Different-direction steel beam oblique crossing waist rib connecting structure and connecting method thereof

A waist bar and section steel technology, which is applied to the connection structure of steel beams in different directions and its connection field, can solve the problems of material waste, enlarged openings, and damage to the steel beam structure, so as to save labor and save steel plates Dosage, to avoid the effect of excessive opening ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

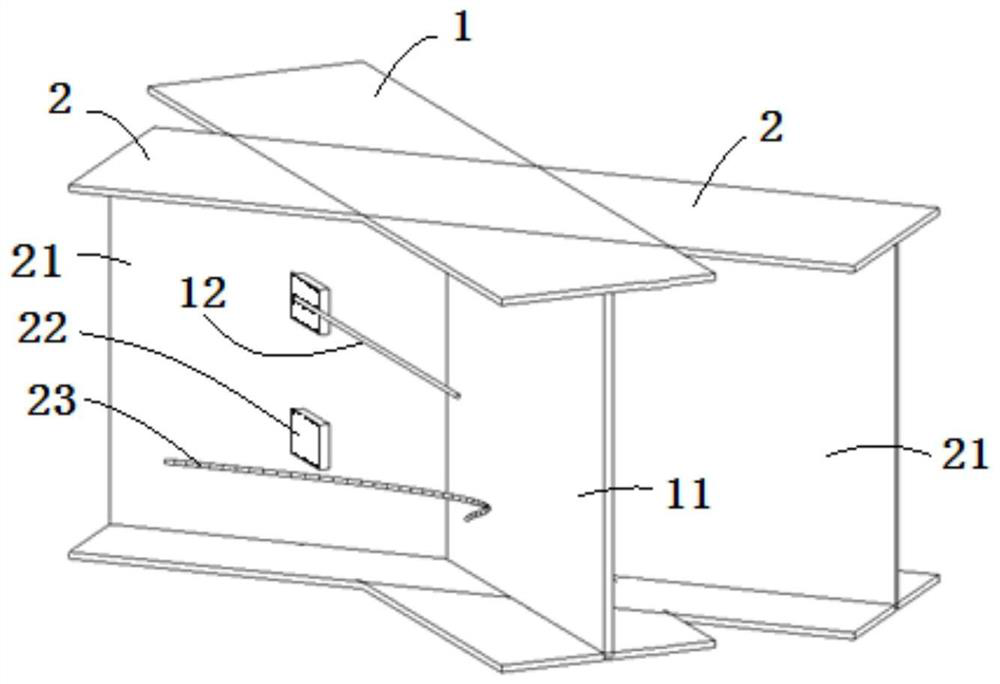

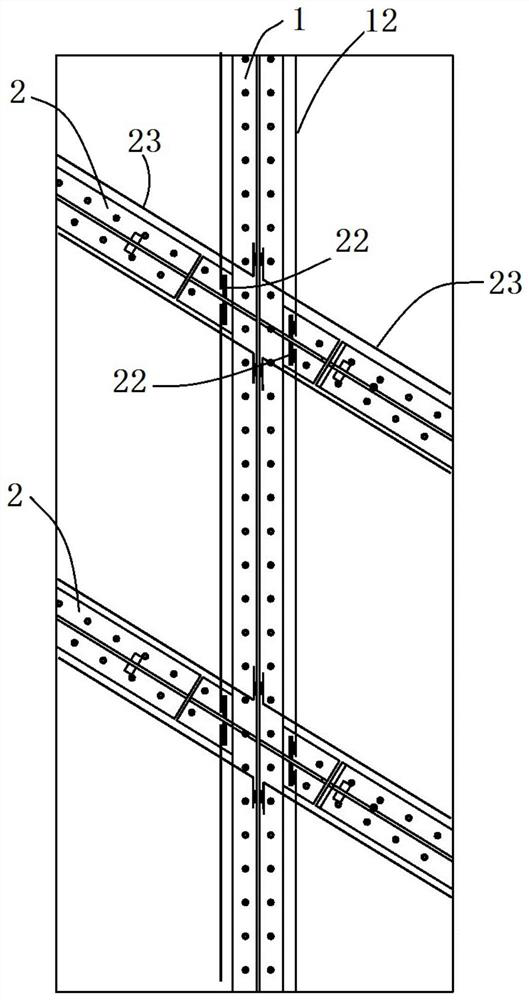

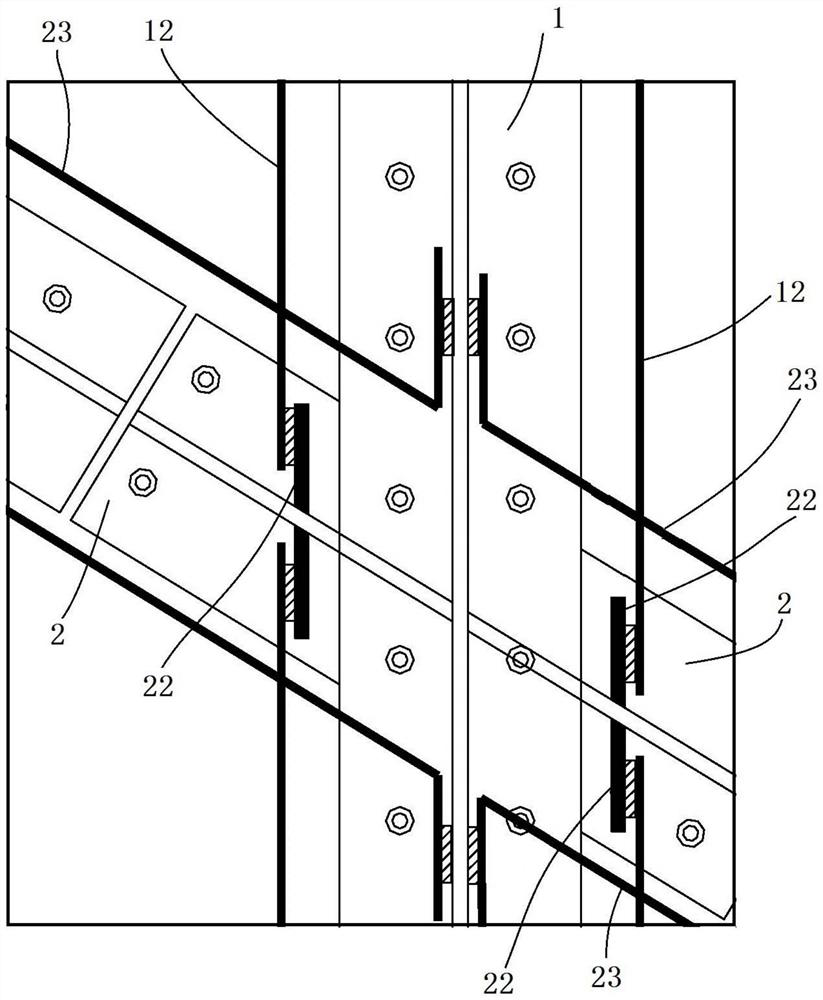

[0022] see Figure 1 to Figure 3 As shown, the present invention provides a steel beam with different directions obliquely intersecting the waist bar connection structure, including the main beam 1 and the secondary beam 2 which are intersected along different directions, and the main beam waist bar 12 arranged parallel to the main beam 1 is connected with the secondary The junction of the beam 2 is disconnected and fixed on the corresponding two sides of the secondary beam 2 through the connecting plate 22, and the waist reinforcement 23 of the secondary beam arranged parallel to the secondary beam 2 is disconnected at the junction with the main beam 1 and fixed by bending anchors on the corresponding two sides of the main beam 1 .

[0023] In the embodiment of the present invention, the main girder 1 is I-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com