Steel plate butt welding method

A welding method and steel plate technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of difficult welding operation, difficult precise positioning, and narrow operating space, so as to improve welding quality and guarantee Welding quality, the effect of solving the stress concentration at the root of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

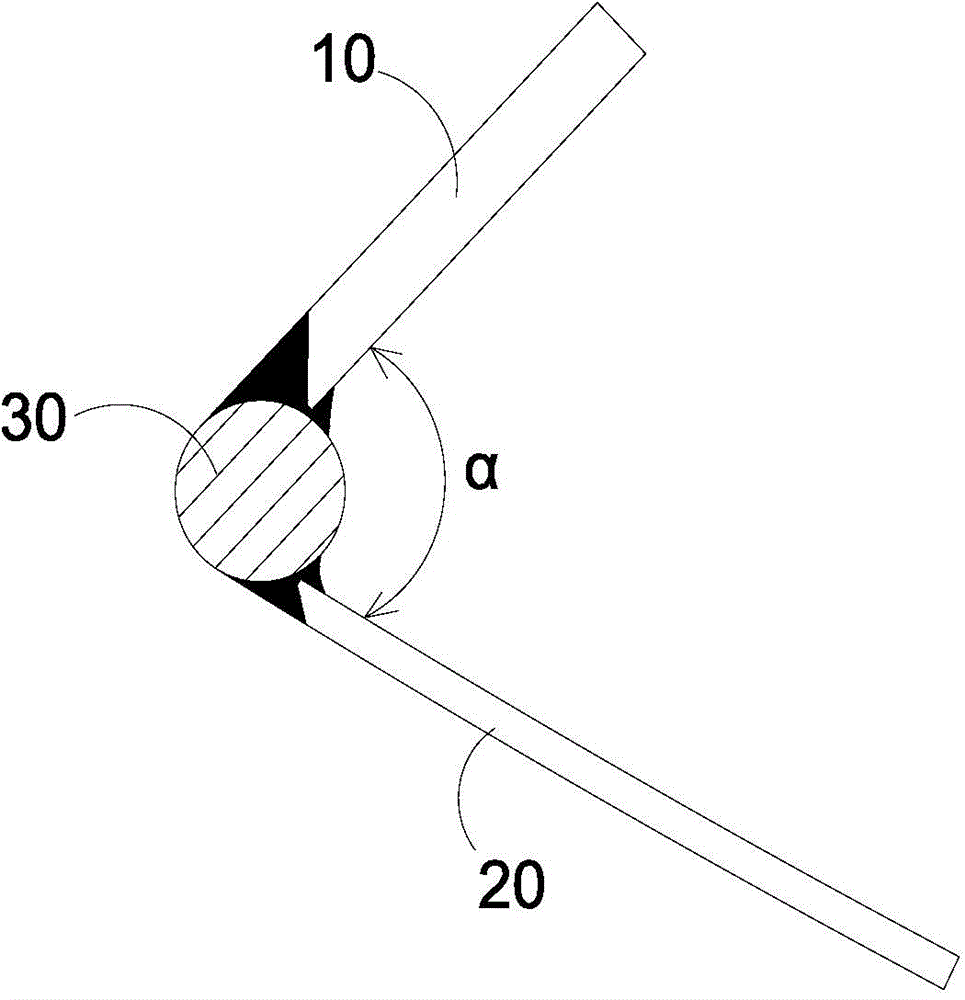

[0030] Such as figure 1 As shown, an embodiment of the steel plate butt welding method of the present invention is used to butt weld the first steel plate 10 and the second steel plate 20 together. In this embodiment, the first steel plate 10 is a rib plate with a thickness of 25 mm and a grade of ABS-A, the second steel plate 20 is a bottom plate with a thickness of 14 mm and a grade of ABS-B, and the rib plate is required The angle α between the ship's bottom plate and the ship's bottom plate is 73° as an example for illustration.

[0031] Of course, in other embodiments, the thickness of the first steel plate 10 and the thickness of the second steel plate 20 may be the same, and the grades may also be the same. The angle between the first steel plate 10 and the second steel plate 20 can also be adjusted as needed, for example, the angle α between the first steel plate 10 and the second steel plate 20 is between 15° and 90°, even lower than 15°. ° such as 10 ° ~ 14 ° is al...

Embodiment approach 2

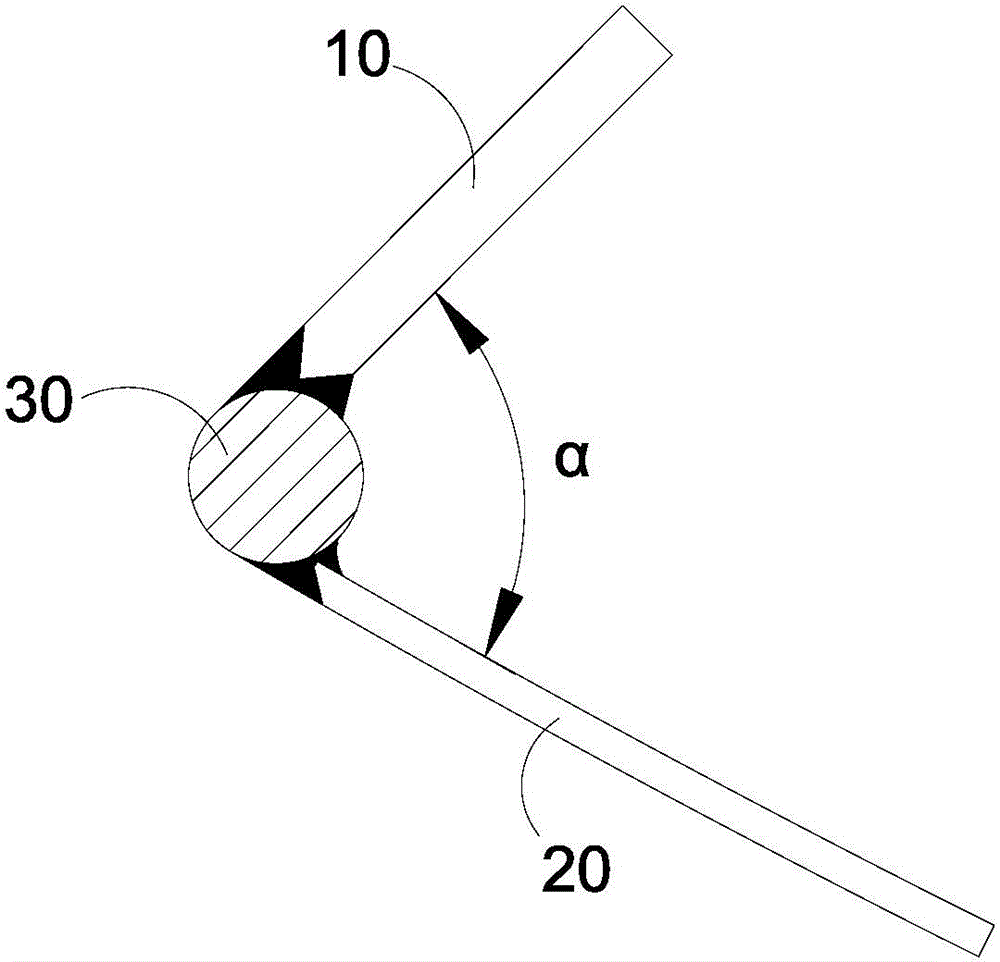

[0049] Such as figure 2 As shown, the difference between the second embodiment of the steel plate butt welding method of the present invention and the first embodiment only lies in:

[0050] The thickness of the bottom plate 20 and the rib plate 10 is relatively thin, for example, the thickness is less than 16mm. Therefore, in the bevel processing step S2, the bottom plate 20 and the rib plate 10 can be machined with a beveling machine to form a "V"-shaped bevel.

[0051] Other steps of the second embodiment of the butt welding method are basically the same as those of the first embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com