Self-service film sticking machine and film sticking method thereof

A film sticking machine and film sticking mechanism technology, applied in chemical instruments and methods, cleaning methods and utensils, other household appliances, etc., can solve the problems of film sticking failure, easy occurrence of air bubbles, dislocation of protective film, etc., so as to reduce the defect rate and improve production. Efficiency, reduce the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

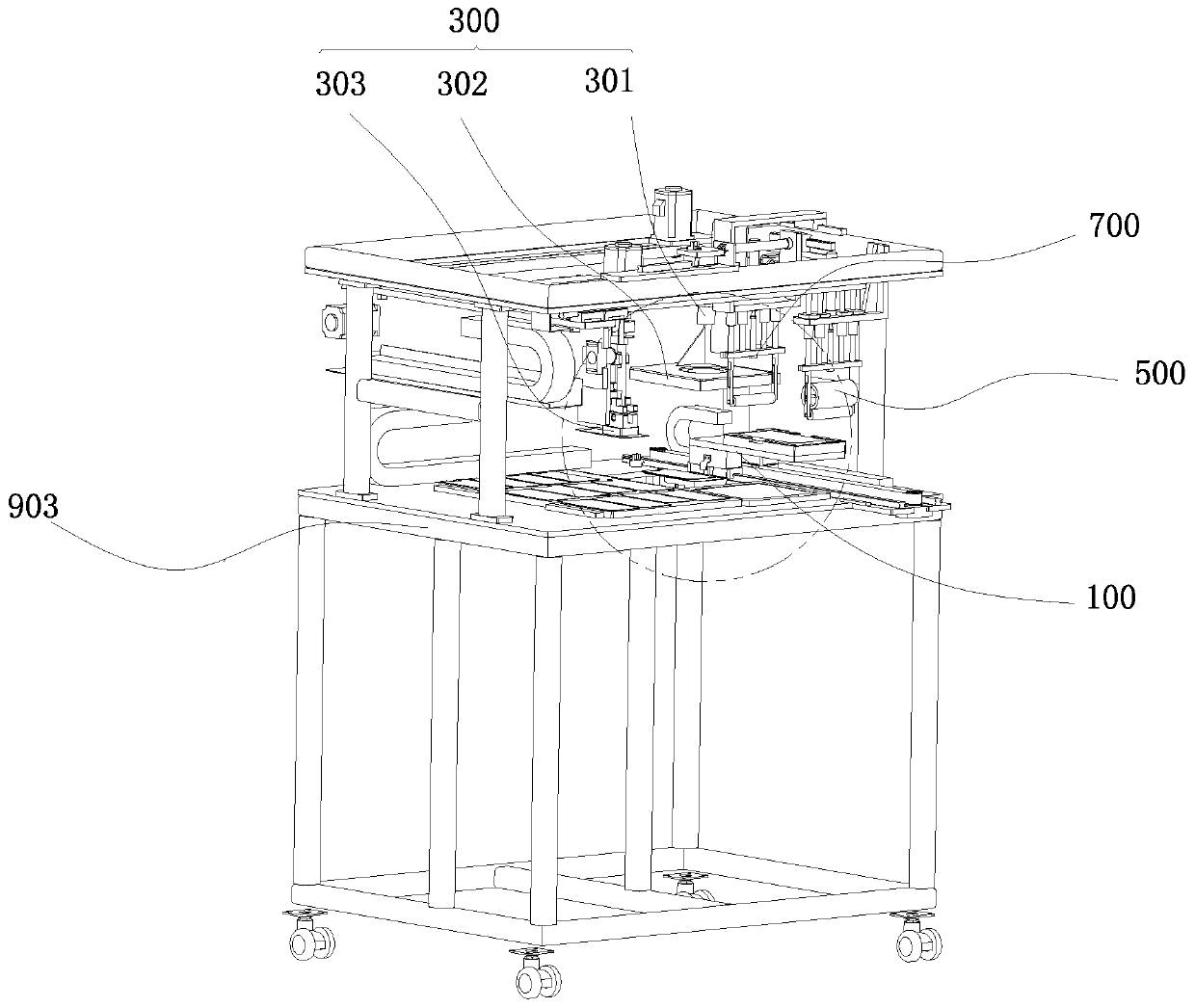

[0051] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0052] A self-service film sticking machine peeling method provided by the present invention is mainly suitable for self-service film sticking of electronic equipment that needs film sticking, that is, automatically attaching the protective film to the electronic device, for example: automatically attaching a tempered film to a mobile phone; Solve the inconvenience caused by the existing manual film application, thereby assisting industrial intelligent production and good quality control when casting film.

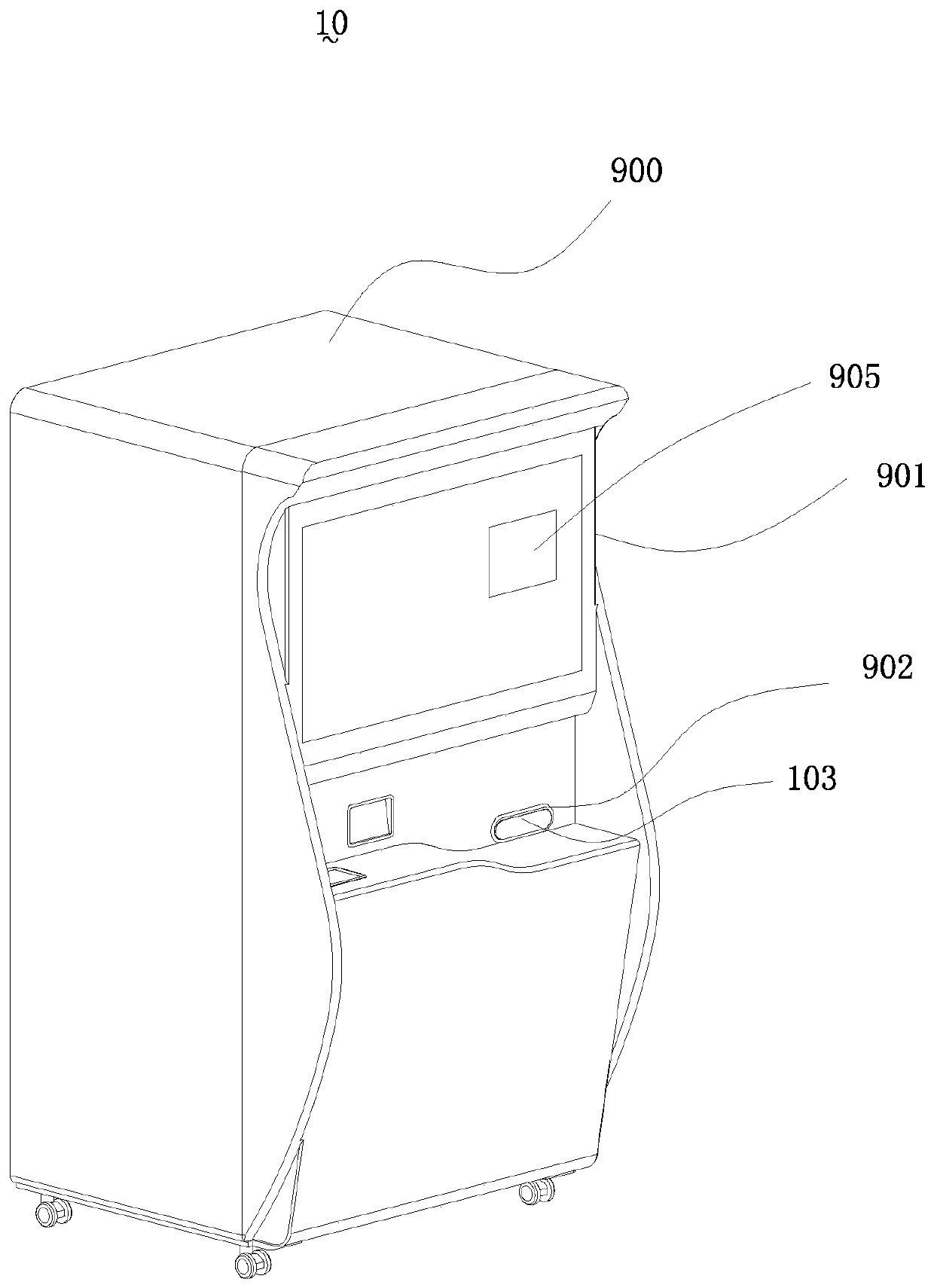

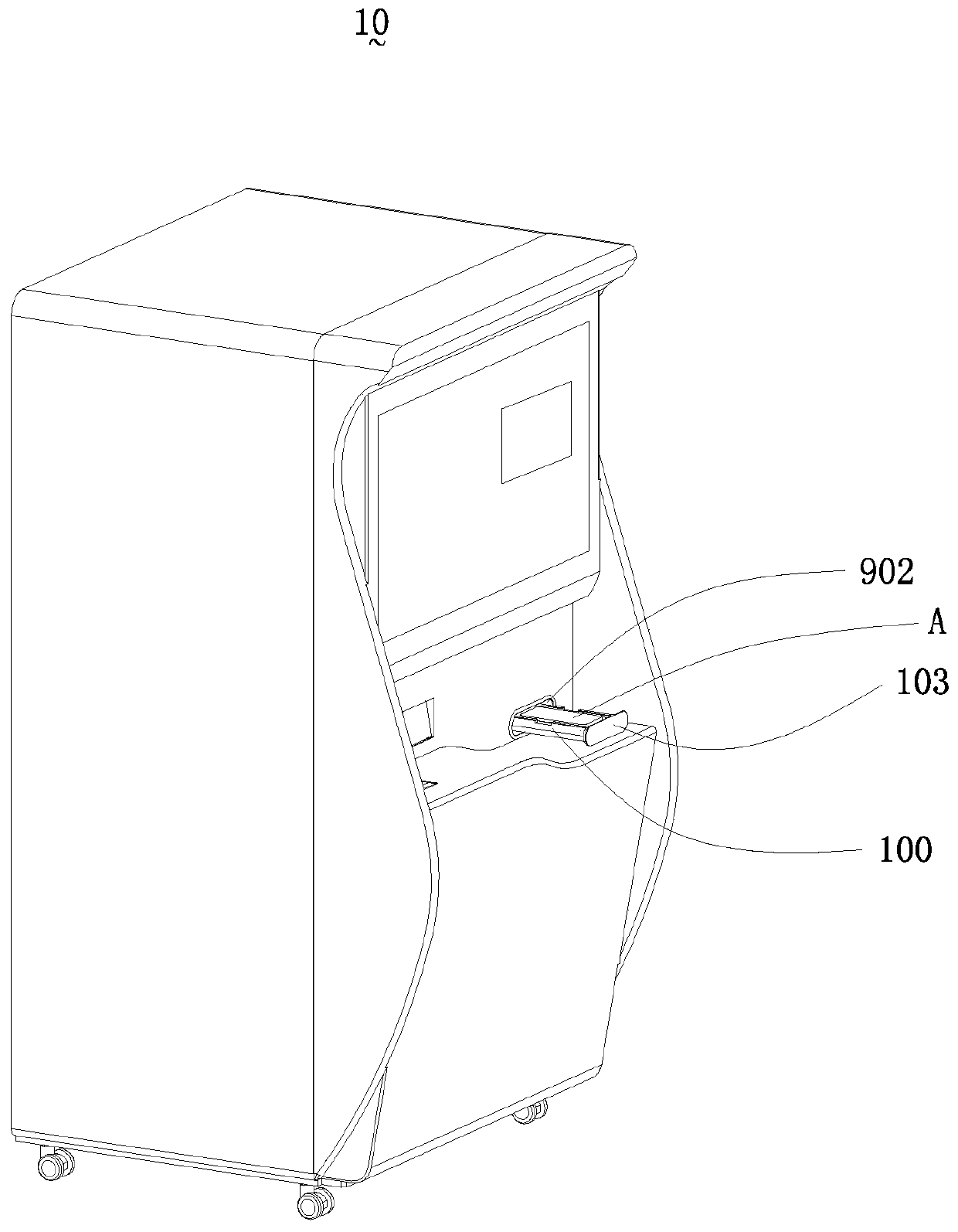

[0053] see Figure 1-Figure 4 , the first embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com