Comb tooth micro-accelerometer capable of resisting high-g-value impact, and preparation method thereof

A technology of micro-accelerometer and accelerometer, which is applied in the direction of measuring acceleration, speed/acceleration/shock measurement, impedance network, etc., can solve the problems of restricting the quality and efficiency of military ammunition weapon systems, poor working stability, and low precision. Achieve the effect of having stress release ability, reducing quality and improving quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in further detail below in conjunction with accompanying drawing:

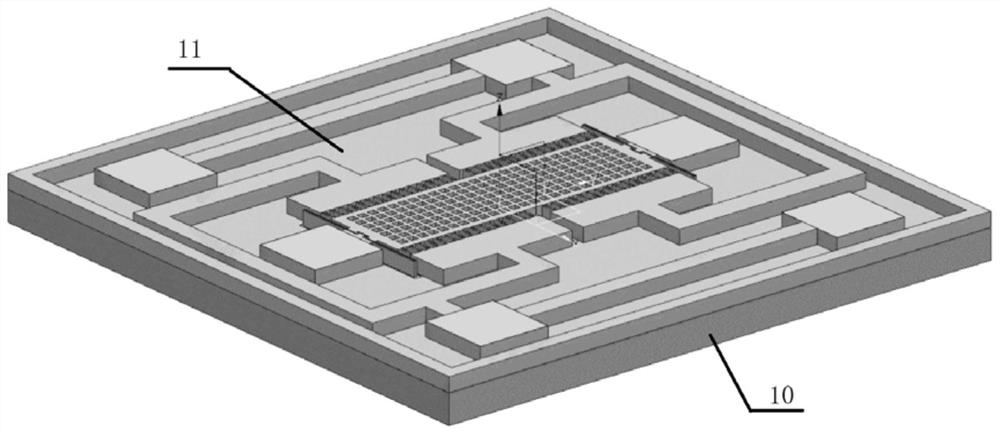

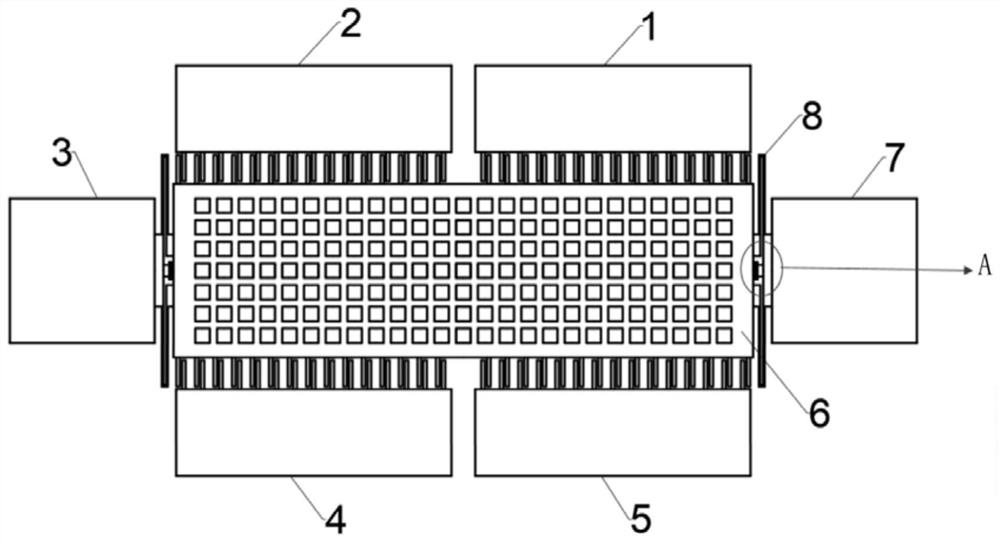

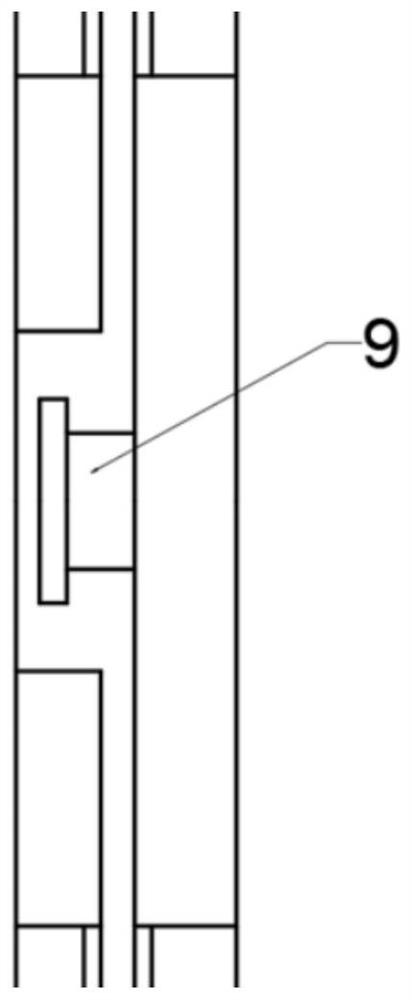

[0050] refer to Figure 1 to Figure 5 , the comb-tooth micro-accelerometer of the high-g impact resistance of the present invention comprises a bottom surface layer 10, a substrate 11 and a silicon micro-accelerometer device layer arranged on the substrate 11, wherein the silicon micro-accelerometer device layer comprises the first A fixed anchor block 3, a movable mass block 6 and a second fixed anchor block 7; the first fixed anchor block 3 is located on the left side of the movable mass block 6, and the second fixed anchor block 7 is located on the right side of the movable mass block 6 , wherein, a first stop block and a first support beam are arranged between the first fixed anchor block 3 and the movable mass block 6, and a second stop block is arranged between the second fixed anchor block 7 and the movable mass block 6 Block 9 and the second support beam 8; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com