Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Solve sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

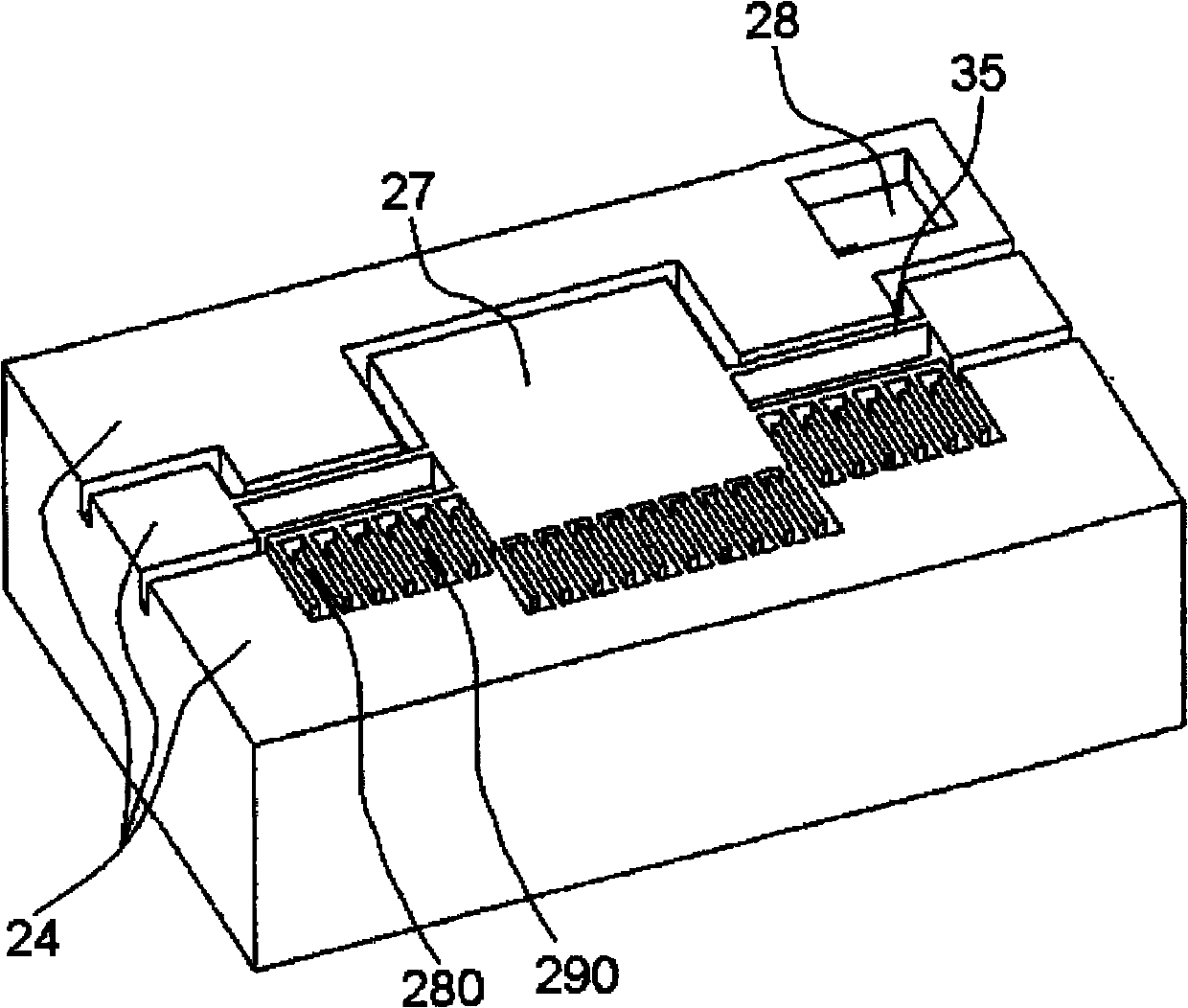

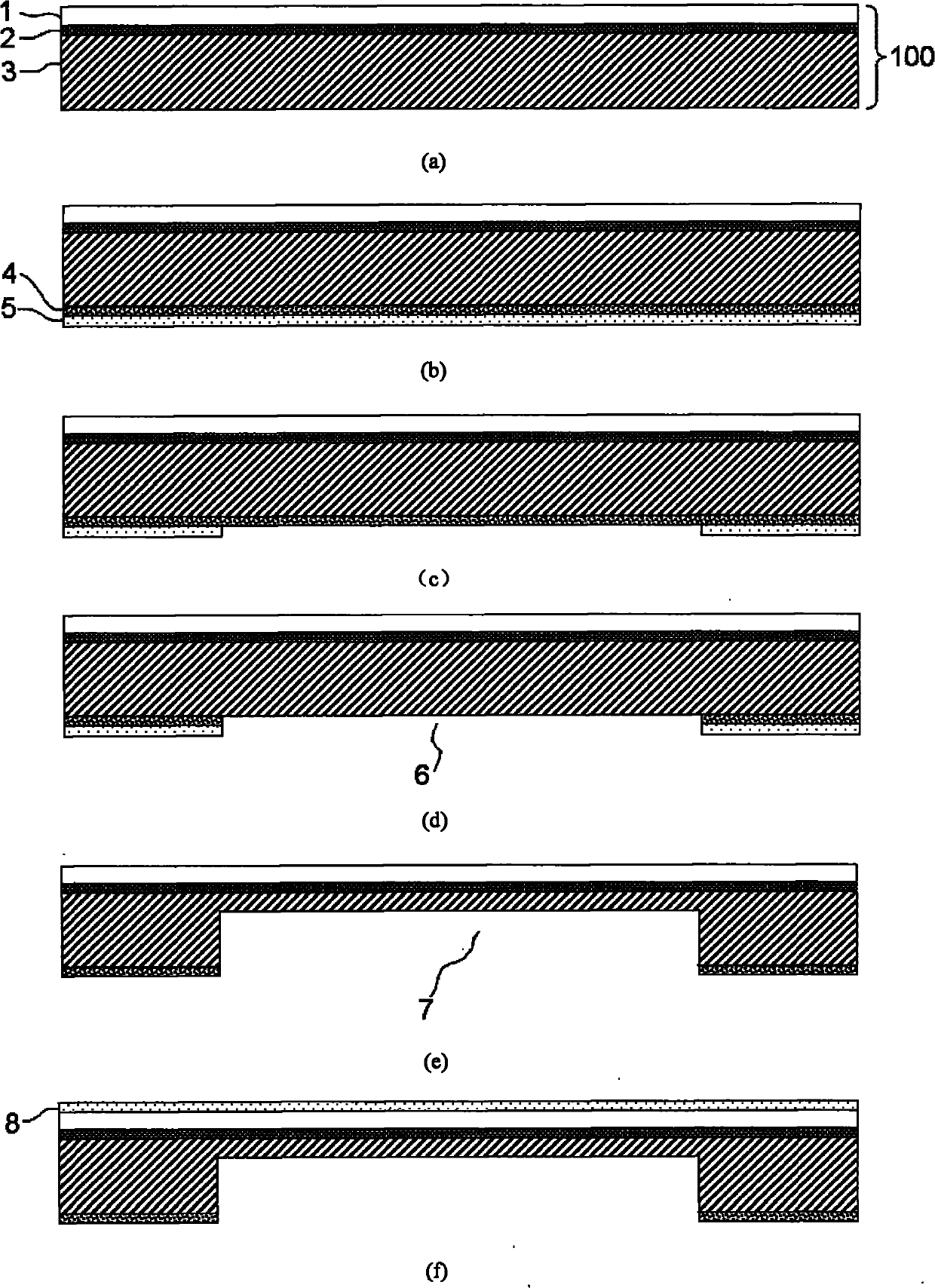

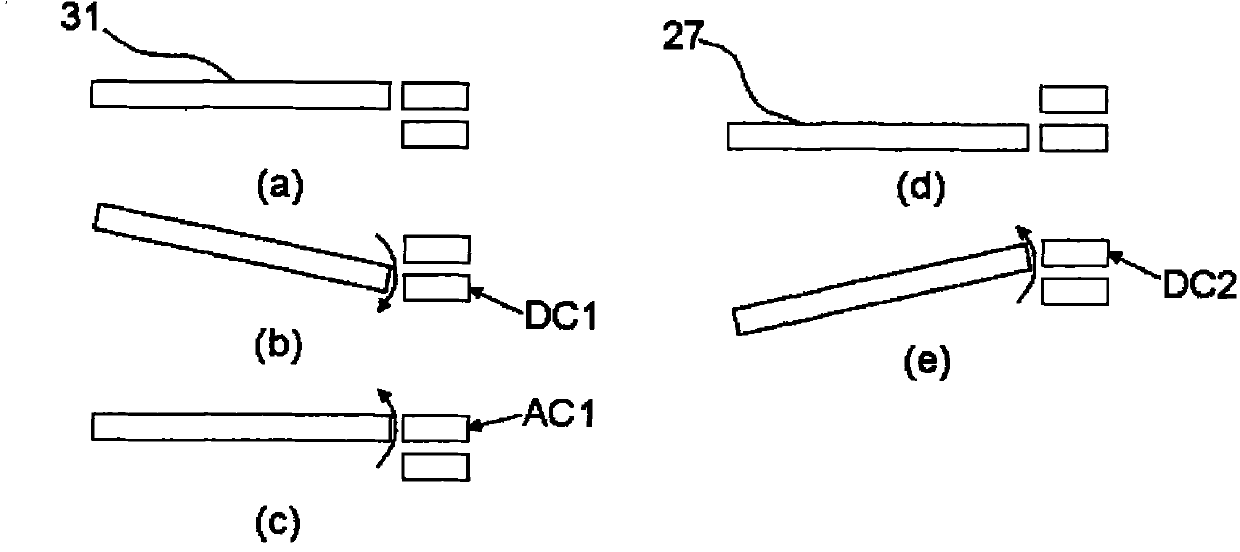

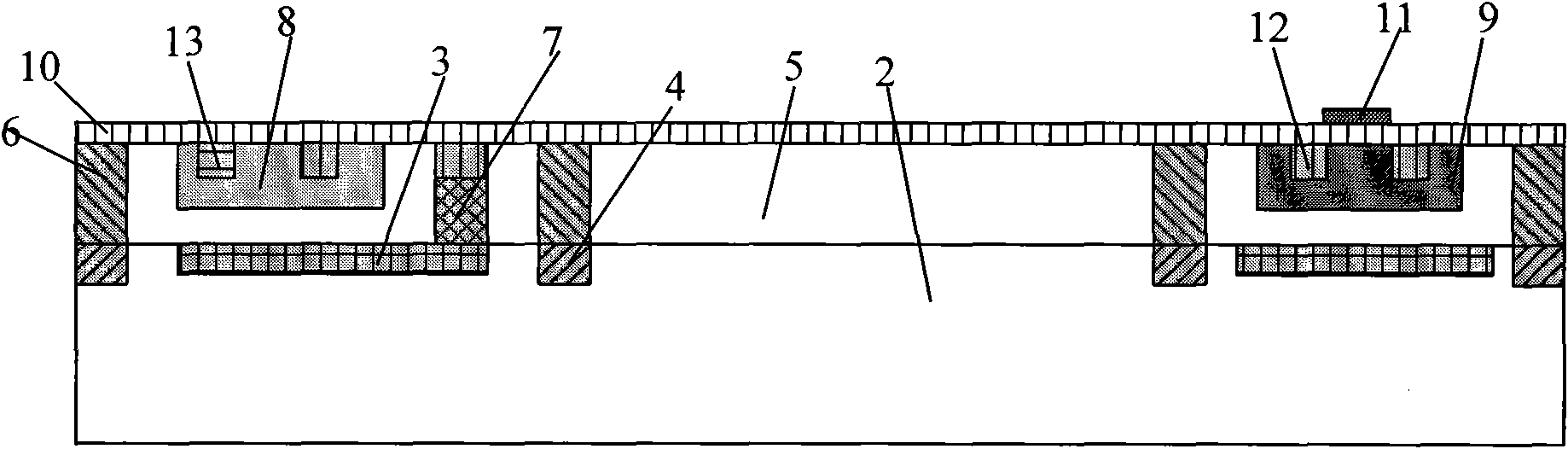

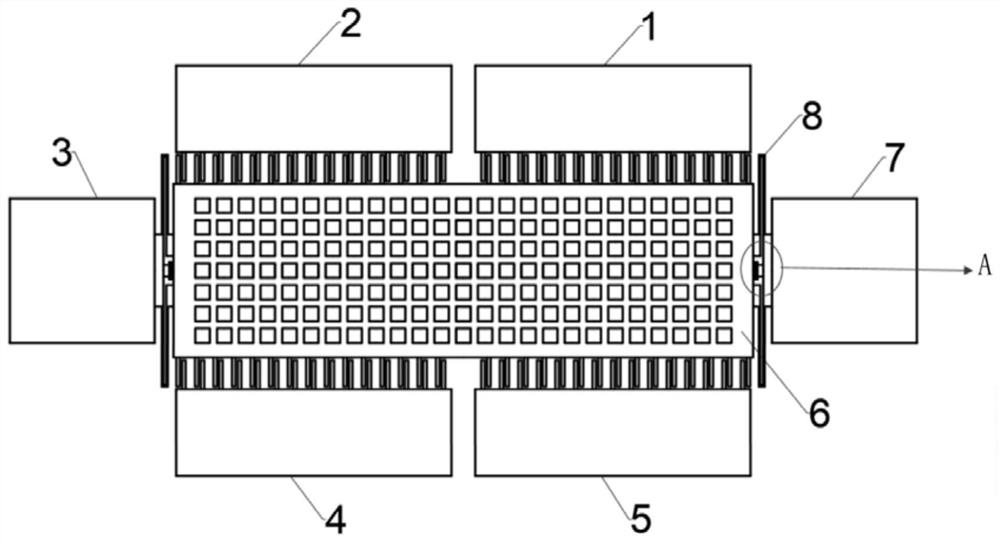

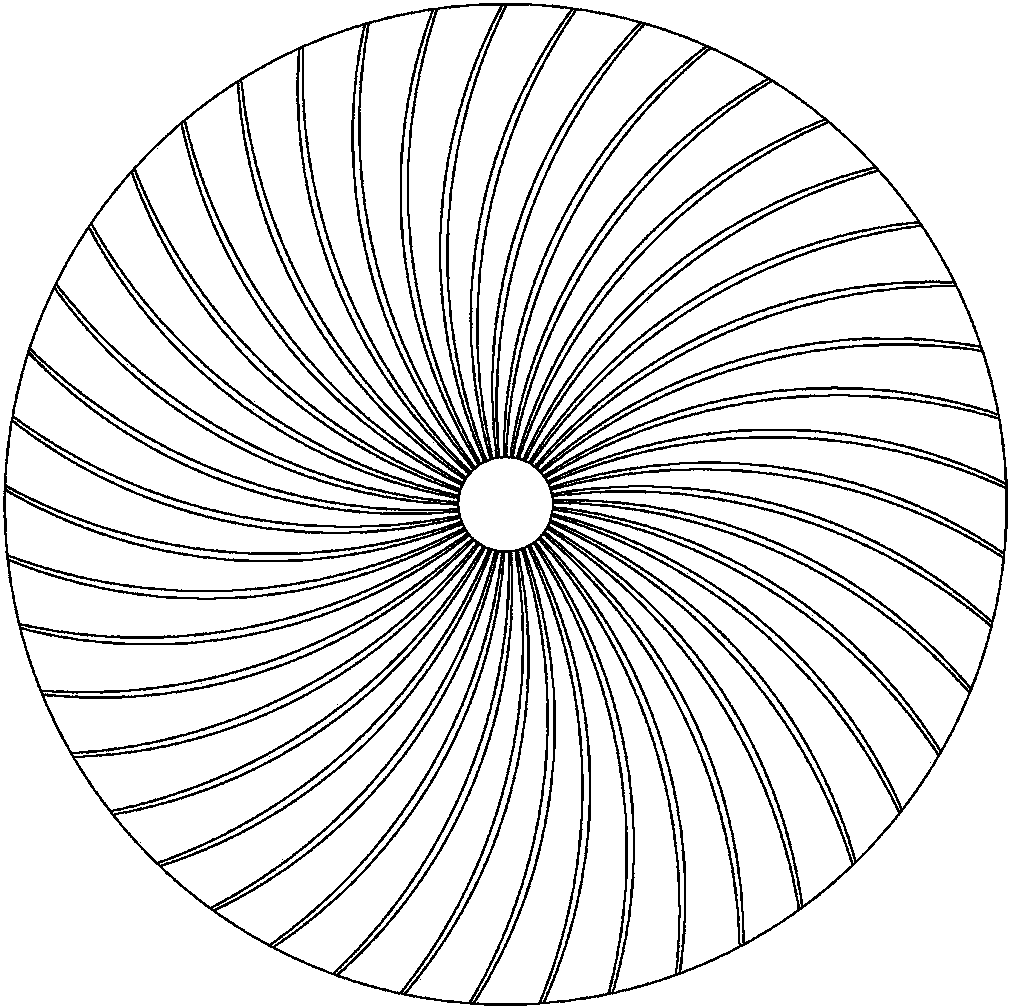

Silicon on insulator (SOI) wafer double-mask etching-based vertical comb teeth driven torsional micro-mirror and manufacturing method thereof

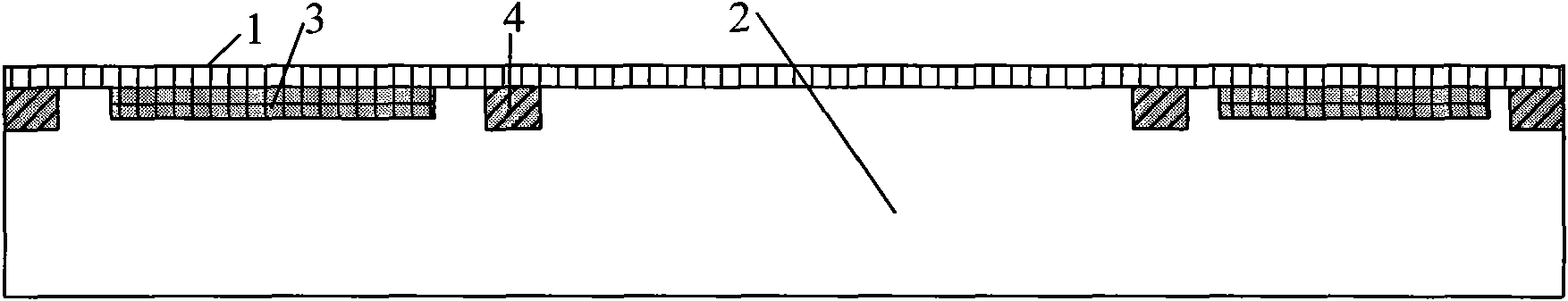

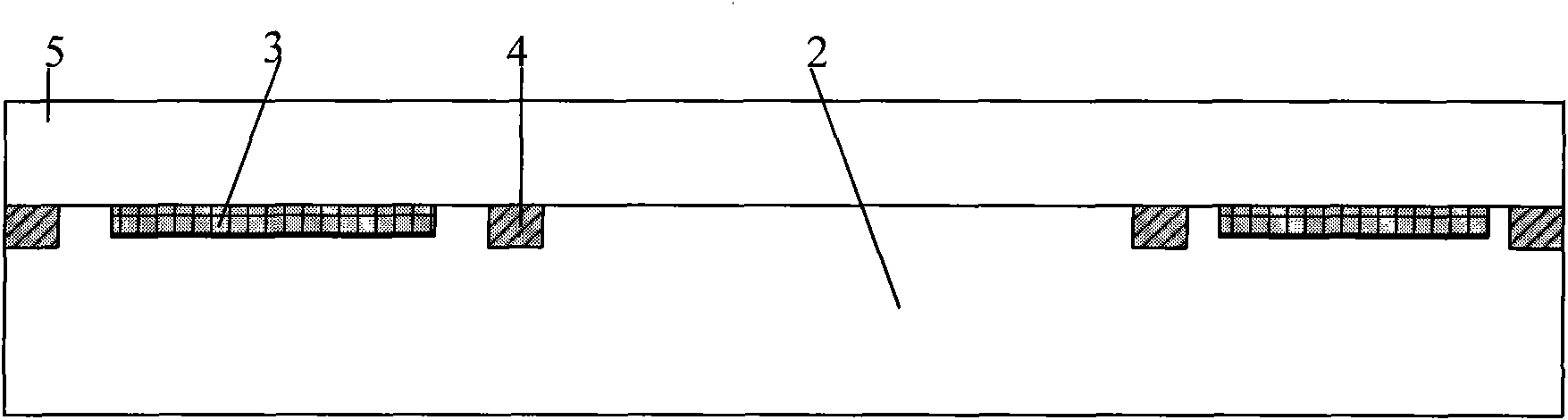

InactiveCN101907769ANo misalignment issuesSolve stickingDecorative surface effectsPhotomechanical apparatusBatch productionStatic mode

The invention discloses a silicon on insulator (SOI) wafer double-mask etching-based vertical comb teeth driven torsional micro-mirror and a manufacturing method thereof, which belong to the fields of micro-electro-mechanical systems and micromachining. The torsional micro-mirror is driven by single side comb teeth and is provided with three layers of moveable parts and fixed parts with the same structure. The torsional micro-mirror can work in a static mode or in a dynamic mode by applying voltage signals to different comb teeth. The method for manufacturing the vertical comb teeth driven torsional micro-mirror is characterized in that: single SOI wafer processing technology is adopted without multi-layer thin film sedimentation or bonding technology; the whole technological process only needs two mask plates; the upper and lower vertical comb teeth are etched by one mask without an alignment error problem of the comb teeth; and the technological process does not need hydrogen fluoride (HF) corrosion so as to effectively avoid adhesion among the comb teeth caused by a liquid environment. The manufacturing method has the advantages of high precision, low cost, small stress, high finished product rate, simple process, high repeatability, easy batch production and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

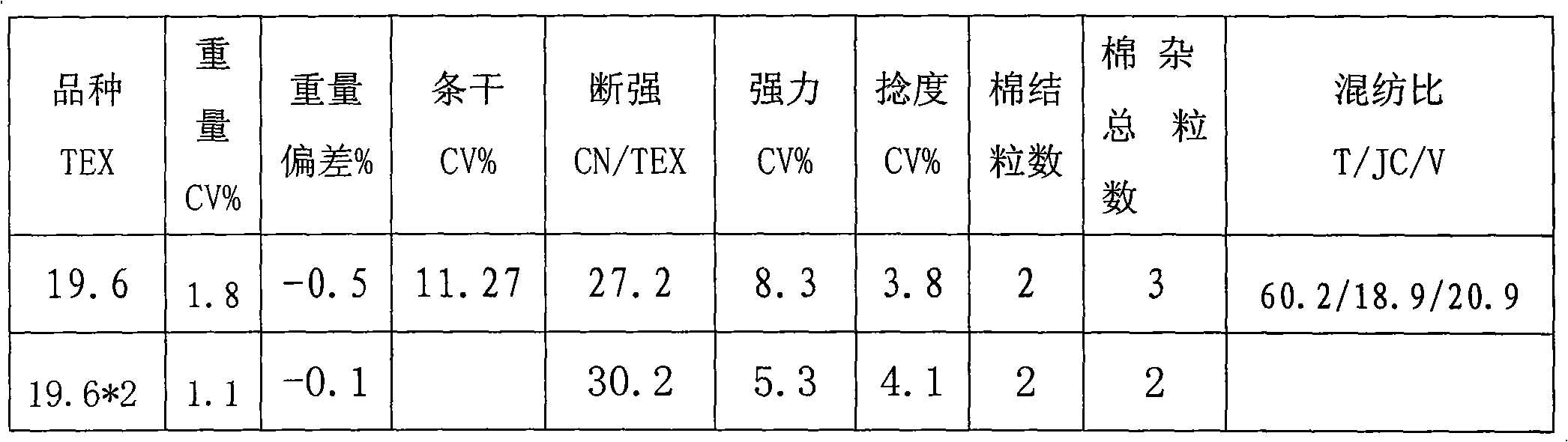

Three-component fiber blended yarns and manufacturing process thereof

The invention discloses three-component fiber blended yarns, which are characterized by comprising 60 to 70 percent of polyester fiber, 15 to 25 percent of vinylon fiber, 15 to 25 percent of upland cotton fiber, wherein the warp and weft count in the yarns is 19.6*2. A manufacturing process of the three-component fiber blended yarns comprises the following steps of: cotton clearing, cotton carding, pre-drawing, combing, drawing, roving and spinning to complete the spinning of the three-component fiber blended yarns. The three-component fiber blended yarns have accurate fiber content and can solve the problem of sticky winding during spinning. Products manufactured by the process can be made into blended fabrics of the polyester fiber, the vinylon fiber and the cotton fiber, so wear-resisting and comfortable blended products are provided for the field of spinning.

Owner:JIHUA 3542 TEXTILE CO LTD

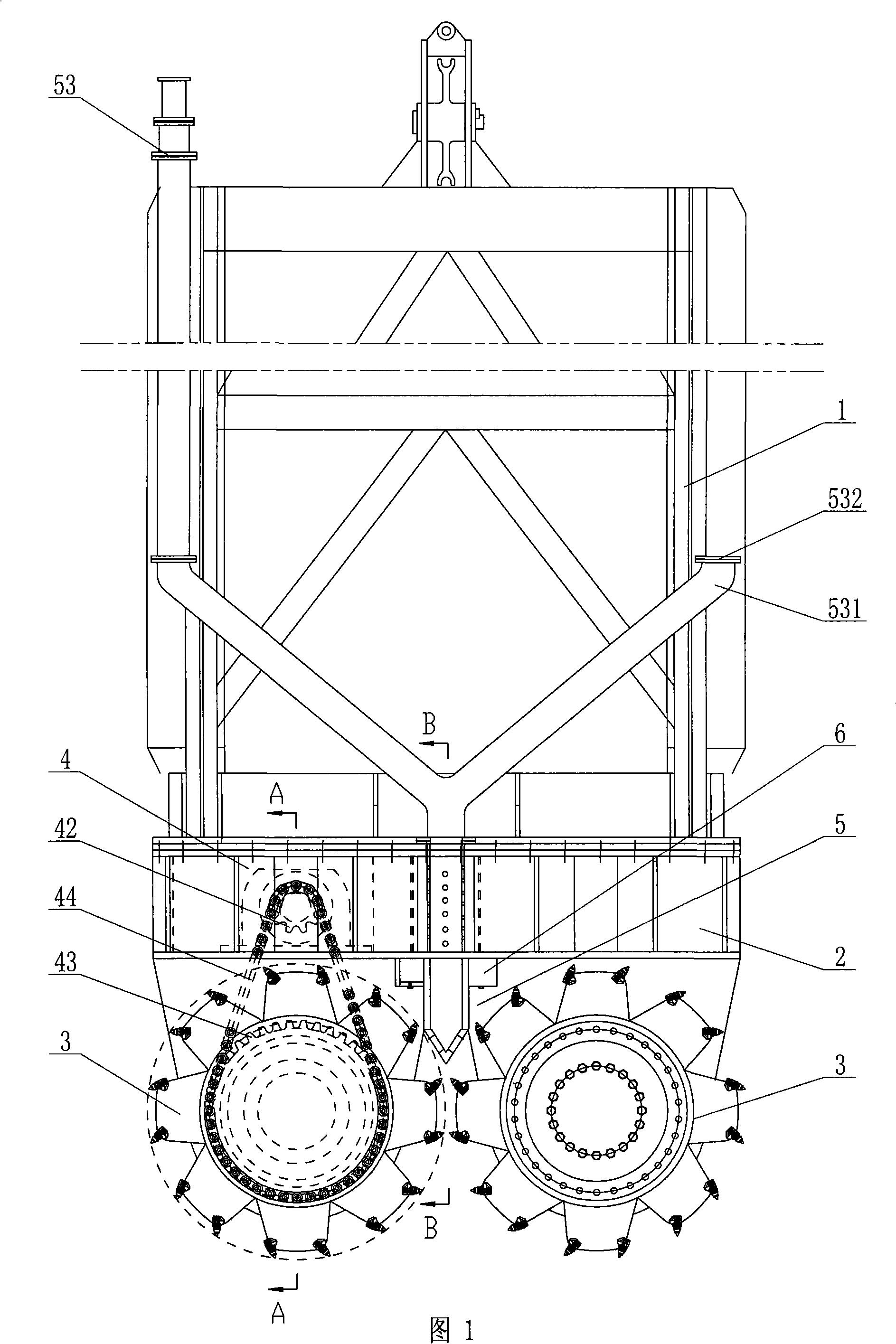

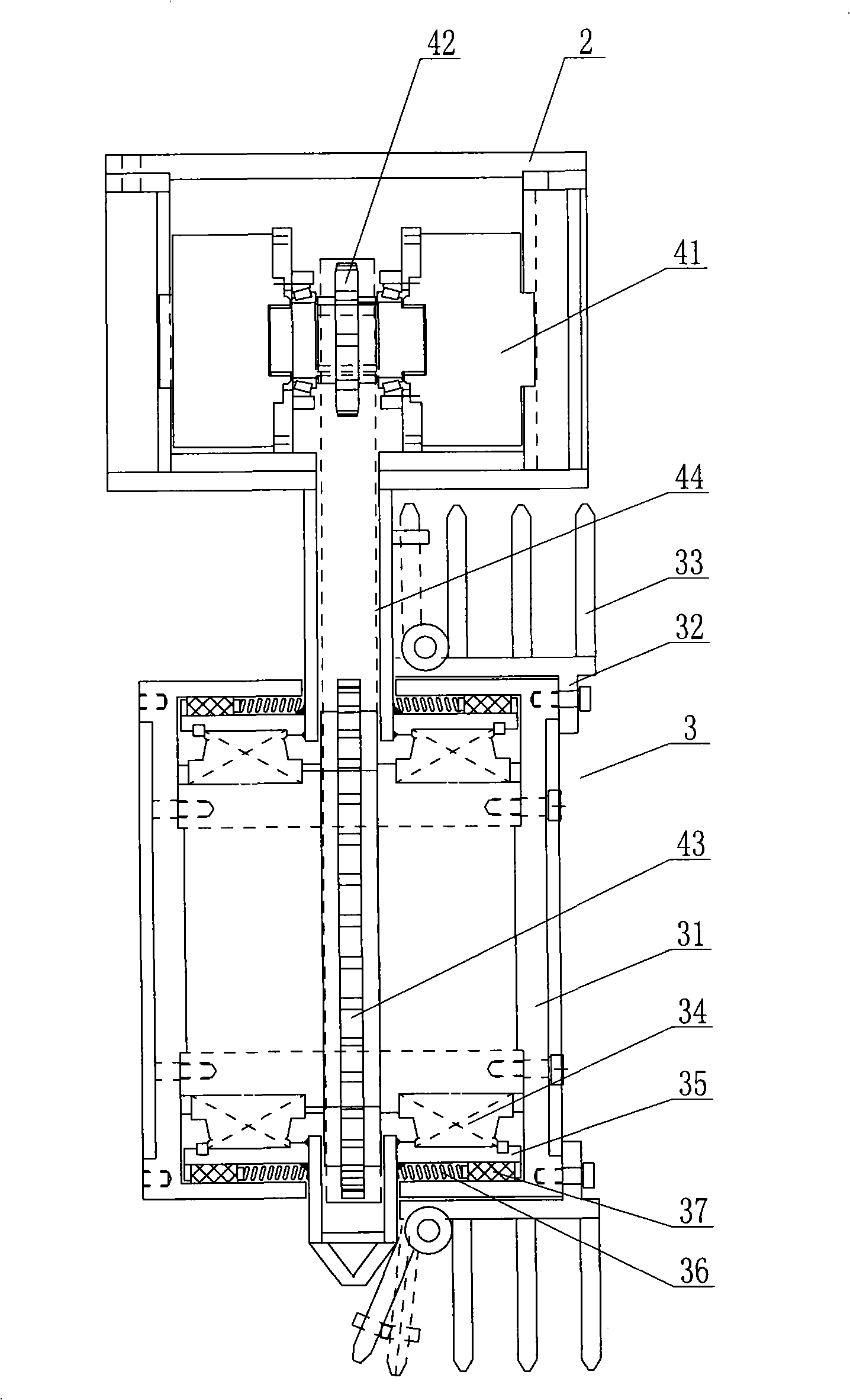

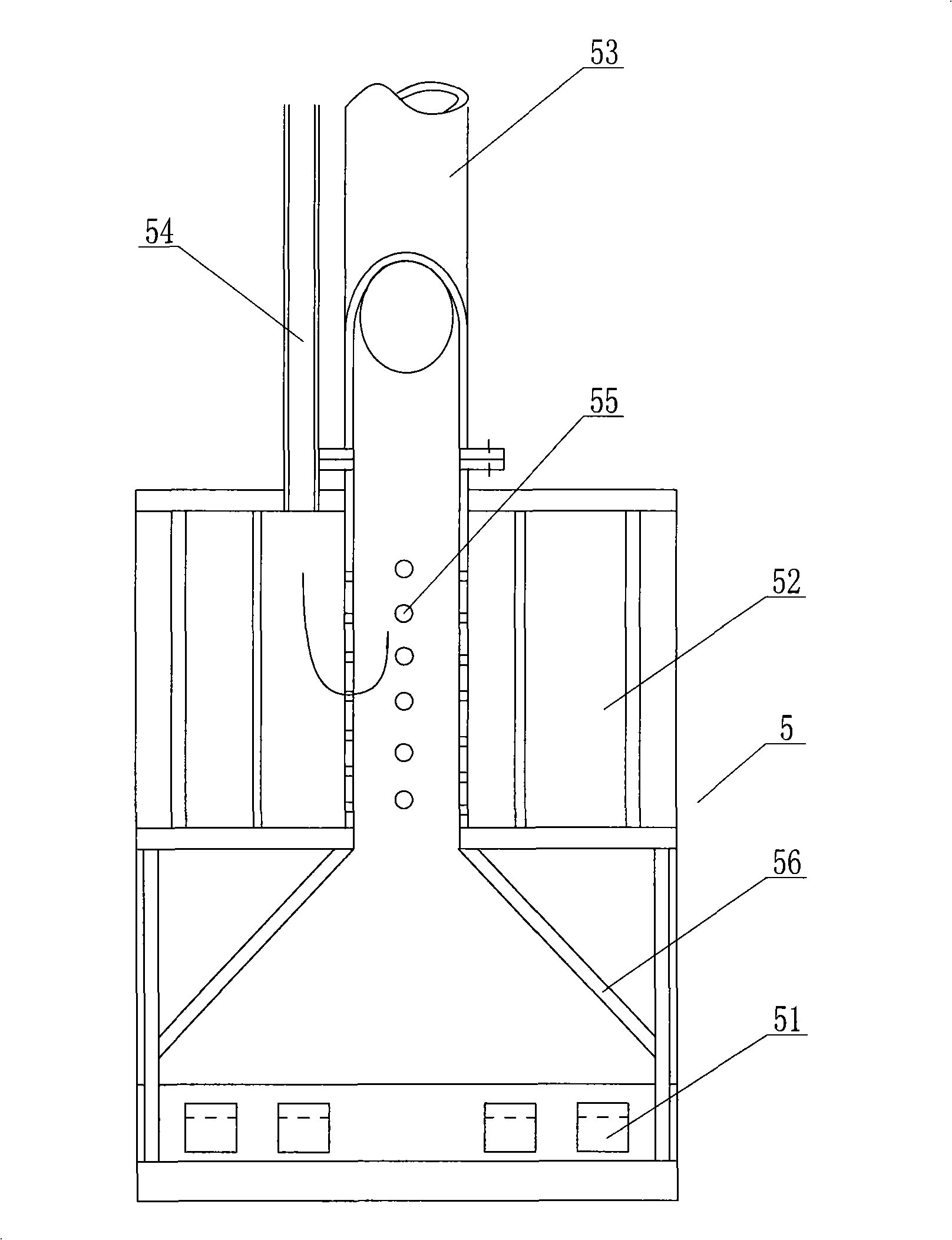

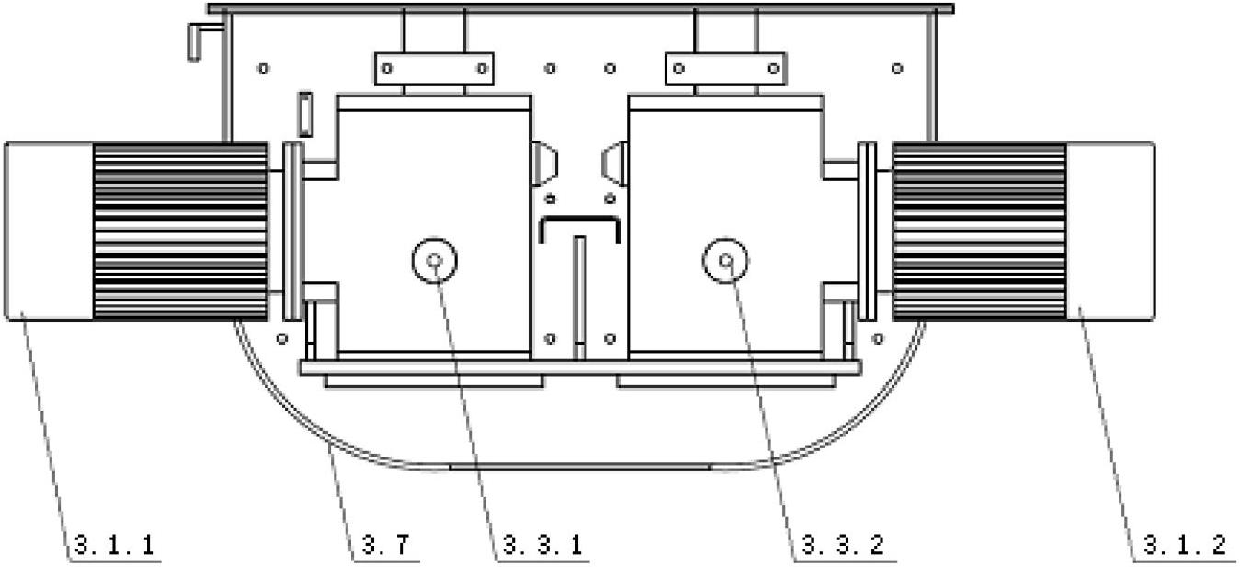

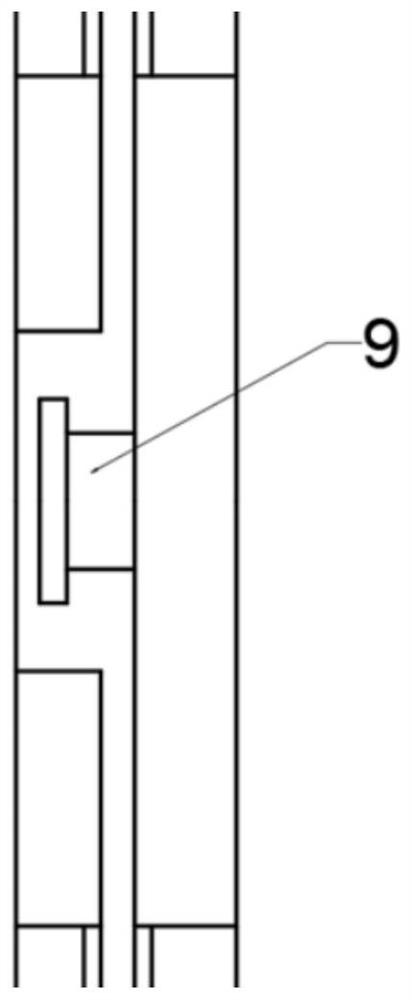

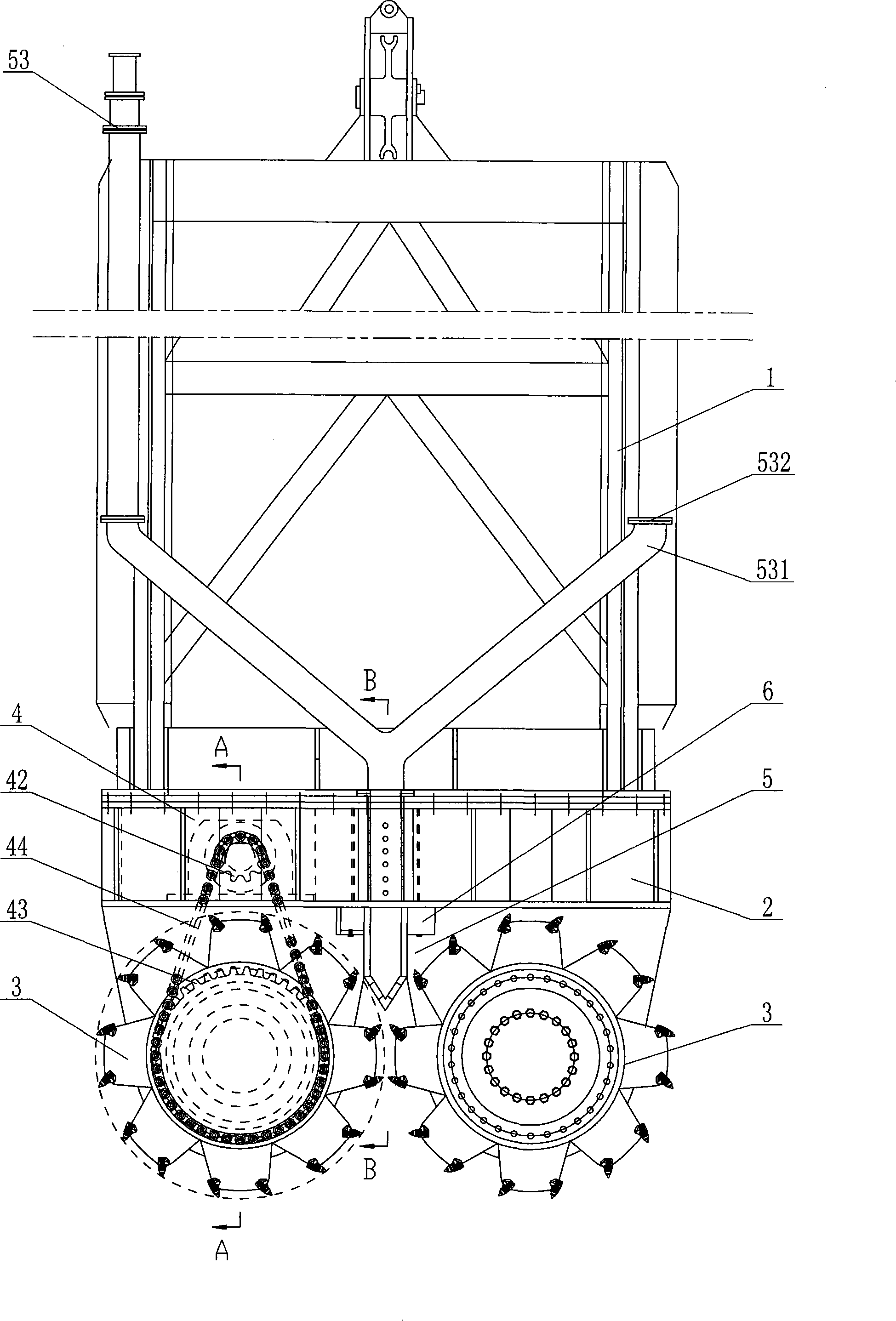

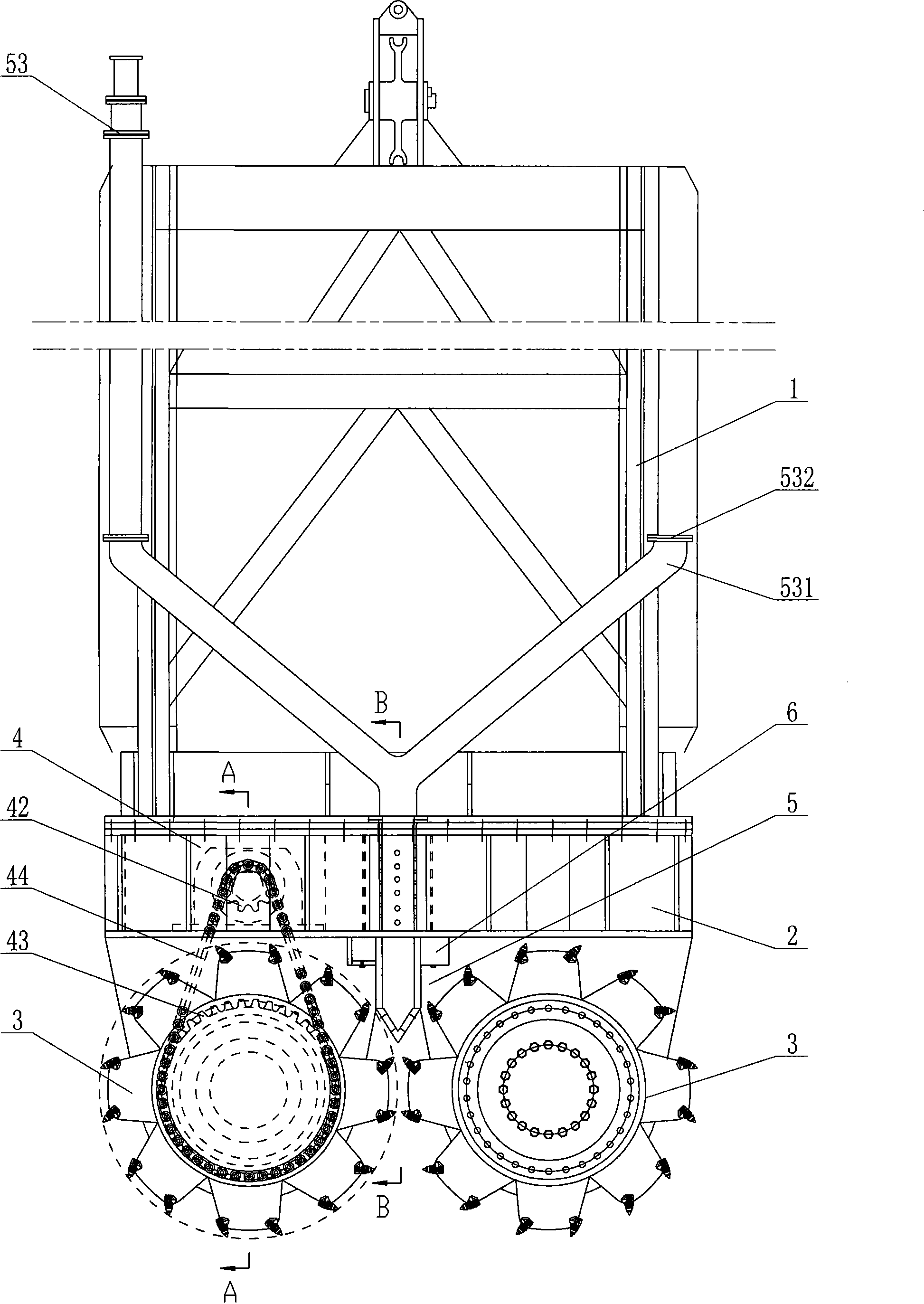

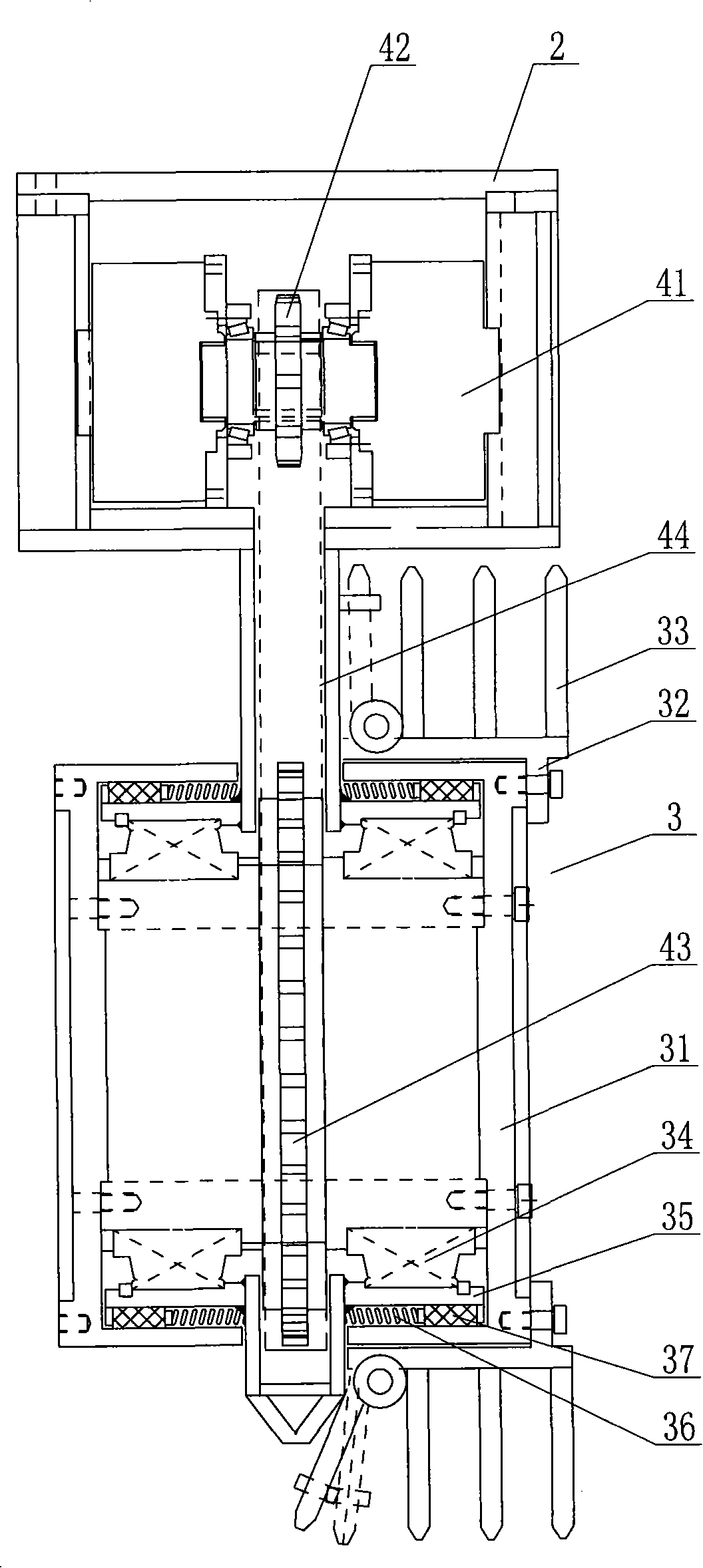

Two-wheel slotter

InactiveCN101285310ASecurity buildEfficient constructionSoil-shifting machines/dredgersExcavationsHydraulic motorMilling cutter

The invention provides a dual wheel slot milling machine, comprising a guide frame, a sealing box body, a driving device and at least one milling wheel which is arranged on the lower part of the sealing box body and provided with a plurality of milling heads along the periphery of the milling wheel and can positively or negatively milling-dig soil layer and rock layer, wherein the driving device comprises a hydraulic motor with low rotary speed and big torque arranged in the sealing box body by the oil immersion lubrication sealing, and a variable speed transmission mechanism consisting of a small chain wheel arranged on an output shaft of the hydraulic motor, a big chain wheel used to drive the milling wheel to turn and a chain used to connect the small chain wheel and the big chain wheel. Due to the adoption of the structure of the driving device with the combination of the hydraulic motor with low rotary speed and big torque and the chain transmission, the slot milling machine is safe and highly efficient, and can perfectly construct the continuous wall with flattening, same thickness and big width, and the work efficiency, rotating speed and torque of the slot milling machine are almost the same as the imported equipment; moreover, the slot milling machine has the advantages of simple and reliable structure, low manufacturing cost, convenient assembly, disassembly and maintenance, low maintenance cost, energy conservation, environmental protection and easy popularization.

Owner:谢沃林

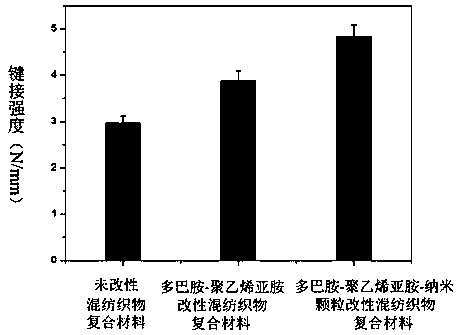

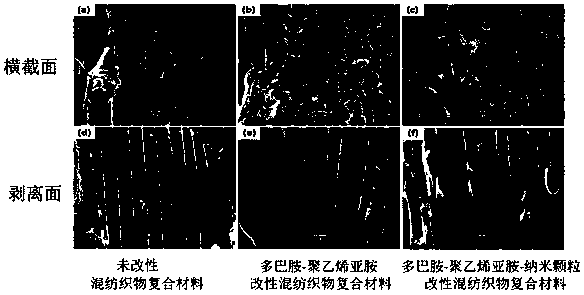

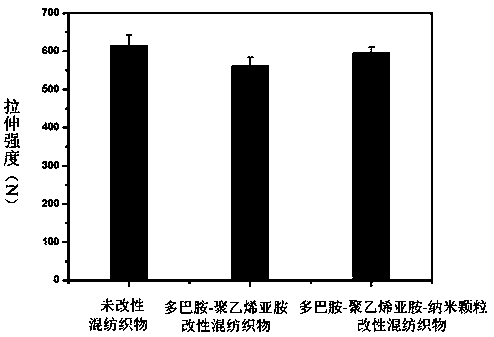

Method for modifying polytetrafluoroethylene-aramid blended fabric jointly by dopamine-polyethyleneimine-nanoparticles

The invention discloses a method for modifying polytetrafluoroethylene-aramid blended fabric jointly by dopamine-polyethyleneimine-nanoparticles; the method includes: adding polytetrafluoroethylene-aramid blended fabric, dopamine hydrochloride, polyethylenimine and nanoparticles into trihydroxymethyl-aminomethane / hydrochloride buffered solution, stirring, ultrasonically dispersing well, and continuously stirring at room temperature to allow for 2-24 h of reaction; after the reaction, taking out the blended fabric, sufficiently washing with deionized water to remove unreacted impurities on thesurface, and then drying in a vacuum oven to obtain the surface-modified polytetrafluoroethylene-aramid blended fabric. An organic-inorganic hybrid functional coating is constructed on the fiber surface through modifying; therefore, both active functional groups and greater surface roughness are imparted to the surface of the blended fabric, and the interface adhesion performance between the blended fabric and phenolic resin matrix can be improved through chemical bonding and mechanical interlocking.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

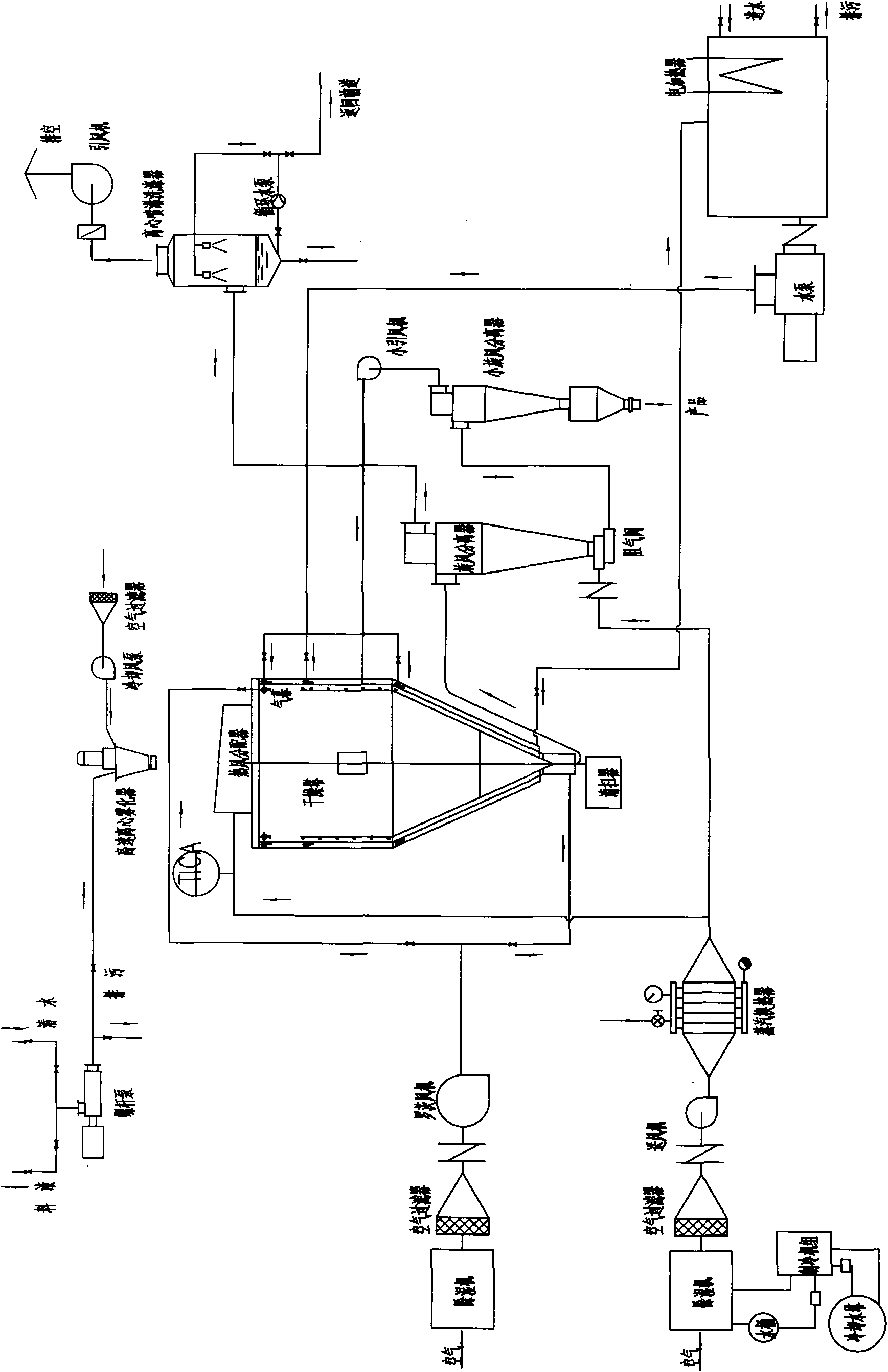

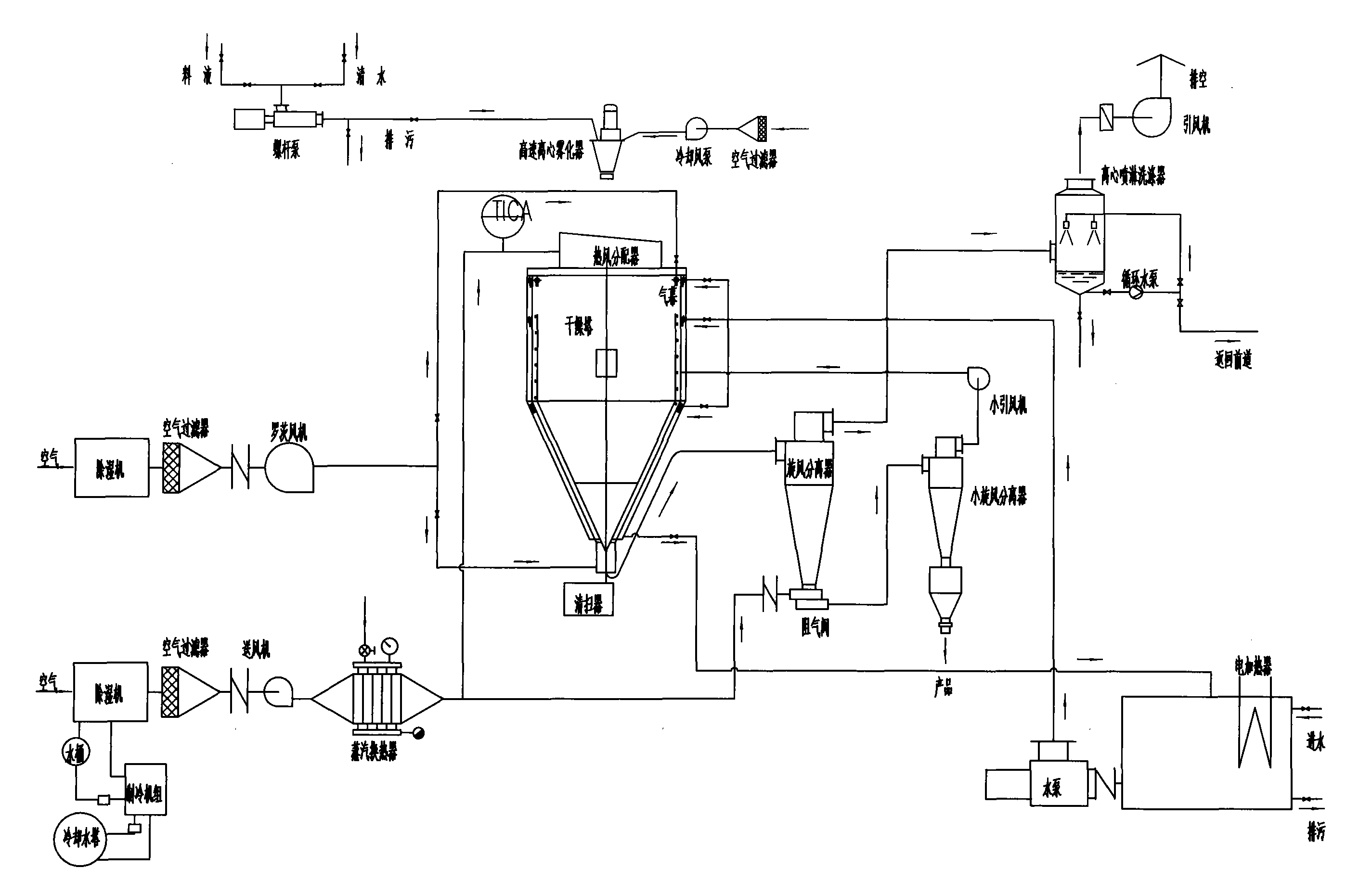

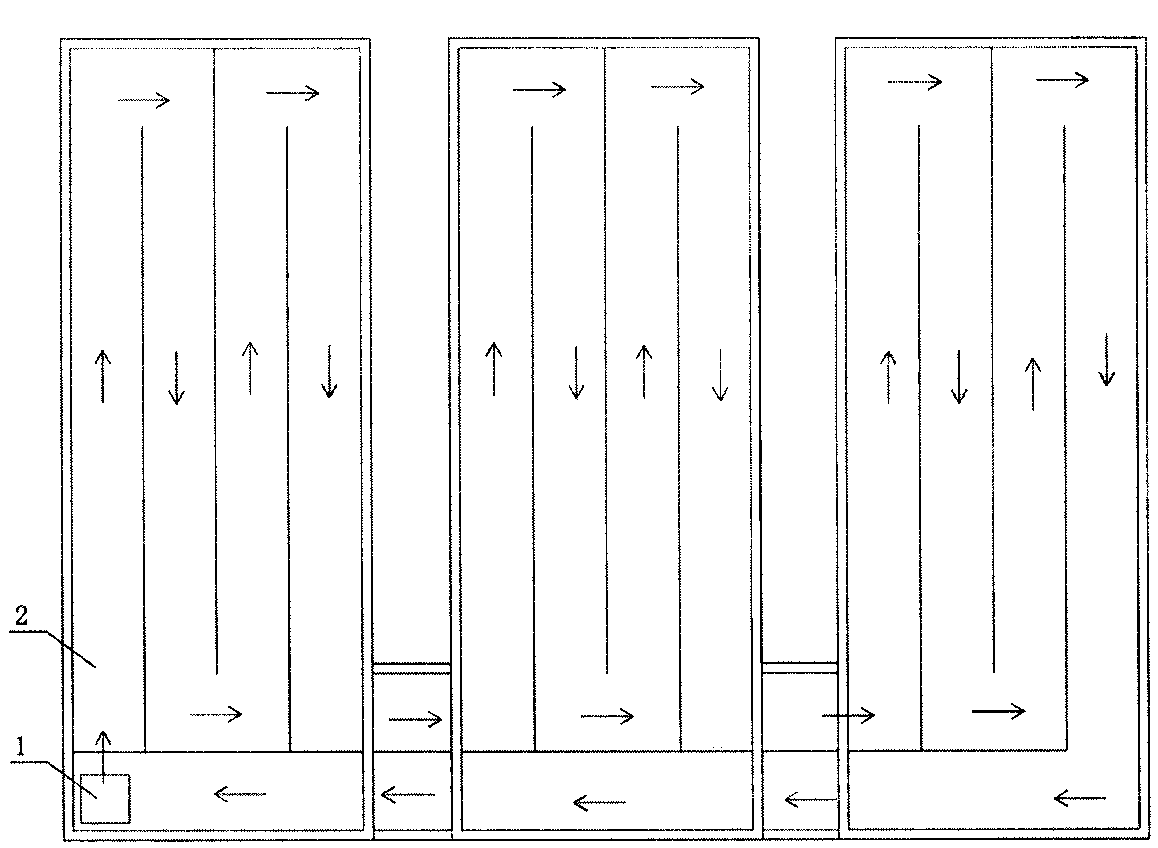

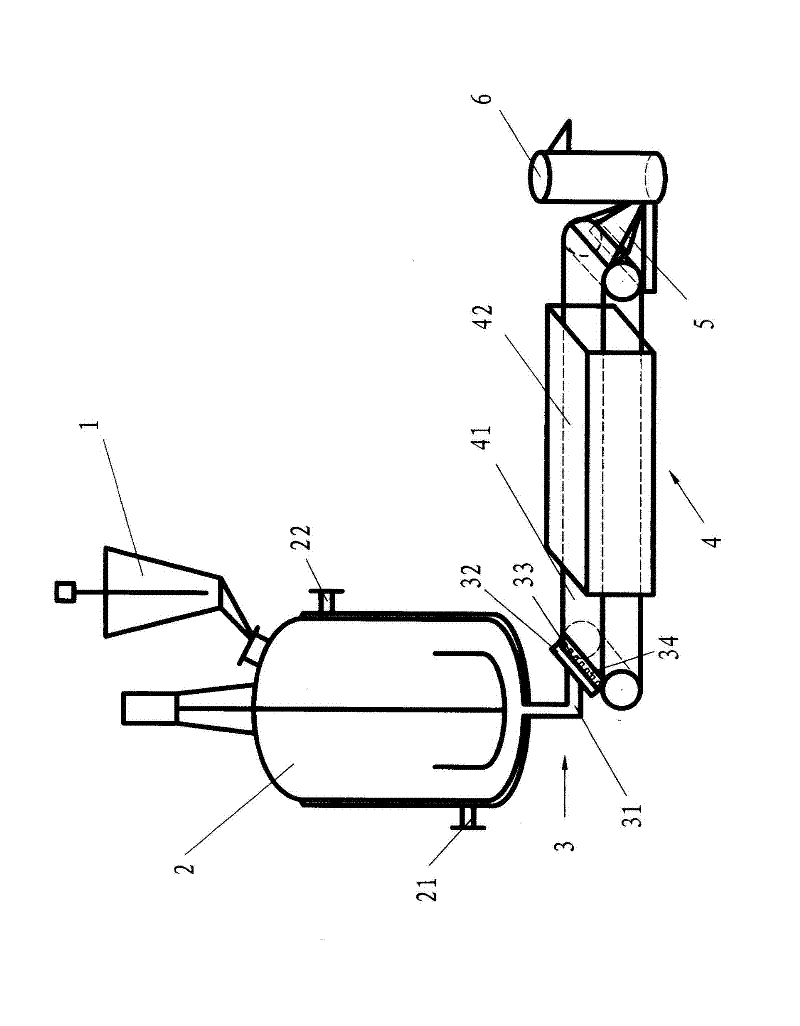

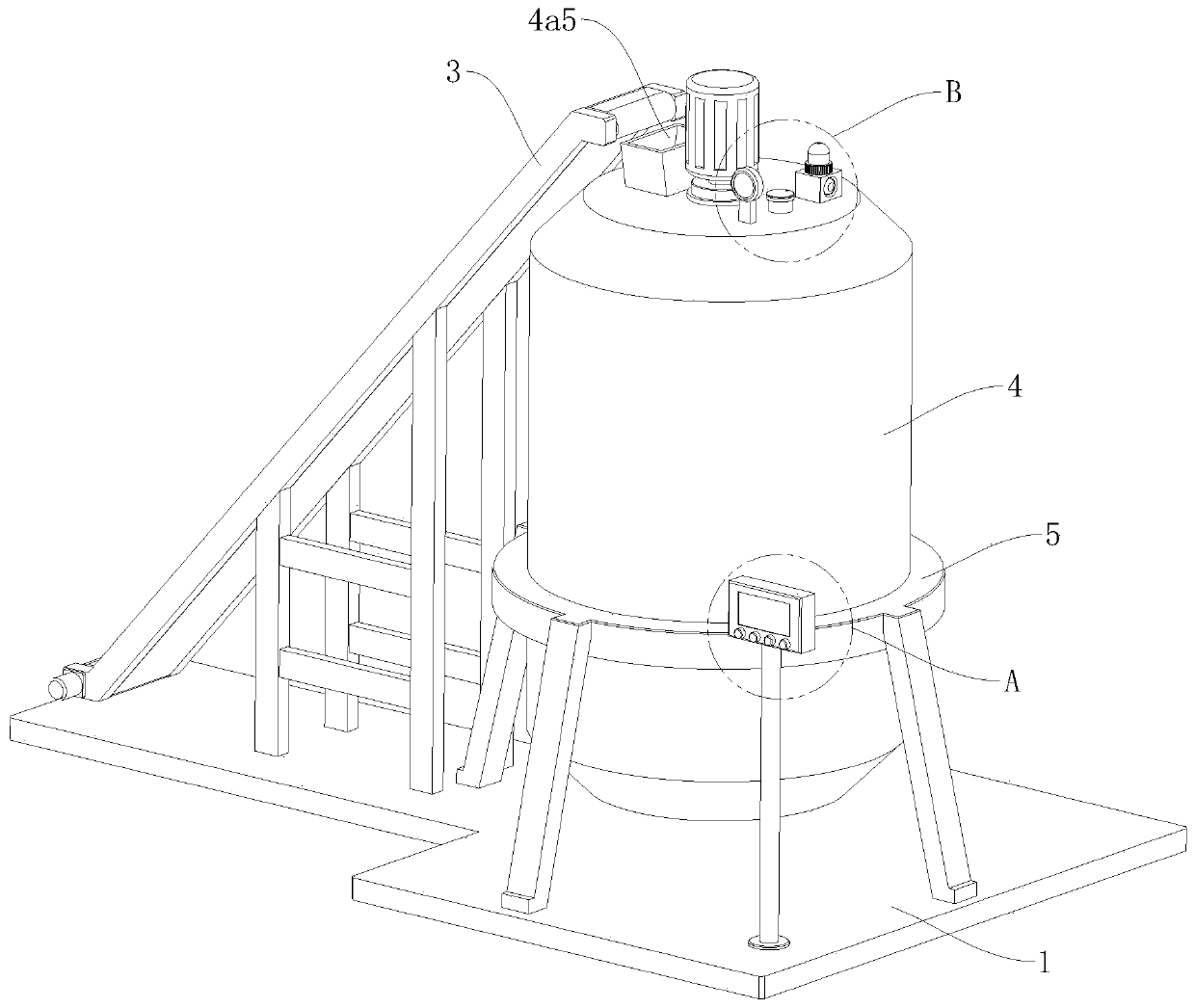

Icing sugar spray drying system with high DE value

ActiveCN101787397APrevent powdered sugar from sticking to wallsGood cooling effectSugar dryingDew pointIcing sugar

The invention discloses an icing sugar spray drying system with a high DE value, which consists of a feeding part, an atomizing part, a drying part and an air supply part; a sizing agent obtained from pretreatment is thrown into a stock chest, the stock chest is connected with the feeding part, the feeding part conveys syrup to the atomizing part, then the syrup enters the drying part after being atomized by the atomizing part, and dry and hot wind is sent to the drying part by the air supply part; the syrup evaporated moisture content at the drying part enters the stage of product package after whirl wind separation; as the icing sugar has lower softening point (about 50 DEG C) and strong hygroscopicity, the icing sugar is soften to stick on the wall if the temperature of the tower wall is too high, while the icing sugar reaches the dew point to stick on the wall if the temperature of the tower wall is too low, therefore, a jacket is utilized to control the temperature of the tower wall, the entering air temperature is controlled at 120-140 DEG C, and the leaving air temperature is controlled at 65-75 DEG C, thus being capable of preventing the icing powder from sticking on the wall.

Owner:山东丰源通达电力有限公司

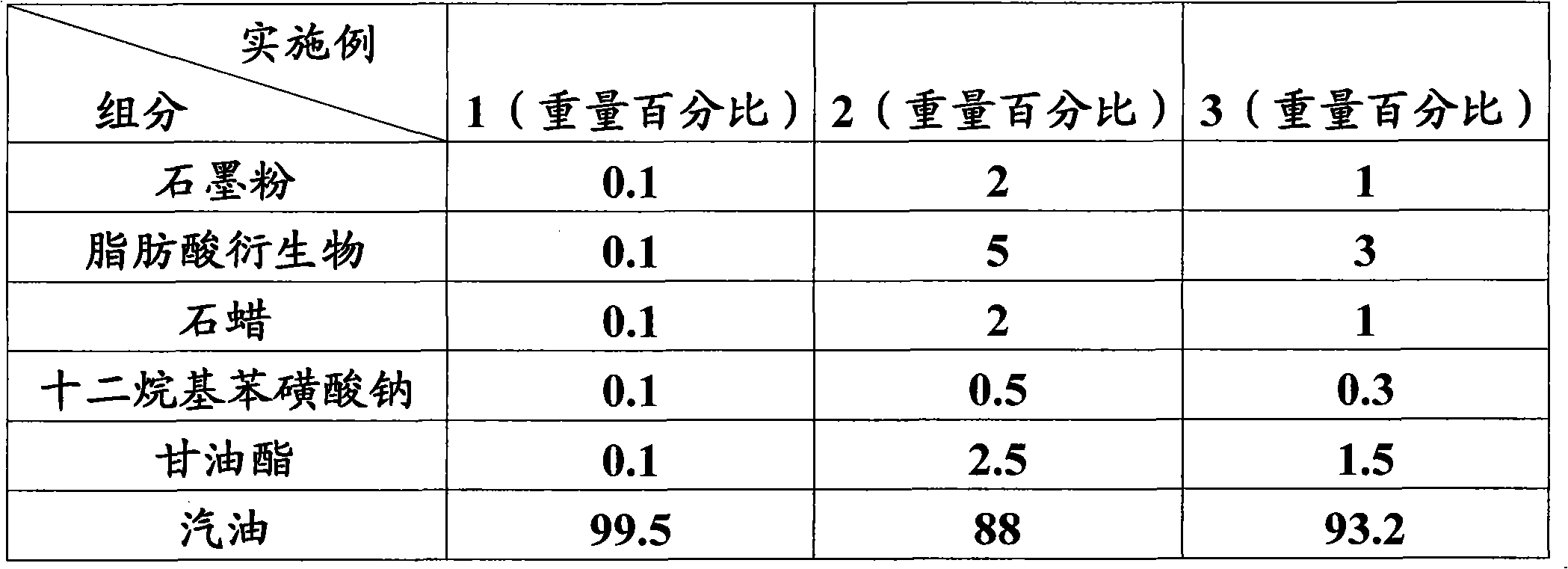

Releasing agent and preparation method thereof

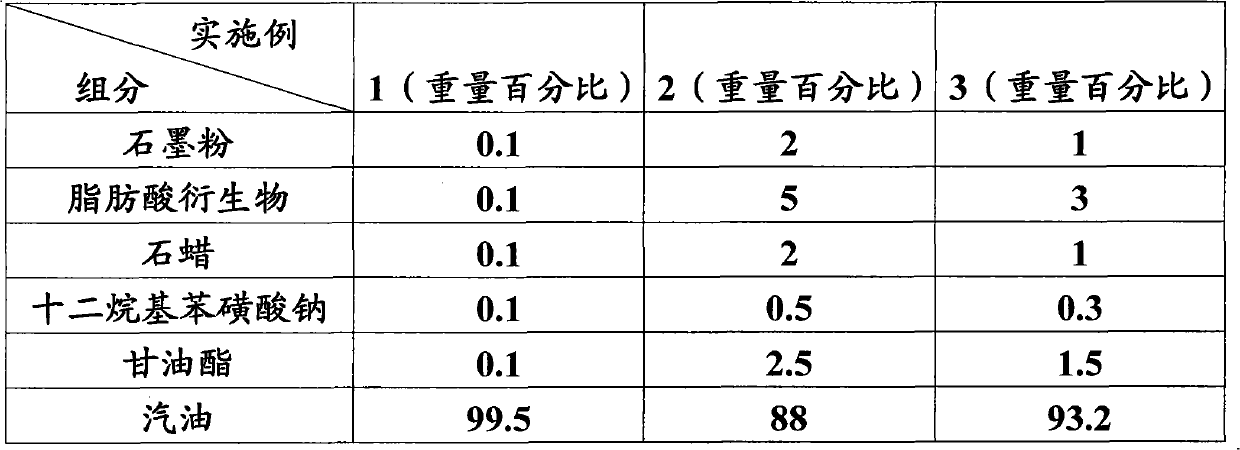

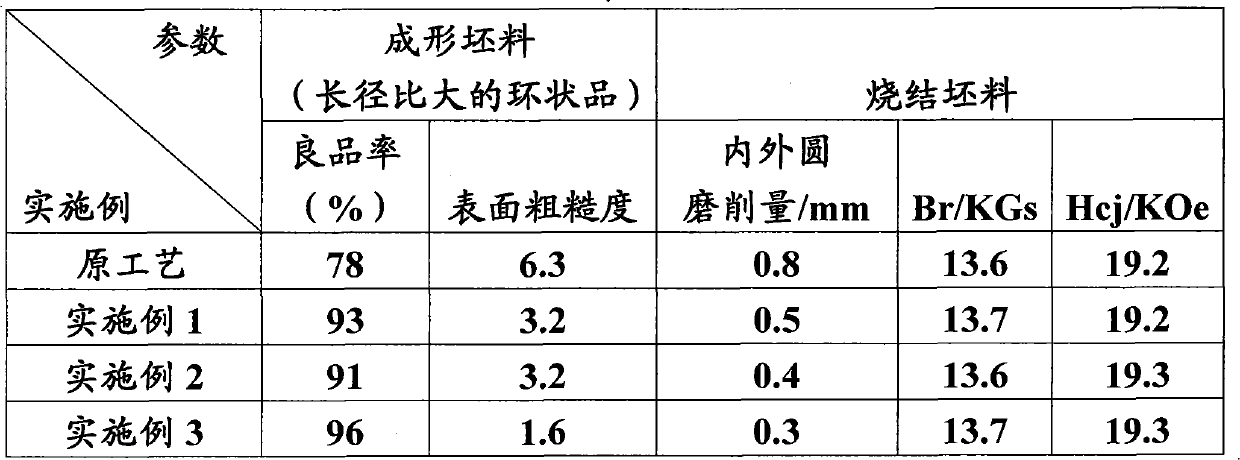

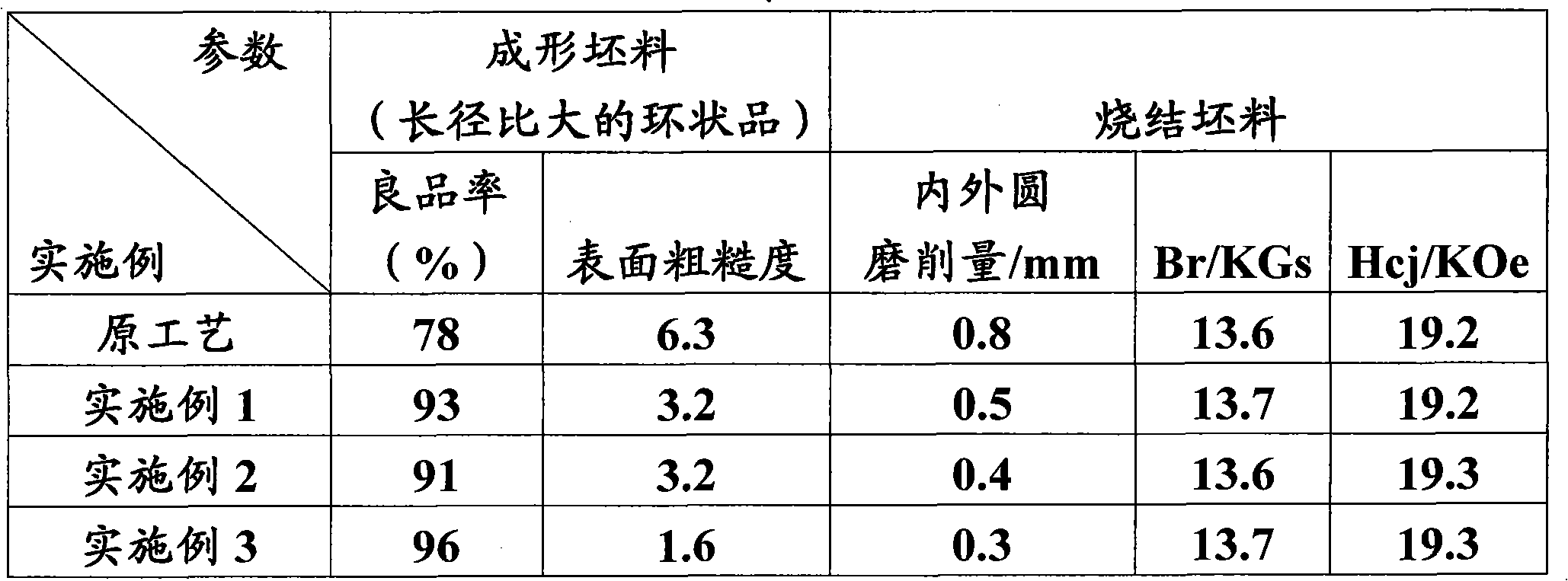

ActiveCN102085563AImprove surface qualityReduce surface roughnessFoundry mouldsFoundry coresChemistryLongest Diameter

The invention provides a releasing agent used in a process of forming a magnetic material, which comprises the following components: 0.1-2 percent by weight of graphite powder, 0.1-5 percent by weight of fatty acid derivative, 0.1-2 percent by weight of paraffin, 0.1-0.5 percent by weight of sodium dodecyl benzene sulfonate, 0.1-2.5 percent by weight of glyceride and 88-99.5 percent by weight of gasoline mixture. The invention also discloses a preparation method of the releasing agent. According to the releasing agent provided by the invention, the problem of adhesion in the process of forming the magnetic material is solved, and the surface quality of a permanent magnet material casting is improved, especially the annular permanent magnet material product with large long diameter ration; and by using the releasing agent, the surface roughness of the permanent magnet material blank product is reduced, and the forming qualified rate of products is improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Method for manufacturing monolithic polysilicon cantilever structure

InactiveCN102086019ASolve stickingAchieve monolithic integrationDecorative surface effectsChemical vapor deposition coatingGyroscopeSignal processing circuits

The invention relates to a method for manufacturing a monolithic polysilicon cantilever structure. In the invention, a processing step of the polysilicon cantilever structure is inserted in a conventional BiCMOS (Bipolar Complementary Metal Oxide Semiconductor) technical process, the deposition and the annealing of polysilicon are finished and an MEMS (Micro-Electro-Mechanical Systems) high-temperature process is prevented from influencing on the metalation process before the metalation process. In the release process of the polysilicon cantilever structure, a special etching solution is adopted, and a negative photoresist is used as a post of the polysilicon cantilever structure so as to effectively avoid the problem of substrate adhesion in the cantilever structure release process by using a wet method. The method provided by the invention solves the technical problems of compatibility between a manufacture process of the polysilicon cantilever structure and a processing process of a BiCMOS circuit, realizes the monolithic integration of the polysilicon cantilever structure and a BiCMOS signal processing circuit, and can be widely applied to the monolithic integration manufacture field of MEMS sensors, such as capacitive accelerometers, gyroscopes, and the like.

Owner:NO 24 RES INST OF CETC

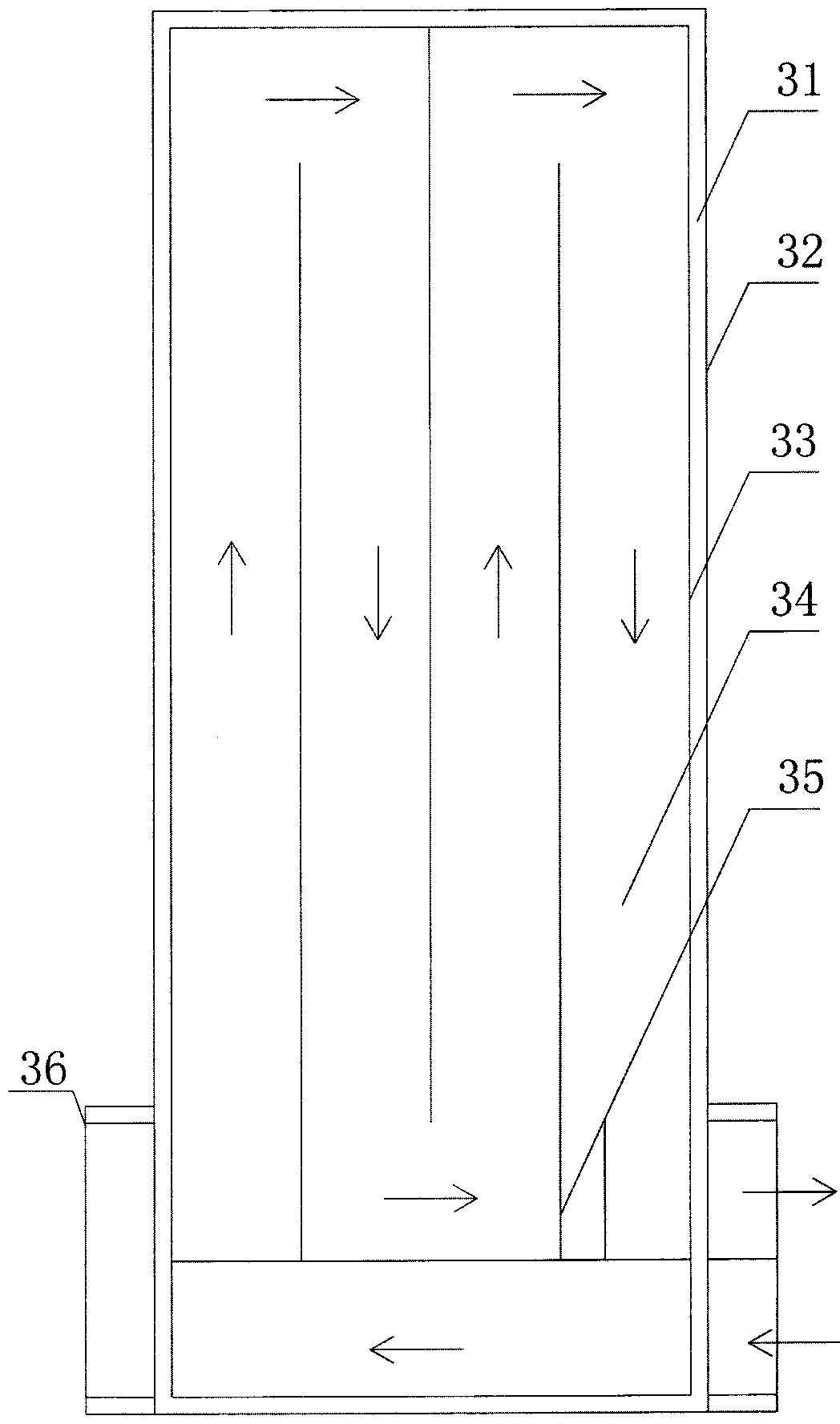

Closed runway pool type photobioreactor

InactiveCN104611221ANo damageUniform light receivingBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlPhotobioreactor

The invention relates to a closed runway pool type photobioreactor applicable to large-scale light culture of a variety of algae. The reactor adopts a water seal method for sealing, and is equipped with a low shearing force circulating device and an automatic temperature control system. The production cost and operation cost are low, and the microalgae yield is high.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI +1

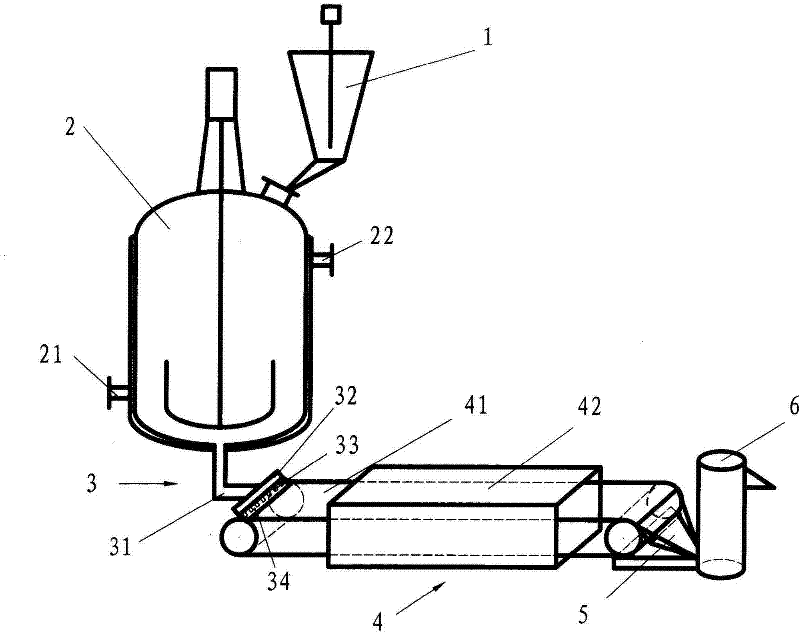

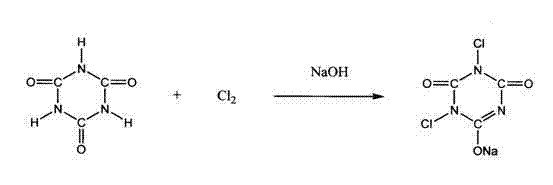

Preparation method of high-yield cyanuric acid and its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid

A preparation method of high-yield cyanuric acid and its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid comprises the following steps of: uniformly mixing urea and a catalyst ammonium sulfate, adding the mixture into a reaction vessel, forming a uniform thin material layer on a conveyor belt when the materials reach a certain temperature, liquid viscosity is increased and the liquid is still at a liquid state, and allowing the thin material layer to pass through a tunnel type heating chamber of a tunnel type heating device for heating at high temperature such that the temperature of the materials is rapidly raised to 250-280 DEG C in a short time. As the reaction time of the materials is short and the reaction speed is fast, there are few side effects and product decomposition is low. The cyanuric acid crude product prepared in the invention has high purity and high yield. During the refining process, inorganic dilute acid is used to process the cyanuric acid crude product. After centrifugation, a cyanuric acid refined product is directly used in the synthesis of its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid without being dried. By the adoption of the method, the adhesive problem of heating surface in production preparation is solved, production speediness and continuity are realized, and industrial production efficiency is raised.

Owner:河北田加力生物科技股份有限公司

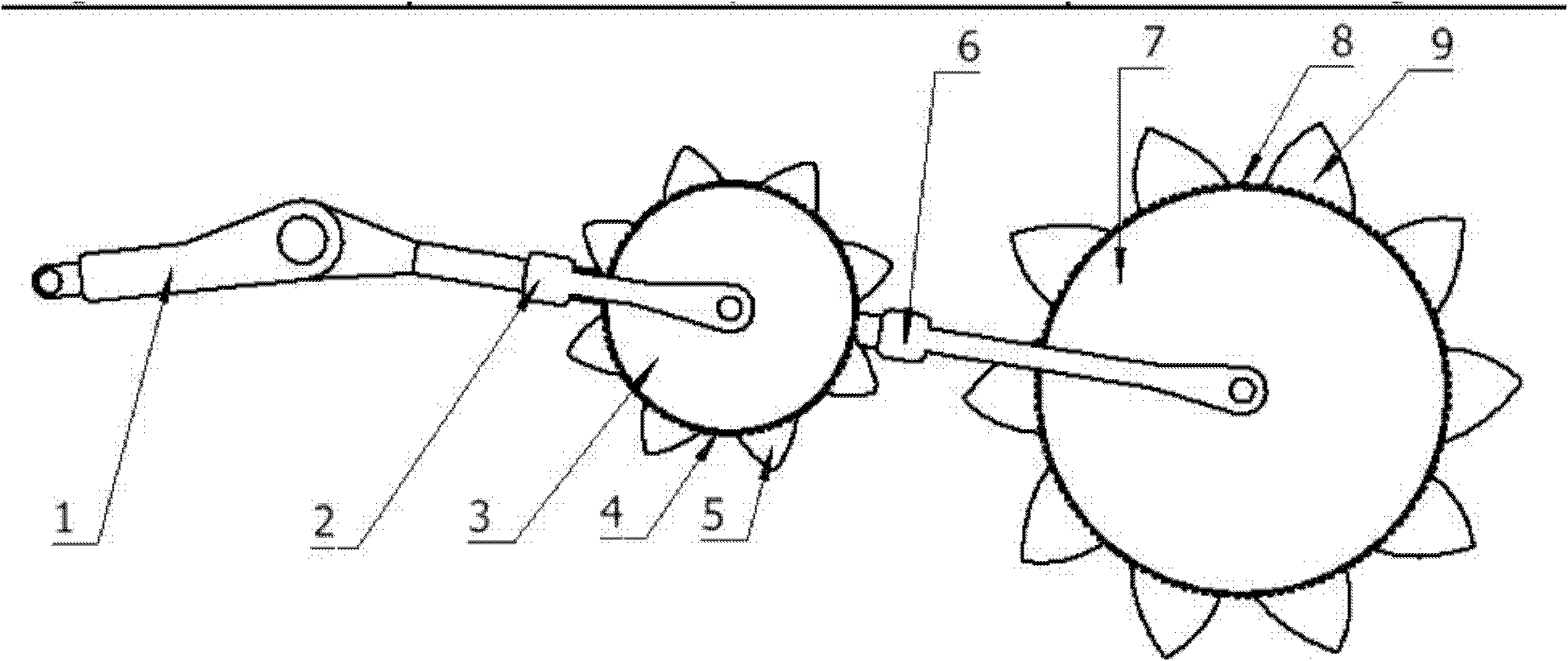

Ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part

The invention belongs to agricultural machinery, in particular relates to a rolling soil-engaging part for compacting soil and changing soil surface microtopography after seeding in a ridge culture mode, and in particular relates to a ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part. The part mainly comprises ridge table rollers, ridge trenchrollers and a total frame, wherein a plurality of ridge table rollers and ridge trench rollers are arranged, are connected in series on the total frame through a ridge table roller frame and a ridge trench roller frame respectively and can rotate around the total frame; a ridge table roller bushing and a ridge trench roller bushing are arranged on the surfaces of the ridge table roller frame and the ridge trench roller frame; and ridge table roller teeth and ridge trench roller teeth having geometric structures are uniformly distributed on the circumferences of the surfaces of the ridge tablerollers and the ridge trench rollers. On the premise of guaranteeing a soil compaction function, the rolling resistance is reduced, the adhesion between the part and soil is reduced, soil microtopography is changed, and soil water storage and soil moisture conservation capacity and agro-ecology are improved; therefore, farmland resists severe weather conditions, and sustainable production increase capacity is improved.

Owner:JILIN UNIV

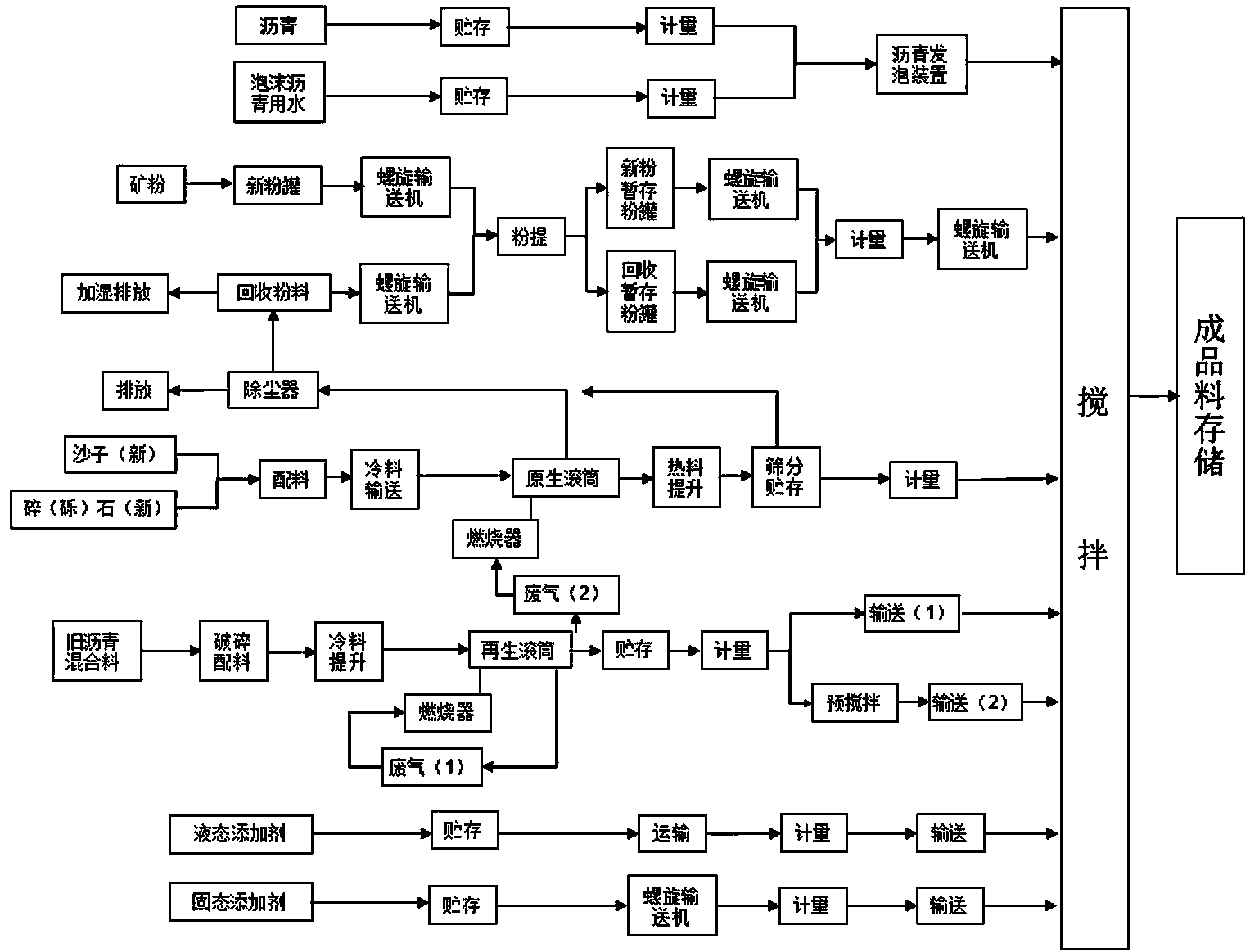

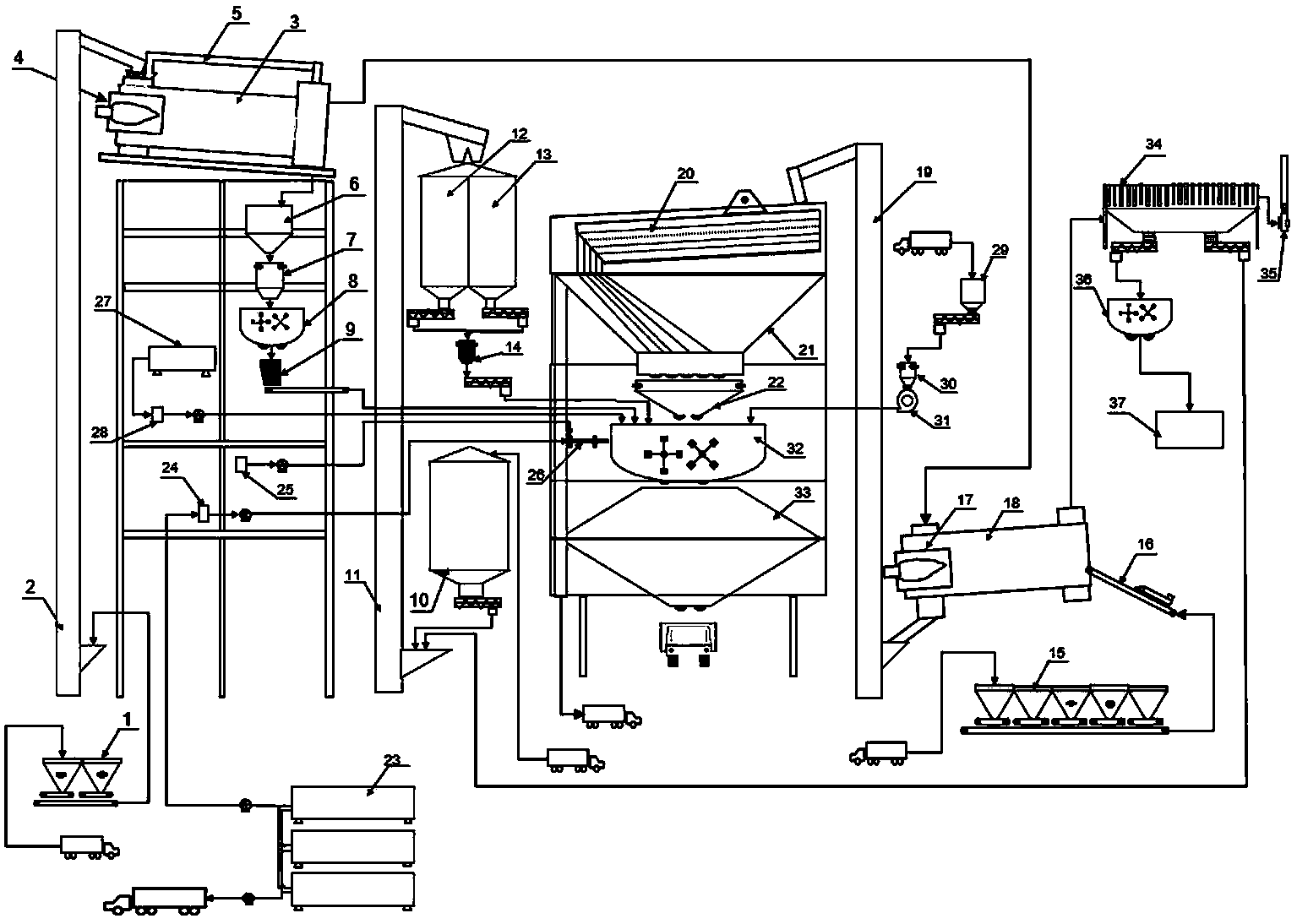

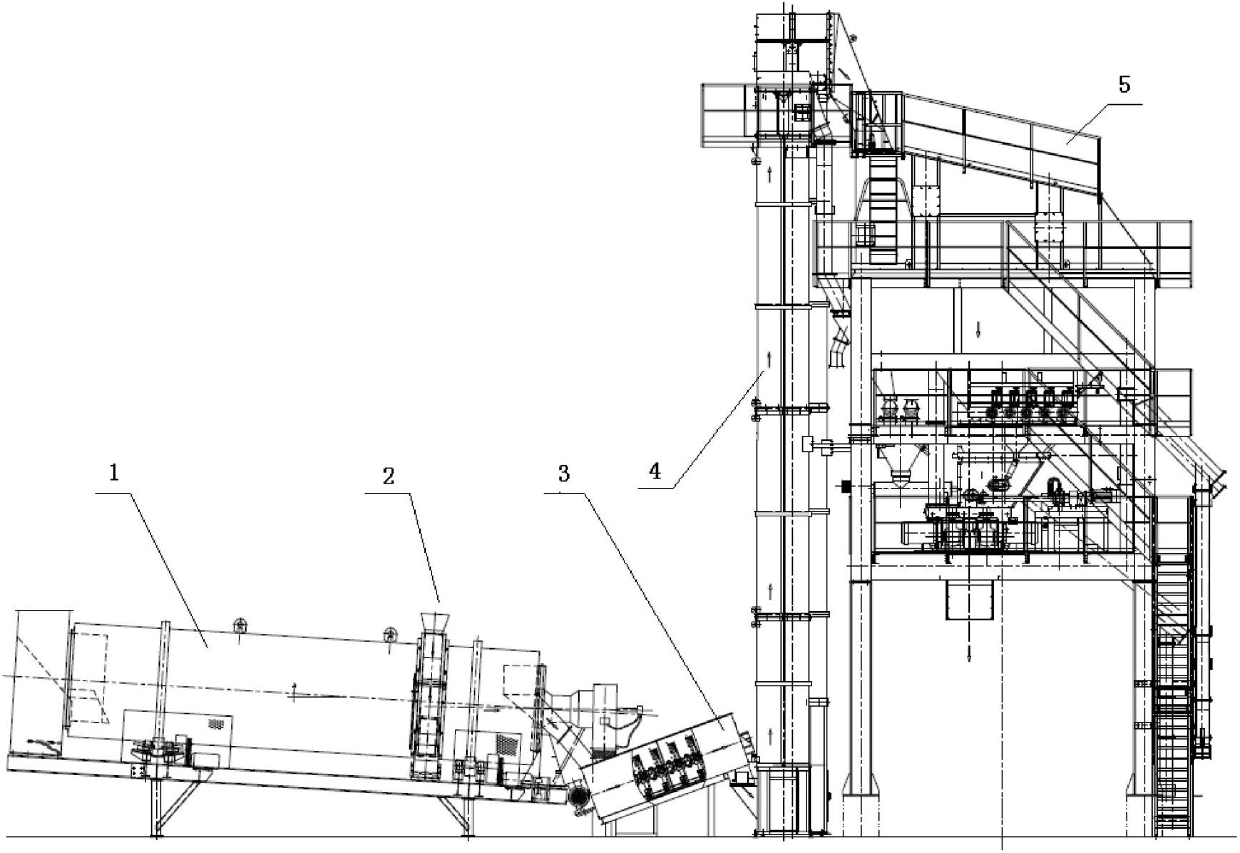

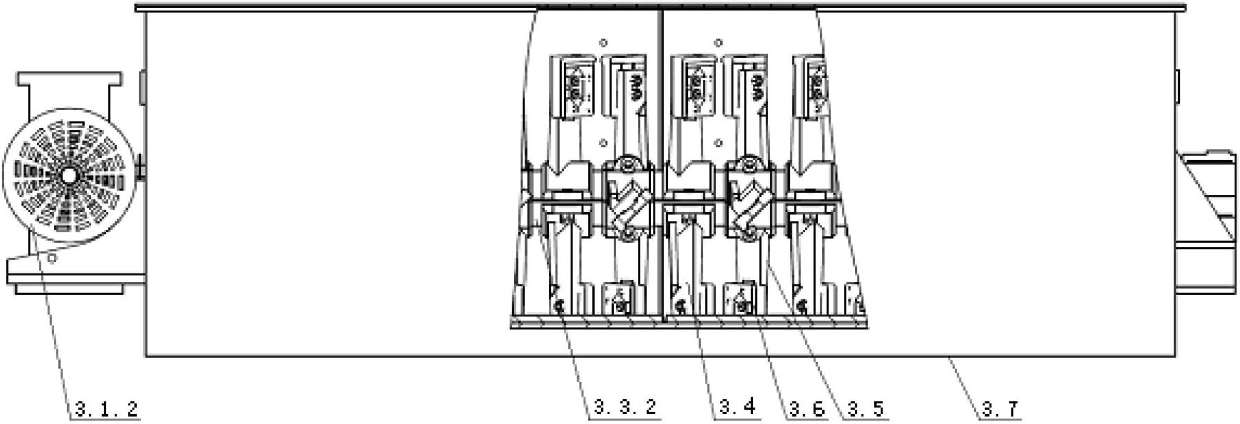

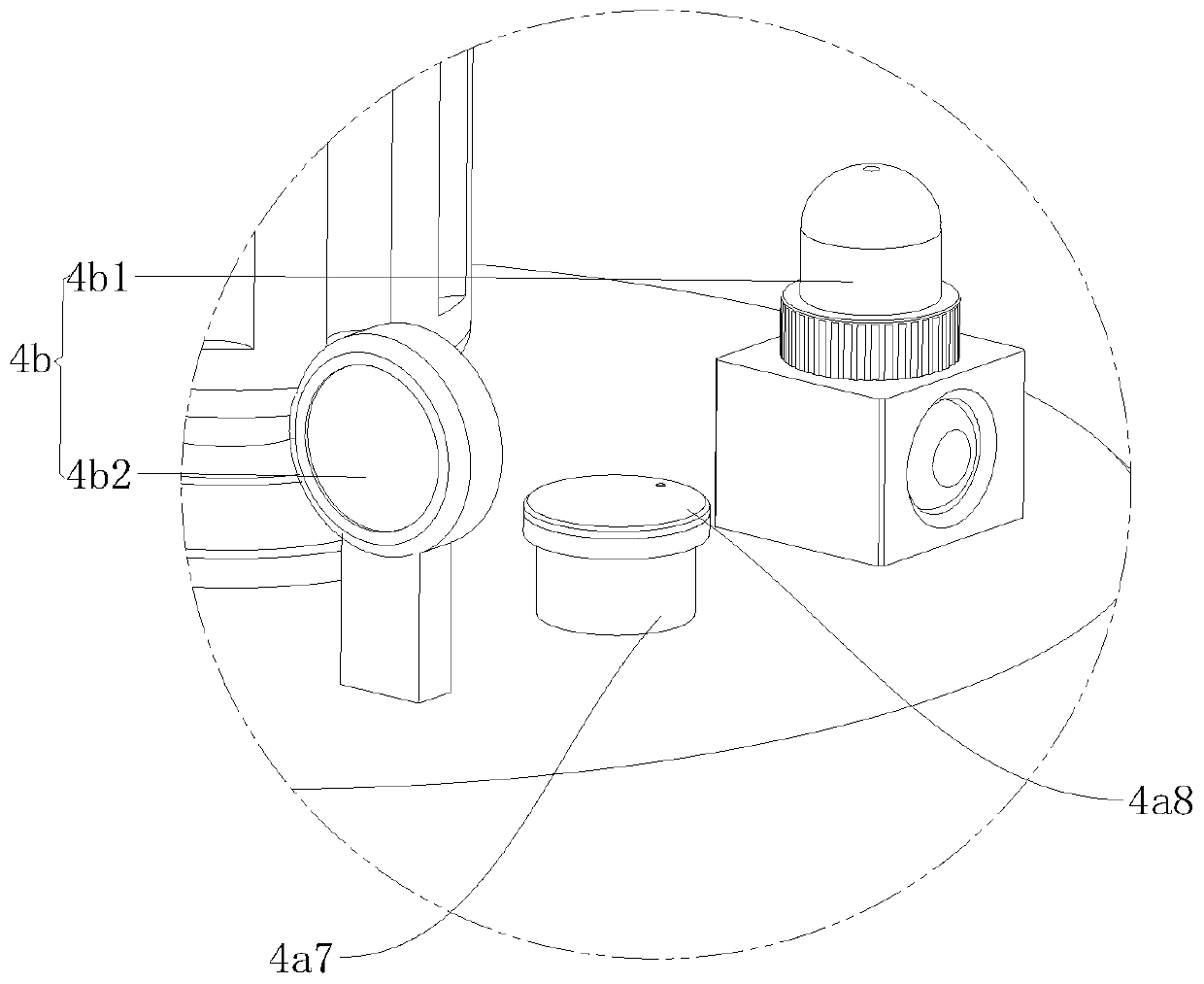

Pitch mixed material warm-mixing and regenerating equipment

ActiveCN104032650AImprove recycling ratesSolve stickingClimate change adaptationRoads maintainenceExhaust gasProcess engineering

The invention discloses pitch mixed material warm-mixing and regenerating equipment. The equipment comprises a pitch mixed material plant-mixing primary system, a pitch mixed material plant-mixing regenerating system, an additive processing system and a tail gas processing system, wherein a pitch sprinkling system in the pitch mixed material plant-mixing primary system is a warm-mixing foam pitch sprinkling system which comprises a foamed pitch foaming device, a foamed pitch water metering device, a pitch metering device and a remote control system. The technical problems of cementation, pitch ageing and the like in traditional pitch mixed material thermal regeneration equipment are effectively solved. The heating temperature required for mixing new aggregate materials and regenerated materials is reduced, and convenience is brought for construction; the pollution of regenerated materials to environment is reduced, so that the working efficiency of the equipment is improved. The equipment has the advantages of simple and practical structure, simplicity in operation and control and stability in work. The equipment is suitable for the production of various pitch mixed materials and regenerated materials, and can be joined and matched with pitch stirring equipment and regenerating equipment for use.

Owner:河南亚龙智能装备有限公司

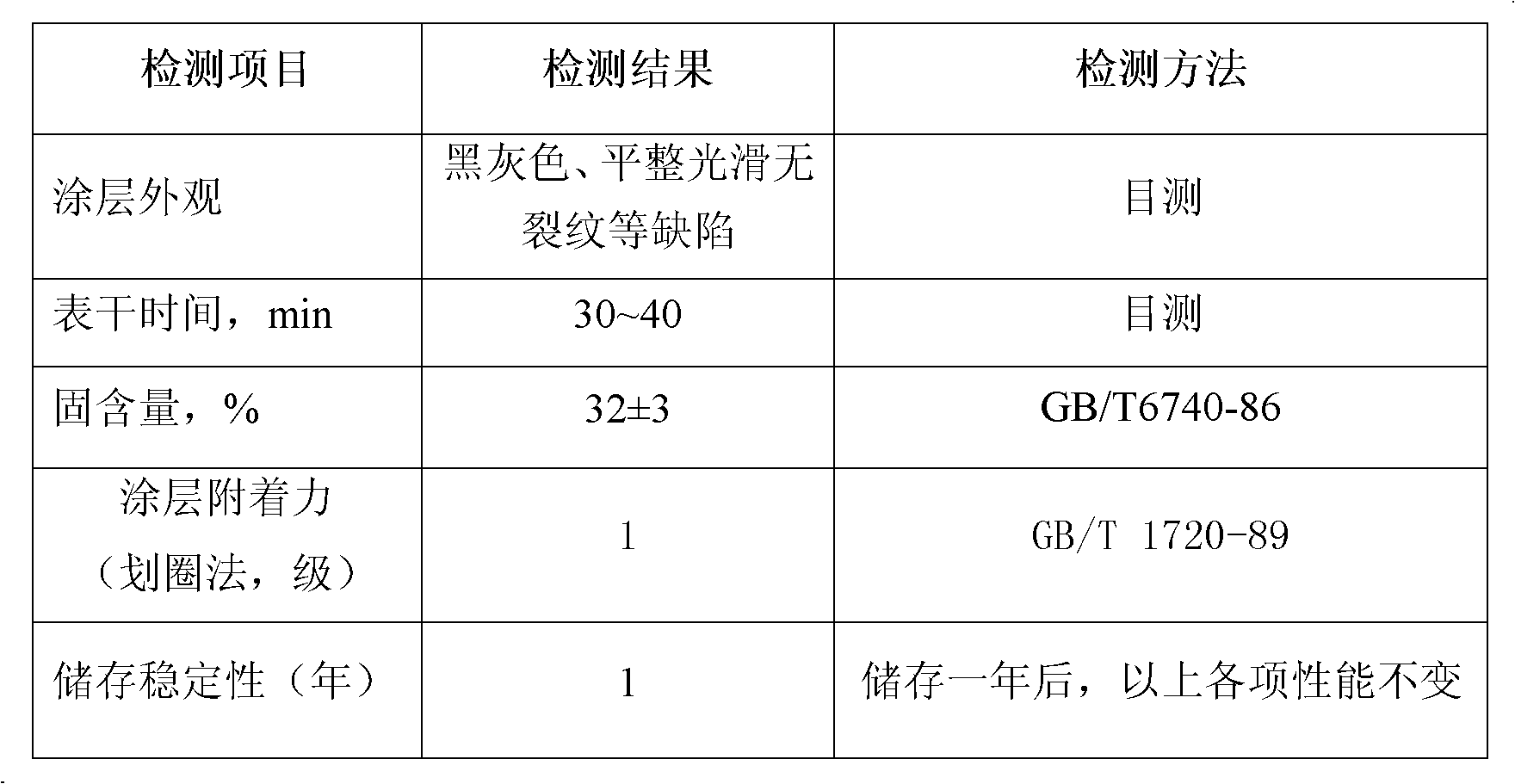

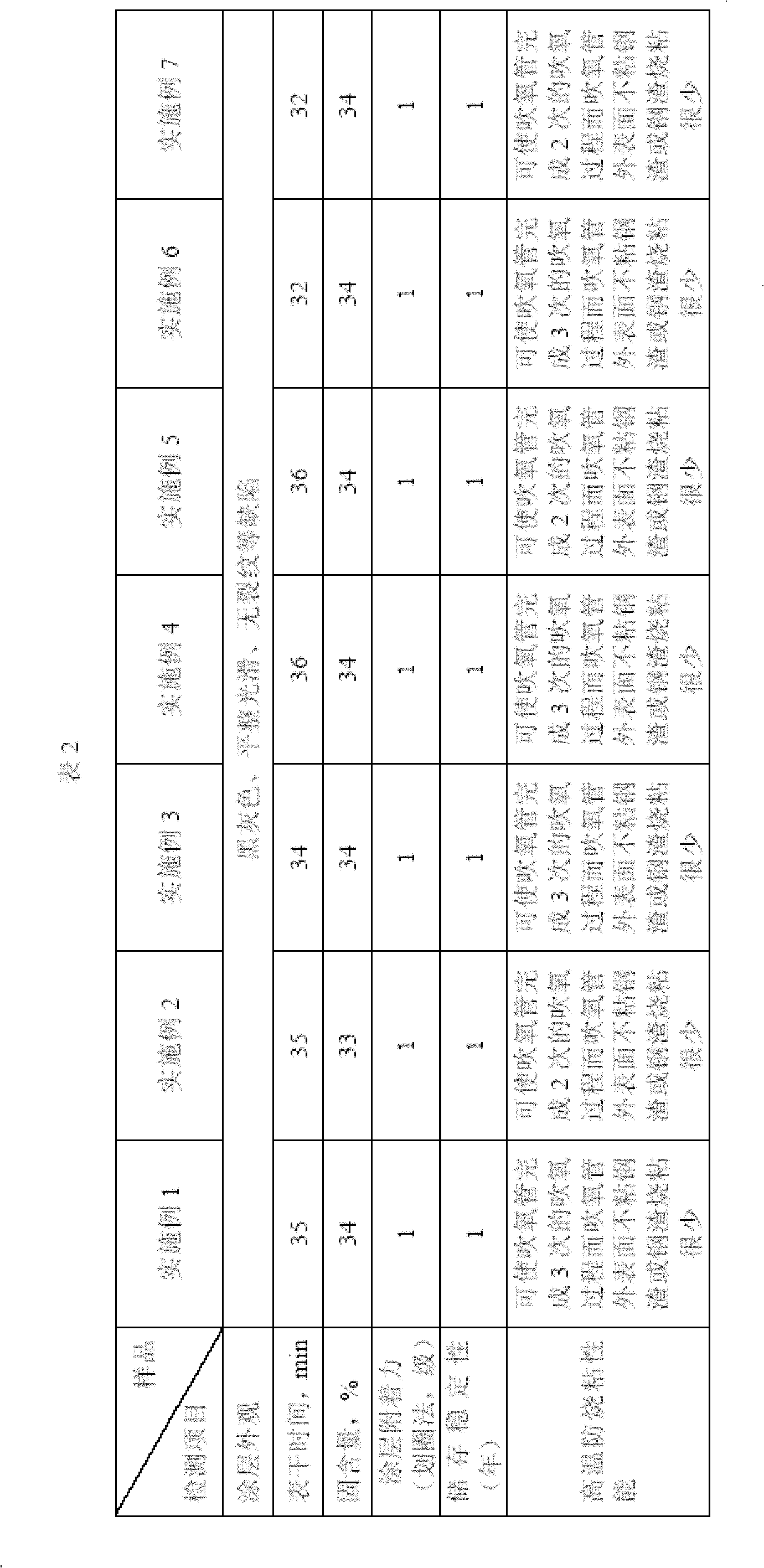

High-temperature burning sticking preventing coating

The invention relates to an ambient self-drying high-temperature burning sticking preventing coating which solves the problem of steel slag burning sticking prevention on the external surface of an oxygen blow pipe of a steel furnace. The high-temperature burning sticking preventing coating comprises the following components: 3.0-8.0% of silicon acrylic emulsion, 15.0-25.0% of graphite, 1.0-5.0% of molybdenum disulfide, 1.0-3.0% of rare earth cerium fluoride, 5.0-10.0% of metallic oxide, 1.0-3.0% of aerosol, 0.1-0.2% of potassium pyrophosphate and the balance of water, wherein the metallic oxide is a mixture of two or three compounds selected from antimony trioxide, copper oxide and aluminum oxide in any proportion. A coating layer prepared by using the high-temperature burning sticking preventing coating has good sticking force and excellent burning sticking preventing function and protection function on a metal base, the coating layer can be rapidly self-dried at room temperature. The oxygen blow pipe can complete 1 to 3 times of oxygen blowing process by painting the high-temperature burning sticking preventing coating on the external surface of the oxygen blow pipe once, and the external surface of the oxygen blow pipe is not stuck to steel slag or a little steel slag is burned and stuck.

Owner:贾文宝 +1

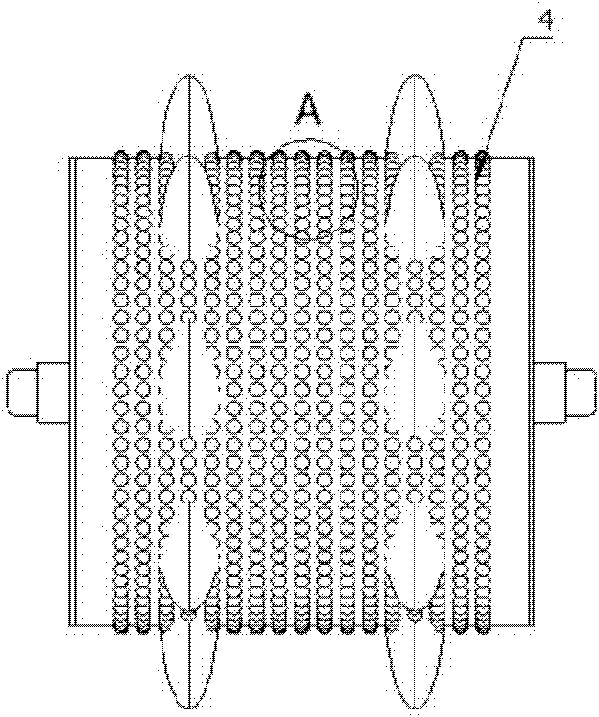

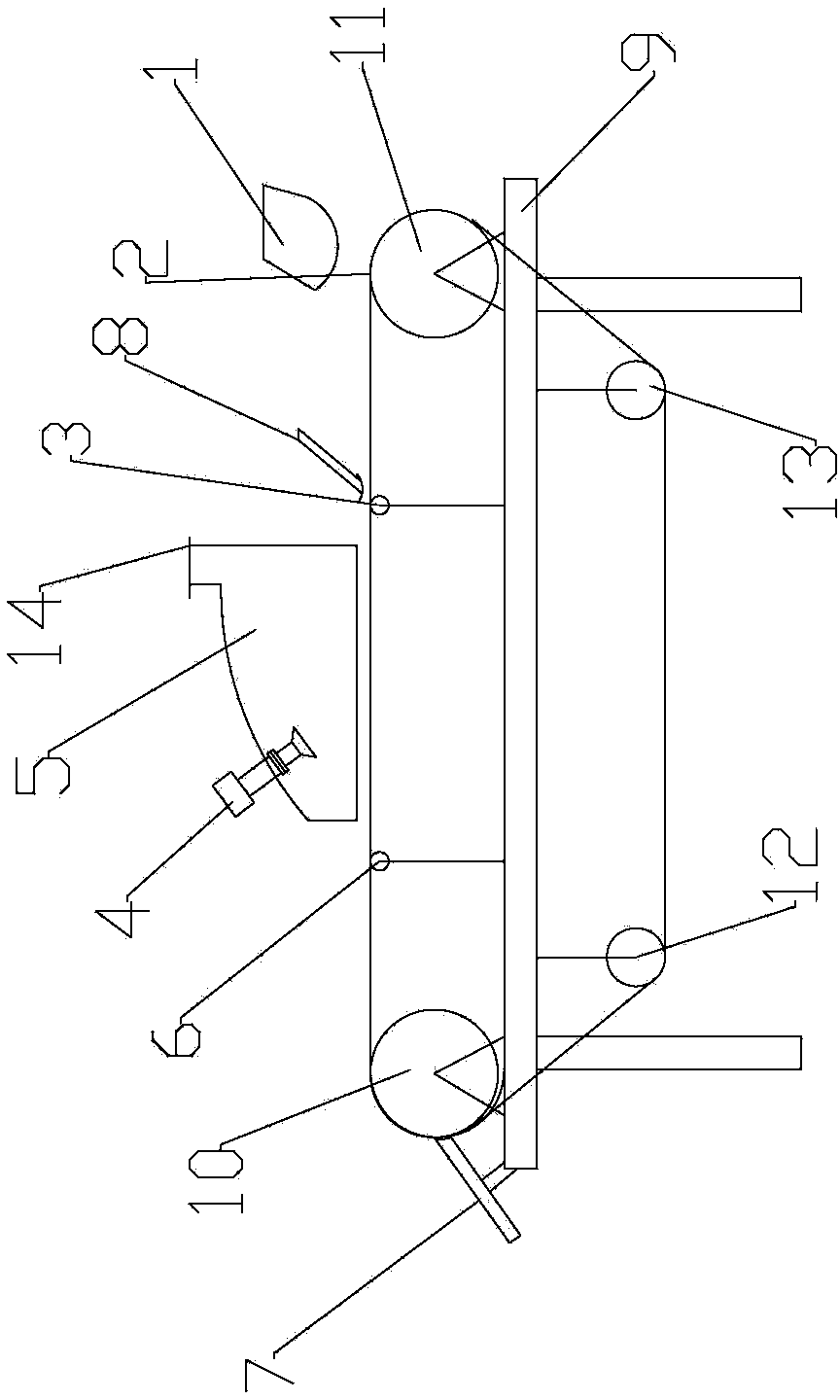

Magnetic separation device for iron ore powder

InactiveCN104028373AContinuous workingSimple structureDirt cleaningMagnetic separationIronstoneEngineering

The invention relates to an ore screening device, in particular to a magnetic separation device for iron ore powder. The magnetic separation device comprises a frame, wherein belt wheels are arranged at the left and right ends of the frame; a conveying belt with magnetism is coated on the two belt wheels; a dust collecting cover with an air blower is arranged above the conveying belt, and is positioned in the middle position between the two belt wheels; an inclined scraper is arranged at the left side of the left belt wheel; the upper end of the scraper is contacted with the outer surface of the conveying belt; and a feeder for conveying iron ore materials onto the conveying belt is arranged above the right belt wheel. The magnetic separation device has the advantages of simple structure, easy maintenance, strong controllability, strong practicability, obvious separation effect, low operation cost and high ore separation rate.

Owner:TAIZHOU BEIYANG METAL MATERIAL

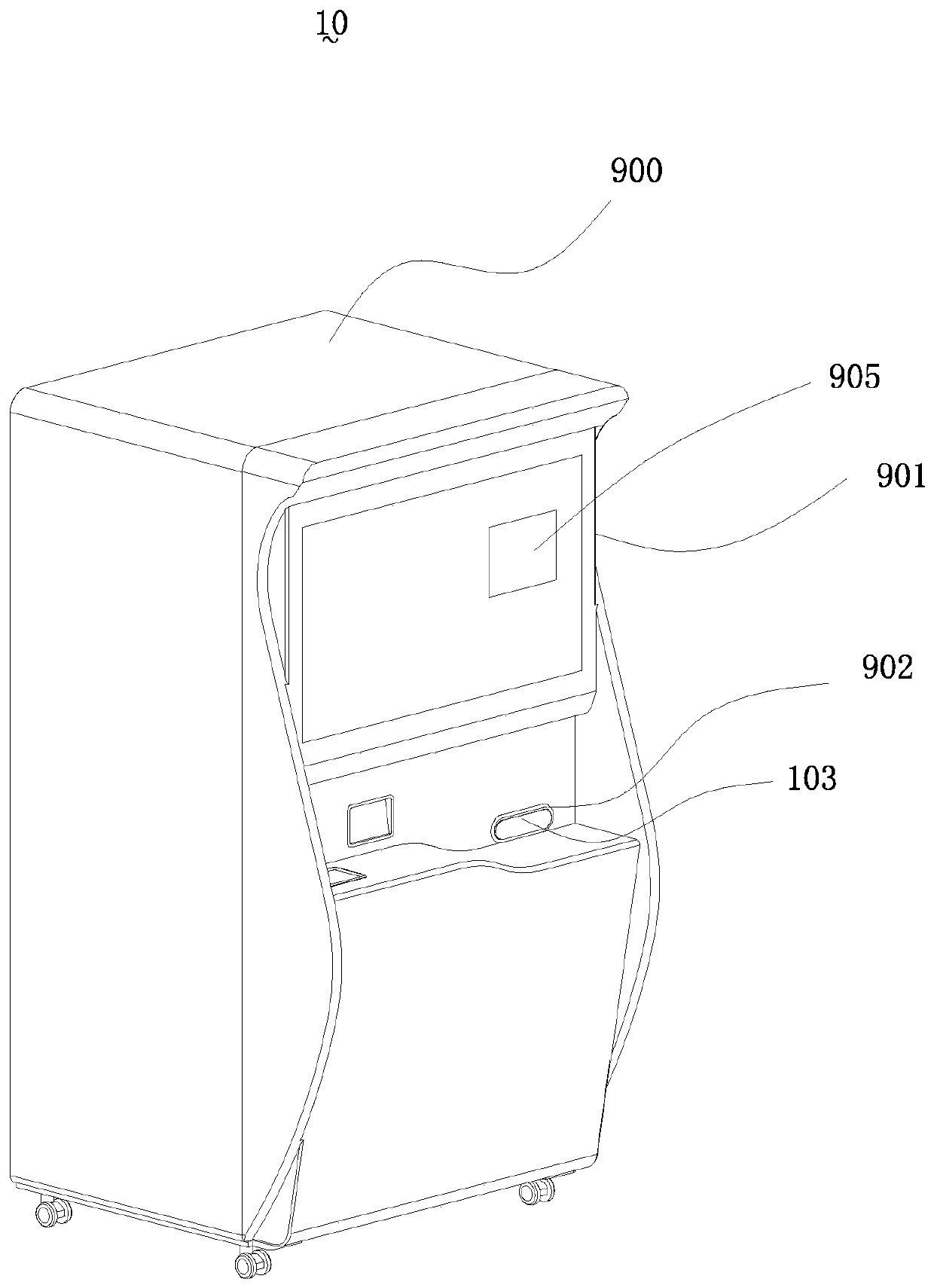

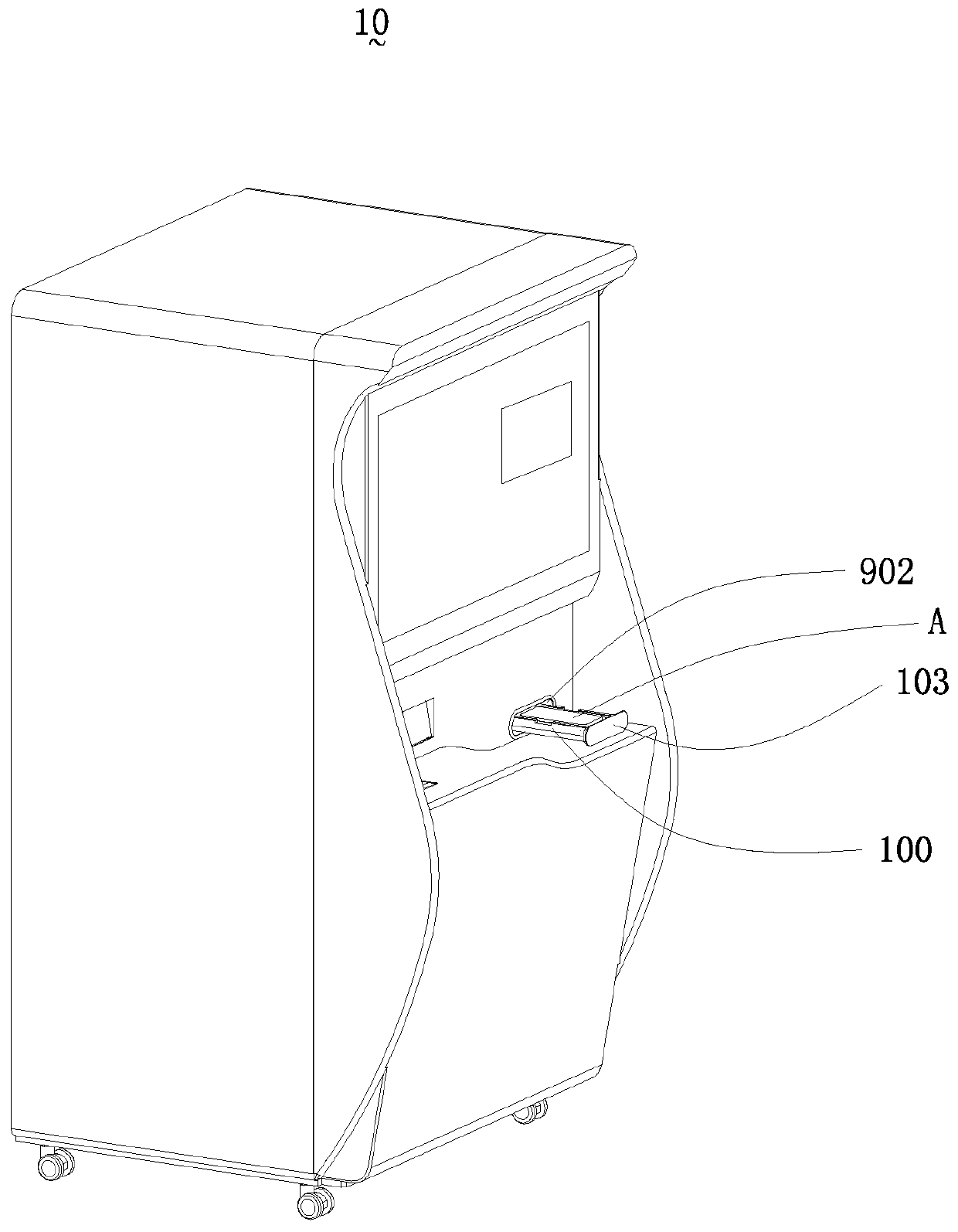

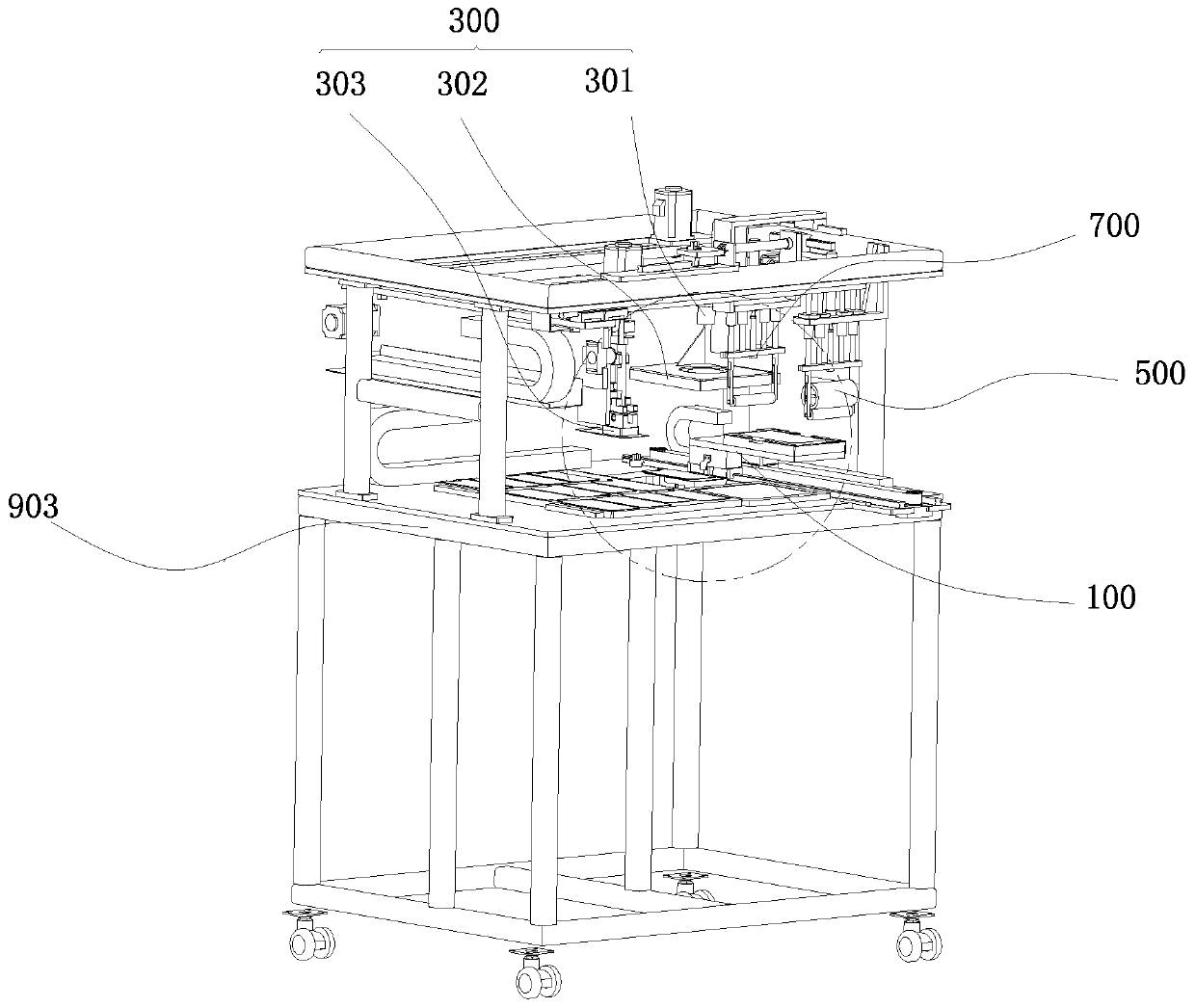

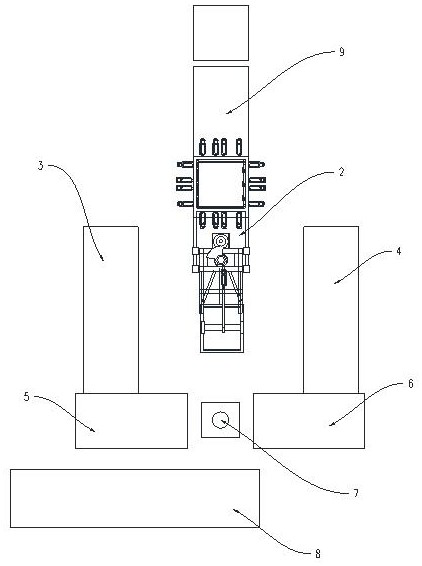

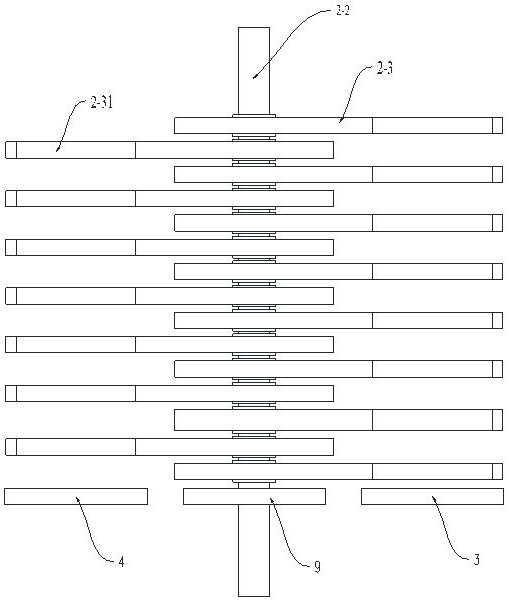

Self-service film sticking machine and film sticking method thereof

ActiveCN110497610AReduce foulingAvoid foamingDomestic articlesCleaning processes and apparatusEngineeringElectronic equipment

The invention discloses a film sticking method of self-service film sticking machine. The film sticking method is used for is used for self-service sticking a protective film on an electronic equipment. The film sticking method is characterized in that the self-service film sticking machine comprises a film sticking mechanism, the film sticking mechanism comprises a film taking component and a film sticking component, and the film sticking method comprises the following steps that 1, the film taking component picks up the protective film and moves the protective film to the upper part of the electronic equipment; 2, the film taking component inclines the protective film to the electronic equipment at an angle of C relative to the electronic equipment and one end of the protective film contacts the electronic equipment; and 3, after pressing this end of the protective film for a preset time, the protective film moves down to cover the electronic equipment. The invention also provides aself-service film sticking machine.

Owner:SHENZHEN BNT INTELLIGENT TECH CO LTD

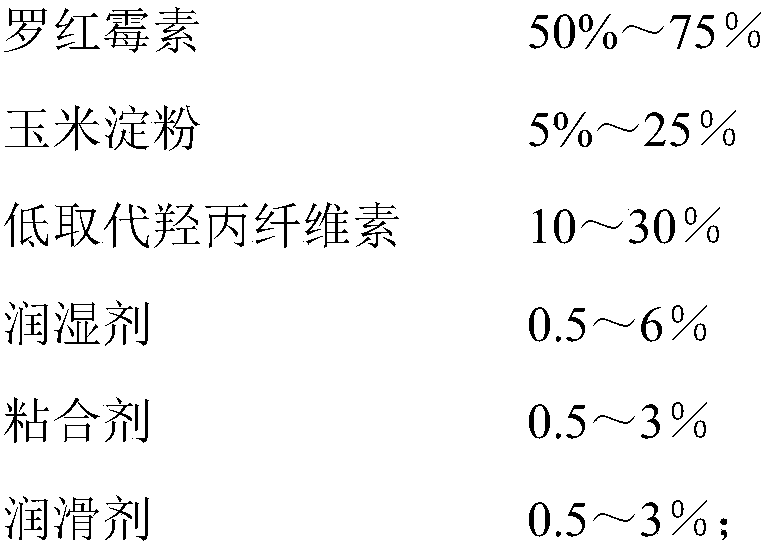

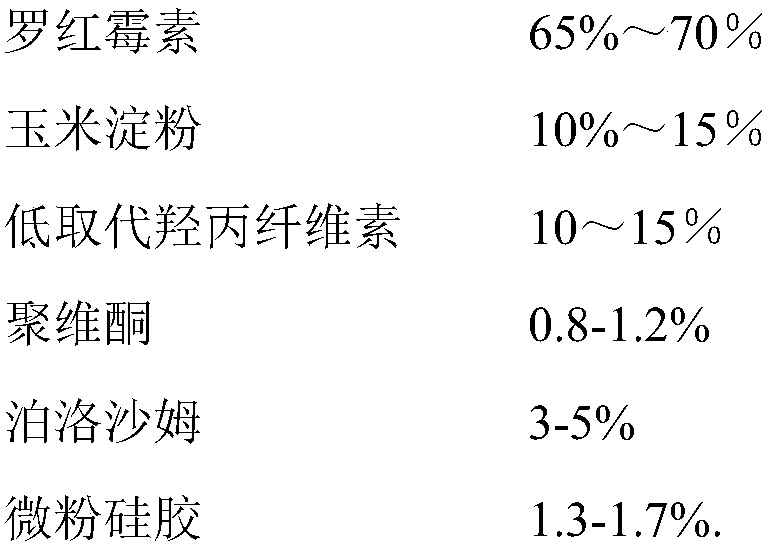

Roxithromycin capsule and preparation process thereof

ActiveCN109248155ASimple manufacturing processExcellent qualityAntibacterial agentsOrganic active ingredientsRoxithromycinMedicine

The invention relates to a roxithromycin capsule and a preparation method of the roxithromycin capsule. The roxithromycin capsule is prepared from the following constituents in percentage by weight:50-75 % of roxithromycin, 5-25 % of corn starch, 10-30 % of low-substituted hydroxypropyl cellulose, 0.5-6 % of a wetting agent, 0.5-3 % of a binder, and 0.5-3 % of a lubricant, wherein the binder ispolyvinylpyrrolidone; the wetting agent is selected from sodium dodecyl sulfate, Tween 80 and poloxamer; and the lubricant is selected from one or more of micropowder silica gel, magnesium stearate and talcum powder.

Owner:北京鑫开元医药科技有限公司

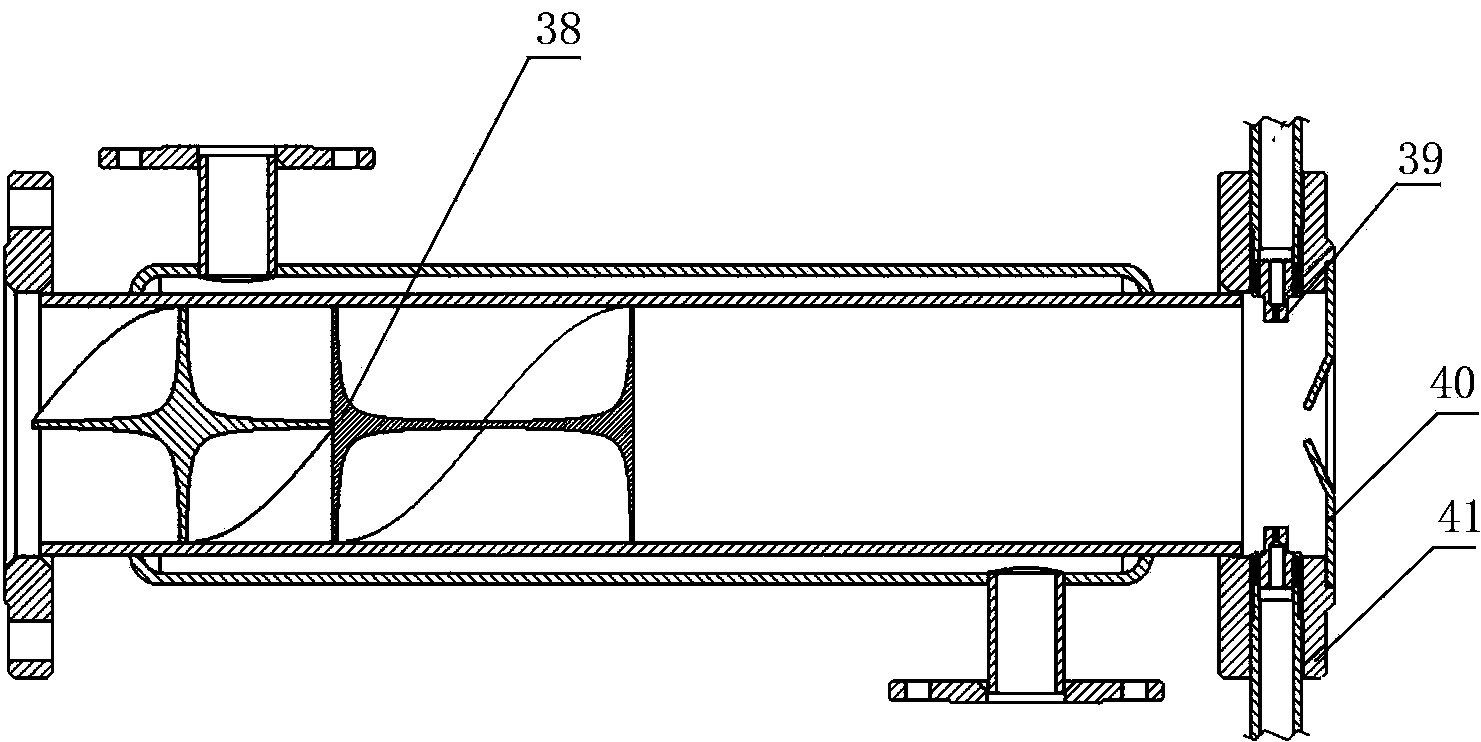

Method for stirring renewable asphalt mixture

ActiveCN102677572ACompletely broken and separatedLarge distribution areaRoads maintainencePulp and paper industryRubbing

The invention relates to a method for stirring a renewable asphalt mixture. The method comprises the following steps that a renewable recycled material is subjected to primary smashing in a cold state; the renewable recycled material enters a drying cylinder through a recycling ring for heating and softening with new aggregate; a renewable recycled asphalt mixture obtained by mixing the renewable recycled material with the new aggregate enters a continuous double-shaft stirring pan for stirring and rubbing; the renewable recycled material is subjected to secondary smashing; and the renewable recycled asphalt mixture flows out from the discharging hole of the continuous double-shaft stirring pan, enters the charging hole of an aggregate hoisting machine, and is fed into a vibration screen by the aggregate hoisting machine for screening. By the method, various types of aggregate are separated thoroughly after the renewable recycled material is treated; the heated mixture cannot be adhered to the screen mesh of the vibration screen when passing through the vibration screen; the graduation precision of the mixture is improved to a great extent; the method is low in cost and convenient to operate; and the addition ratio of the renewable recycled material is improved.

Owner:廊坊德基机械科技有限公司

Manufacturing method for ohmic contact with low specific contact resistance and low roughness

ActiveCN102231363AImprove overlay accuracyReduce process stepsVacuum evaporation coatingSemiconductor/solid-state device manufacturingOhmic contactBinary alloy

The invention discloses a manufacturing method for ohmic contact with low specific contact resistance and low roughness. The manufacturing method is characterized in that hardly compatible Mo metal is introduced to an ohmic contact metal seed to form a TiAlNiMoAu combination, thus the surface roughness and the specific contact resistance after alloying are reduced under the same alloying condition. In the manufacturing method, the low diffusivity of the Mo is utilized, and a binary alloy phase is matched, thus low contact resistance is realized, the roughness of the ohmic contact after alloying is also reduced, the overlay accuracy of a photolithographic process is improved, the number of process steps is reduced, the stability of the ohmic contact is improved, and a firm foundation is established for device process practicability.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

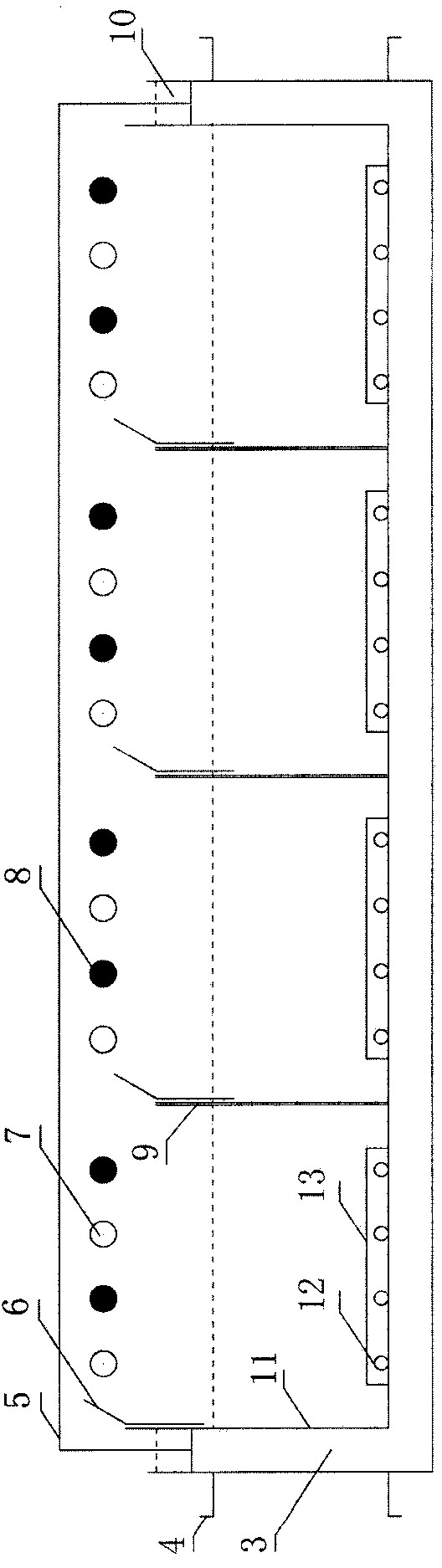

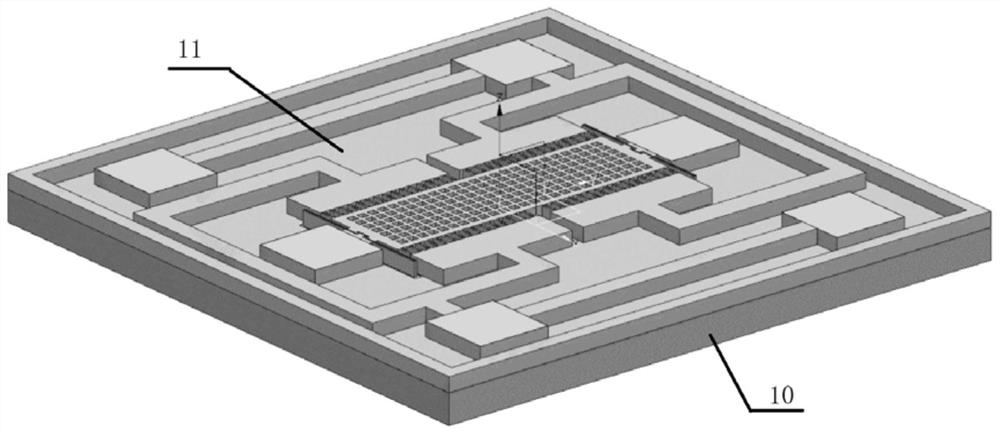

Comb tooth micro-accelerometer capable of resisting high-g-value impact, and preparation method thereof

ActiveCN111766403AImprove impact resistanceSolve stickingTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesAccelerometerClassical mechanics

The invention discloses a comb tooth micro-accelerometer capable of resisting high-g-value impact, and a preparation method thereof. A first fixed anchor block is located on the left side of a movablemass block, a second fixed anchor block is located on the right side of the movable mass block, a first stop block and a first supporting beam are arranged between the first fixed anchor block and the movable mass block, and a second stop block and a second supporting beam are arranged between the second fixed anchor block and the movable mass block. The first supporting beam and the second supporting beam are each of a U-shaped folding structure. One end of the first supporting beam is fixed on the first fixed anchor block; the other end of the first supporting beam is fixed on the left sidesurface of the movable mass block; one end of the second supporting beam is fixed to the second fixed anchor block, the other end of the second supporting beam is fixed to the right side face of themovable mass block, the first stop block is fixed to the first fixed anchor block, and the second stop block is fixed to the second fixed anchor block. The accelerometer has high stability and high gvalue impact resistance.

Owner:XI AN JIAOTONG UNIV

Polylactic acid hot molding method

The invention discloses a polylactic acid hot molding method. A mold is adopted and an anti-sticking coating layer is sprayed on the internal surface of the mold. The polylactic acid hot molding method comprises the following steps of: 1) heating a first preheating box and a preheating roll, wherein the temperature of the first preheating box is controlled to be 70-130 DEG C; and heating the mold, wherein the temperature of the internal surface of the mold is kept to be 80-110 DEG C; 2) fermenting raw materials into lactic acid, polymerizing the lactic acid into polylactic acid and feeding the polylactic acid into a tunnel caterpillar blister positive-pressure and negative-pressure hot molding machine to form sheets; and 3) conveying the sheets to a second preheating box for crystallization, when the polylactic acid sheets reach a critical point of hot molding crystallization and the crystallization degree reaches 10-20 percent, feeding the polylactic acid sheets into the mold to realize hot molding, and molding the polylactic acid through positive-pressure and negative-pressure blister molding to obtain polylactic acid products with the crystallization degree being 20-30 percent and heat-resistant temperature being higher than 90 DEG C. The polylactic acid hot molding method provided by the invention has the advantages that the polylactic acid materials can be used more widely, the carbon emission is reduced and the environment is protected.

Owner:浙江启泰生物材料有限公司

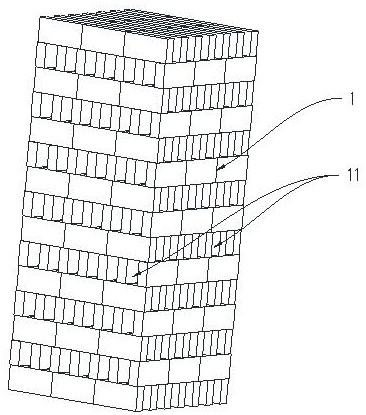

Brick discharging and packaging production line and brick discharging and packaging method

PendingCN113443199AEliminate gapsSmooth transferPackagingStacking articlesBrickStructural engineering

The invention relates to the technical field of brick production, and discloses a brick discharging and packaging production line and a brick discharging and packaging method. The brick discharging and packaging production line comprises a brick stack conveying frame, a stack dividing mechanism, a first brick receiving conveying frame, a second brick receiving conveying frame, a first brick conveying frame, a second brick conveying frame and a brick stacking mechanical arm. According to the brick discharging and packaging method, the brick stack conveying frame conveys brick stacks to the stack dividing mechanism, the stack dividing mechanism carries out stack arranging, stack supporting and stack dividing, bricks on the two sides of stack dividing chucks are received through the first brick receiving conveying frame and the second brick receiving conveying frame, the bricks are conveyed to the first brick conveying frame and the second brick conveying frame respectively, and then the bricks are conveyed to the brick stacking mechanical arm to be stacked again and packaged. According to the brick discharging and packaging production line and the brick discharging and packaging method, the speed is high, and the effect is good; and the problem that bricks adhere to one another which puzzles industry development all the time is effectively solved through brick arranging, brick clamping and jacking separation gaps, the bricks are stably transferred through a brick shifting mechanism, and the using effect is good.

Owner:南阳力王机械有限公司

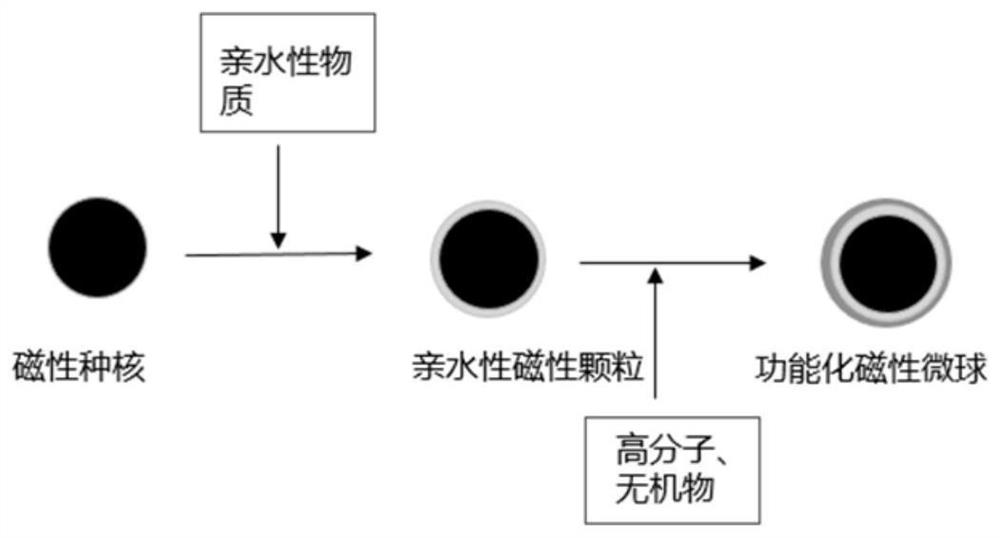

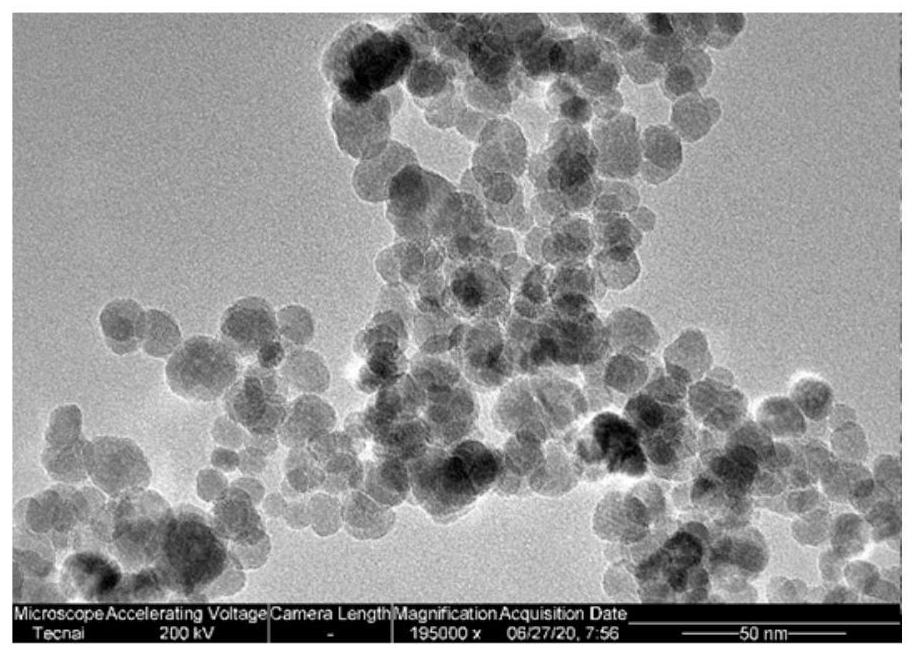

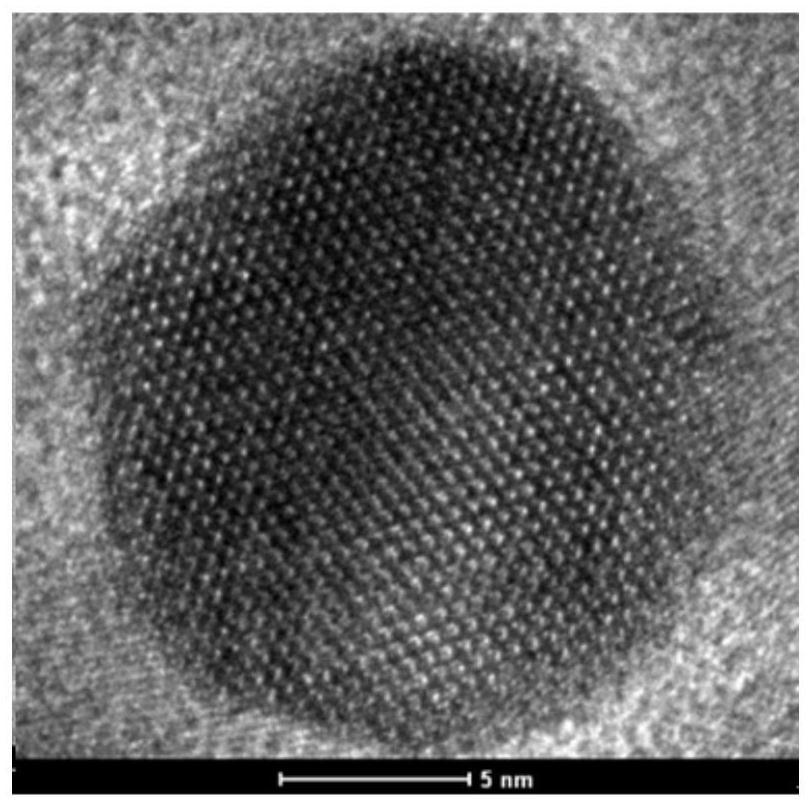

Preparation method of functionalized magnetic microspheres, magnetic microspheres and application thereof

ActiveCN112246196AImprove hydrophilicityGood dispersionMicroballoon preparationMicrocapsule preparationMicrosphereSilicon

The invention belongs to the technical field of functionalized magnetic materials, and particularly discloses a preparation method of functionalized magnetic microspheres, the prepared magnetic microspheres and an application thereof. The preparation method of the functionalized magnetic microspheres comprises the following steps: preparing magnetic seed balls; performing surface hydrophilic modification on the magnetic seed balls to obtain hydrophilic magnetic particles; and carrying out surface functional modification on the hydrophilic magnetic particles to prepare functional magnetic microspheres; wherein the surface functional modification comprises silicon hydroxyl modification and sulfonation modification. According to the functionalized magnetic microsphere prepared by the invention, due to the combined action of silicon hydroxyl and sulfonic acid group, the stability of the microsphere is remarkably improved, the suspension property is good, the hydrophilicity is good, and theproblem of wall adhesion of the magnetic microsphere is effectively solved.

Owner:SICHUAN ANKERUI NEW MATERIAL TECH CO LTD

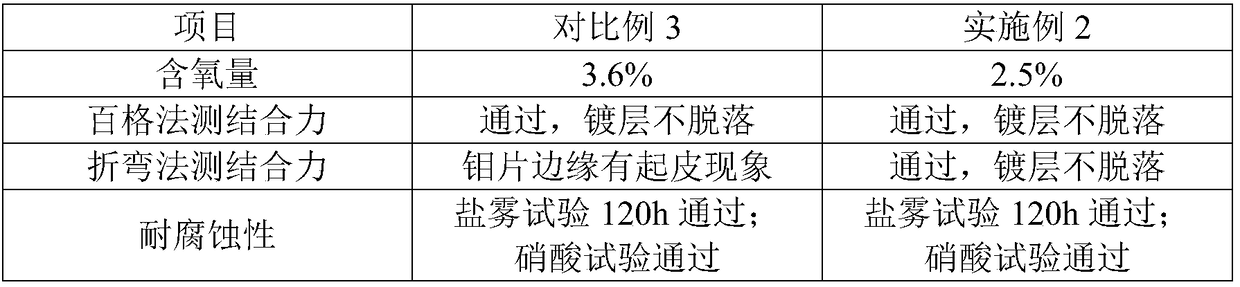

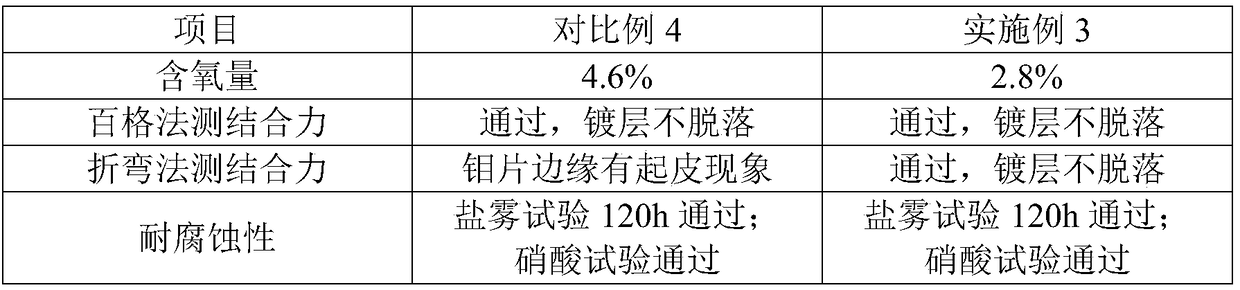

Pretreatment process of vacuum ruthenium plating technology

InactiveCN108690948AThe connection effect is uniform and strongFirmly connectedVacuum evaporation coatingSputtering coatingElectrolysisPhysical chemistry

The invention belongs to a ruthenium plating technical process and particularly relates to a pretreatment process of a vacuum ruthenium plating technology. The pretreatment process comprises the following steps that 1, a molybdenum sheet is placed into an electrolytic tank to be subjected to an electrolytic degreasing reaction and then is washed out through pure water; 2, the washed molybdenum sheet is added into mixed acid liquor to be subjected to surface film removing treatment and then washed out through pure water; 3, the molybdenum sheet subjected to film removing treatment is placed into vacuum equipment to be subjected to a vacuumizing heating reaction; and 4, the temperature is constant, the molybdenum sheet is subjected to plasma cleaning, and after cleaning is finished, the pretreated molybdenum sheet is obtained in a cooled mode. The problems that in the prior art, pollution is large, and the adhesion effect is poor are solved, through an alkali electrolysis plus mixed acidcleaning plus plasma cleaning combined technology, the cleanliness degree of the surface of the molybdenum sheet is effectively increased, and binding force between the molybdenum sheet and a ruthenium layer is increased.

Owner:江苏时代华宜电子科技有限公司

Hydrophobic plastic film and preparation method thereof

The invention provides a hydrophobic plastic film and a preparation method thereof. The preparation method comprises the following steps of polishing a metal sheet, and cleaning the polished metal sheet; performing sand blasting treatment on the cleaned metal sheet; laminating a plastic plate above the sand-blast metal sheet, and performing stamping treatment; and demolding the stamped plastic plate to obtain the hydrophobic plastic film. The plastic film prepared according to the preparation method has the advantages that the hydrophobicity of the plastic film can be effectively improved, andthe adhesion problem of viscous fluid to the surface of the plastic film is effectively solved.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

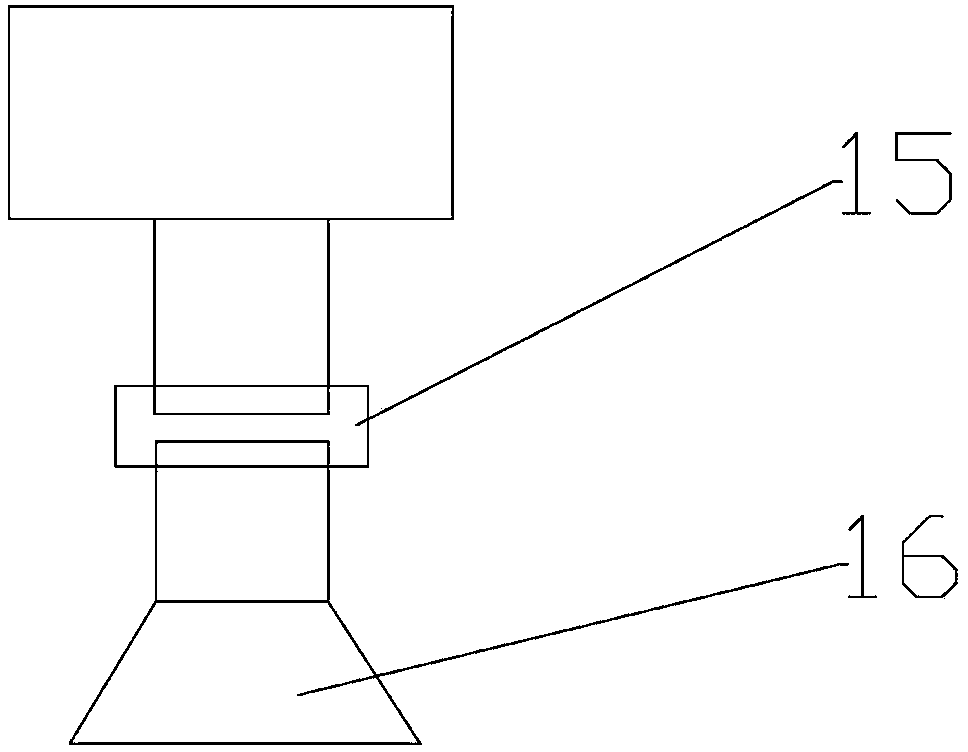

Magnetic separation device for iron ore powder

ActiveCN104028374ASimple structureEasy to maintainDirt cleaningMagnetic separationEngineeringControllability

The invention relates to an ore screening device, in particular to a magnetic separation device for iron ore powder. The magnetic separation device comprises a frame, wherein two belt wheels are arranged at the left and right ends of the frame, and are coated with a conveying belt; a magnetic plate trailer with magnetism is arranged below the conveying belt at the upper sides of the belt wheels; a dust collecting cover with an air blower is arranged above the conveying belt, and is positioned rightly above the magnetic plate trailer; and a feeder for conveying iron ore materials onto the conveying belt is arranged above the right belt wheel. The magnetic separation device has the advantages of simple structure, easy maintenance, strong controllability, strong practicability, obvious separation effect, low operation cost and high ore separation rate.

Owner:毕辅成

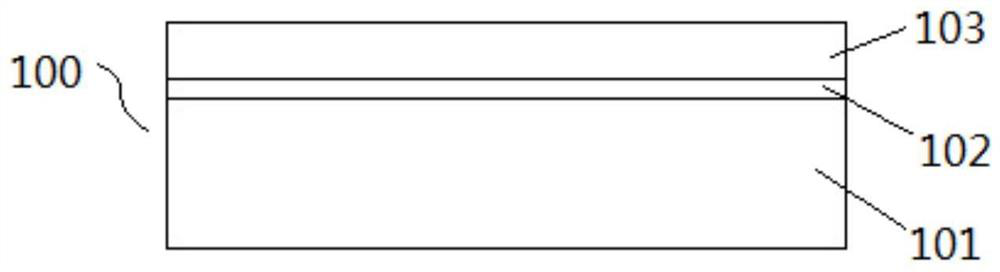

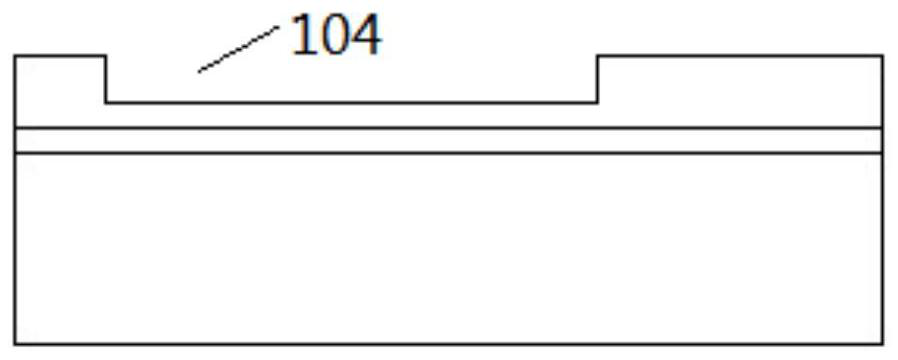

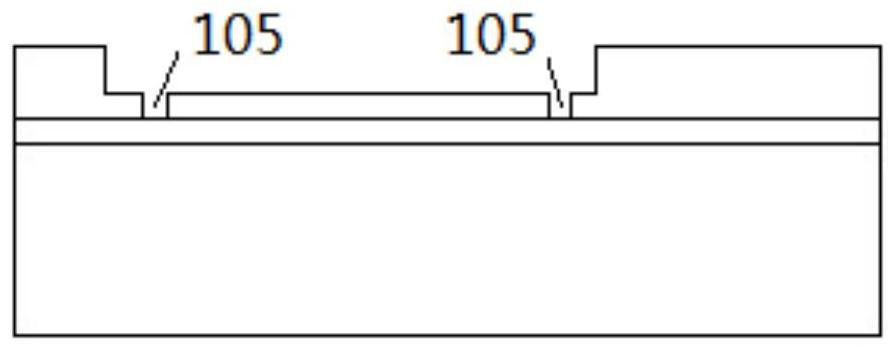

MEMS device manufacturing method and MEMS device

PendingCN113735055AClean removal effectSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesOrganic filmSilicon chip

The invention relates to an MEMS device manufacturing method and an MEMS device, an SOI insulator silicon wafer is selected as a substrate, and silicon-silicon bonding is carried out through SOI top silicon and a silicon wafer serving as a structural layer, so that the whole manufacturing process can be compatible with a VHF process; before the hydrophobic organic film is formed, a layer of sacrificial layer silicon dioxide is deposited in the area where the hydrophobic organic film needs to be removed, and after the hydrophobic organic film is formed, the silicon dioxide sacrificial layer on the bonding area and the electrode area can be etched off by means of the VHF technology. The hydrophobic organic films on the bonding area and the electrode area are removed while the silicon dioxide is removed, and the hydrophobic organic films needing to be reserved in other areas are not affected. The manufacturing method disclosed by the invention is simple in process and high in feasibility, the hydrophobic organic films on the bonding region and the electrode region can be removed completely at the same time, and the hydrophobic organic films reserved in other regions cannot be damaged.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

Two-wheel slotter

InactiveCN101285310BSecurity buildEfficient constructionMechanical machines/dredgersHydraulic motorMilling cutter

The invention provides a dual wheel slot milling machine, comprising a guide frame, a sealing box body, a driving device and at least one milling wheel which is arranged on the lower part of the sealing box body and provided with a plurality of milling heads along the periphery of the milling wheel and can positively or negatively milling-dig soil layer and rock layer, wherein the driving device comprises a hydraulic motor with low rotary speed and big torque arranged in the sealing box body by the oil immersion lubrication sealing, and a variable speed transmission mechanism consisting of a small chain wheel arranged on an output shaft of the hydraulic motor, a big chain wheel used to drive the milling wheel to turn and a chain used to connect the small chain wheel and the big chain wheel. Due to the adoption of the structure of the driving device with the combination of the hydraulic motor with low rotary speed and big torque and the chain transmission, the slot milling machine is safe and highly efficient, and can perfectly construct the continuous wall with flattening, same thickness and big width, and the work efficiency, rotating speed and torque of the slot milling machine are almost the same as the imported equipment; moreover, the slot milling machine has the advantages of simple and reliable structure, low manufacturing cost, convenient assembly, disassembly and maintenance, low maintenance cost, energy conservation, environmental protection and easy popularization.

Owner:谢沃林

Releasing agent and preparation method thereof

ActiveCN102085563BSolve stickingImprove surface qualityFoundry mouldsFoundry coresLongest DiameterGasoline

The invention provides a releasing agent used in a process of forming a magnetic material, which comprises the following components: 0.1-2 percent by weight of graphite powder, 0.1-5 percent by weight of fatty acid derivative, 0.1-2 percent by weight of paraffin, 0.1-0.5 percent by weight of sodium dodecyl benzene sulfonate, 0.1-2.5 percent by weight of glyceride and 88-99.5 percent by weight of gasoline mixture. The invention also discloses a preparation method of the releasing agent. According to the releasing agent provided by the invention, the problem of adhesion in the process of forming the magnetic material is solved, and the surface quality of a permanent magnet material casting is improved, especially the annular permanent magnet material product with large long diameter ration; and by using the releasing agent, the surface roughness of the permanent magnet material blank product is reduced, and the forming qualified rate of products is improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

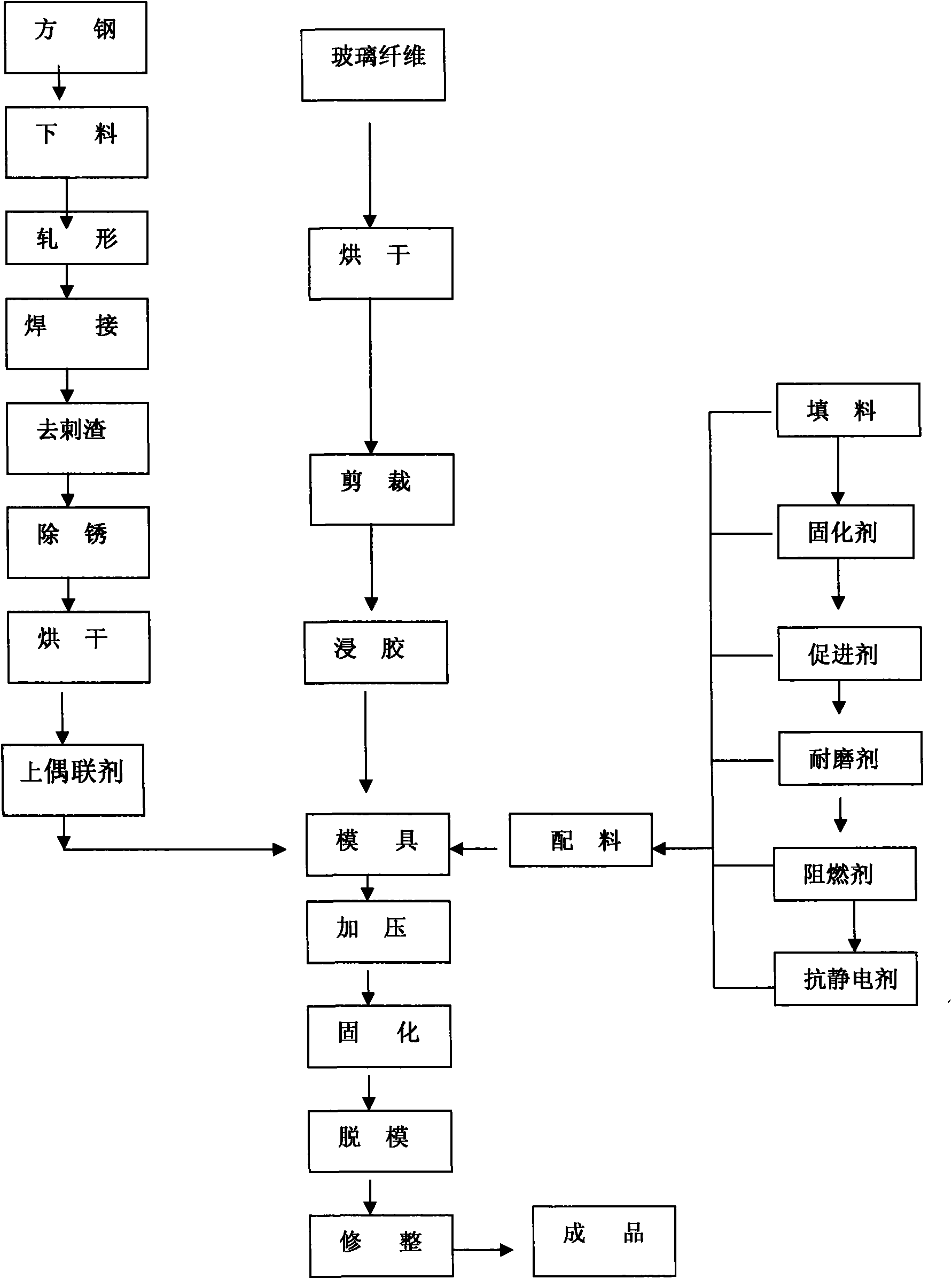

Bonding technology of steel-glass reinforced plastic composite material for tank path and tank path beam

The invention discloses a bonding technology of a steel-glass reinforced plastic composite material for a tank path and a tank path beam. The bonding technology comprises the following steps: firstly, selecting steel material, carrying out alkali washing, acid washing, sand beating and passivation; coating the surface of the steel material after being processed with a coupling agent; coating a parting agent on a mould, dipping glass fibre cloth in gum, and filling the glass fibre cloth after gum dipping into a mould cavity of the mould; pressing the steel material in the center of the mould, compacting to manufacture a product, removing, stripping mould t after natural curing is carried out for 20 to 50 minutes, and flatly placing the manufactured product after mould stripping and then fully curing naturally. The coupling agent is used as a first layer of isolation for enhancing the bonding force between the steel material and glass reinforced plastics, and specially prepared glue liquid with strong bonding force is used for isolating the steel material and outside oxygen and is used as a second layer of isolation. By adopting glass reinforced plastic fibre multi-layer protection, on one hand, striking force is dispersed in the collision process, and on the other hand, the oxidation of the steel material is avoided. The invention solves the problem of the bonding of glass reinforced plastics and square steel, saves energy, lowers consumption, reduces pollution and obtains a favorable renovation benefit.

Owner:JIANGSU JINGYUAN ENERGY SAVING ENVIRONMENTAL PROTECTION

Efficient three-return-stroke roller dryer for wet sand treatment

InactiveCN110849110AImprove drying effectExtended drying strokeSand dryingDrying machines with non-progressive movementsStructural engineeringProcess engineering

The invention relates to the technical field of drying equipment, in particular to an efficient three-return-stroke roller dryer for wet sand treatment. The efficient three-return-stroke roller dryercomprises a base, a controller, a conveying belt and a drying mechanism, wherein the controller is arranged at the top of the base through a supporting rod, the drying mechanism comprises a drying box, a warning assembly, a driving assembly and three sets of stirring assemblies, the drying box is vertically arranged through an annular frame body, the warning assembly is arranged at the top of thedrying box, the driving assembly is vertically inserted into the drying box through a bearing, the three sets of stirring assemblies are arranged in the drying box at equal intervals and are connectedwith the driving assembly in a sleeving mode, and the warning assembly and the driving assembly are electrically connected with the controller. According to the efficient three-return-stroke roller dryer for wet sand treatment, the wet sand can be dried in step-by-step and layer-by-layer mode, the drying work can be prompted gradually, the drying stroke is effectively prolonged, the drying efficiency is improved, and the drying effect of wet sand is obviously improved.

Owner:安徽金砖建筑节能材料有限公司

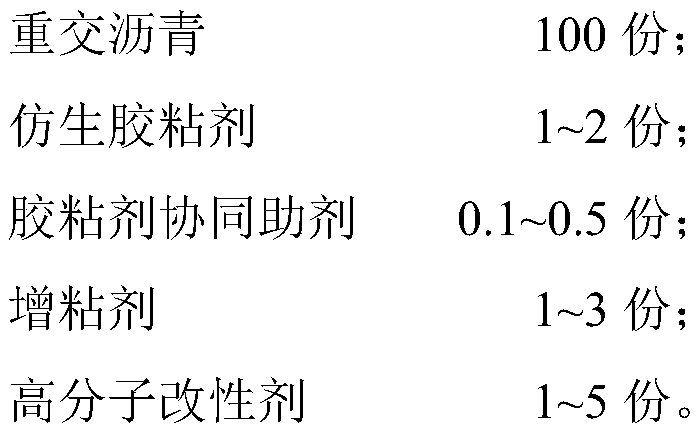

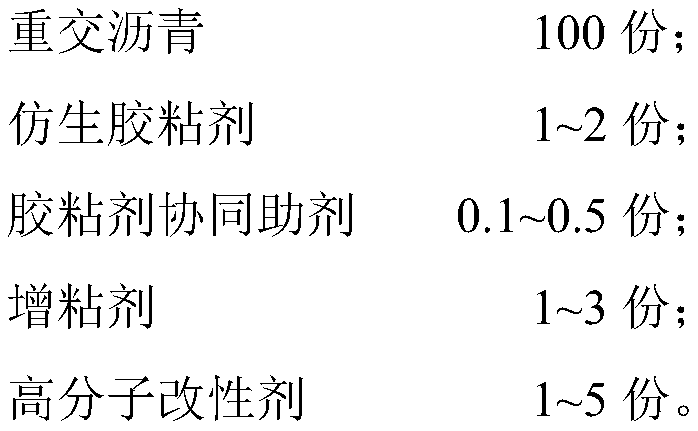

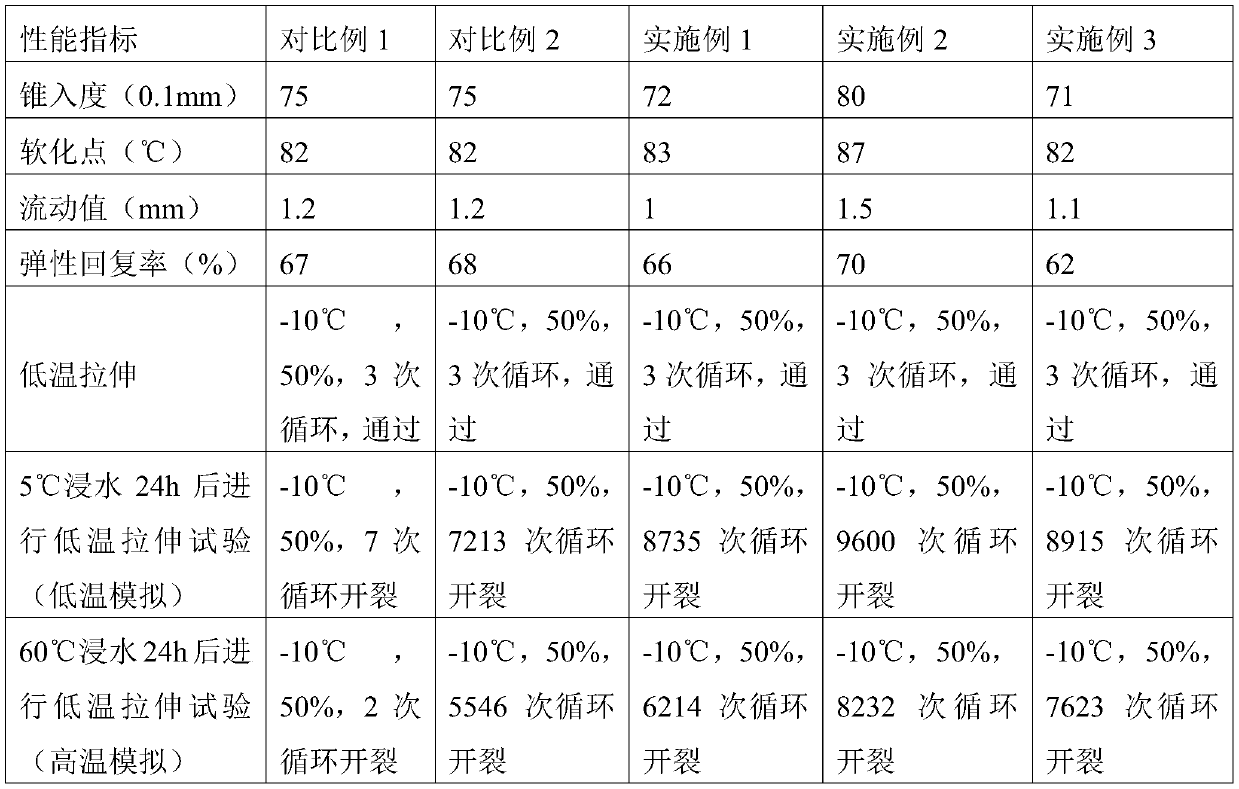

Bionic asphalt-based crack pouring glue material and preparing method thereof

ActiveCN110117479ASolve stickingAdjust \"stickiness\"Non-macromolecular adhesive additivesBituminous material adhesivesPolymer scienceAdhesive

The invention discloses a bionic asphalt-based crack pouring glue material and a preparing method thereof, and belongs to the technical field of asphalt pavement maintenance. The bionic asphalt-basedcrack pouring glue material is prepared from, by weight, 100 parts of heavy traffic asphalt, 1-2 parts of a bionic adhesive, 0.1-0.5 part of an adhesive synergistic aid, 1-3 parts of a tackifier and 1-5 parts of a polymer modifier. According to the bionic asphalt-based crack pouring glue material and the preparing method thereof, a water-resistance structure unit catechol secreted by aquatic organisms is utilized as a basis, and the bionic adhesive is synthesized through molecular design, and then introduced into an asphalt-based crack pouring glue system. The bionic asphalt-based crack pouring glue material overcomes the defects of a current crack pouring glue material that construction cannot be achieved in the presence of water on an interface or the adhesion performance is poor and thevalidity period is short in the presence of water on the interface, and is an asphalt-based crack pouring glue material with a wide application prospect.

Owner:SHANDONG JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com