Preparation method of high-yield cyanuric acid and its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid

A technology of cyanuric acid and materials, which is applied in the field of preparation of high-yield cyanuric acid and its dichloro and trichloro derivatives, achieves the effects of less side reactions, rapid production and solving adhesion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

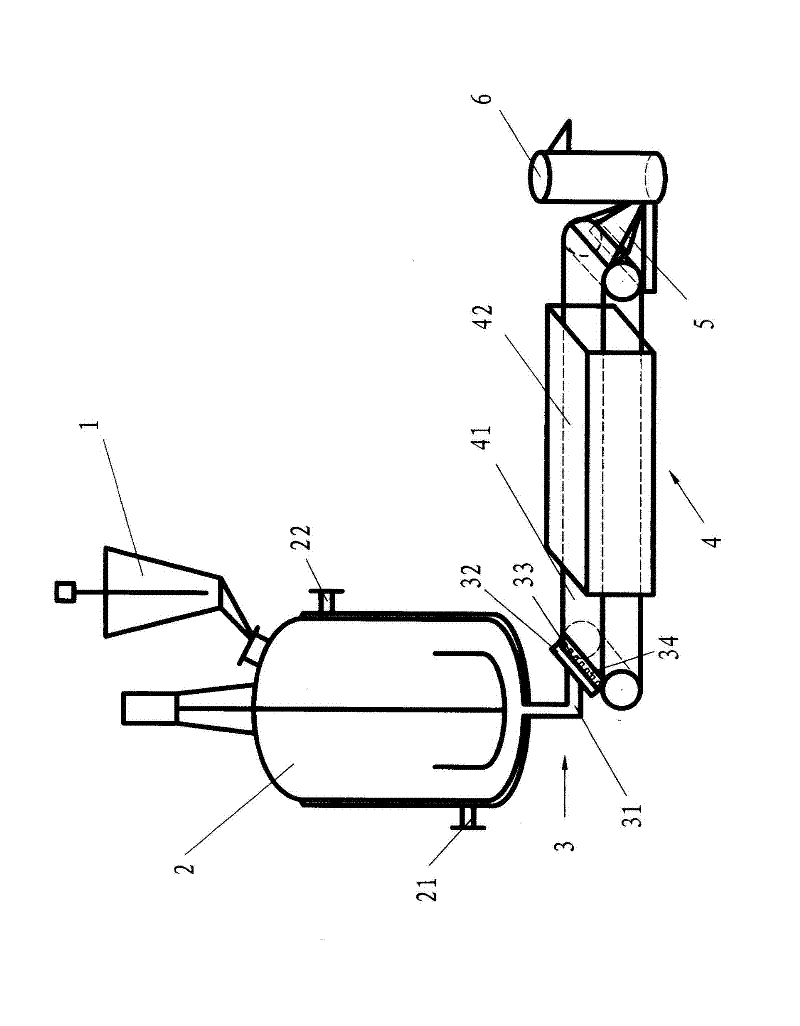

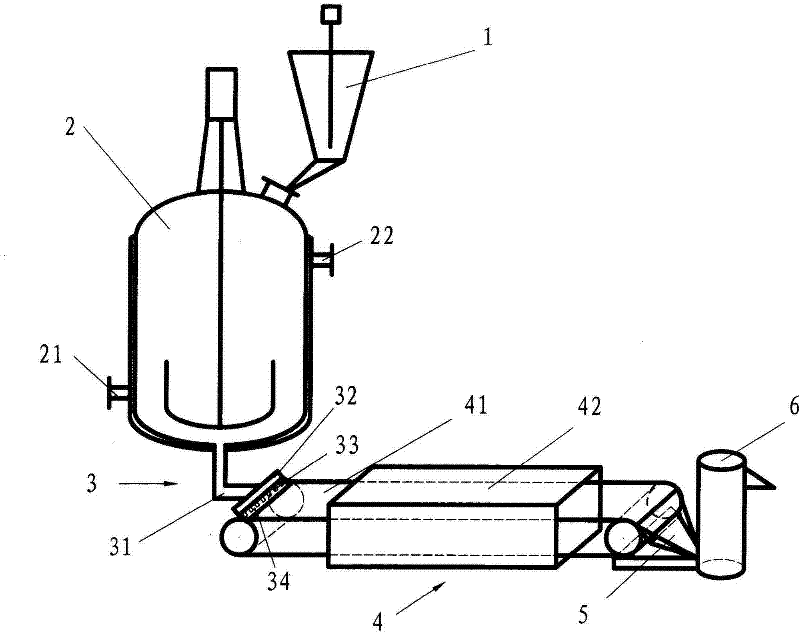

[0016] Embodiment 1: (high yield) The preparation method of cyanuric acid is to make cyanuric acid product through the following process steps in sequence (see the following reaction formula):

[0017]

[0018] ①Mix 1500 kg of urea and 150 kg of catalyst ammonium sulfate in the mixer according to the weight ratio of 1:0.1 (the mixing of urea and catalyst ammonium sulfate should be uniform to reduce the occurrence of side reactions of urea), and mix them Add it into a (2000 liters) reactor with a heat transfer oil circulation heating method, and start stirring. ② Control the temperature of the heat-conducting oil in the jacket of the reaction kettle to 190°C, open the jacket valve, feed hot oil, and heat up the material. The material will gradually melt at 80-90°C (at 90°C, it will become a slurry liquid). As the temperature rises to 110-130°C (120°C in this embodiment), the material becomes a clear liquid (clarified liquid). ③When the material is completely melted, continu...

Embodiment 2

[0019] Embodiment 2: (high yield) The preparation method of cyanuric acid is to make the cyanuric acid product through the following process steps successively:

[0020] ①Mix 1,500 kg of urea and 300 kg (or 200 kg) of catalyst ammonium sulfate in a mixer evenly (the mixture of urea and catalyst ammonium sulfate should be uniform to reduce the side reactions of urea), and add it to the In the oil circulation heating method (2000 liters) reactor, start stirring. ② Control the temperature of the heat transfer oil in the jacket of the reaction kettle to 150°C (or 175°C), open the jacket valve, feed hot oil, and heat up the material. The material will gradually melt at 80-90°C (90°C becomes slurry liquid). As the temperature rises to 110-130°C (125°C in this embodiment), the material becomes a clear liquid (clarified liquid). ③When the material is completely melted, continue to heat up, and when the temperature rises to 180°C, the material begins to become turbid and appear milky...

Embodiment 3

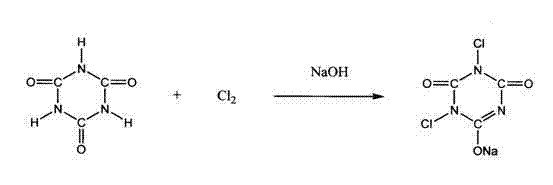

[0021] Embodiment 3: the preparation method of the derivant sodium dichloroisocyanurate of cyanuric acid is to make the sodium dichloroisocyanurate product (referring to the following reaction formula) through the following process steps successively:

[0022]

[0023] Step 1., 2., 3., 4., 5., 6. are the same as embodiment 1. Step ⑦ is to directly produce its derivative sodium dichloroisocyanurate according to the conventional method without drying the high-quality wet material cyanuric acid, and finally obtain the sodium dichloroisocyanurate product (finished product). Specifically, 1000 kilograms of the wet material cyanuric acid refined product obtained in Example 1 or the present example was added to a 5000-liter reactor, which was equivalent to 6.2 kmol in pure form. Add 1800 kg (12.4 kmol) of NaOH solution with a concentration of 30% by weight, stir and heat up to 40°C, all the materials are dissolved, and a light yellow transparent solution is obtained. Cool down to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com