Metal-coated ceramic baseplate and manufacturing method thereof

A ceramic substrate, metal-clad technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of unusable power electronic devices, improve service life, improve temperature cycle reliability, manufacturing process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preparation method of the metal-ceramic substrate of the present invention is carried out according to the following steps,

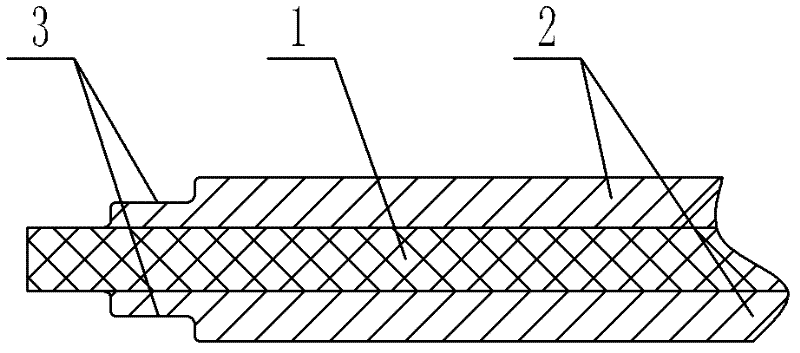

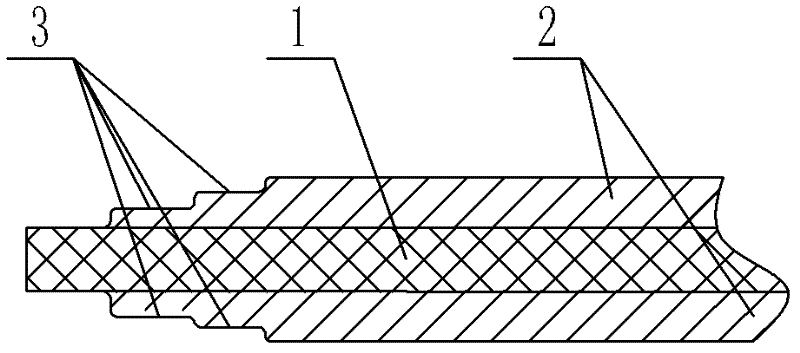

[0016] (1), clean both sides of the ceramic substrate 1, the ceramic substrate 1 can be aluminum oxide (Al2O3), aluminum nitride (AlN), bismuth oxide (BiO2), silicon nitride (Si3N4), silicon carbide (SiC) one of them,

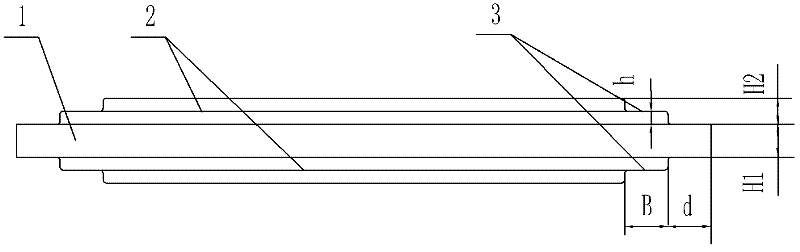

[0017] (2), the metal layer 2 is directly welded on the upper and lower sides of the ceramic substrate 1, such as direct copper welding on the upper and lower sides of the ceramic substrate 1, or the metal layer 2 is brazed on the upper and lower sides of the ceramic substrate 1, such as using active metal Brazing is to braze the metal layer on the upper and lower sides of the ceramic substrate 1, and the metal layer 2 is a copper layer or an aluminum layer or a copper-aluminum composite layer. In the present invention, there is a distance between the outer peripheral surface of the metal layer 2 and the outer peripheral surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com