Method of clamping and anchoring high strength composite material

A composite material, high-strength technology, applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of complex manufacturing process, inconvenient promotion and application, high cost, etc., and achieve simple manufacturing process, good applicability, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, further illustrate the present invention.

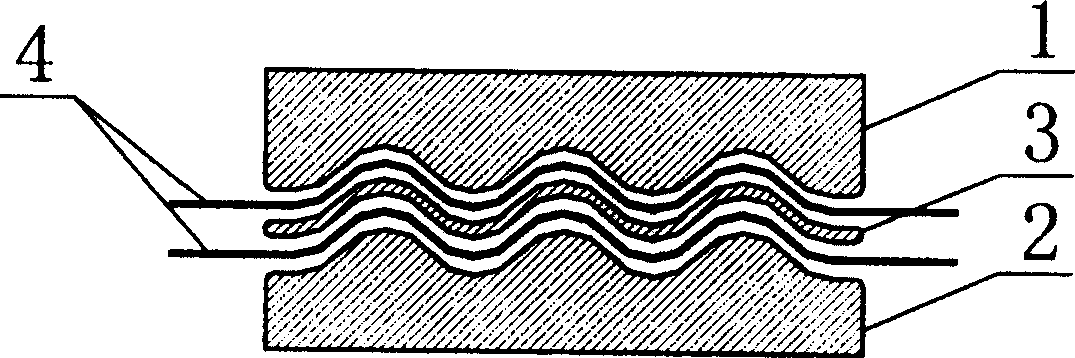

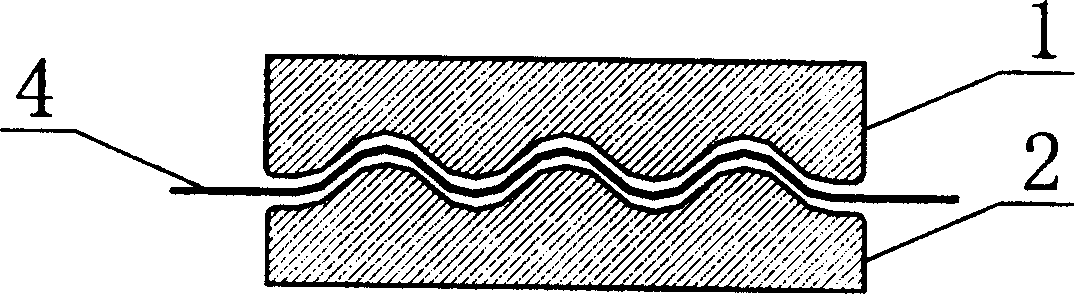

[0031] like figure 1 , 3 As shown, the method steps for clamping and anchoring the thin carbon fiber composite sheet are as follows:

[0032] Step One: Choose the Shape of the Clamp Anchor

[0033] Since this embodiment is to clamp and anchor the carbon fiber cloth sheet, and the carbon fiber cloth sheet is relatively thin and the number of layers is small (that is, 2×0.111mm), so this embodiment chooses a parallel linear wave-tooth clamp anchor , and no stiffening corrugated plates are added.

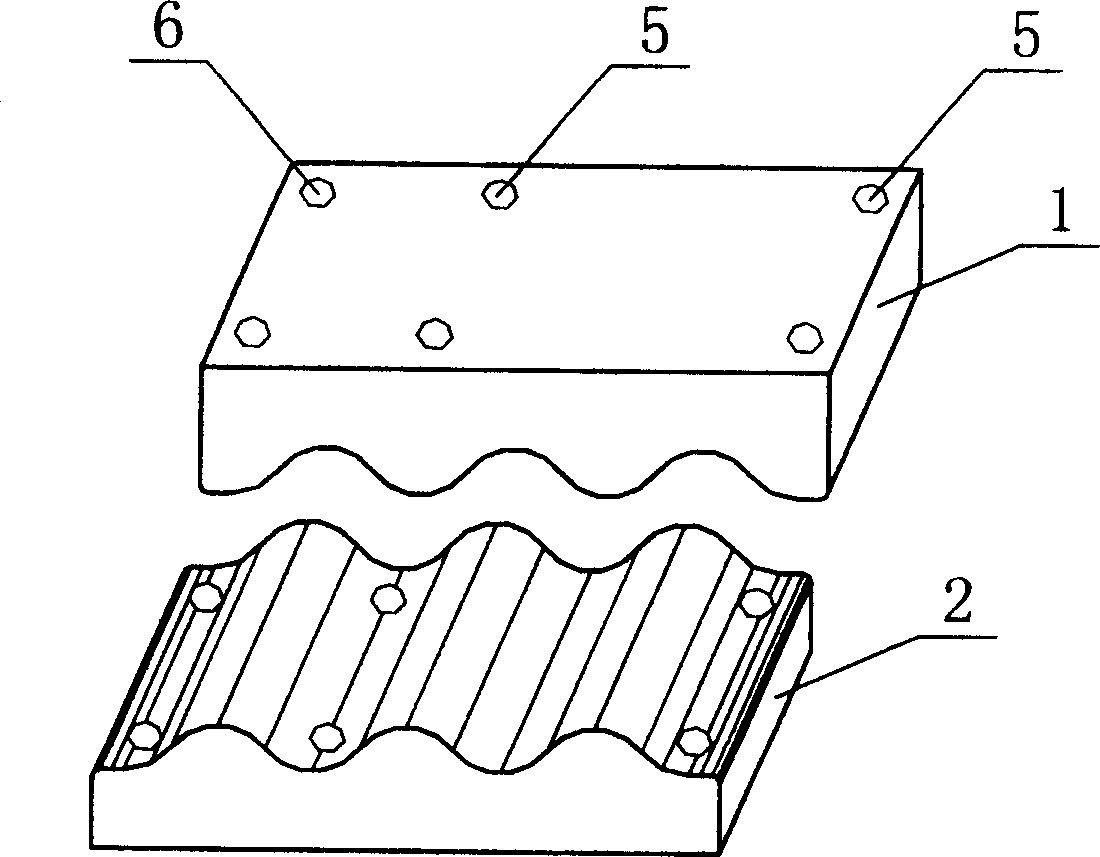

[0034] In this embodiment, four steel plates with a length of 200 mm, a width of 100 mm and a thickness of 25 mm are used to make two upper corrugated tooth plates 1 and lower corrugated tooth plates 2 respectively to form two corrugated tooth clamp anchors. Each corrugated tooth jig anchor is composed of an upper corrugated tooth plate 1 and a lower corrugated tooth plate 2 matched with each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com