A prestressed cfrp slab tension anchor device for strengthening steel beams and composite beams

An anchoring device and prestressing technology, which is applied in the processing of building materials, construction, building maintenance, etc., can solve the problems of reducing the space for tensioning and reducing the production cost of anchors, so as to avoid fatigue hidden dangers, high anchoring efficiency, well-distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

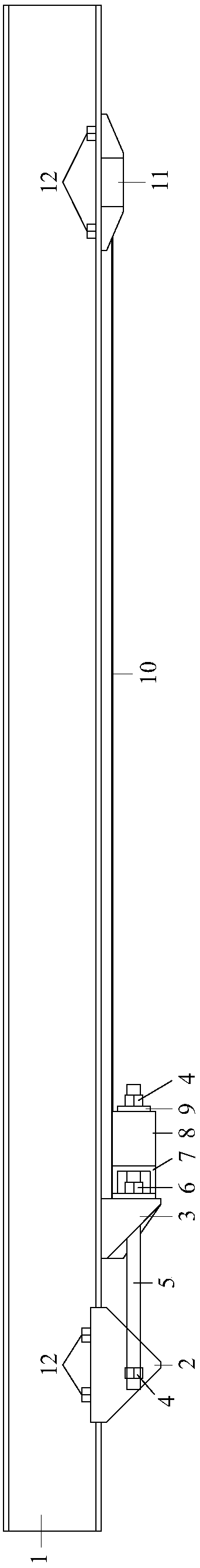

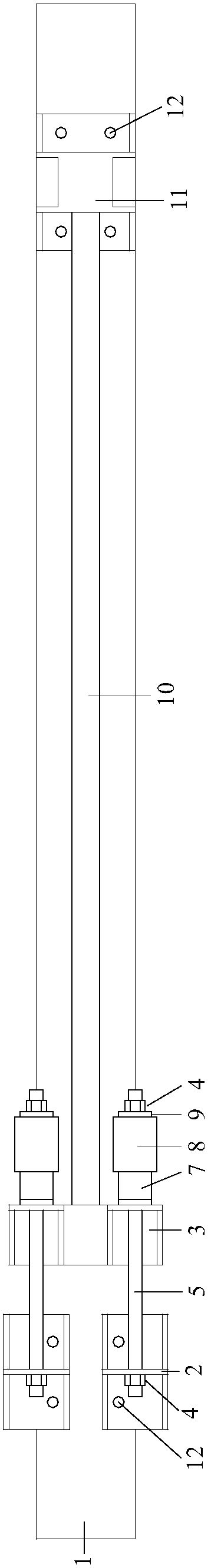

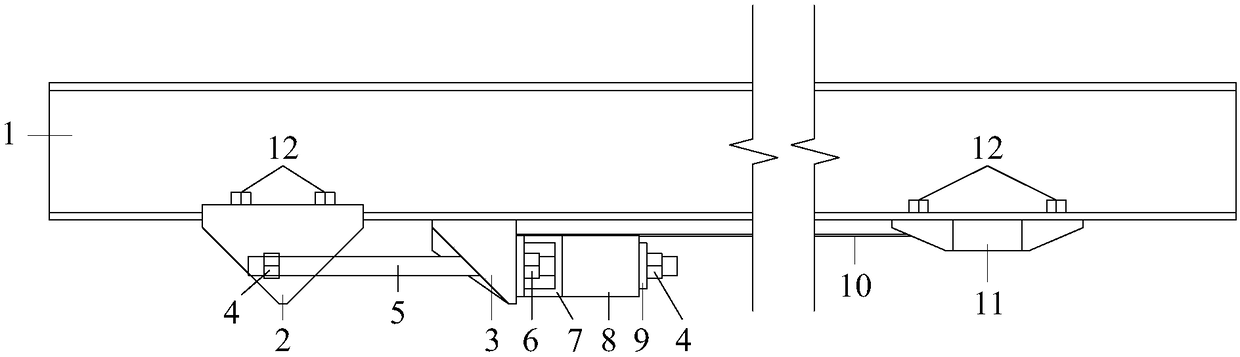

[0043] A prestressed CFRP plate tensile anchorage device for reinforced steel beams and steel-concrete composite beams of this embodiment is as follows: figure 1 , figure 2 with image 3 As shown, it includes positioning steel angle 2, tensioning steel angle 3, lock nut 4, guide screw 5, adjusting nut 6, clutch steel channel 7, through-hole jack 8, positioning baffle 9, steel angle support 11, High-strength bolts 12. The wedge-shaped clips are respectively located inside the tension steel angle 3 and the steel angle support 11, and are embedded in them to form a whole.

[0044]The fixing of the tensioning device and the anchoring device is respectively realized by the positioning steel angle 2 and the steel angle support 11, and the two are connected with the beam 1 to be reinforced by high-strength bolts 12. The positioning steel angle 2 is separated in the transverse direction, so as to facilitate clamping and installation, and it needs to be arranged symmetrically along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com