Brick discharging and packaging production line and brick discharging and packaging method

A production line and brick stacking technology, which is applied in the field of brick production and packaging production line and brick production and packaging, can solve the problems of low efficiency, brick bonding, high labor intensity, etc., and achieve the effect of good use effect, reasonable design and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

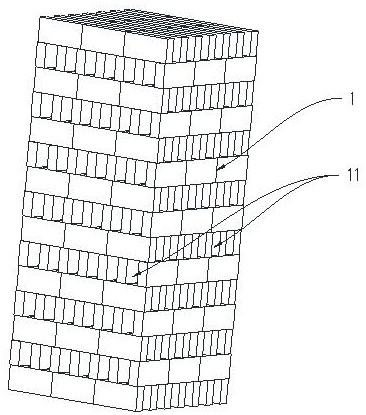

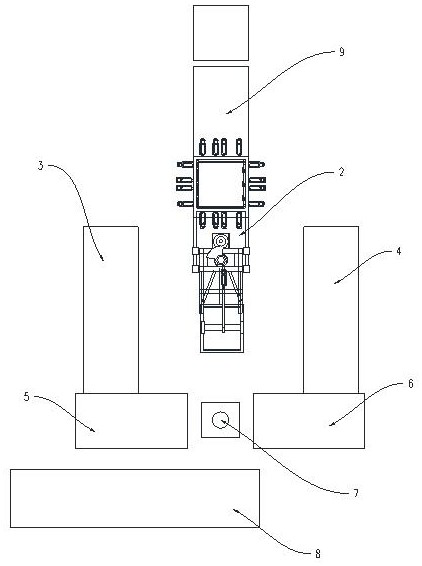

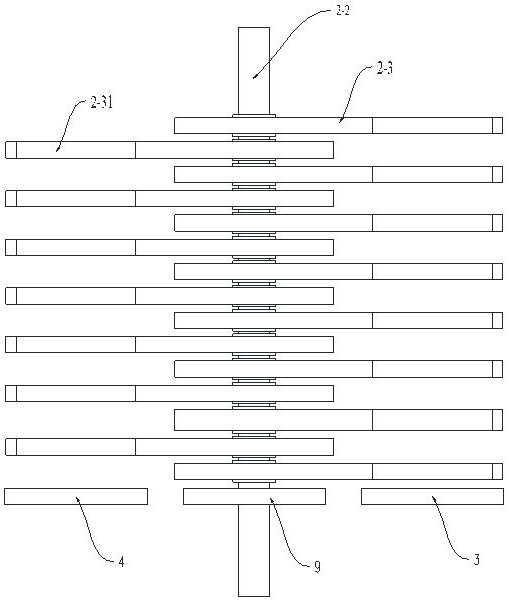

[0044] see Figure 2-4 , a brick packing production line, comprising a brick stack conveyor 9, a stacking mechanism 2, a first brick conveyor 3, a second brick conveyor 4, a first brick conveyor 5, a second brick conveyor 6, The brick stacking manipulator 7 and the packaging section 8, the brick stack conveying frame 9 transports the brick stack 1 to the bottom of the stacking mechanism 2, and the stacking mechanism 2 includes a column 2-2 and a multi-layer stacking chuck arranged on the column 2-2 2-3, the stacking chucks 2-3 of each layer are rotatably connected with the column 2-2, the stacking chucks 2-3 include a jacket part 2-31, and the clamping parts of the stacking chucks 2-3 of each layer The cover part 2-31 is equipped with a first clamping mechanism 2-311 corresponding to the length direction of the two ends of the brick and a second clamping mechanism 2-312 corresponding to the thickness direction of the two sides of the brick. The jacket part 2-31 of 2-3 corresp...

Embodiment 2

[0049] see Figure 7-11 , the difference between the present embodiment and the first embodiment is that: in the present embodiment, the stacking mechanism 2 adopts two columns 2-2, and the stacking chucks 2-3 of each layer are successively arranged crosswise on the left and right and passed through the rotating fixed seat 2-2. 33 is arranged on the column cover 2-21, and each column cover 2-21 is connected with a lifting adjustment mechanism. Lifting and adjusting the counterweight 2-5, through the lifting and adjusting the counterweight 2-5 on both sides, the overall lifting and adjusting of the sub-stacking chucks 2-3 on the two columns is realized. The lifting adjustment mechanism in the present application can also be provided with a lifting adjustment hydraulic cylinder or air cylinder above or below the column sleeve 2-21, and the lifting adjustment of the column sleeve 2-21 can be realized by pulling or jacking.

[0050] In this embodiment, the stacking chucks 2-3 are...

Embodiment 3

[0053] A brick packing method for a brick packing production line, comprising the following steps:

[0054] 1) The brick stack conveying frame 9 transports the brick stack 1 to the stacking mechanism 2, and the upper and lower jacket parts 2-31 of the stacking chucks 2-3 of each layer of the stacking mechanism 2 correspond to the stacking jackets, and the stacking Outside the brick stack 1, make the jacket portion 2-31 of each layer of the stacking chuck 2-3 correspond to each layer of brick layer of the brick stack 1;

[0055] 2) The first clamping mechanism 2-311 of the stacking chuck 2-3 of each layer is closed and clamped first, and the two ends of the bricks corresponding to the brick layer are clamped and stabilized;

[0056] 3) From top to bottom, the first clamping mechanism 2-311 of the uppermost stacking chuck 2-3 is released first, and the second clamping mechanism 2-312 of the uppermost stacking chuck 2-3 is closed and clamped , gather the bricks of the uppermost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com