Three-component fiber blended yarns and manufacturing process thereof

A technology of fiber blending and manufacturing process, which is applied in textiles, papermaking, yarn and other directions to achieve accurate fiber content and solve sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

[0017] Since the vinylon fiber is thicker than the polyester fiber, according to the fiber characteristics, the vinylon fiber transfers outward in the yarn, which plays a role in improving wear resistance. Selecting 20% of high-strength vinylon can meet the requirements for clothing wear resistance, and choosing 20% of The purpose of grade 3 fine-staple cotton is to meet the functional requirements of human comfort.

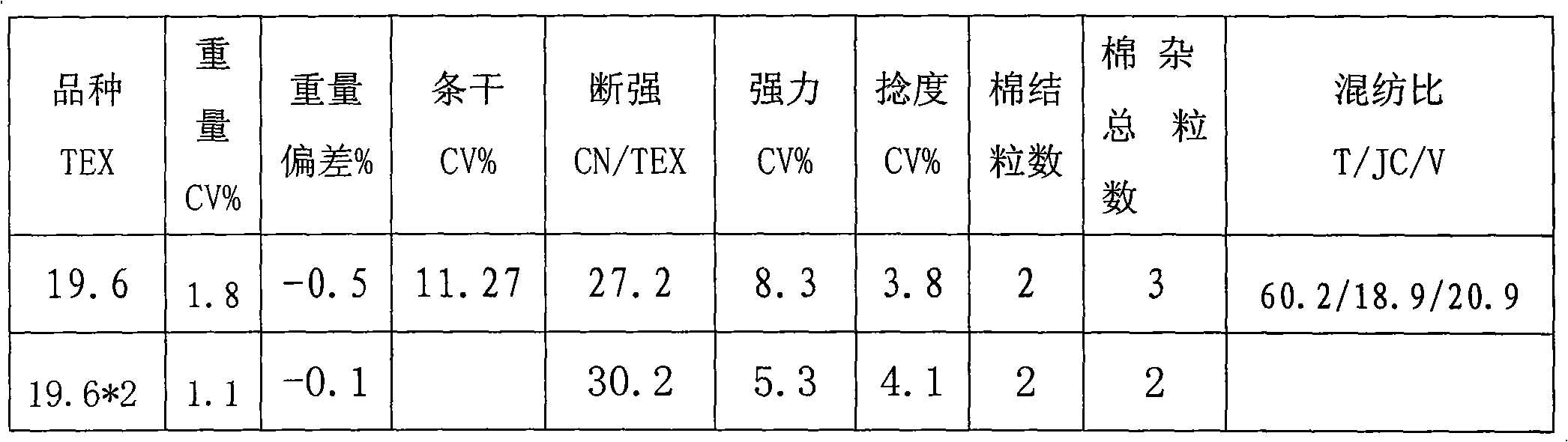

[0018] Example 1: 60% ordinary polyester fiber, 20% vinylon fiber and 20% fine-staple cotton, choose 1.33dtex*38mm for polyester fiber, choose high-strength type for vinylon fiber, specification 1.65dtex*38mm.

[0019] Its three-component fiber blended spinning process steps are:

[0020] 1. Blowing process: Since the fine-staple cotton contains impurities and short fibers, and needs to go through the combing process, the fine-staple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com