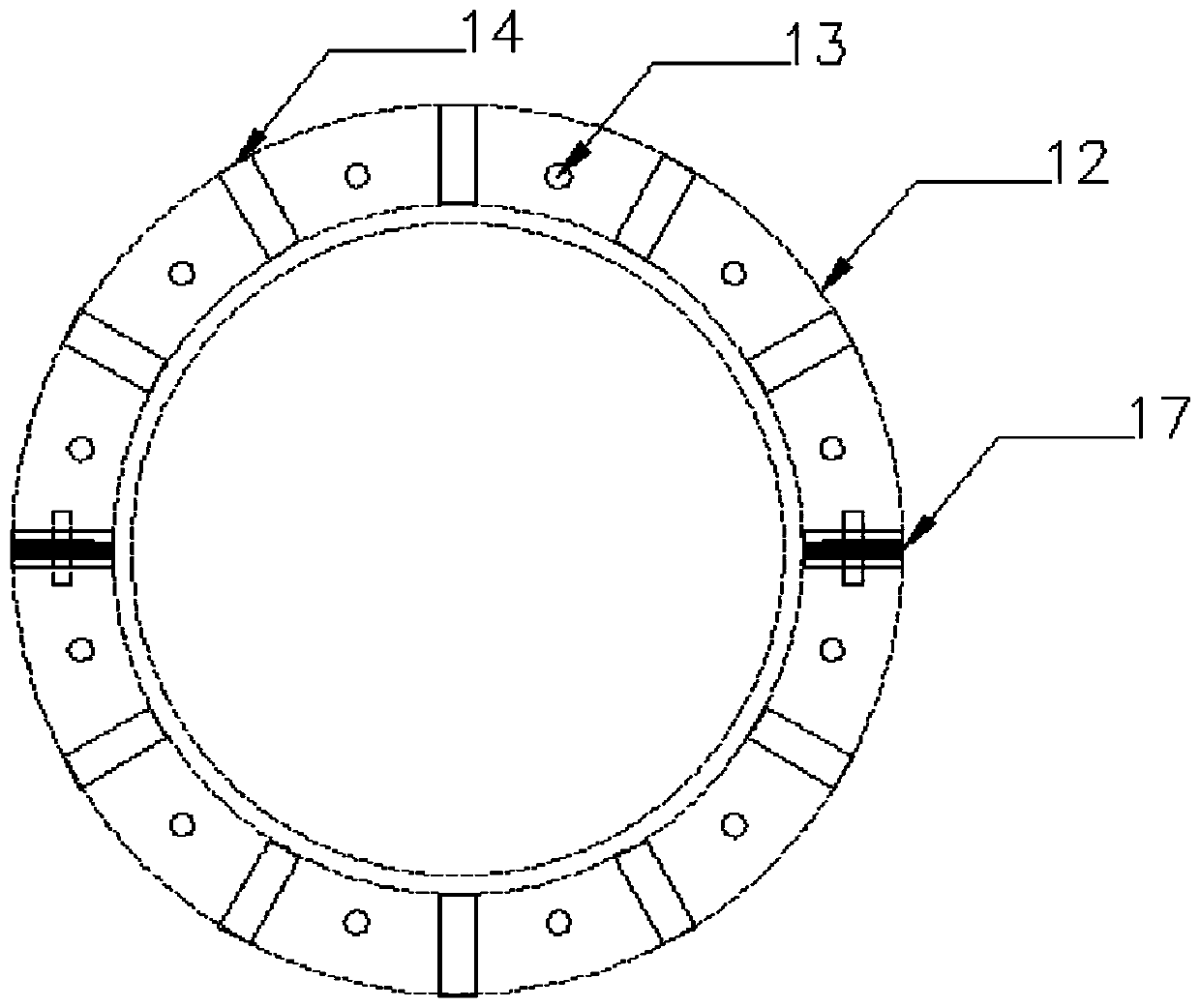

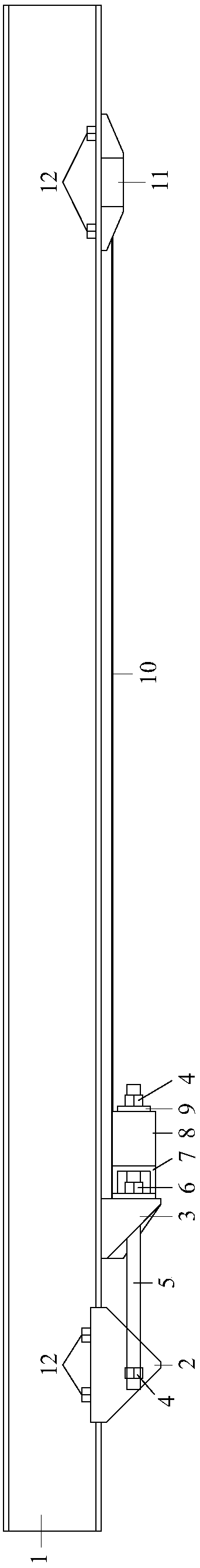

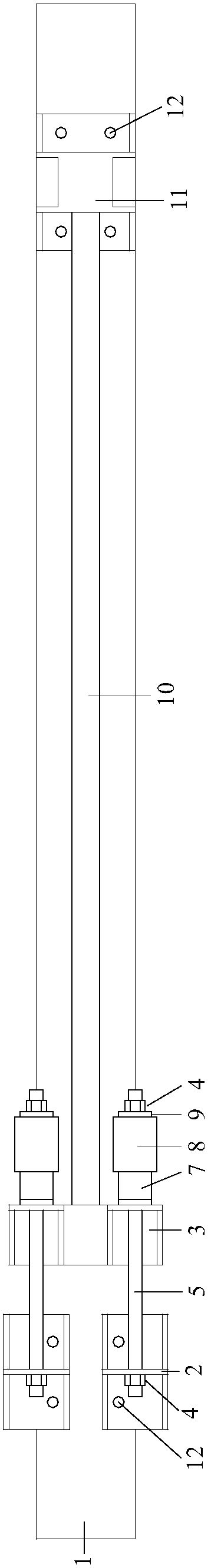

Comb breakwater system simultaneously giving consideration to oscillating float type wave energy generation

PendingCN109083092AReduce risk of damageGood for overall stabilityBreakwatersQuaysEngineeringEnergy device

The invention discloses a comb breakwater system simultaneously giving consideration to oscillating float type wave energy generation, and belongs to the technical field of ocean power generation andwave resistance. The comb breakwater system comprises chamfering caissons 1, a diversion wall 2, breast walls 3, wing plates 4, a bottom plate 5 and a float type power generating device; wherein the chamfering caissons 1 are arranged in the axial direction of a breakwater at intervals to form a breakwater wave-eliminating chamber, the wing plates 4 are arranged on the back wave surfaces between the adjacent caissons; the breast walls 3 are arranged above the chamfering caissons 1 and the wing plates 4, and therefore the integrity of the structure is enhanced; and the bottom plate 5 is immersedat the bottom of the breakwater wave-eliminating chamber, and the float type power generating device is fixed on the bottom plate 5. From the point of view of design, two functions are realized in one project, and the overall cost is reduced; from the point of view of construction, the comb breakwater provides a fixed condition for the float type wave energy device and reduces the anchoring costof the wave energy device; and from the point of view of later period operation and maintenance, assessment of the breakwater and maintenance of the power generation device can be carried out simultaneously during one attendance period, and later period operation and maintenance are facilitated.

Owner:HARBIN ENG UNIV

Fabricated adjustable carbon fiber reinforced plastic (CFRP) cable anchoring tool

ActiveCN106522098AIncrease preloadCounteract micro-retractionBridge erection/assemblyBuilding reinforcementsBridge engineeringFiber

The invention discloses a fabricated adjustable carbon fiber reinforced plastic (CFRP) cable anchoring tool and belongs to the technical field of bridge engineering. According to the fabricated adjustable CFRP cable anchoring tool, later stage cable adjustment is convenient, internal stress is reasonable, and repeated use is available. The fabricated adjustable CFRP cable anchoring tool comprises a steel sleeve and an anchoring nut, and is characterized in that a first annular rib is arranged inside one end of the steel sleeve, a thread is arranged on the outer side of the other end of the steel sleeve, and the thread is matched with the anchoring nut; a steel barrel is arranged inside one side of the first annular rib of the steel sleeve, a rib steel barrel is arranged inside the other side of the first annular rib of the steel sleeve, a second annular rib is arranged in the middle of the inner side of the rib steel barrel, a wedge-shaped clamping piece penetrates through the second annular rib of the rib steel barrel to be arranged in the rib steel barrel, an anchoring ring is arranged between the outer end of the wedge-shaped clamping piece and the rib steel barrel, and the inner end of the wedge-shaped clamping piece is connected with the inner end of the steel barrel; and a first spring is arranged outside the portion, located between the second annular rib of the rib steel barrel and the steel barrel, of the wedge-shaped clamping piece, a second spring is arranged outside the portion, located between the rib steel barrel and the first annular rib of the steel sleeve, of the steel barrel, and the outer end of the rib steel barrel makes contact with the anchoring nut.

Owner:LIAONING TECHNICAL UNIVERSITY

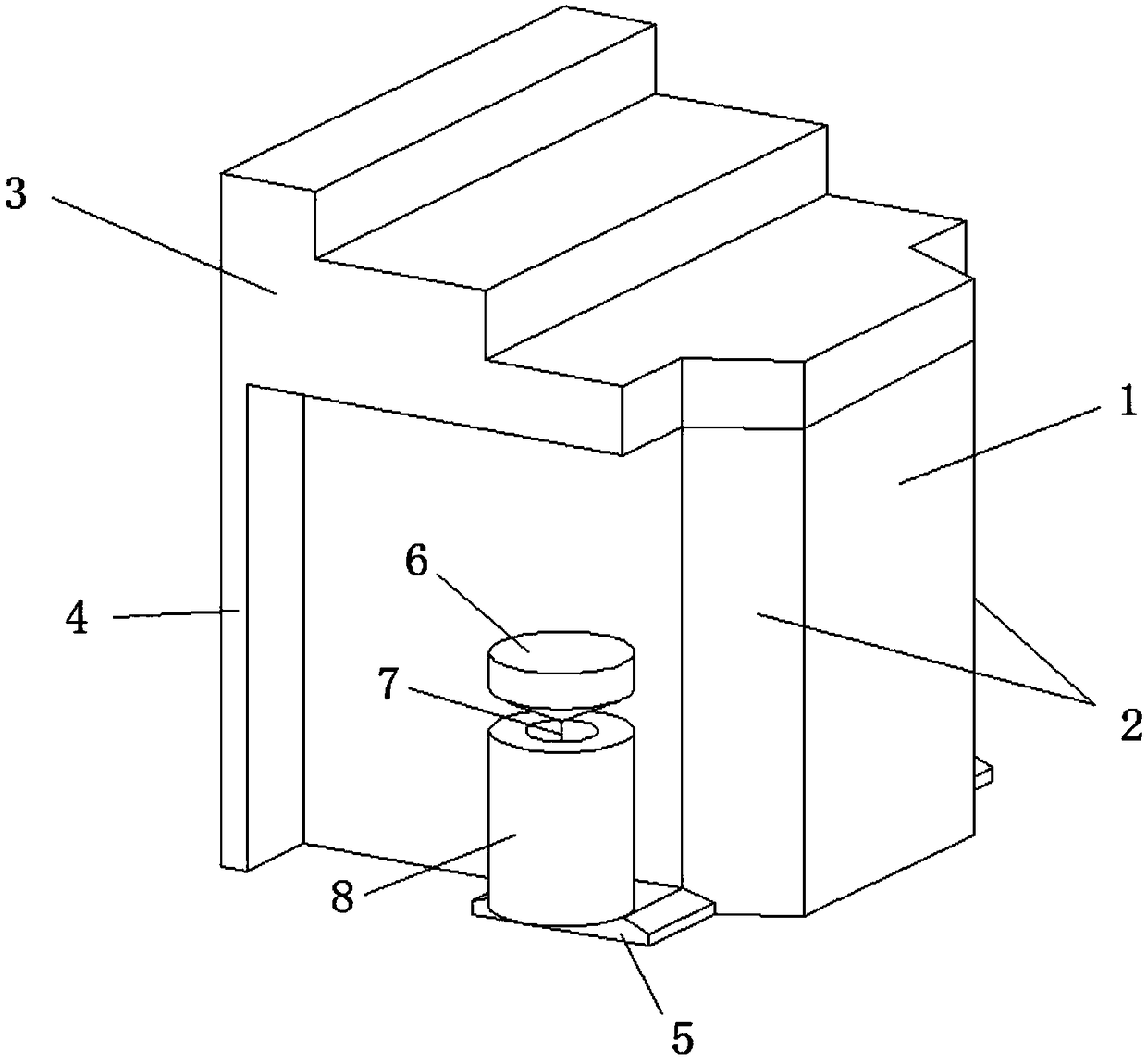

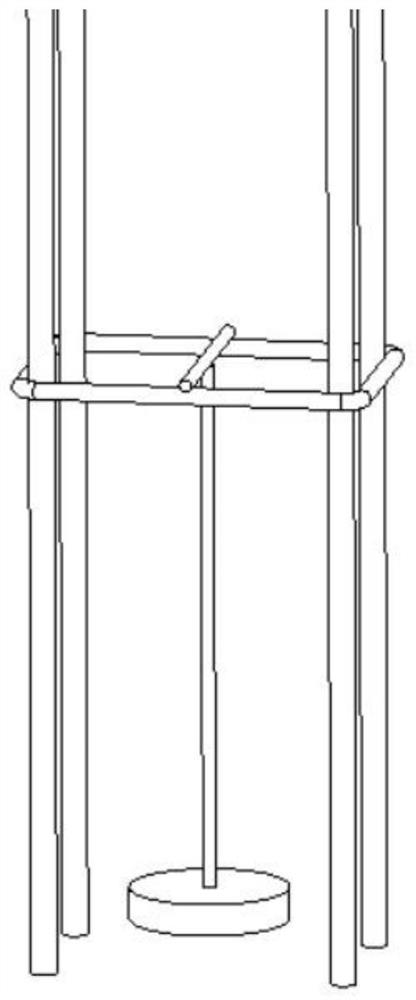

Supporting anchoring structure suitable for large-water-level-amplitude water surface floating photovoltaic power station and construction method

PendingCN108750014ASolve anchoring problemsIncrease the utilization areaFloating buildingsAnchoring arrangementsReinforced concrete columnMarine engineering

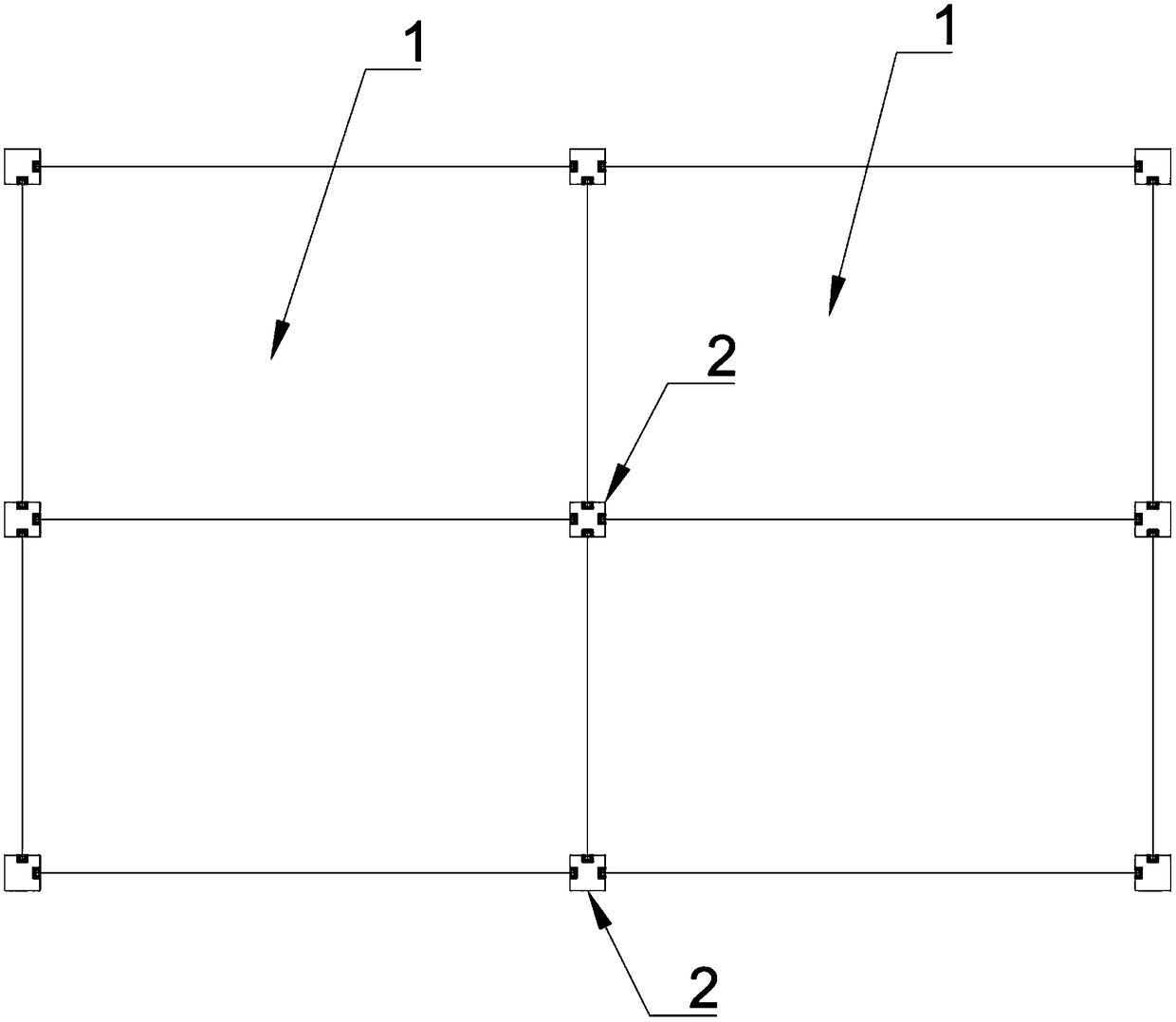

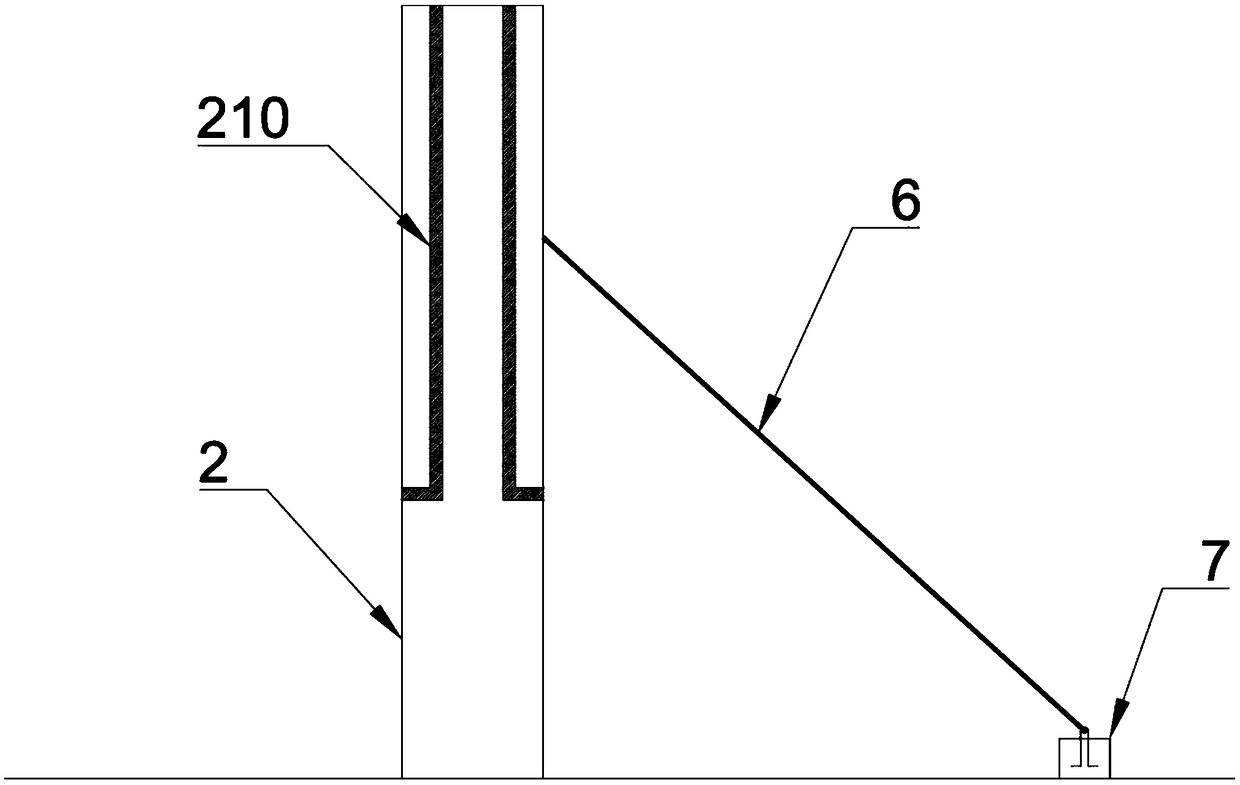

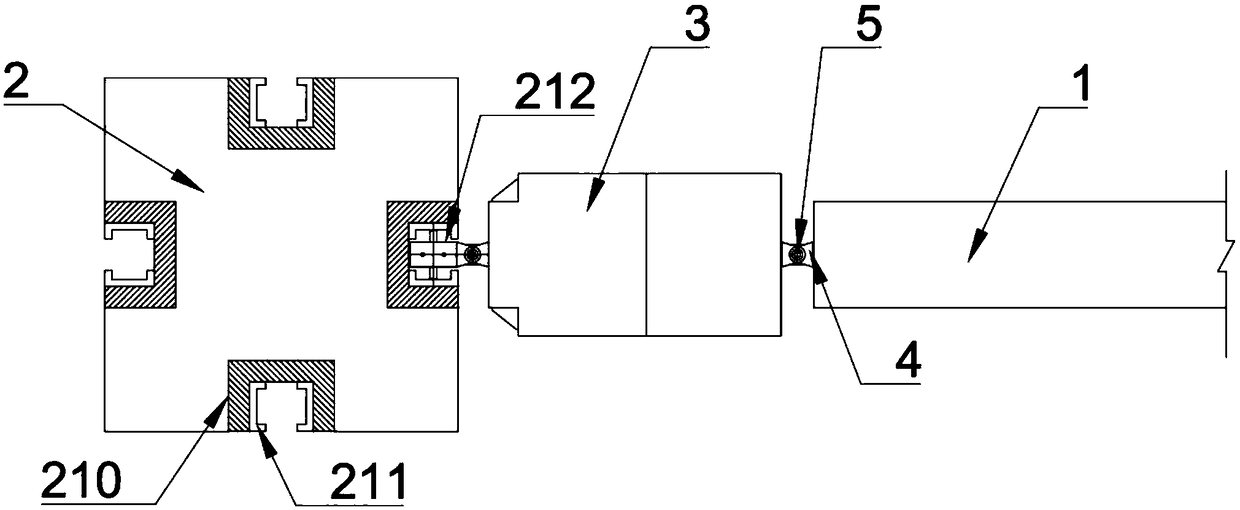

The invention belongs to the technical field of water conservancy and hydropower and particularly relates to a supporting anchoring structure suitable for a large-water-level-amplitude water surface floating photovoltaic power station and a construction method. The supporting anchoring structure suitable for the large-water-level-amplitude water surface floating photovoltaic power station comprises reinforced concrete columns, the reinforced concrete columns are arranged on the periphery of the water surface floating photovoltaic power station, vertically-formed guide grooves are formed in theside faces of the reinforced concrete columns and internally provided with supporting restraint wheels, the ends, facing openings of the guide grooves, of the supporting restraint wheels are connected with floating boxes, and the ends, away from the supporting restraint wheels, of the floating boxes are connected to the water surface floating photovoltaic power station. The supporting anchoring structure suitable for the large-water-level-amplitude water surface floating photovoltaic power station is provided, the anchoring problem of the water surface floating photovoltaic power station under the condition of the large water level amplitude can be solved so that the water surface floating photovoltaic power station can be built in a reservoir with the large water level amplitude, and thewater surface use area of the reservoir is increased.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

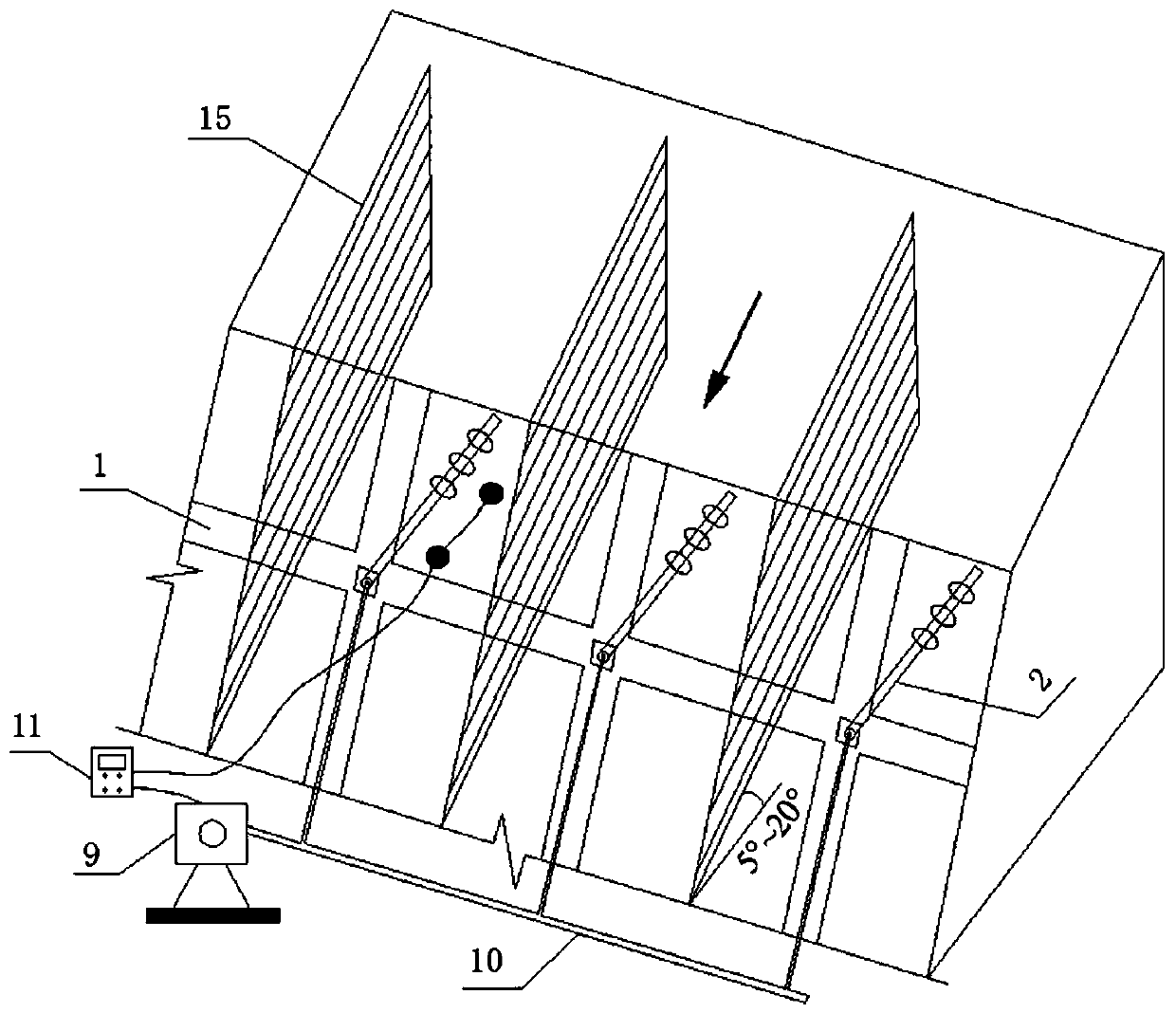

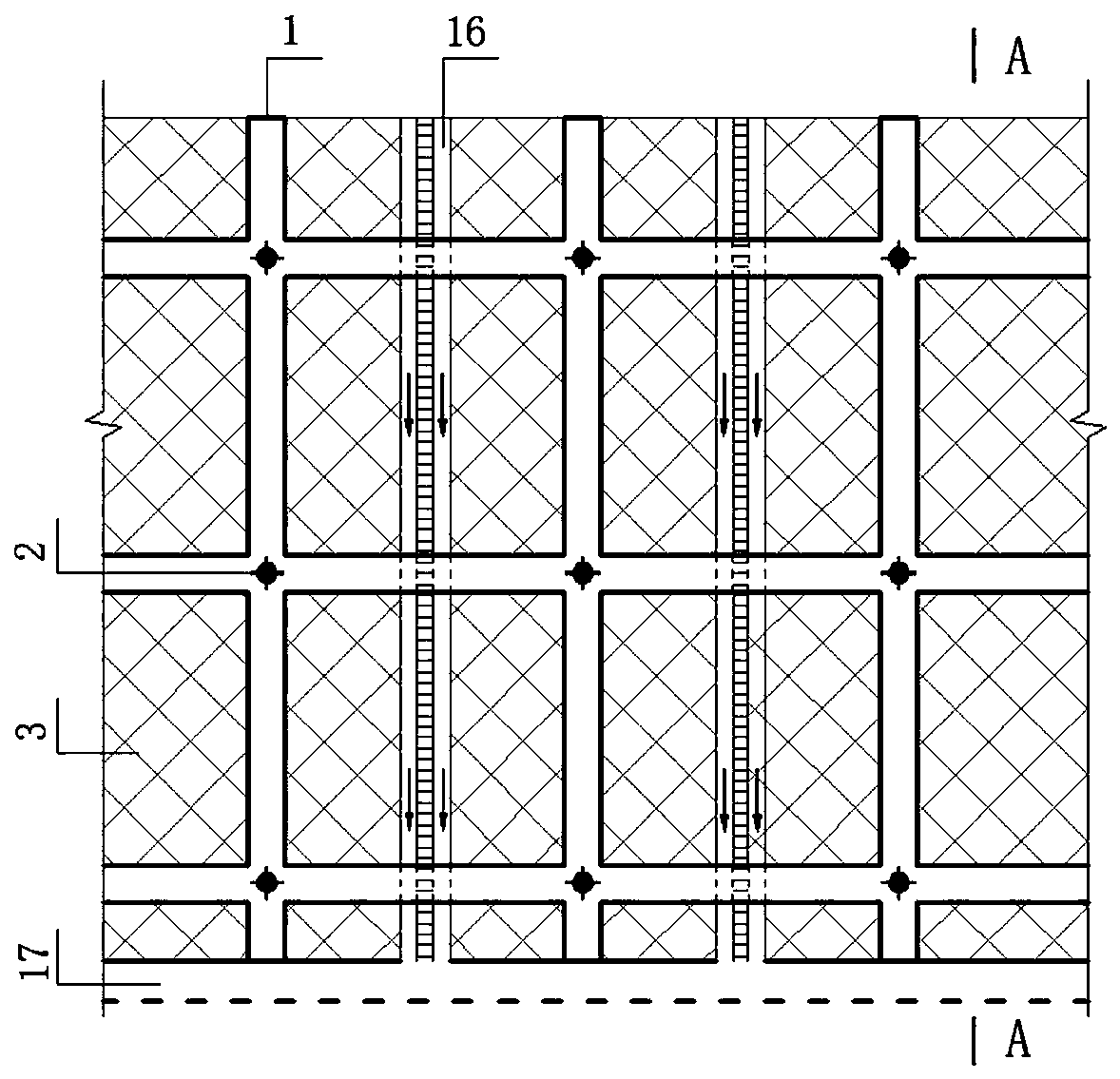

Air inflation dewatering type slope anchoring body system and construction method thereof

InactiveCN110424417AGood governanceSolve the supportExcavationsBulkheads/pilesWater level riseLandslide

The invention provides an air inflation dewatering type slope anchoring body system and a construction method thereof. The system comprises an anchoring structure, an air inflation device and a dewatering system; a frame and hollow anchor pipes are fixed through anchorage devices, and dewatering plates and moisture meters are arranged between the two hollow anchor pipes; an air compressor is connected with the hollow anchor pipes through an air inflation pipe; the two sides of the dewatering plates are provided with vertical dewatering grooves; the root of a slope is provided with a transversedrain; a controller is connected with the water meters and the air compressor through wires; and when the water content of the slope is higher than the set water content, the controller is connectedwith the air compressor, air is injected into the hollow anchor pipes, water in the slope is drained from plate openings of the dewatering plates under action of air pressure, and otherwise, dewatering is not conducted. According to the air inflation dewatering type slope anchoring body system and the construction method thereof, the effect that air inflation dewatering and grouting anchorage areconducted at the same time is achieved, a new idea is provided for the landslide problem caused by raining or underground water level rising, the anchoring and dewatering effects are obvious, the structure is simple and easy to implement, and the landslide risk can be reduced.

Owner:NINGXIA UNIVERSITY

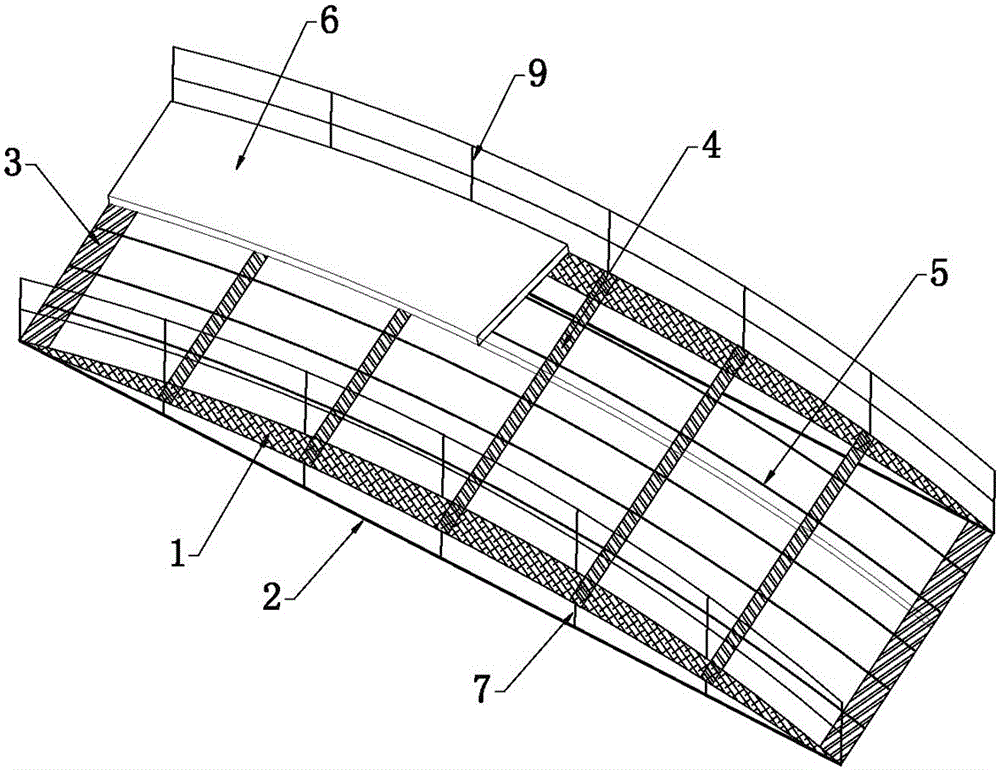

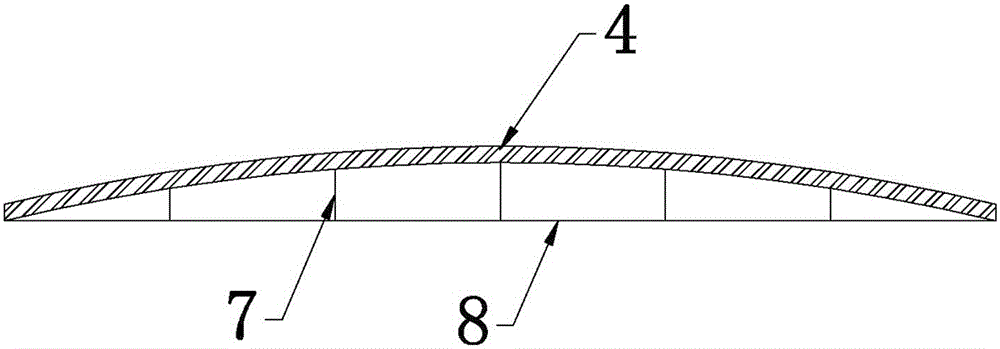

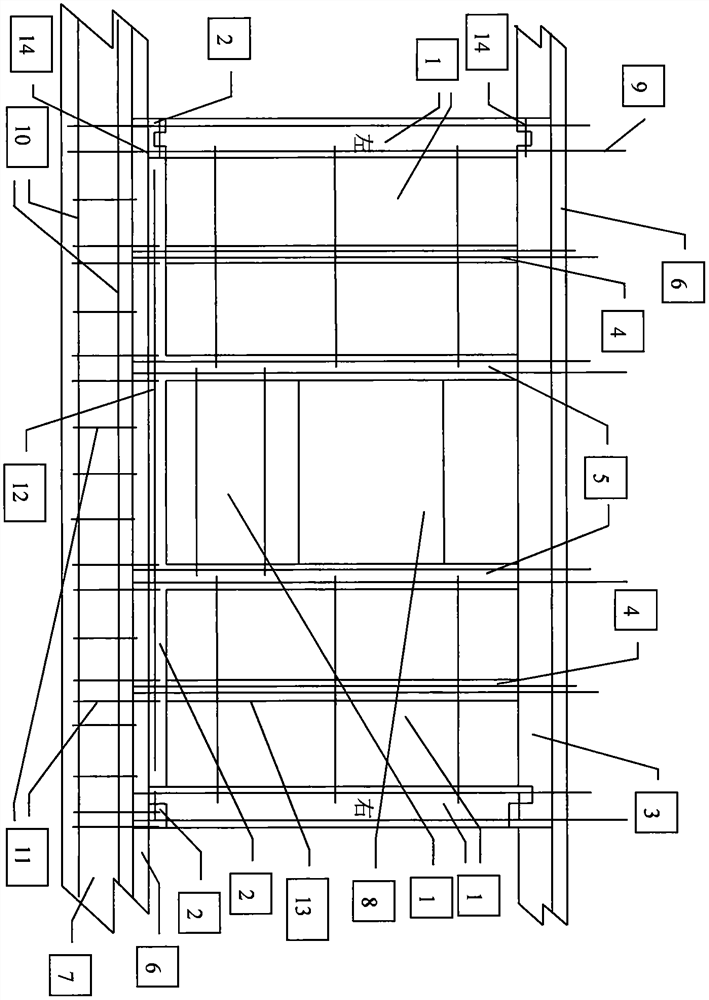

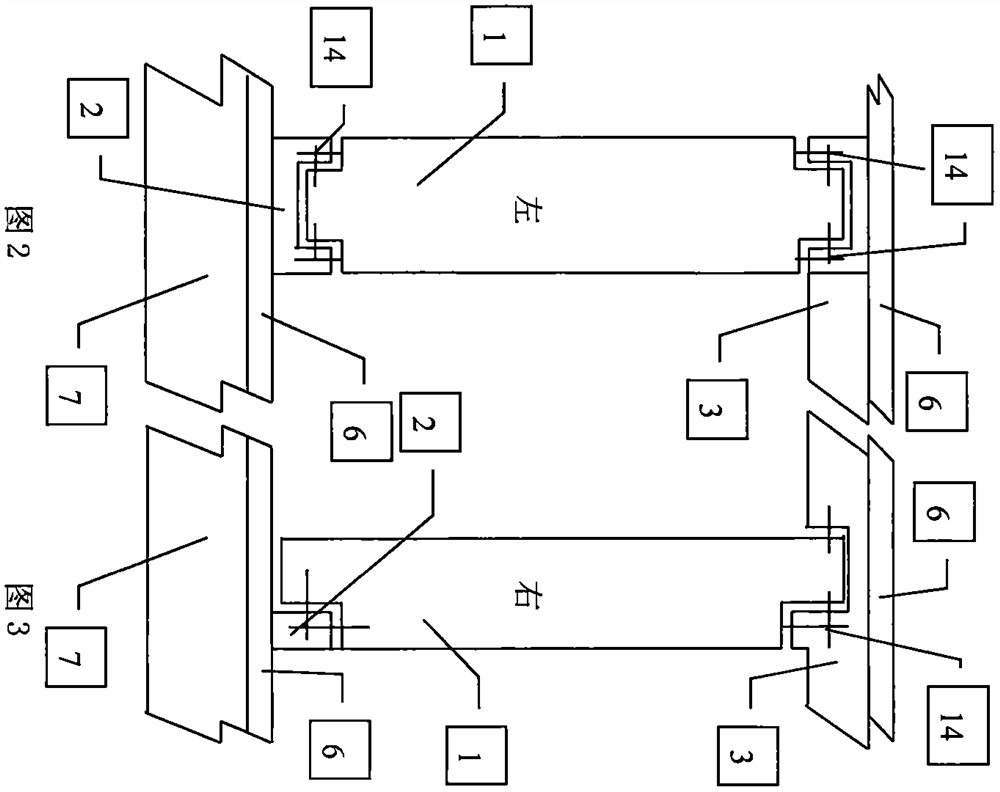

A kind of upper bearing type cable-arch composite structure bridge

ActiveCN103774543BSolve anchoring problemsActing as thrust balanceArch-type bridgeBridge deckStructural engineering

The invention discloses a deck bridge with a cable-arch combination structure. The deck bridge comprises arch ribs (1), wherein the two ends of each arch rib are connected by an arch rib balance cable (2); the same ends of the two parallel arch ribs (1) are fixedly connected by end cross beams (3) respectively; a middle cross beam (4) is arranged in a region defined by the two end cross beams (3) and the two arch ribs (1); the two ends of the middle cross beam (4) are connected with the parallel arch ribs (1) respectively; the two end cross beams (3) are connected by a bridge-deck cable (5); the bridge-deck cable (5) is arranged on the middle cross beam (4); a bridge-deck steel plate (6) is paved above the bridge-deck cable (5). The deck bridge adopts the cable-arch combination structure for bringing the characteristics of pull bearing of steel cables and pressure bearing of steel pipes into full play, solves the problems of cable anchorage and stabilization, is wide in application range, good in overall stress, light and safe in structure, easy to anchor, convenient to transport and quick to construct, can be subjected to factory production, and is suitable for popularization and application.

Owner:王新民

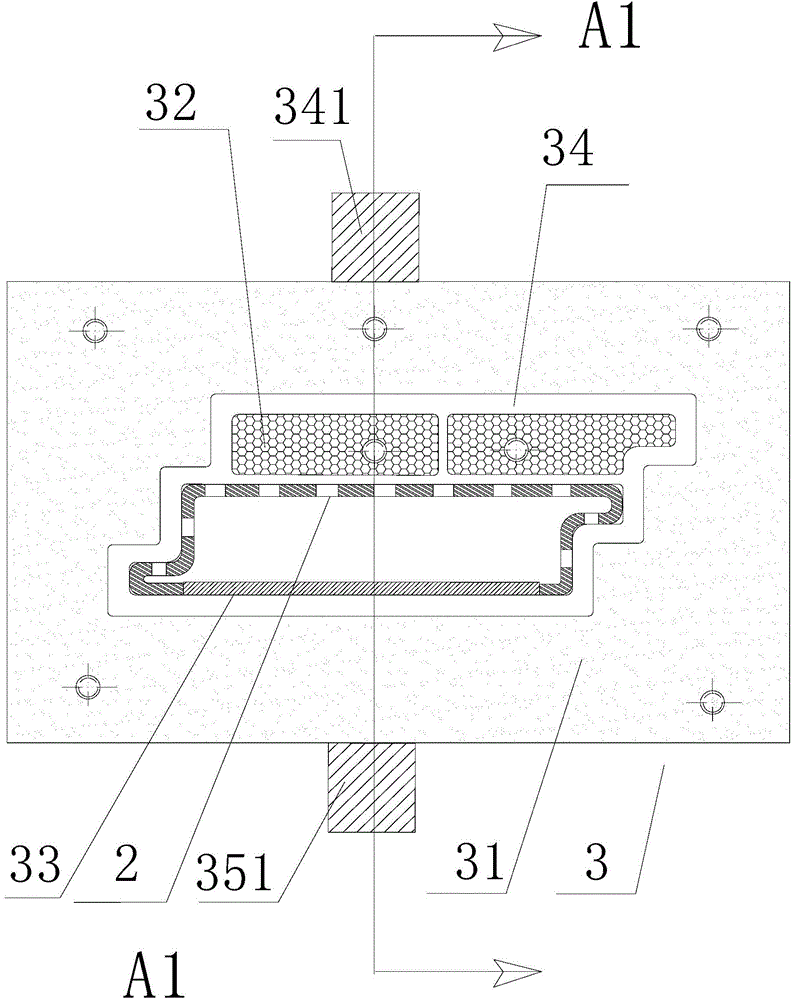

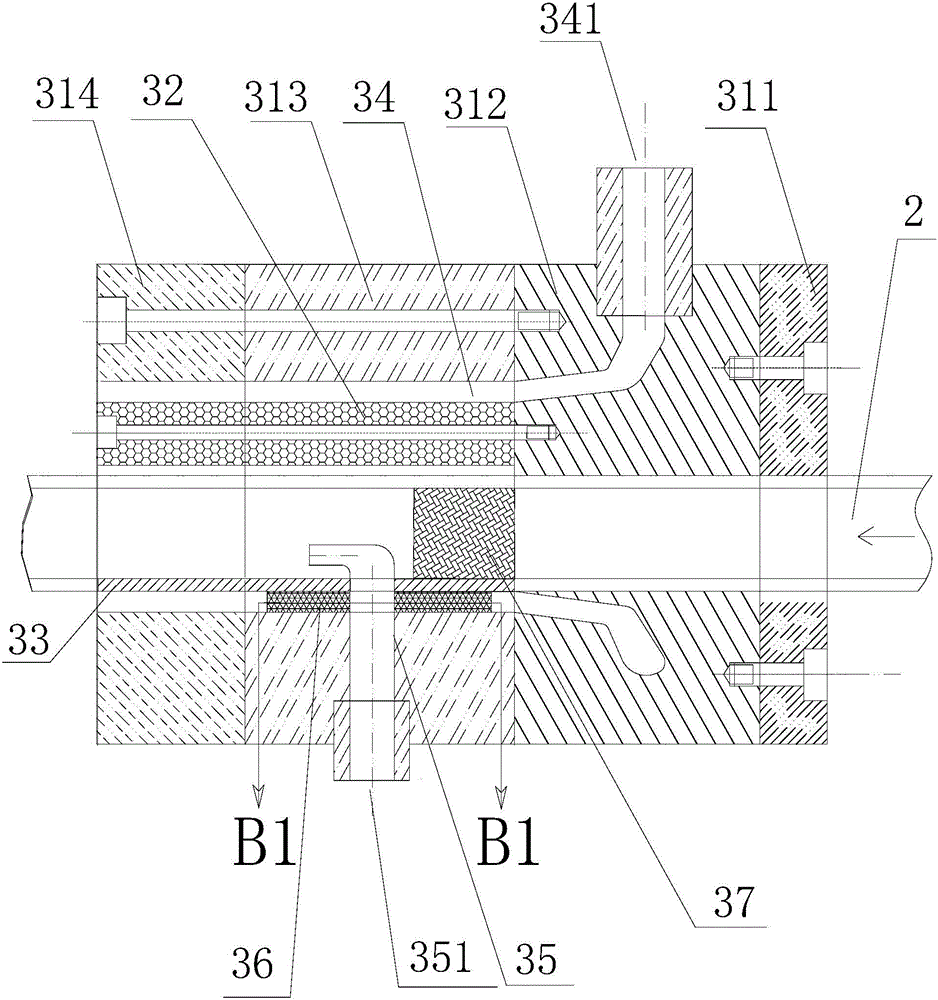

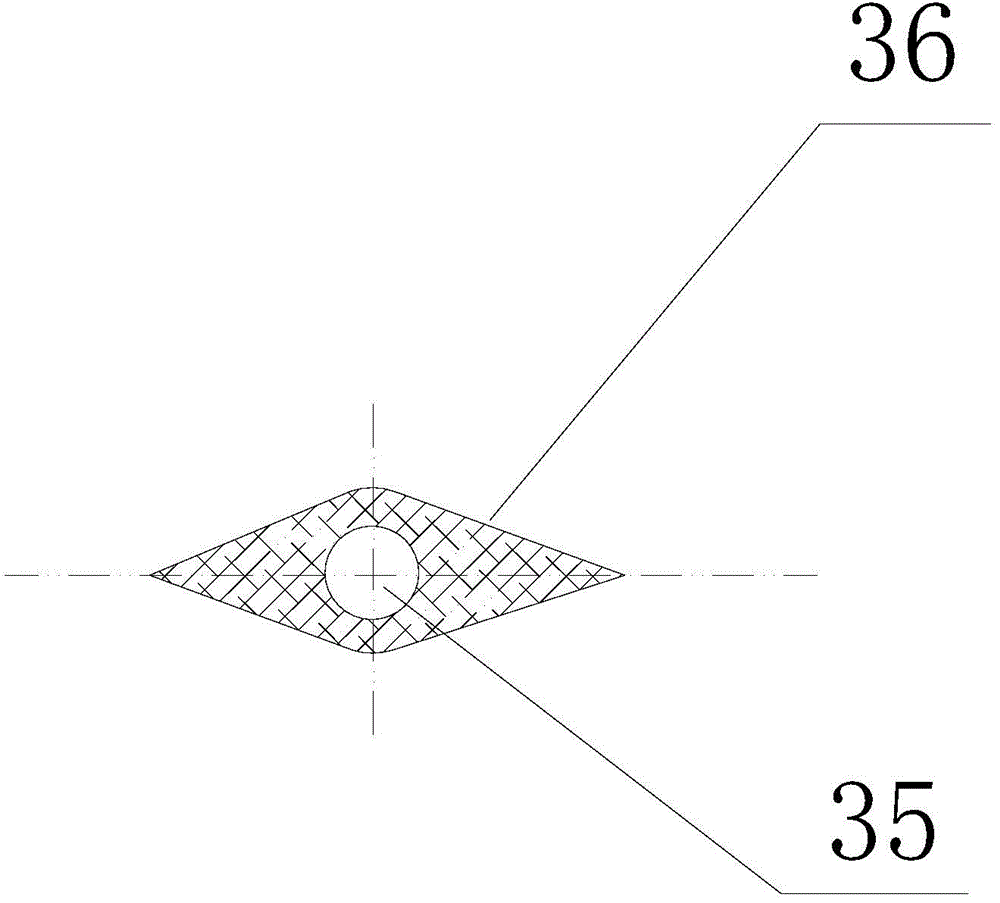

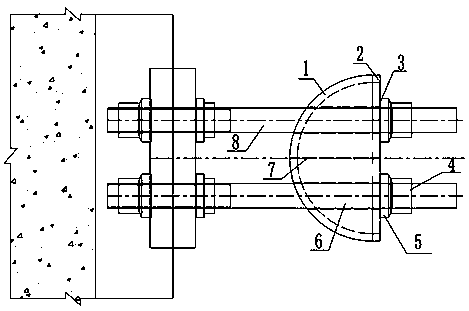

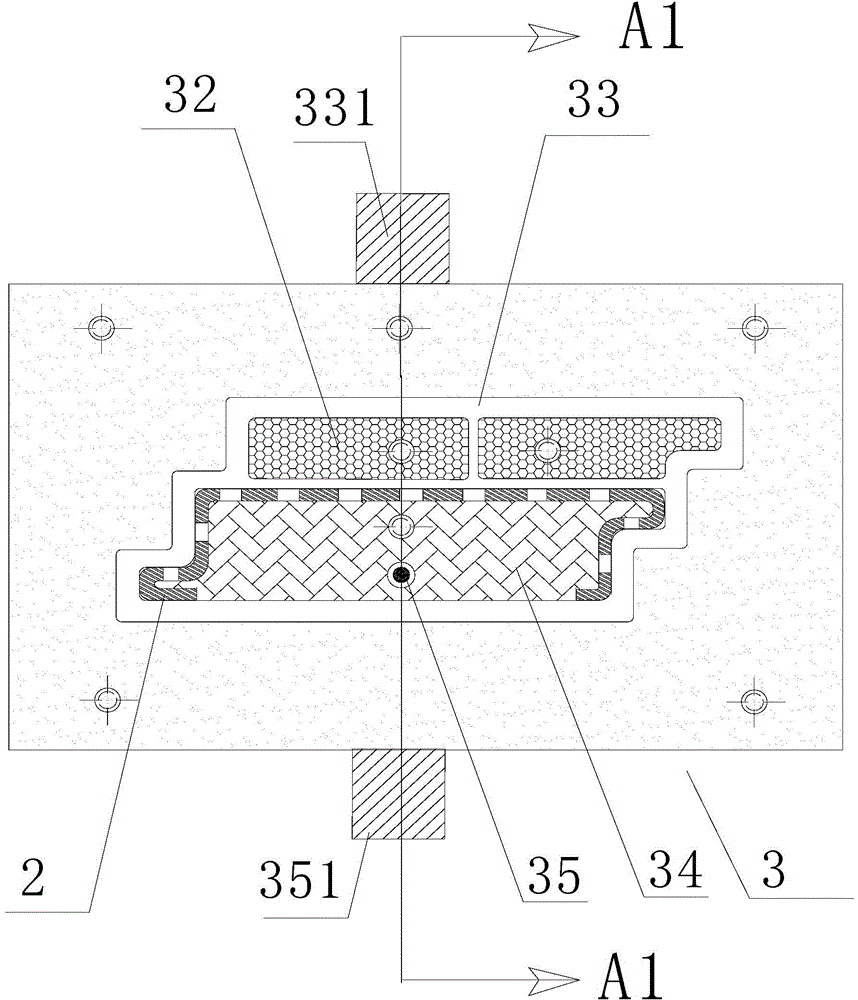

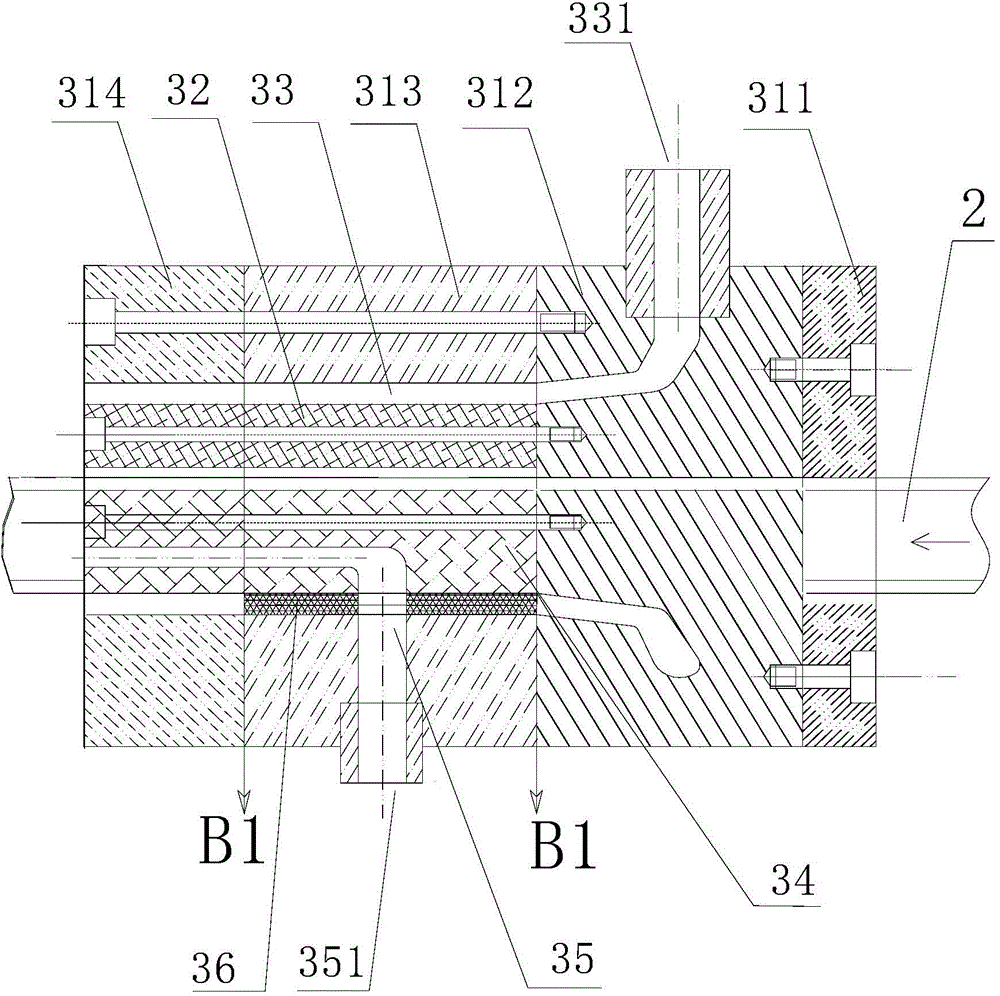

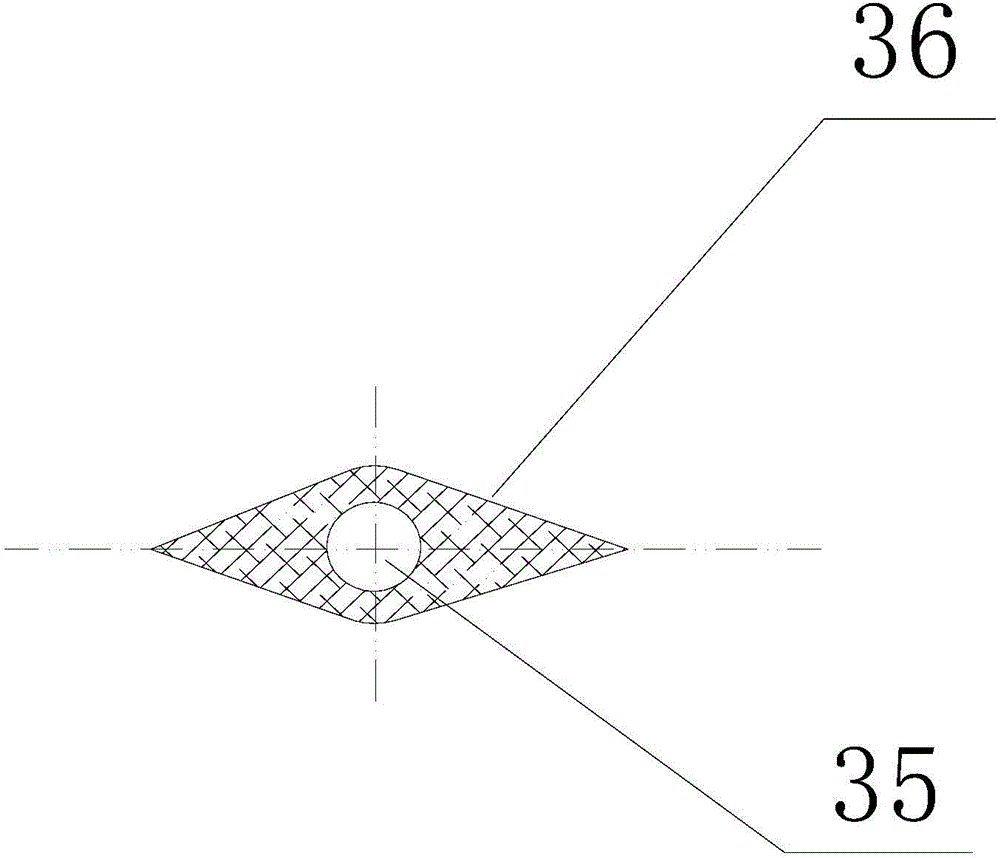

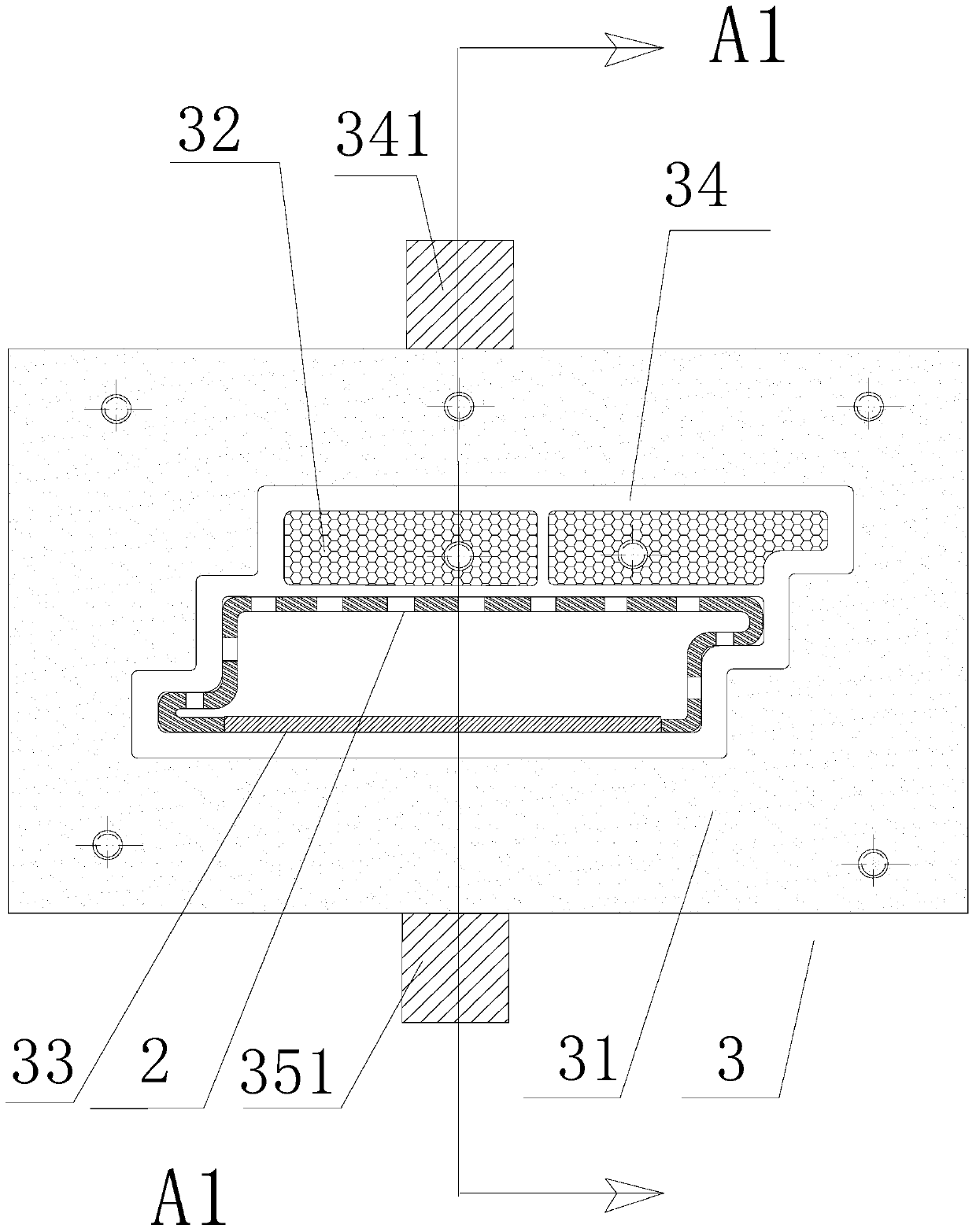

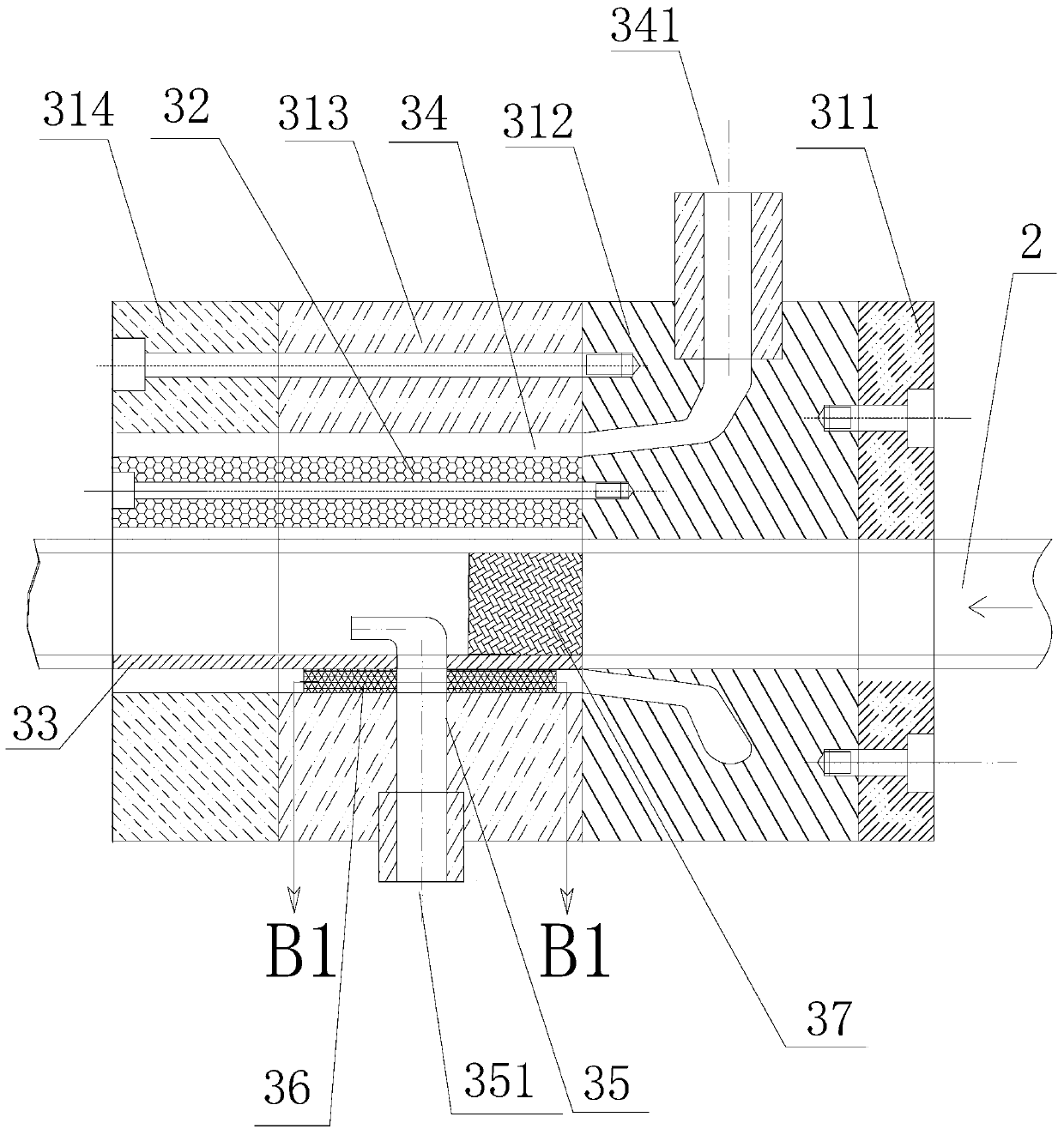

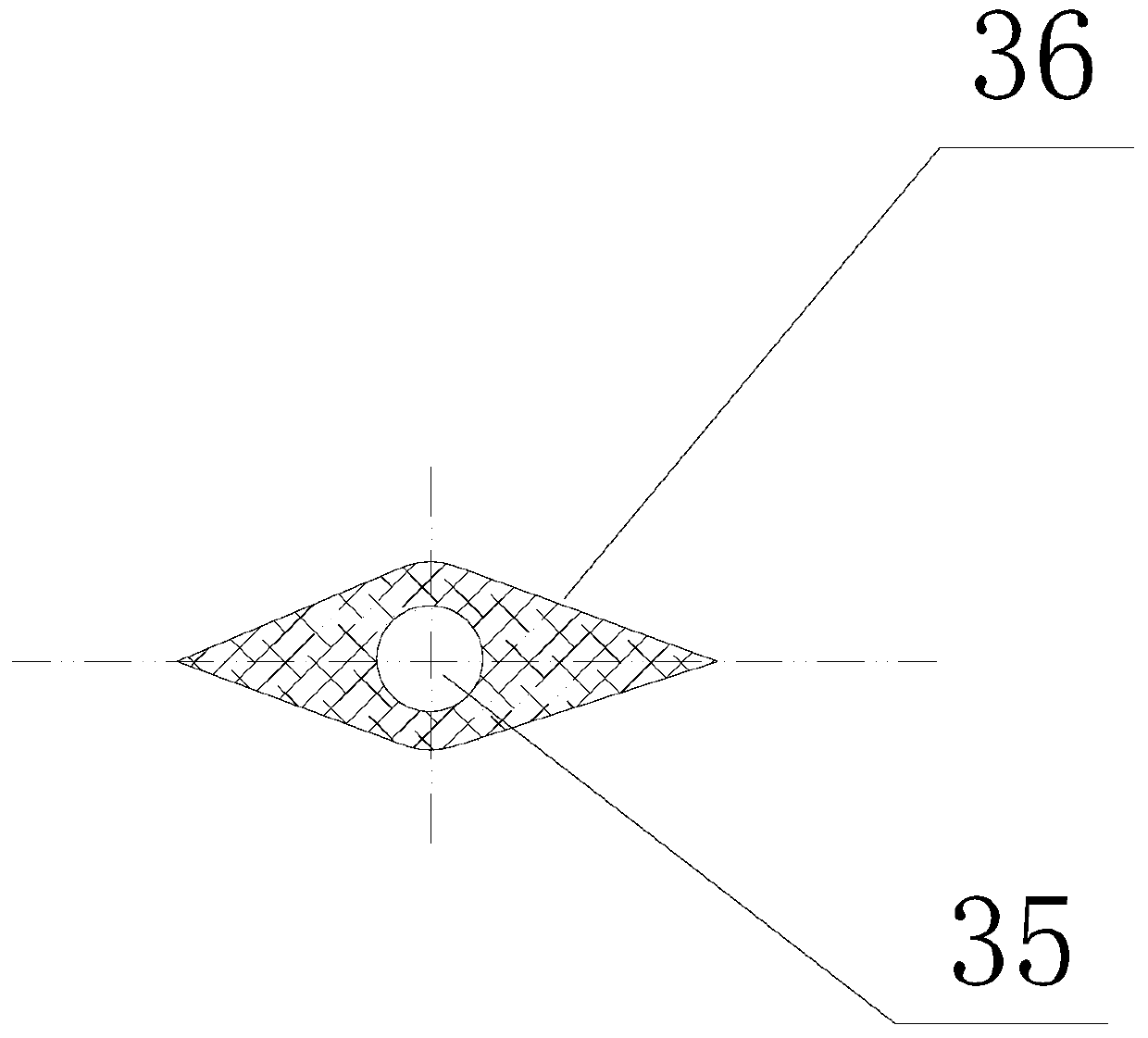

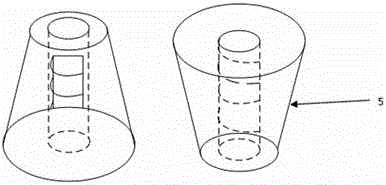

Extrusion die for composite sheet material formed through co-extrusion molding of wood plastic, foaming layer and metal section material

ActiveCN105437495AImprove thermal insulation performanceGuaranteed basic strengthPlastic materialsMetal

The invention provides an extrusion die for a composite sheet material formed through co-extrusion molding of wood plastic, a foaming layer and a metal section material. The die comprises a die body and a first die core, the first die core is arranged in a cavity formed in the die body, the metal section material is an opened metal section material; the first die core possesses an appearance structure matched with the opened metal section material, and can form a sealed solid body together with the metal section material sent into the cavity through cooperation, and a gap for injecting the fused wood plastic material is reserved between the sealed solid body and the die body; and the extrusion die is provided with a flow channel, and the flow channel successively passes through the die body, the cavity and the first die core and reaches the extrusion end of the die. The extrusion die in the embodiment is capable of producing the composite sheet material which is a composite integral body formed by wood plastic, the metal section material and the foaming layer.

Owner:BEIJING NEW BUILDING MATERIALS PLC

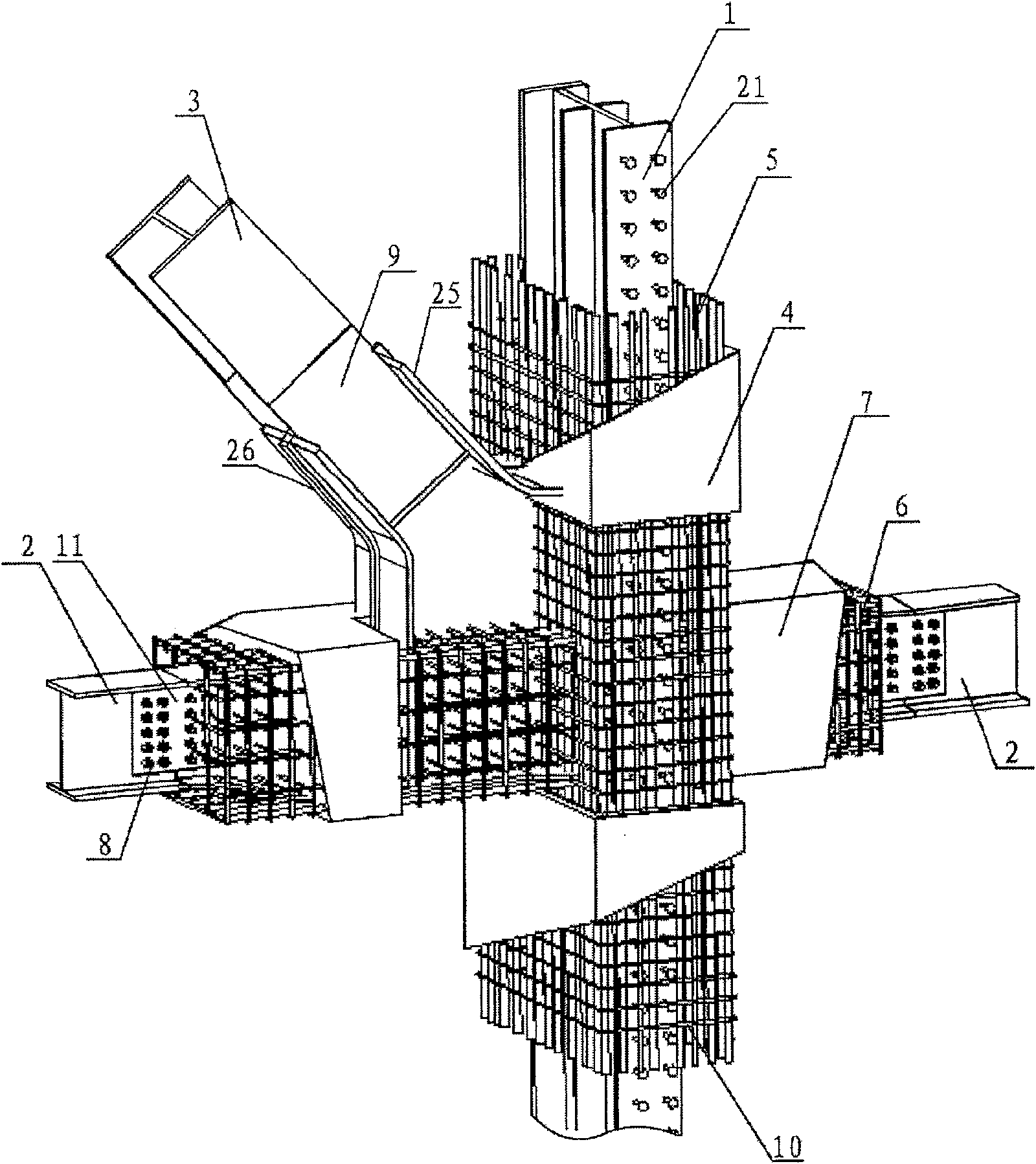

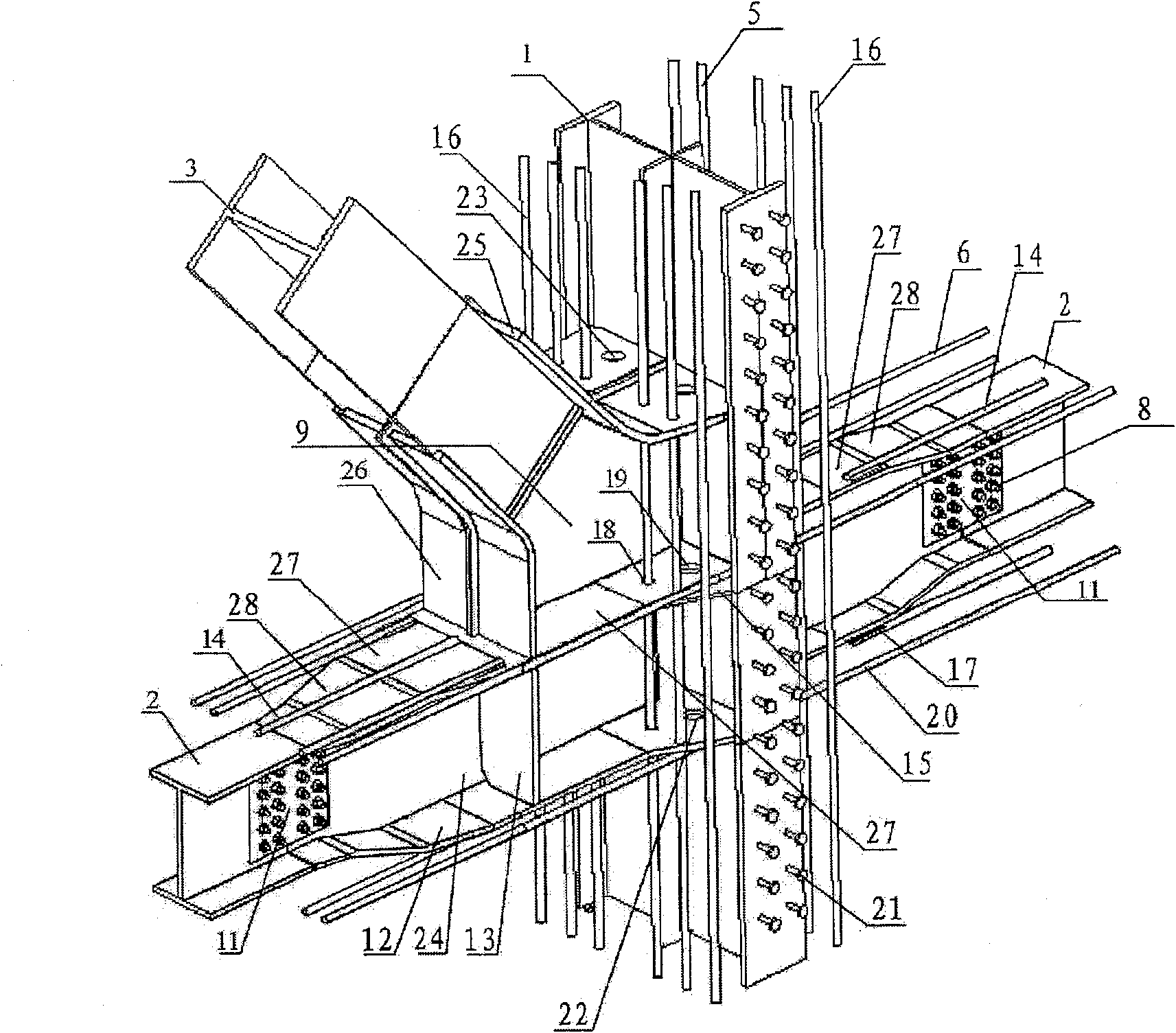

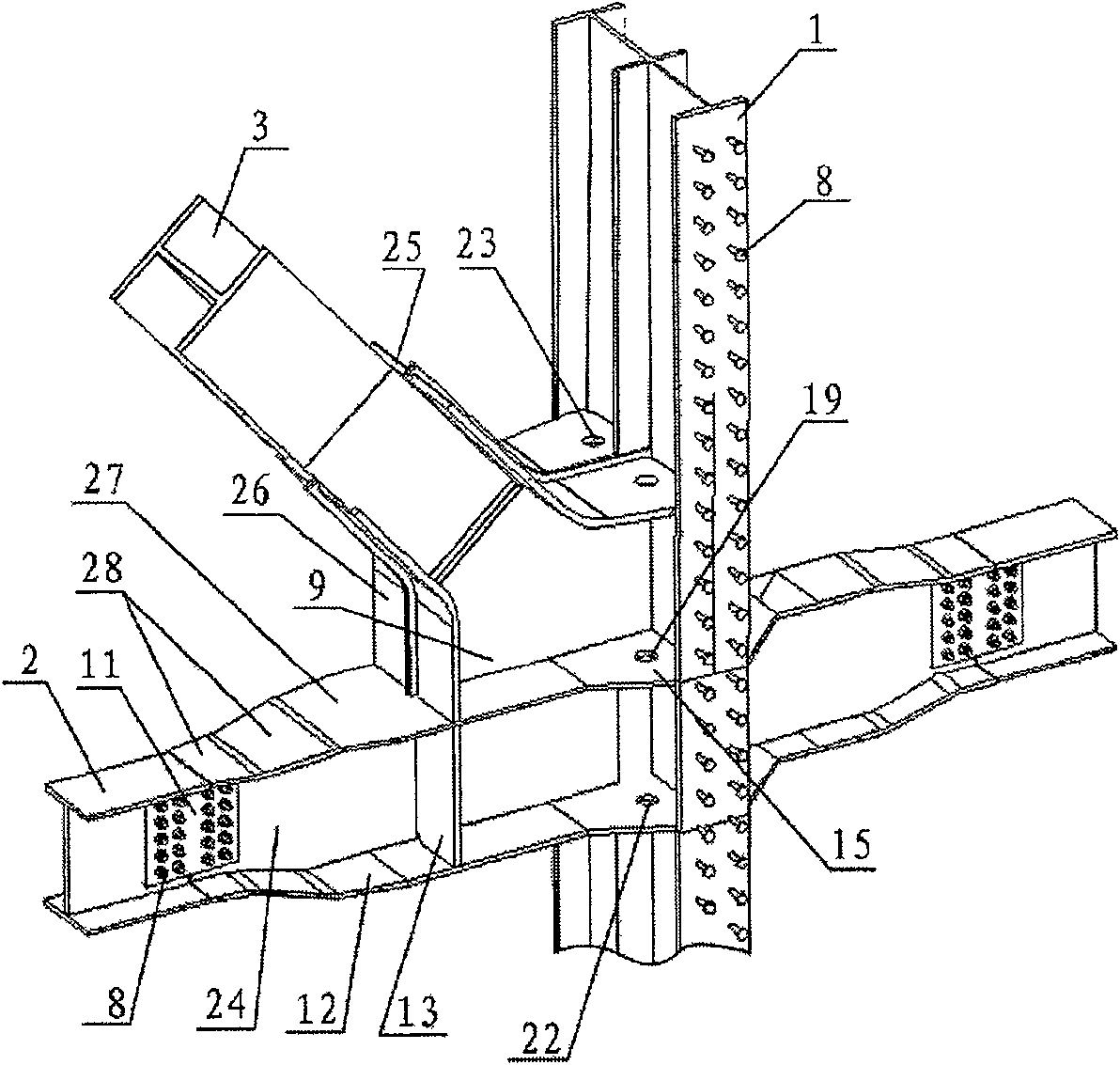

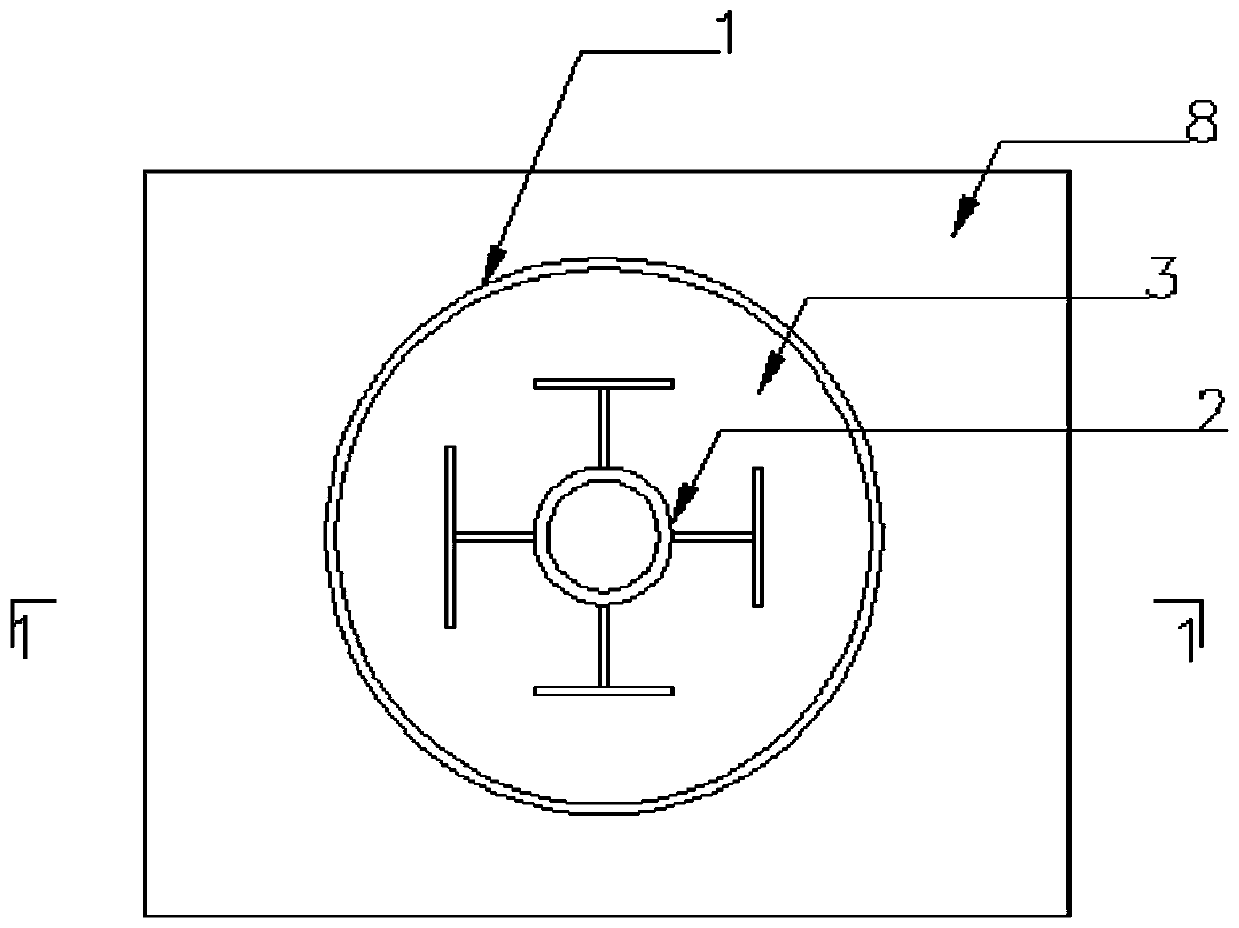

Shaped-steel concrete frame-steel supporting structure section-changeable conversion node

ActiveCN100558996CConvenience constraintsIncrease the moment of resistance of the sectionBuilding constructionsReinforced concreteSteel bar

A type of steel concrete frame-steel support structure variable cross-section conversion node, which is connected and poured into one by the medium-shaped steel in the column, the medium-shaped steel in the beam, the steel support, the reinforced concrete in the column, and the reinforced concrete in the beam. The section steel and the beam medium-section steel flange plate are connected orthogonally, the web of the beam medium-section steel at the node junction is converted into a web with increased height and variable section, and the upper side of the web with increased height and variable section is welded to the upper flange with increased width and variable section, and the height and variable section The underside of the web plate is welded with the lower flange of the widened and variable section; the shape of the steel support at the junction of the nodes is converted into a structure in the transition zone of the variable section node, and the two flange plates of the steel support in the transition zone of the variable section are respectively connected with the steel in the column and the The beams are connected orthogonally in steel sections. The invention enhances the stress performance of the section steel concrete frame-steel support structure joint area and the synergistic effect ability of the section steel and reinforced concrete.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

A kind of gfrp pipe-concrete-steel composite column foot joint and construction method thereof

ActiveCN108867341BHigh strengthSolve anchoring problemsBridge structural detailsBridge erection/assemblySteel tubeEarthquake resistant

The invention discloses a GFRP pipe-concrete-structural steel combination column base joint and a construction method thereof. The joint comprises a GFRP pipe, round steel pipe crossed T-shaped combination structural steel, self-compaction concrete and a box beam; the structural steel is nested into the GFRP pipe, and the lower end of the structural steel is provided with a stretching-out sectionrelative to the GFRP pipe; self-compaction concrete is poured between the structural steel and the GFRP pipe; the lower end of the structural steel is welded to the box beam, and a shearing force nailis welded to the stretching-out section; at the section above the box beam and below the surface of a foundation bearing table, the outer surface of the GFRP pipe-concrete-structural steel combination column is wrapped with two outer sleeve semi-round steel pipes; by adopting the outer sleeve steel pipe mode, shearing force nails are welded to the inner sides of the outer sleeve steel pipes, thestrength of column bottom concrete is improved, and axial force and bending torque of the column can be effectively transmitted to a foundation. By adopting the column foot node mode, axial force canbe transmitted, the large upsetting moment can be resisted, and the requirement for stress, deformation and earthquake resistance of the GFRP pipe-concrete-structural steel combination column can be met.

Owner:ZHEJIANG UNIV CITY COLLEGE

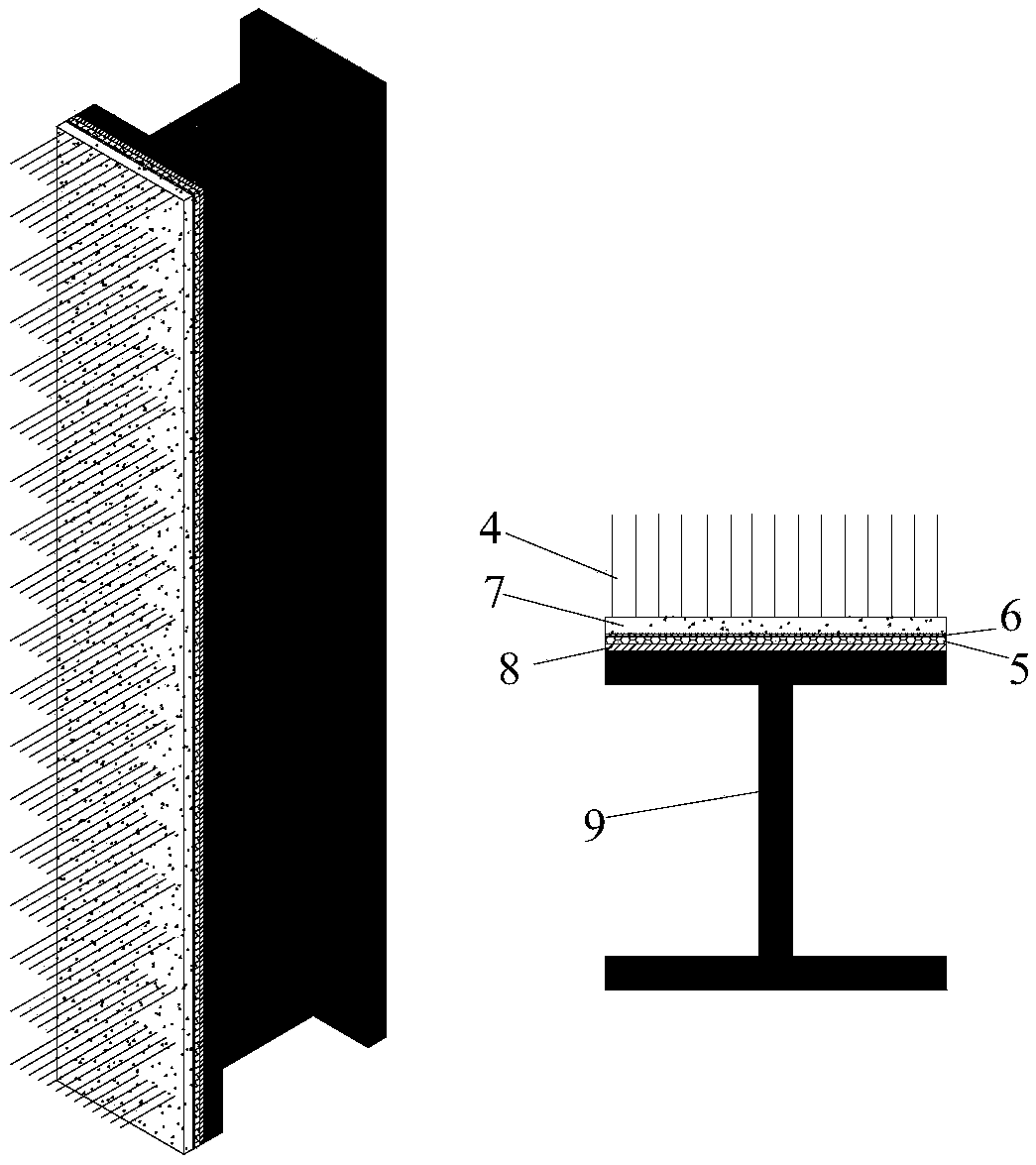

A prestressed cfrp slab tension anchor device for strengthening steel beams and composite beams

ActiveCN106193643BSolve anchoring problemsSolve the durability problemBuilding repairsBuilding material handlingFiberAdhesive

The invention discloses a prestressed CFRP plate tensioning and anchoring device for reinforcing steel beams and composite beams. The prestressed CFRP plate tensioning and anchoring device comprises a positioning steel bracket, a tensioning steel bracket, a lock nut, a guiding screw, an adjusting nut, a separation and union steel channel, a center hole jack, a positioning baffle, a steel bracket support and high-strength bolts. Wedged clamping pieces are arranged inside the tensioning steel bracket and the steel bracket support, and a CFRP plate is clamped through friction force, so that clamping is safe, reliable and durable; and structural adhesives and chemical anchor bolts are not used. The positioning steel bracket, the tensioning steel bracket and the steel bracket support are provided with triangular stiffening ribs, so that the strength and local stability of the device are improved. The jack is located outside a tensioning unit, tensioning construction longitudinal space is greatly reduced, and the jack can be conveniently removed after tensioning is completed. The prestressed CFRP plate tensioning and anchoring device provided by the invention is simple in structure, clear in mechanics-flow and convenient to construct; the high strength performance of fiber materials is fully utilized, the application field of the prestressed CFRP plate reinforcing technology is widened, and the prestressed CFRP plate tensioning and anchoring device can be widely applied to reinforcing engineering of steel bridge structures and combined structures.

Owner:SOUTHEAST UNIV

A composite sheet formed by co-extrusion of metal profile and wood-plastic and preparation method thereof

ActiveCN105484423BGuaranteed basic strengthReduce dosageBuilding componentsCo extrusionComposite plate

Owner:BEIJING NEW BUILDING MATERIALS PLC

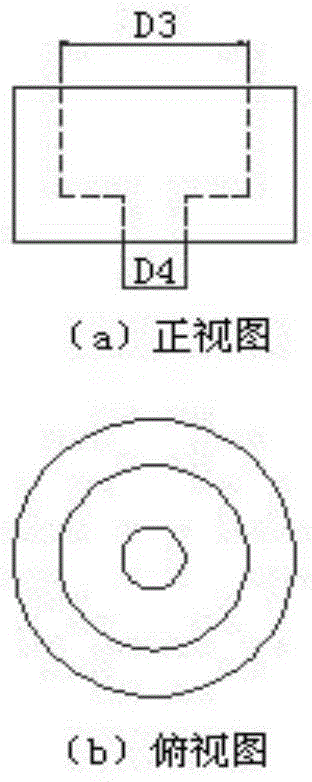

Connecting bridge member of concrete external wall

InactiveCN107747361ASolve anchoring problemsSimple structural designHeat proofingThin walledFastener

The invention relates to a connecting bridge member of a concrete external wall, and belongs to the technical field of buildings. The connecting bridge member of the concrete external wall is dividedinto a sleeving hollow pipe fitting and a sleeved hollow pipe fitting which are both thin-walled prefabricated hollow tubes. A concave notch is formed in the sleeving hollow pipe fitting. The outer wall of the sleeving hollow pipe fitting is provided with a thread. A connecting plate with a fastener reserved hole is added according to engineering actual conditions. A protruding tooth is arranged on the sleeved hollow pipe fitting. A sleeving hollow pipe fitting connecting plate with a sleeving hollow pipe fitting connecting plate fastener reserved hole is arranged at one end of the sleeved hollow pipe fitting. The connecting bridge member is simple in structural design; by means of the design of pipe sleeving, by means of the effect of the meshing of the concave notch of the sleeving hollow pipe fitting and the protruding tooth of the sleeved hollow pipe fitting and the positioning of the reserved holes, in cooperation with fasteners during installation, a good fastening effect is formed, a loosening phenomenon can not easily happen, and the connecting bridge member has good practicability; compared with the prior art, the product has outstanding practicability and makes a remarkable progress.

Owner:SHENYANG JIANZHU UNIVERSITY

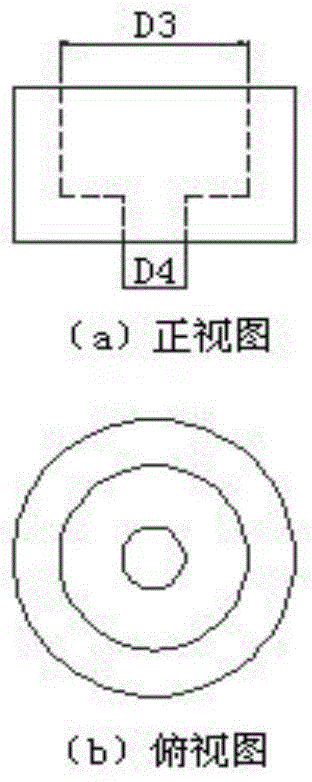

A hydrophobic composite steel core glass fiber anti-floating anchor rod and its construction method

ActiveCN104912069BIncrease buoyancyAvoid the danger of "collapsing holes"Protective foundationBulkheads/pilesGlass fiberFiber

The present invention involves a hydrophobic composite steel core glass fiber anti -floating anchor rod. The aspect of the anchor rod is cylindrical as a whole.There are threads at both ends of the body, and the middle part of the anchor body is a smooth surface and a hydrophobic film.The present invention makes up for the lack of existing anti -floating techniques. The end of the anti -floating anchor rod has a self -anchoring device to form a focus point for anti -floating anchor rods. Except for anchoring section, the surface of the anti -floating anchor rod is applied to hydrophobic.The membrane has a weak adhesion between the surface of the anchor rod and the cement pulp, which simplifies the construction process, improves the construction speed, and ensures the quality of construction.

Owner:HENAN UNIVERSITY

Soft base ground anchoring method

A ground anchoring method on a soft ground belongs to the technical field of ground anchoring, and aims to solve the problems in the prior art that the fixation is not firm and affects the implementation of a vehicle resistance system. The present invention comprises the following steps: punch out mounting holes at the position to be installed on the soft ground and the corresponding position of the connection hole on the connection base through the soft ground punching device, and clean with a brush or blower; pour the planting glue into the step In each installation hole, ensure that there are no air bubbles or gaps in the hole, inject glue to the 2 / 3 position of the hole depth; drive the two-way internal expansion bolts through each connection hole on the connection base to the part filled with planting glue , complete anchoring after hardening. The present invention pours the rebar-planting glue into the hole, and due to the quick-drying characteristics of the rebar-planting glue, the position where the rebar-planting glue is poured and the surrounding soft ground that is extended due to the fluidity of the rebar-planting glue hardens rapidly, so that the ground installed on the ground The friction between the expansion bolt and the hardened soft ground increases, which can achieve the anchoring effect on the hard ground.

Owner:JILIN UNIV

A device and method for tensile testing of brittle tendons

ActiveCN103604689BIncrease squeezeEasy to removeMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention provides a device and a method for a tensile test of a fragile rib material. The device comprises a sleeve 1, a binding screw cap 2, a ball socket type screw cap 3 and a ball head pull rod 4, wherein the inner part of the sleeve 1 is a circular-platform-shaped cavity and the inner diameters of the two ends of the sleeve 1 are different; the binding screw cap 2 is screwed down on the outer part of one end with the smaller inner diameter of the sleeve 1; after the ball head pull rod 4 penetrates through the ball socket type screw cap 3, the ball socket type screw cap 3 is screwed down on the outer part of one end with the larger inner diameter of the sleeve 1. When the device and the corresponding method are used for carrying out the tensile test on the fragile rib material, a test sample does not need to be directly clamped so as to protecting end parts of the test sample from being damaged by a too large transverse concentrated force; the test sample is anchored firmly and cannot be unstuck in the testing process; and the device can be used conveniently and repeatedly.

Owner:JINLING INST OF TECH

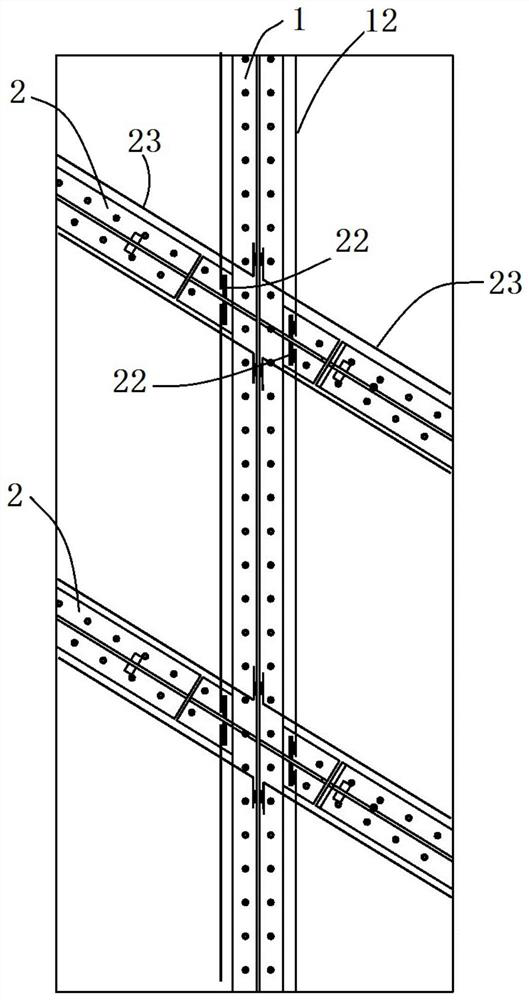

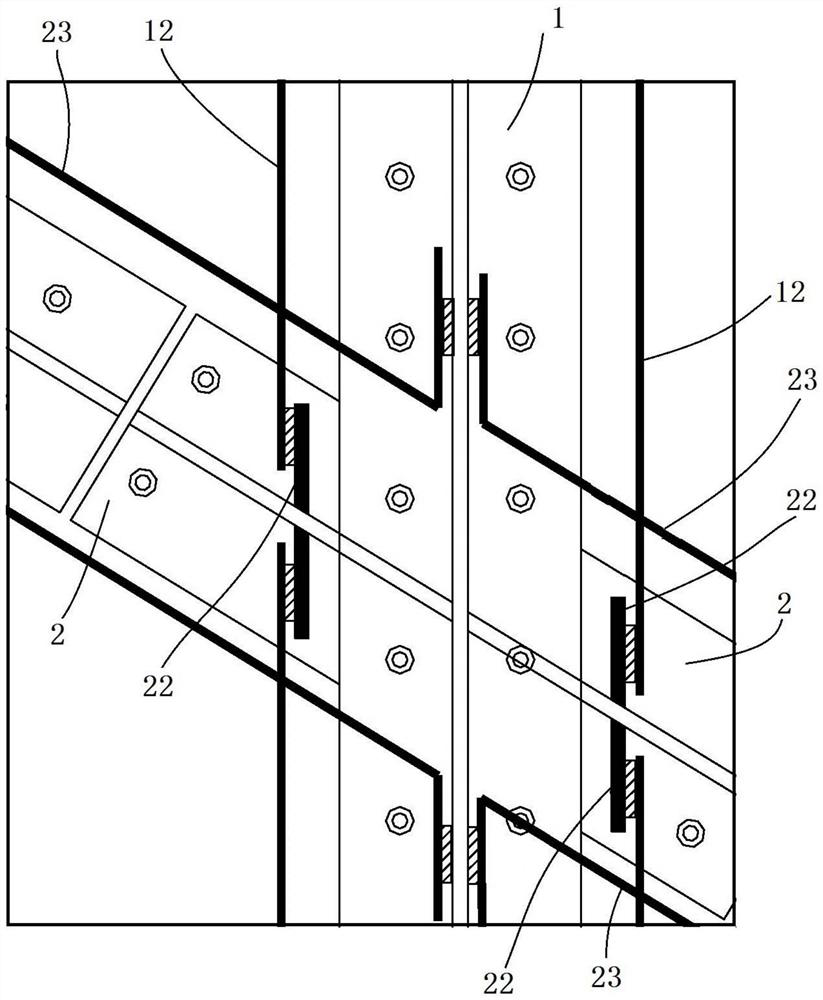

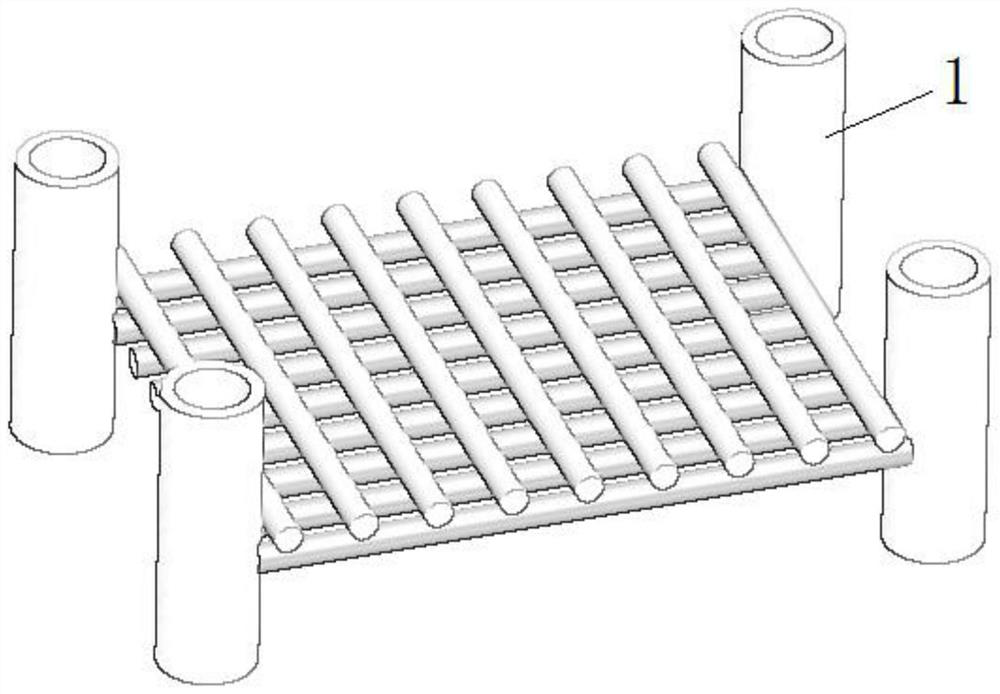

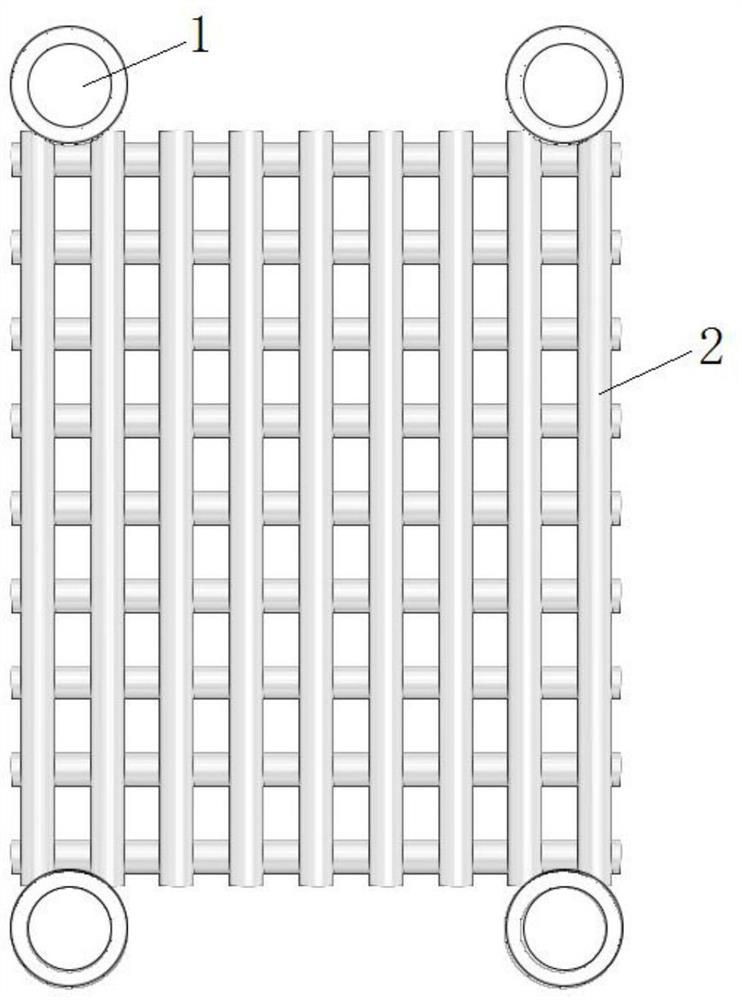

Different-direction steel beam oblique crossing waist rib connecting structure and connecting method thereof

InactiveCN112095797AReduce dosageAvoid crossingBuilding constructionsEngineeringStructural engineering

The invention provides a different-direction steel beam oblique crossing waist rib connecting structure and a connecting method thereof. The different-direction steel beam oblique crossing waist rib connecting structure comprises a main beam and a secondary beam which are crossed in different directions, wherein a main beam waist rib parallel to the main beam is disconnected at the joint of the main beam waist rib and the secondary beam and fixed to the two corresponding sides of the secondary beam through connecting plates, and a secondary beam waist rib parallel to the secondary beam is disconnected at the joint of the secondary beam waist rib and the main beam and fixed to the two corresponding sides of the main beam in a bent anchoring mode. The anchoring problem of the main beam waistrib and the secondary beam waist rib when different-direction steel beams are crossed is solved, and the phenomenon that the aperture ratio of a steel beam web is too large is avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

3D printing concrete constructional column bottom vertical steel bar anchoring component and construction method

The invention provides a 3D printing concrete constructional column bottom vertical steel bar anchoring component and a construction method, a combined steel sleeve prefabricated part of the anchoring component is pre-buried on a concrete beam or plate, a plurality of lap joint steel bars are longitudinally placed in the combined steel sleeve prefabricated part, each fixing plug pin prefabricated part is installed on one lap joint steel bar, and a plurality of fixing plug pin prefabricated parts are installed on the corresponding lap joint steel bar. A prefabricated reinforcement cage is installed on the lap joint steel bars, lap joint end plate prefabricated parts are installed on the lower portion of the reinforcement cage, and the vertical lap joint steel bars and the reinforcement cage are further fixed through lap joint of the fixing plug pin prefabricated parts and the lap joint end plate prefabricated parts. The construction problem of a 3D printing concrete constructional column root joint provided with vertical steel bars is solved, the bottom vertical steel bar anchoring component of the 3D printing concrete constructional column and the construction method are provided, and the construction method is provided for improving the joint strength of a 3D printing concrete vertical component.

Owner:HARBIN INST OF TECH

Prefabricated building and component anchoring method thereof

PendingCN113718938ASolve anchoring problemsSolve problems that cannot be anchored into a unified wholeStrutsConstruction materialFloor slabConcrete beams

The invention relates to a prefabricated building and a component anchoring method thereof, and belongs to the field of buildings. The prefabricated building is composed of a prefabricated wallboard, a cast-in-place anchoring beam, a cast-in-place concrete beam, a cast-in-place concrete constructional column, a cast-in-place concrete column, a cast-in-place concrete floor, a raft (strip-shaped) foundation, a window (hole), a column main reinforcement, a beam main reinforcement, a beam stirrup, a cast-in-place anchoring beam main reinforcement, a hollow pipeline, an anchoring steel bar and other components. The component anchoring method comprises the following steps of anchoring the cast-in-place concrete beam, the cast-in-place anchoring beam and the cast-in-place concrete column on the prefabricated wallboard, wherein notches are reserved in the upper and lower ends of the prefabricated wallboard, and anchoring steel bars are reserved on the side vertical surfaces; and anchoring the cast-in-place concrete beam, the cast-in-place anchoring beam and the raft (strip-shaped) foundation or the cast-in-place concrete floor at the two ends of the cast-in-place concrete constructional column on the prefabricated wallboard. The problems of long construction period, high cost, serious material waste and many potential safety hazards of construction of a traditional building are solved, and the problems of difficulty in anchoring a filler wall of the prefabricated building, infirmness in anchoring and poor corrosion resistance are also solved.

Owner:夏祥军

A kind of co-extruded composite plate and its preparation method

ActiveCN105484373BImprove thermal insulation performanceGuaranteed basic strengthHeat proofingFoam polyurethanesCo extrusion

The present invention provides a co-extrusion molding composite board. The co-extrusion molding composite board comprises a wood plastic frame, a foaming layer and a metal profile; the wood plastic frame is provided with a first cavity; the metal profile has an opening; the metal profile is positioned in the first cavity; the wall surface of the first cavity is bonded to the surface of the metal profile; the foaming layer is put in a space enclosed by the first cavity and the metal profile; the foaming layer is bonded to the wall surface of the first cavity and the surface of the metal profile; and the foaming layer is prepared by foaming polyurethane materials. According to the composite board, the internal metal profile effectively provides mechanical strength, the metal profile, the foaming layer and the wood plastic frame are composited and integrated, so that the requirement for strength of the wood plastic part is reduced, the foaming technology can be adopted for materials of the wood plastic frame, wood plastic materials are saved, and heat and sound insulation performance of the composite board applied as a wall board is largely improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com