A hydrophobic composite steel core glass fiber anti-floating anchor rod and its construction method

A technology of anti-floating anchor rod and glass fiber, which is applied in the fields of geotechnical engineering and civil construction engineering, and can solve the problem of increasing the bonding force between plastic rods and cement slurry, failing to meet the requirements of anti-floating anchor rods, and poor ductility of fiber plastic reinforcement, etc. problems, to achieve the effect of solving anchoring problems, saving materials and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the soft soil drilling design and construction technical requirements, the cement-soil mix ratio and construction technical requirements, the construction technical requirements of deep-mixed cement-soil piles or high-pressure rotary grouting piles, and the construction technical requirements of raft slab concrete pouring are all in this embodiment. The conventional technology in the field, so it will not be repeated in this embodiment, and the embodiment of the structure related to the present invention will be emphasized.

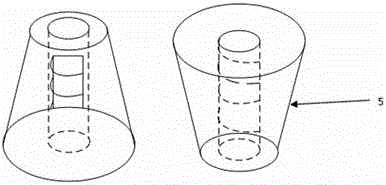

[0046] like figure 1 and 2 As shown, a hydrophobic composite steel core glass fiber anti-floating anchor rod, the overall body of the anchor rod is cylindrical, and the anchor rod body is composed of a fiber resin layer 2 and a steel strand 1 wrapped in the fiber resin layer 2; Both ends of the bolt body are provided with threads 4 , and the middle part of the bolt body is smooth and coated with a hydrophobic film 3 .

[0047]...

Embodiment 2

[0063] like figure 1 and 2 As shown, a hydrophobic composite steel core glass fiber anti-floating anchor rod, the overall body of the anchor rod is cylindrical, and the anchor rod body is composed of a fiber resin layer 2 and a steel strand 1 wrapped in the fiber resin layer 2; Both ends of the bolt body are provided with threads 4 , and the middle part of the bolt body is smooth and coated with a hydrophobic film 3 .

[0064] The hydrophobic membrane includes liquid A and liquid B with a mass ratio of 3:1; liquid A is composed of epoxy resin and curing agent with a mass ratio of 100:5, and liquid B is composed of a fluoropolymer with a mass ratio of 100:8 Emulsion and accelerator composition. The epoxy resin is bisphenol A liquid epoxy resin; the curing agent is cobalt naphthenate. The fluorine-containing polymer emulsion is a polyperfluoroethylene propylene emulsion and a perfluoroalkylate emulsion with a viscosity of 750-1000 cst; the accelerator is a DMP-30 accelerator....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com