Bonding technology of steel-glass reinforced plastic composite material for tank path and tank path beam

A composite material and tank beam technology, applied in the field of steel-glass fiber reinforced plastic composite material bonding technology, can solve the problems of immature glass fiber reinforced plastic and square steel bonding process, shelling of glass fiber reinforced plastic and square steel, and reducing the service life of glass fiber reinforced plastic tank. , to achieve the effect of shortening the installation period, avoiding steel oxidation, and achieving good innovation benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

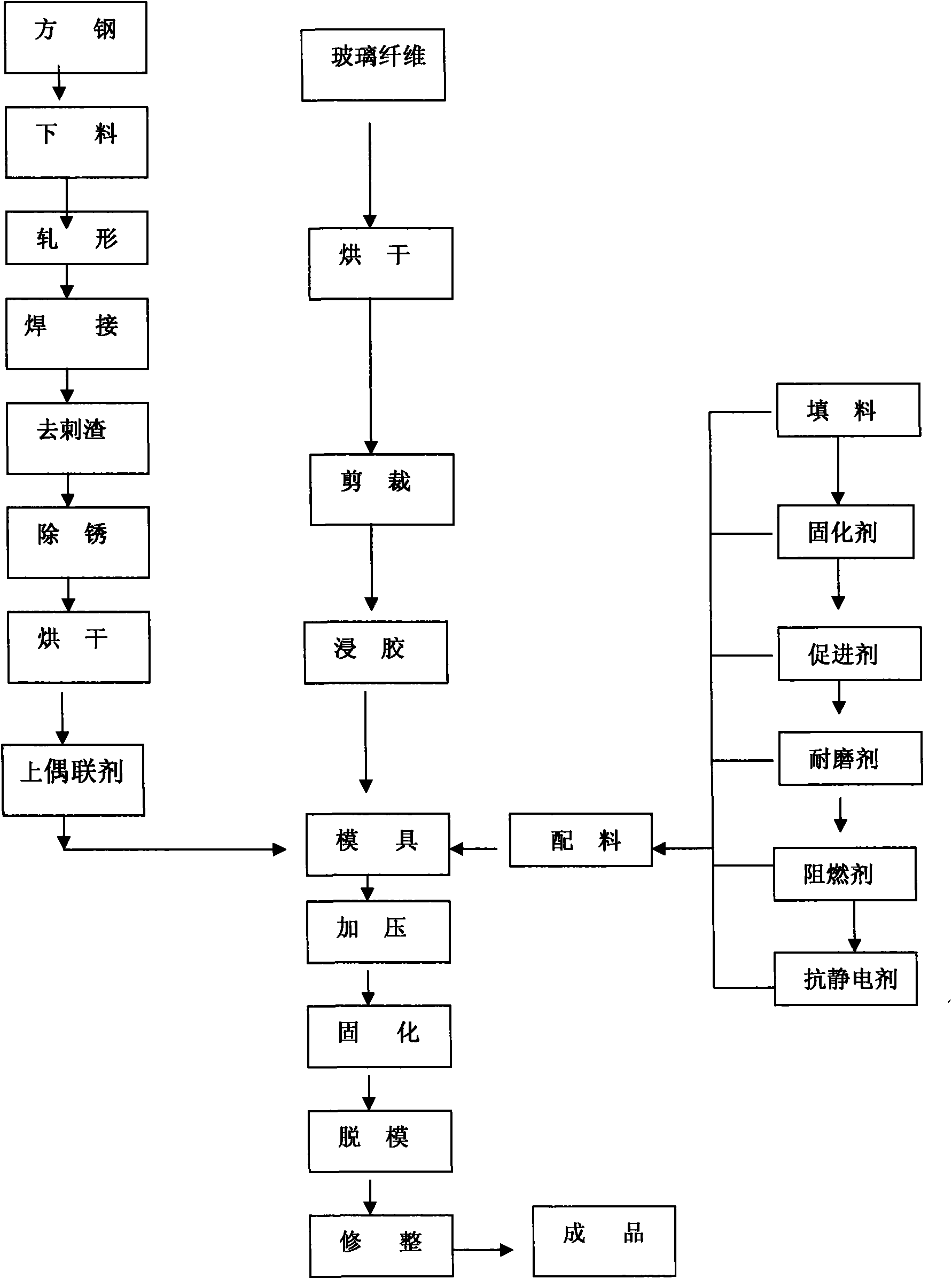

[0021] Such as figure 1 As shown, the steel-glass reinforced plastic composite material bonding process for the tank road and the tank road beam of the present invention is mainly divided into three parts: preparation and processing of raw materials, synthesis and curing of products, trimming and inspection of products.

[0022] 1. Preparation and pre-processing of raw materials

[0023] (1) Pretreatment of tank road steel

[0024] Select the steel with corresponding specifications, first go through the alkali solution of 5-20% sodium hydroxide solution to remove the grease on the surface of the steel, then rinse it with clean water, and then pickle to remove the floating rust on the surface of the steel, rinse it with clean water , play sand, increase surface roughness. The components are put into the passivation pool, the passivation time is 20-50 minutes, and then dried until silvery white, ready for use. After degreasing and chemical corrosion, the steel tank forms a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com