Supporting anchoring structure suitable for large-water-level-amplitude water surface floating photovoltaic power station and construction method

A technology for water surface floating and photovoltaic power plants, which is applied in the direction of anchoring arrangements, floating buildings, ship parts, etc., and can solve the problems of anchoring of photovoltaic power plants that cannot be floated on the water surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

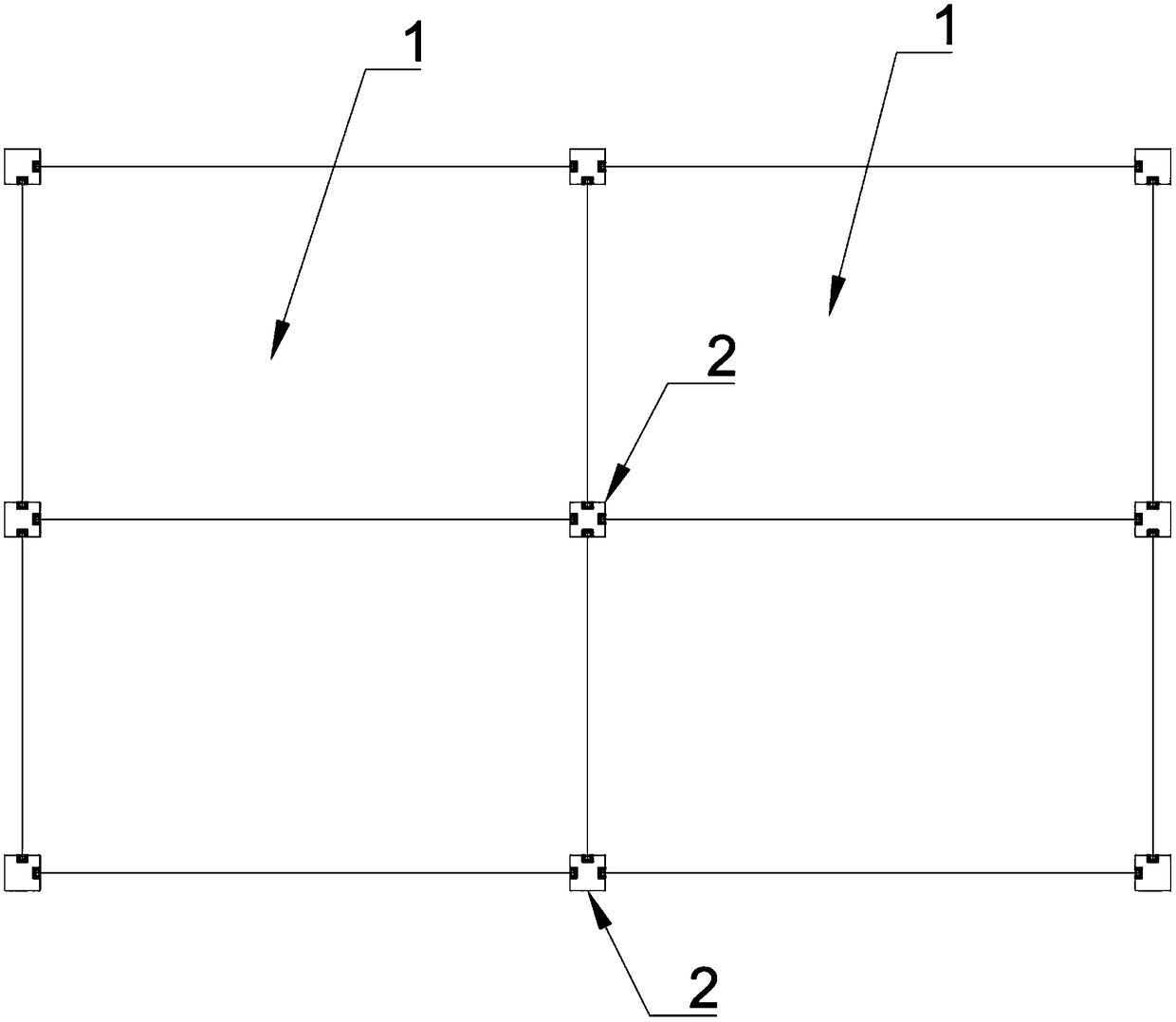

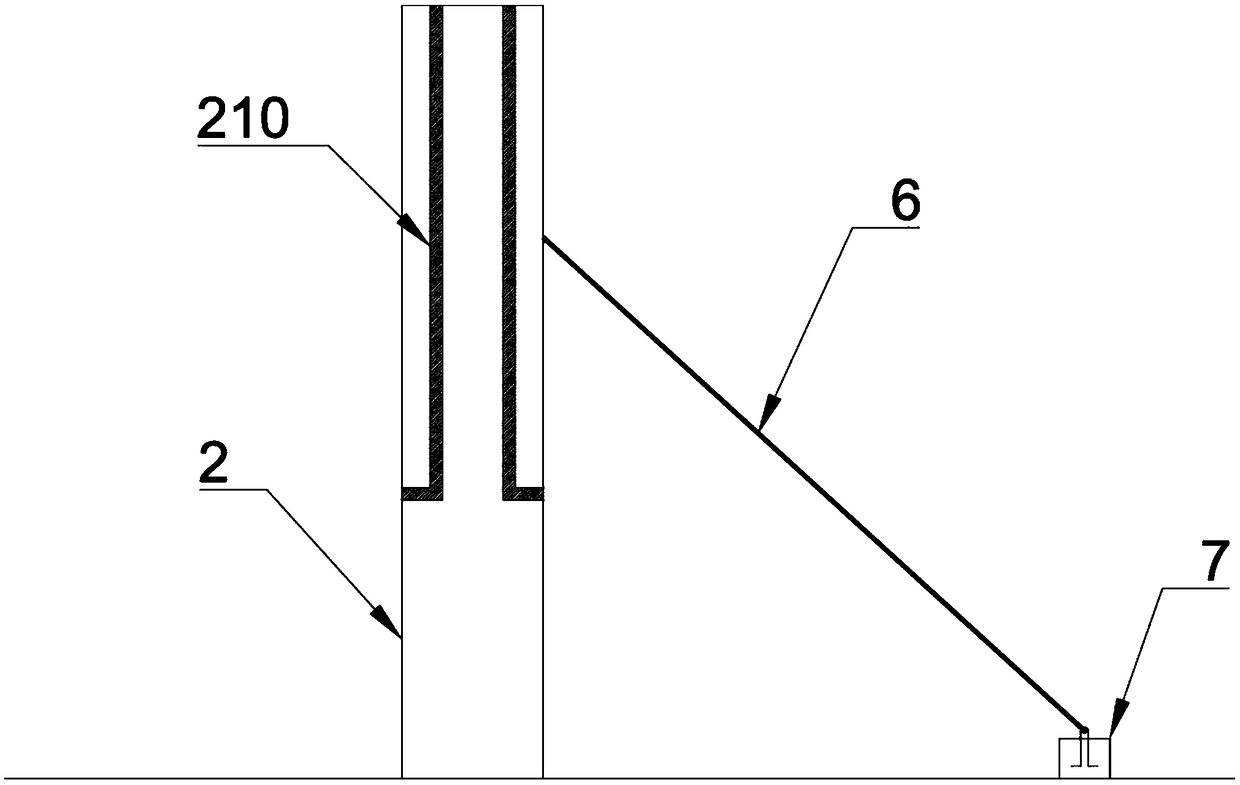

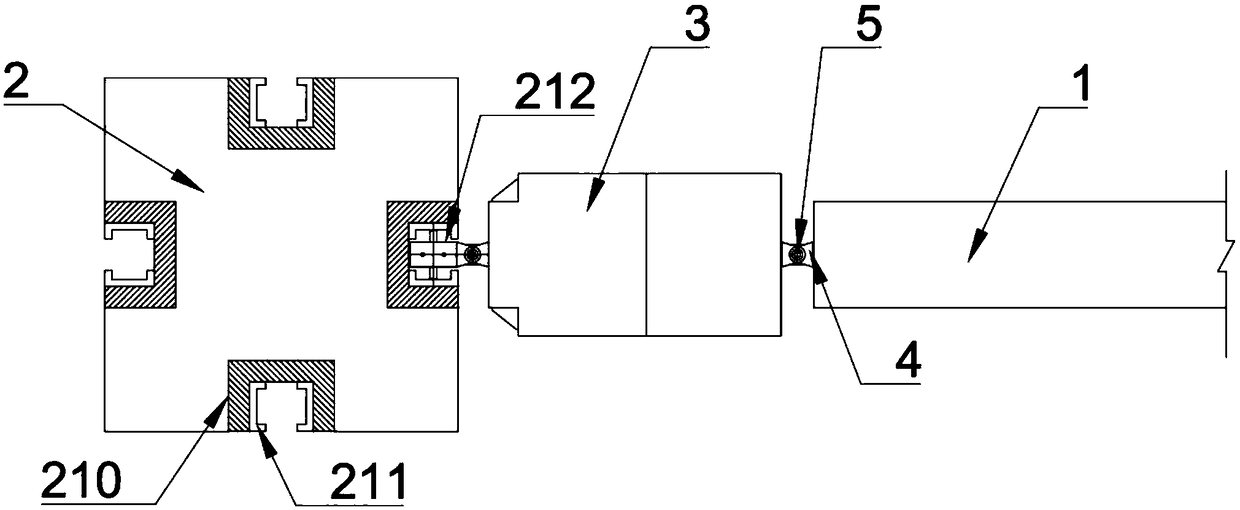

[0023] A supporting and anchoring structure suitable for floating photovoltaic power stations with large water level changes, including reinforced concrete columns 2 arranged around the floating photovoltaic power station 1 on the water surface, and vertically arranged on the sides of the reinforced concrete columns 2 The guide groove 210 of the vertically arranged guide groove 210 is provided with a support and constraint wheel 212, and the end of the support and constraint wheel 212 facing the opening of the guide groove 210 is connected to the buoyancy tank 3, and the end of the buoyancy tank 3 away from the support and constraint wheel 212 is connected to the water surface to float Photovoltaic power station 1.

[0024] The guide groove 210 is provided with oppositely arranged C-shaped steels 211 on both sides perpendicular to its opening; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com