Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Small stretch rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc alloy for manufacturing die

Owner:ZHUZHOU SMELTER GRP

Easy-to-use ink-jet heat sublimation transfer paper

InactiveCN105711280ASmall stretch rateFast dryingSpecial paperDuplicating/marking methodsDisperse dyeCellulose

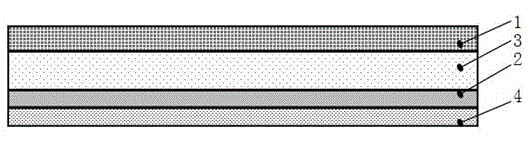

The invention discloses an easy-to-use ink-jet heat sublimation transfer paper. The paper comprises an ink holding layer, a paper fiber binding layer, a base paper layer and a back coating. The top layer of the transfer paper is the ink holding layer, the bottom layer of the transfer paper is the back coating and the paper fiber binding layer and the base paper layer are arranged between the ink holding layer and the back coating or a mixture layer of the paper fiber binding layer and the base paper layer is arranged between the ink holding layer and the back coating. The base paper layer is coated with the paper fiber binding layer through a coating machine or through a glue applicator in a paper machine in base paper layer preparation. Only one layer of the ink holding layer with very small thickness can prevent a dispersed dye from permeating into paper fibers and has an ink dye holding capacity which is 1.5-2.5 times that of carboxymethylcellulose and is more than 5 time that of polyvinyl alcohol so that a transfer rate is effectively improved. The coating has pore number greater than or equal to 20 per square millimeter so that an ink absorption capability is improved. Through use of the dried filling material in the transfer paper, a drying rate is fast in printing, a transfer paper shrinkage ratio is low, transfer paper water absorption arching-caused friction on a printer is avoided in ink-jet printing and the transfer paper can be used easily.

Owner:TRANSFER INNOVATIVE MATERIAL SUZHOU

Diaphragm paper for mercury-free alkaline zinc-manganese dioxide cell, and preparation method of diaphragm paper

ActiveCN104631198AImprove densification performanceHigh strengthWater-repelling agents additionPaper coatingPapermakingManganese

The invention discloses diaphragm paper for a mercury-free alkaline zinc-manganese dioxide cell, and a preparation method of the diaphragm paper, and belongs to the technical field of fiber-containing paper and a preparation method thereof. A sizing agent comprises the following raw materials in parts by weight: 40-55 parts of superfine nylon fibers, 25-35 parts of tencel fibers and 20-30 parts of pulp fibers; the sizing agent is prepared by dispersing a dispersing agent by adopting a papermaking machine wet-process papermaking technology. The three types of fibers are mixed to prepare an alkaline zinc-manganese dioxide cell diaphragm, so that not only can the physical strength performance of the diaphragm paper be improved and the relatively good alkaline absorption performance can be guaranteed; due to the improvement of the strength of the diaphragm paper, the usage amount of the sizing agent can be properly reduced, so that the quantitation and the thickness fluctuation of the diaphragm paper can be favorably stabilized, and thus guarantee for meeting the use of the mercury-free alkaline zinc-manganese dioxide cell can be provided.

Owner:浙江鹏辰造纸研究所有限公司

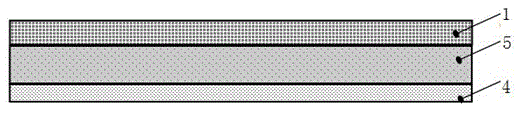

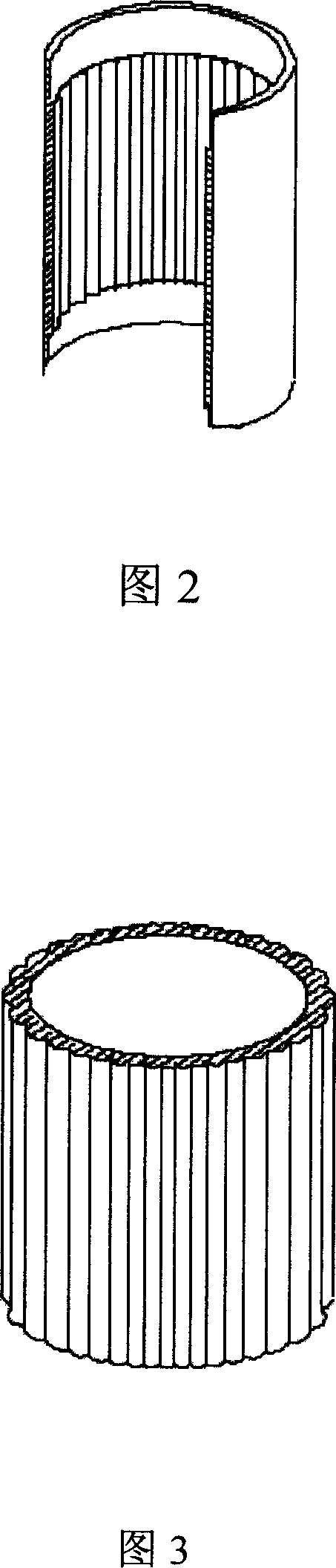

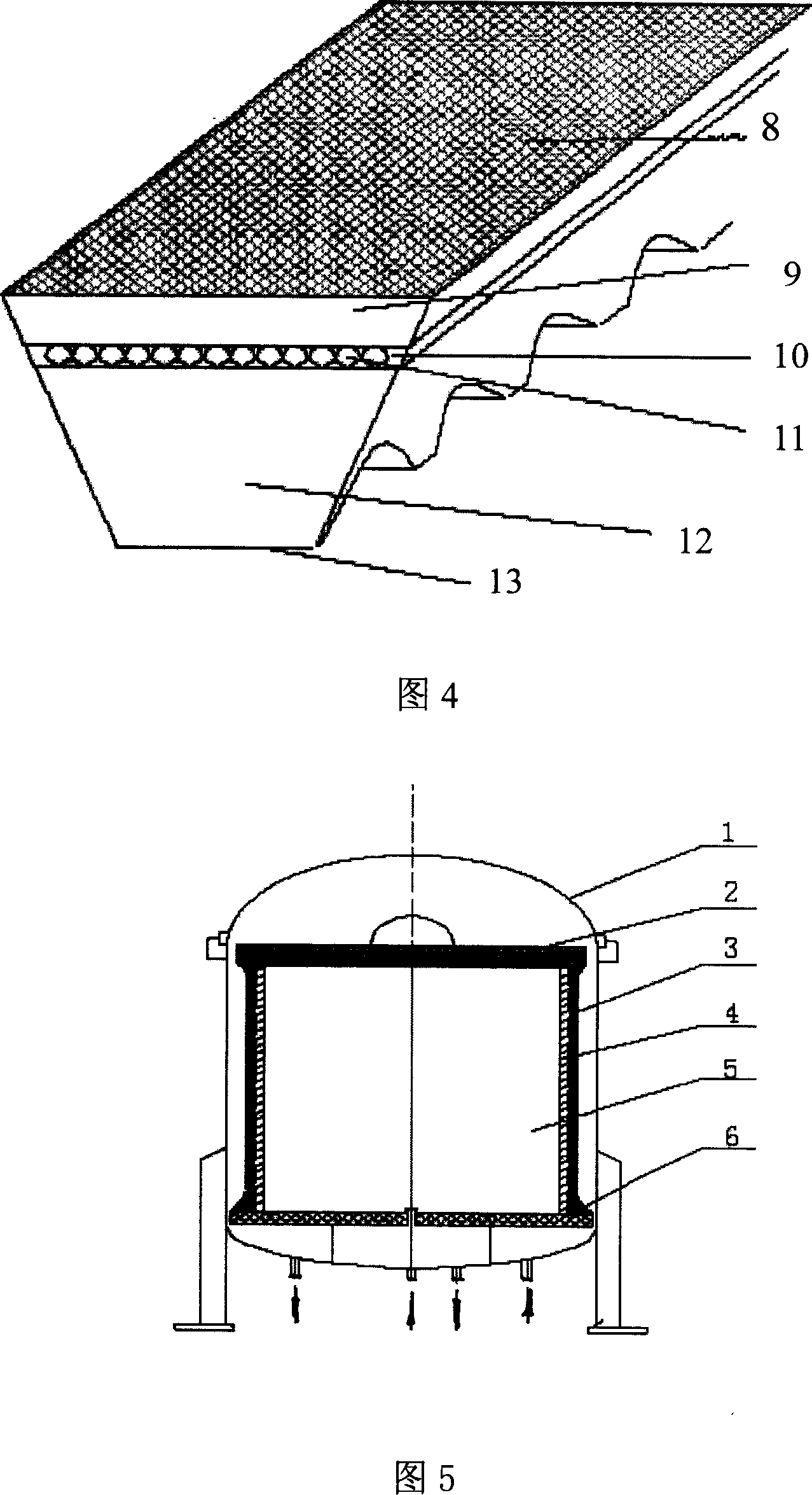

Reverse-forming sulfuration method for sealed type tooth-shaped edge V tape of rubber lagging

It relates to the glue sleeve seal teeth shape reversed V shape forming sulfuration. It makes belt blank at the inner mold, installs the round cylinder glue sleeve with teeth on the surface inside and smooth surface inside both ends on the glue sleeve base and fastened with shrouding rings, putting them into sulfur can, hanging belt blank into glue sleeve, covering the top cap and the cap of the sulfur can, sequentially opening the outside pressure and inner pressure steam for sulfuration, stripping the belt blank round cylinder with vertical rack outside and the cutting belt blank round cylinder, getting many teeth shape cutting V belt. It solves the sealing issue at both ends of the glue sleeve, eliminating the bubbling stratification defect of the product, increasing effective cutting 2-4 lines, reducing material consumption and cost.

Owner:ZHEJIANG ZIJINGANG RUBBER BELT

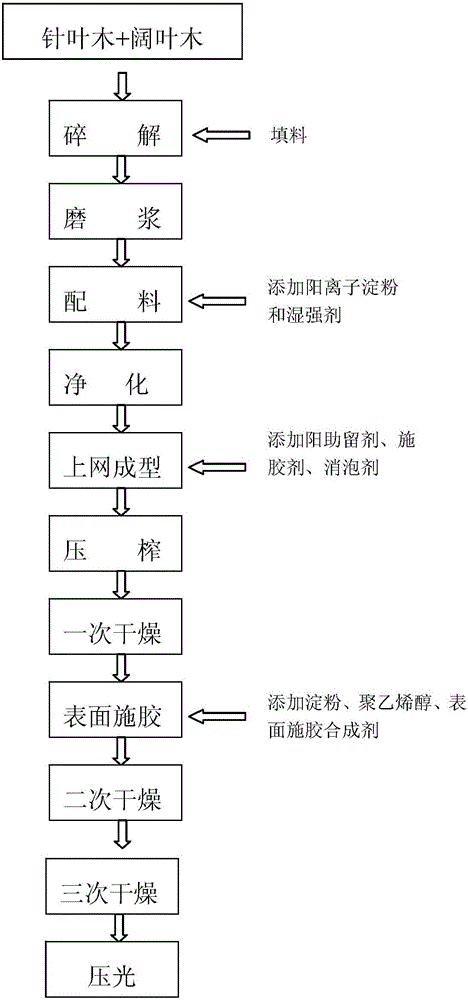

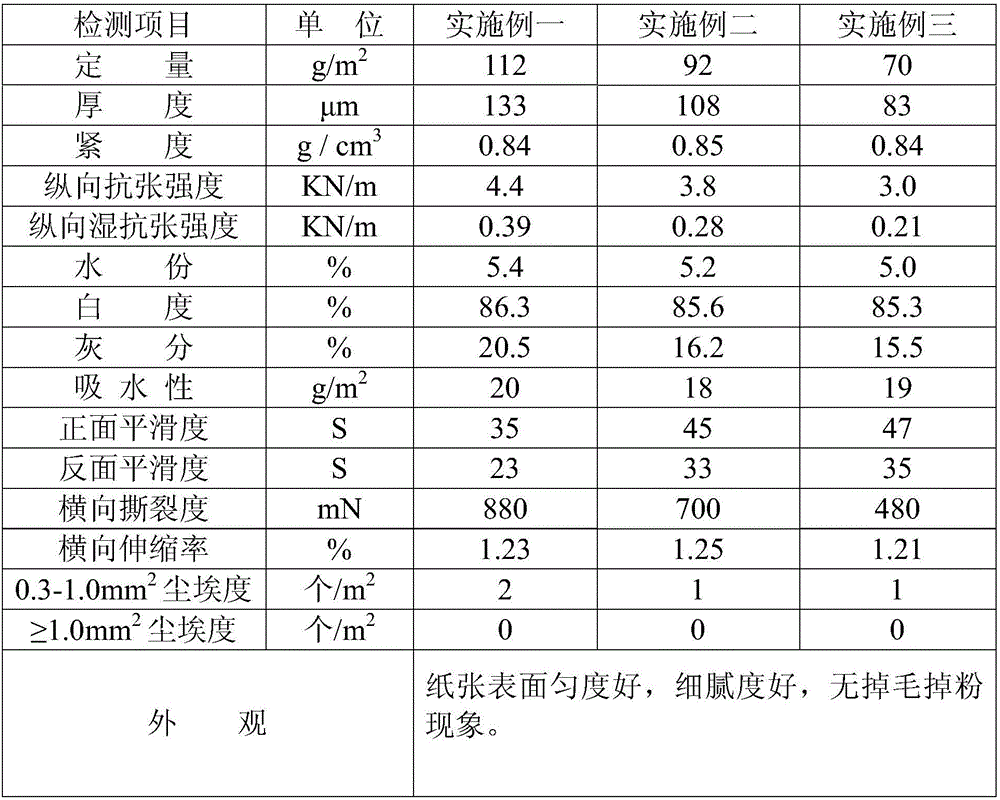

Process for producing thermal dye sublimation raw paper

InactiveCN105951498AImprove surface smoothnessImprove uniformityWater-repelling agents additionDryer sectionFiberPapermaking

A process for producing raw paper by thermal dye sublimation is related to the technical field of papermaking and includes: pulping coniferous wood and broad-leaved wood in a mass ratio of 15:85-30:70 through a pulper, and adding a filling material, the mass ratio of plant fiber to the filling material being 70:30-85:15; subjecting obtained pulp to pulp grinding under controlled beating degree of 25-35 degrees SR, and adding a cationic starch and a wet strength agent respectively into the pulp; performing dilution purification, web-forming and pressing, and subjecting obtained wet paper sequentially to primary drying, surface gluing, secondary drying and tertiary drying to obtain the thermal dye sublimation raw paper. Indexes of the thermal dye sublimation raw paper such as tear, uniformity, shrinkage, tensile strength and smoothness can be effectively controlled, preventing the problems occurring during use of raw paper produced by traditional process, such as picking, poor printing effect, wrinkling during printing, and proneness to breakage during printing.

Owner:SHANDONG TIANYANG PAPER

Light partition plates

InactiveCN1583653ASolve the cracking problemAvoid yellowingSolid waste managementPhosphatePhosphoric acid

The invention is about a sort of lightweight partition wall board. It is made from magnesium oxide, magnesium chloride, dry rock powder, flyash, French chalk, high alumina cement, ferrous sulfate, tertiary sodum phosphate, phosphoric acid solution and sawdust. The lightweight partition wall board has the following advantage: the fist, it can save energy, reduce cost and have no pollution. The second, the board has fine intensity, good water resistance and resistance to aging. The third, it has small shrinkage, get over the problem that appear when the boards join. The fourth, the partition wall board no longer distort for using inorganic material and controlling the quality of material. Lastly, it has good shock resistance, waterproof, fire resistance, soundproofing and it get over the partition wall board to be yellow.

Owner:刘炳林

Preparation method of white water-resistant and oil-proof paper

ActiveCN111636247AHigh oil resistance levelHigh densityCoatings with pigmentsSpecial paperCellulosePolymer science

The invention relates to the technical field of papermaking, and provides a preparation method of white water-resistant and oil-proof paper so as to solve the problems of insufficient oil resistance and poor waterproof performance of the oil-proof paper. The preparation method comprises the steps: (1) preparing raw paper: mixing bleached chemical pulp, filler and cationic starch, dehydrating, squeezing and drying at a net part to obtain the raw paper; (2) coating for the first time: coating with a chitosan-culsageeite solution; (3) coating for the second time: coating with hydroxypropyl methylcellulose-silicon nano-particle coating liquid, and drying in sections; and (4) coating for the third time: coating with a polydimethylsiloxane solution dispersed by n-hexane. The double-proof paperhas extremely strong waterproof and oil-proof effects, and the surface of the double-proof paper is provided with multiple layers of liquid-proof coating layers and is provided with a compact internalstructure, so that the oil-proof paper is ensured to have high oil-proof grade, high density, good water resistance, low expansion rate, high strength and small paper banner thickness difference.

Owner:XIANHE CO LTD

Preparation method of high-strength wear resistant polyester harness

InactiveCN104975401AHigh breaking strengthImprove wear resistanceJacquardsSucessive textile treatmentsBreaking strengthPolyester

The invention provides a preparation method of a high-strength wear resistant polyester harness. The preparation method comprises the following steps: 1) doubling; 2) first twisting; 3) second twisting; 4) stranding; 5) size mixing in a size pool and dyeing; 6) dehydration; 7) first drafting setting and air-drying until the humidity is lower than 3%; 8) second drafting setting. The polyester harness provided by the invention has the advantages that the breaking strength is obviously enhanced; the wear resistance is improved; the ratio of expansion and contraction is reduced; the friction coefficient is increased by 30-60%.

Owner:安徽创星实业有限公司

Energy-saving and environmental-friendly light partition board and preparation method thereof

InactiveCN108276023AHigh compressive strengthImprove crack resistanceConstruction materialSolid waste managementFiberModified carbon

The invention discloses an energy-saving and environmental-friendly light partition board and a preparation method thereof and relates to the technical field of partition boards. The partition board comprises the following raw materials in parts by weight: 65-70 parts of Portland cement, 40-50 parts of calcium carbonate, 32-35 parts of calcium oxide, 25-30 parts of a paraffin-kieselguhr compositephase change material, 20-24 parts of a modified carbon fiber, 10-18 parts of activated bentonite, 10-14 parts of a rubber powder, 9-10 parts of a modified loess powder, 9-10 parts of industrial solidwastes, 9-10 parts of modified fiber granules, 4-6 parts of an early strength agent, 4-6 parts of a water reduction agent, 4-6 parts of a foaming agent, 1-3 parts of a rare-earth catalyst and 75-95 parts of water. The energy-saving environmental-friendly light partition board is relatively good in pressure resistance strength, tensile strength, anti-cracking strength and hanging property, and inaddition has sound insulation and heat preservation effects.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for manufacturing polyvinyl terylene harness cord

The invention provides a method for manufacturing a polyvinyl terylene harness cord, and the method comprises the following steps: 1) doubling threads; 2) primarily twisting the threads; 3) retwisting the threads; 4) winding the threads; 5) mixing slurry in a slurry pool and dyeing the threads; 6) carrying out dehydration; 7) carrying out first drawing for shaping and air drying until the humidity is lower than 3%; and 8) carrying out second drawing for shaping. A product produced by the invention has a substantially enhanced breaking tenacity and a reduced expansion and contraction ratio, and the friction coefficient is increased by 30-60%.

Owner:安徽创星实业有限公司

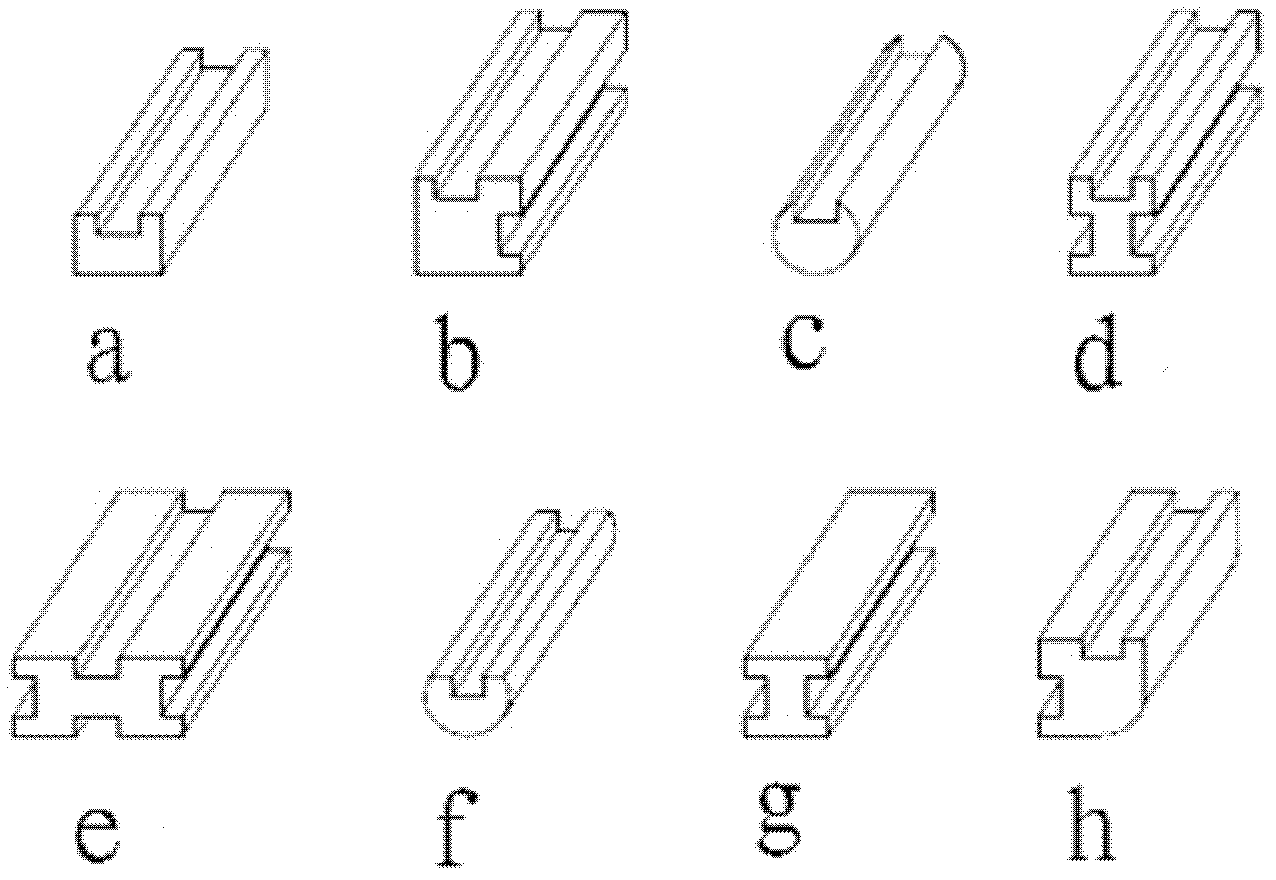

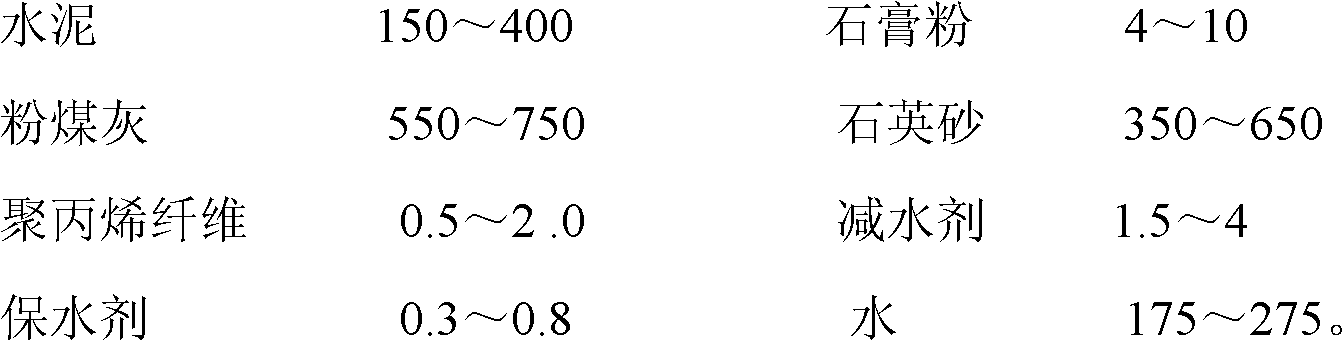

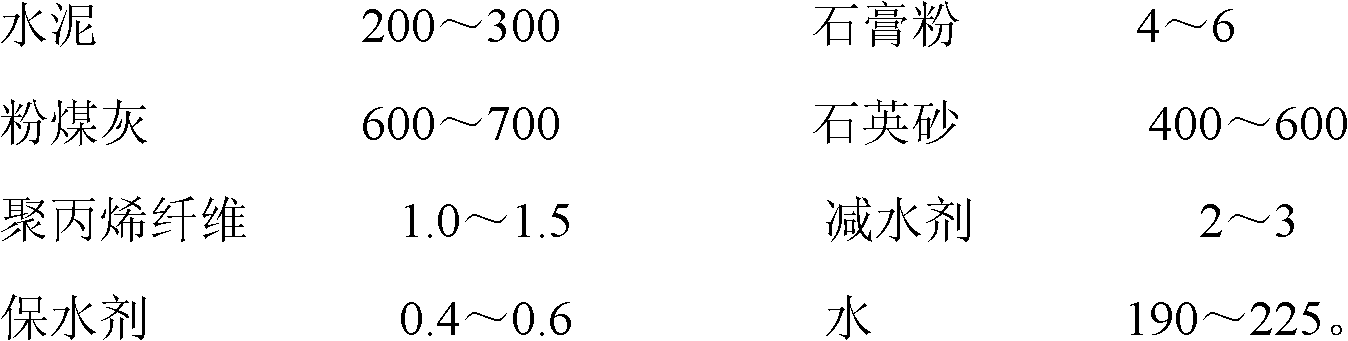

Partition plate connection member and preparation method

InactiveCN103319136AHigh strengthReduce moisture contentCeramic shaping apparatusBattenHigh pressure

The invention discloses a high-performance concrete extrusion partition plate connection member and a preparation method, comprising the following raw materials: cement, gesso, fly ash, quartz sand, mekralon, water reducer, water-retaining agent and water. The raw materials of the connection member, after mixing and stirring, are orderly extruded by a high pressure and vacuum extruder. The partition plate connection member prepared through forming treatment and twice maintenance treatment has high intensity, and an ultimate flexural capacity and compressive strength exceeds a government standard. The connection member has advantages of small drying shrinkage, low expansion and contraction ratio, high distortion-resistant performance, aging resistance, water proof, fire proof and sound insulation. After the connection member is connected with the partition plate, no crack and no shedding are generated between the connection member and the partition plate, and the connection member accords with installation requirement, and reaches requirement of a government standard of lightweight batten for construction (GB / T 23451-2009).

Owner:福建朗创建科新材料有限公司

Production technology of annual ring floor and annual ring wall plate

InactiveCN108789743AIncrease profitAvoid crackingWood treatment detailsProfiling/shaping machinesRing patternPulp and paper industry

The invention belongs to the technical field of building materials, and particularly relates to a production technology of an annual ring floor and an annual ring wall plate. The solid composite floorwith natural annual ring patterns is manufactured through selecting of annual ring wood, air drying of the wood, sectional cutting, drying treatment, manufacturing and bonding of wood cores, manufacturing of a surface plate, bonding of the surface plate and a base material, slotting and painting, the deficiencies in the prior art are overcome, the wood utilization rate is high, the compression resistant effect is good, and cracking is not prone to occurring.

Owner:嘉善奥林木业有限公司

Vinylon/polyester oil harness string production process and product thereof

InactiveCN105063836AHigh breaking strengthSmall stretch rateSucessive textile treatmentsFibre typesWaxPolyester

The invention provides a vinylon / polyester oil harness string production process and a product thereof. The production process comprises the following steps: 1) plying; 2) first twisting; 3) second twisting; 4) winding the plied yarn, which is formed after second twisting and the twisting degree of which is 180-270, by a yarn reeler to form a stranded yarn; 5) carrying out size mixing in a pulp chest; 6) putting the stranded yarn into the mixed size; 7) removing 60-70% of the size in the vinylon / polyester stranded yarn, which is sized, by a dehydrator; 8) carrying out drafting and setting for 15-25 minutes by a yarn waxing machine on the sized stranded yarn; 9) carrying out drying on the stranded yarn obtained through first drafting and setting, the humidity being lower than 3%, and the wax temperature being 90-130 DEG C; and 10) putting the dried stranded yarn into a wax bucket and lifting the stranded yarn after being soaked for 5-10 minutes, and then, carrying out second drafting and setting by the yarn waxing machine. The breaking strength of the vinylon / polyester oil harness string provided in the invention is obviously improved; the ratio of expansion and contraction thereof is reduced; and the friction coefficient is improved by 30%-60%.

Owner:安徽创星实业有限公司

Light partition plates

InactiveCN1274630CSolve the cracking problemAvoid yellowingSolid waste managementPhosphatePhosphoric acid

Owner:刘炳林

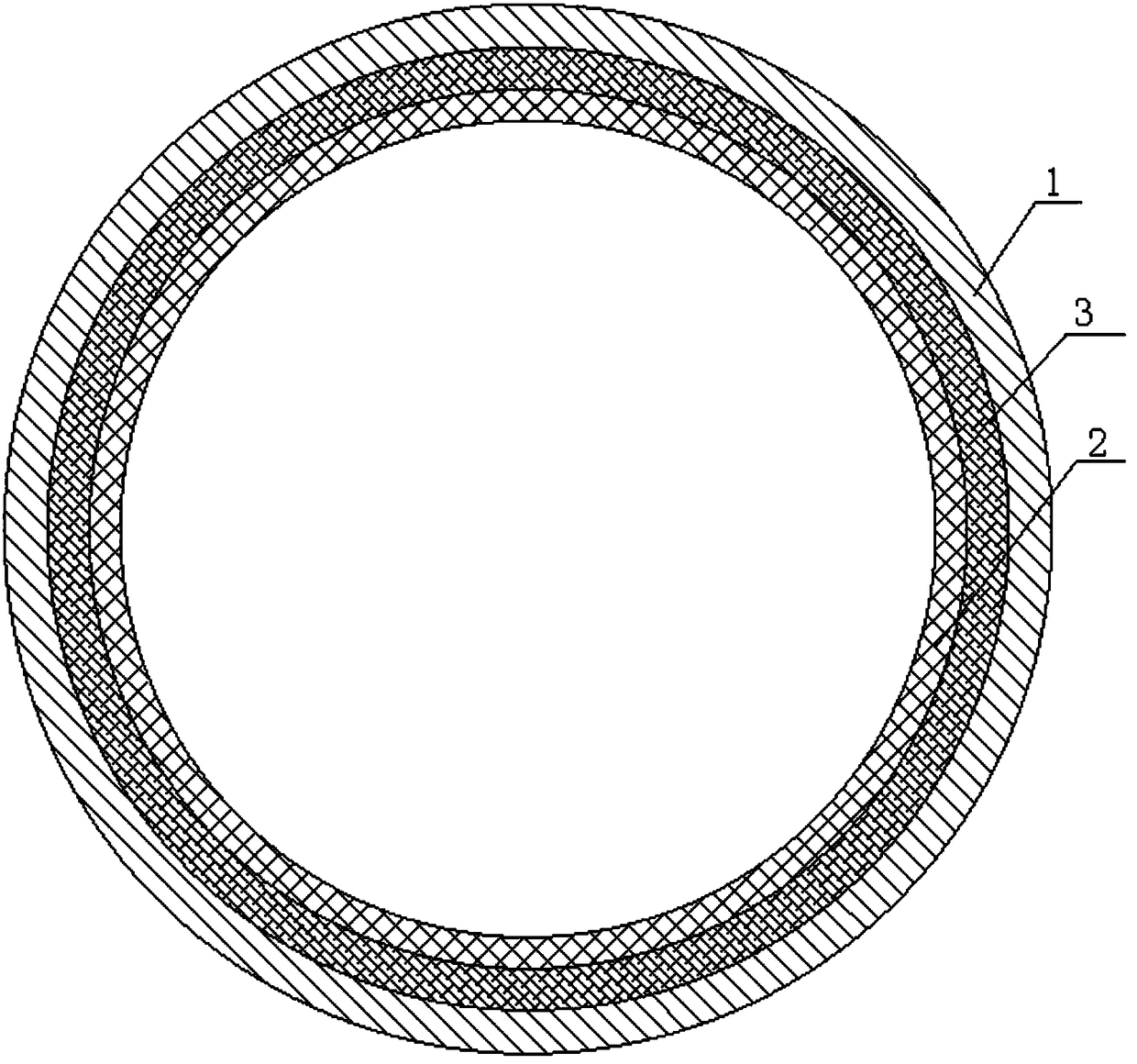

Disposable woven double layer integrated fire hose and manufacture method thereof

InactiveCN108443600AFit closelySmall expansion rateFlexible pipesMulti-ply fabricsEngineeringWear resistance

The invention relates to a fire hose, in particular to a disposable woven double layer integrated fire hose. The disposable woven double layer integrated fire hose comprises an outer layer tube blank,an inner layer tube blank and a woven wire layer; the outer layer tube blank and the inner layer tube blank are synchronously woven and fixed by the woven wire layer between the outer layer tube blank and the inner layer tube blank to form an integration. According to the fire hose, a tube blank consists of the outer layer tube blank and the inner layer tube blank, and the outer layer tube blankand the inner layer tube blank are closely combined together to form an inseparable double layer structure, so that the outer layer tube blank and the inner layer tube blank look like two layers, butare of an integrated structure actually, the goodness of fit is great, and the fire hose prepared by the method has the characteristics of being small in expansion rate and stretching rate and capableof realizing wear resistance, compression resistance and zero waste of bursting force value.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

Vinylon and polyester white harness thread and production method thereof

InactiveCN104975403AHigh breaking strengthSmall stretch rateJacquardsFibre typesBreaking strengthYarn

The invention provides a vinylon and polyester white harness thread and a production method thereof. The production method comprises the following steps: 1) carrying out doubling; 2) carrying out first twisting; 3) carrying out second twisting; 4) winding 240-320 strands subjected to second twisting into a stranded thread by a yarn reeler; 5) mixing size in a size pool; 6) putting the stranded thread in the mixed size; 7) removing 60-70% of size from the sized polyester / vinylon stranded thread by a dehydrator; 8) putting the sized stranded thread on a waxed thread machine to undergo drafting setting for 15-25 minutes, carrying out manual waxing for 2-3 minutes when the dryness of the polyester / vinylon harness thread is 70-80%, and air-drying the thread after the thread comes off the waxed thread machine until the humidity is lower than 3%, thus preparing the vinylon and polyester white harness thread. The vinylon and polyester white harness thread provided by the invention has the advantages that the breaking strength is obviously enhanced; the ratio of expansion and contraction is reduced; the friction coefficient is increased by 30-60%.

Owner:安徽创星实业有限公司

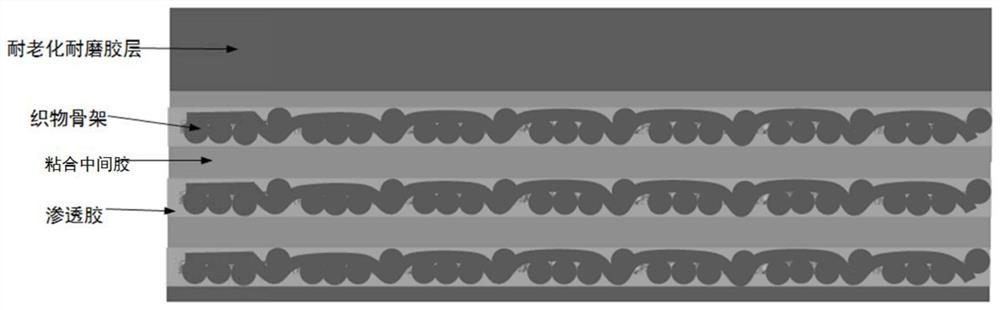

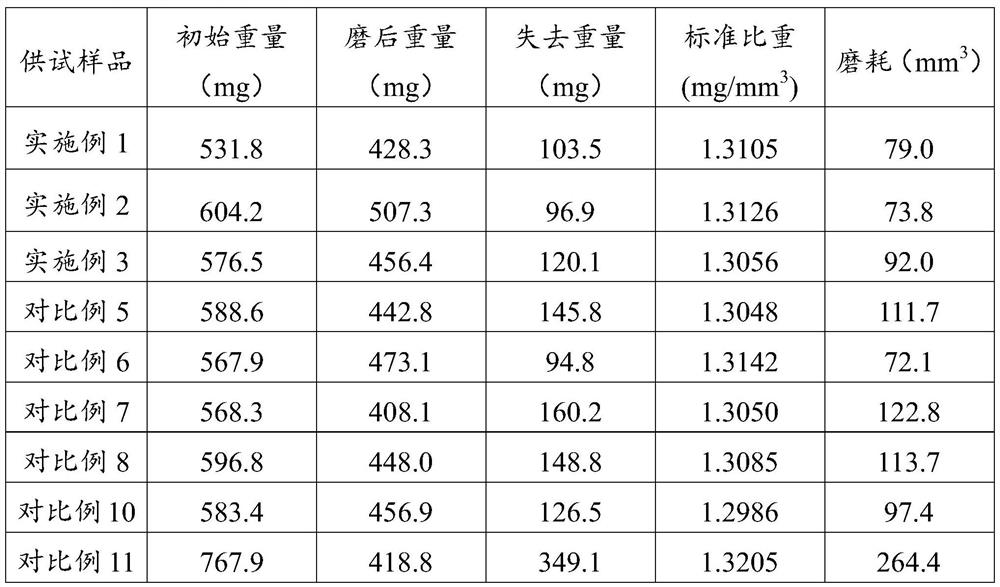

Aging-resistant and wear-resistant light conveying belt and preparation method thereof

InactiveCN111775522AImprove aging resistanceImprove wear resistanceConveyorsSynthetic resin layered productsPolymer sciencePlasticizer

The invention discloses an aging-resistant and wear-resistant light conveying belt which comprises aging-resistant and wear-resistant glue, and the aging-resistant and wear-resistant glue comprises the following components in parts by weight: 100 parts of PVC resin, 30-40 parts of a plasticizer, 20-30 parts of an aging-resistant modifier, 1-2 parts of an organic silicon wear-resistant agent, 4 parts of a heat stabilizer and 3 parts of color paste, Wherein the polymerization degree of the PVC resin is 1800-2200, and the K value of the PVC resin is 60-85. The 1% definite elongation strength of the conveying belt reaches 45 N / mm or above, the elongation is small, the specific gravity of the adhesive layer is low, the conveying belt is made of a thermoplastic material, the aging phenomena of cracking, falling and the like are not likely to happen even if the conveying belt is used in a high-temperature environment, the abrasion resistance is good, and the service life is long.

Owner:江西嘉润良工业皮带有限公司

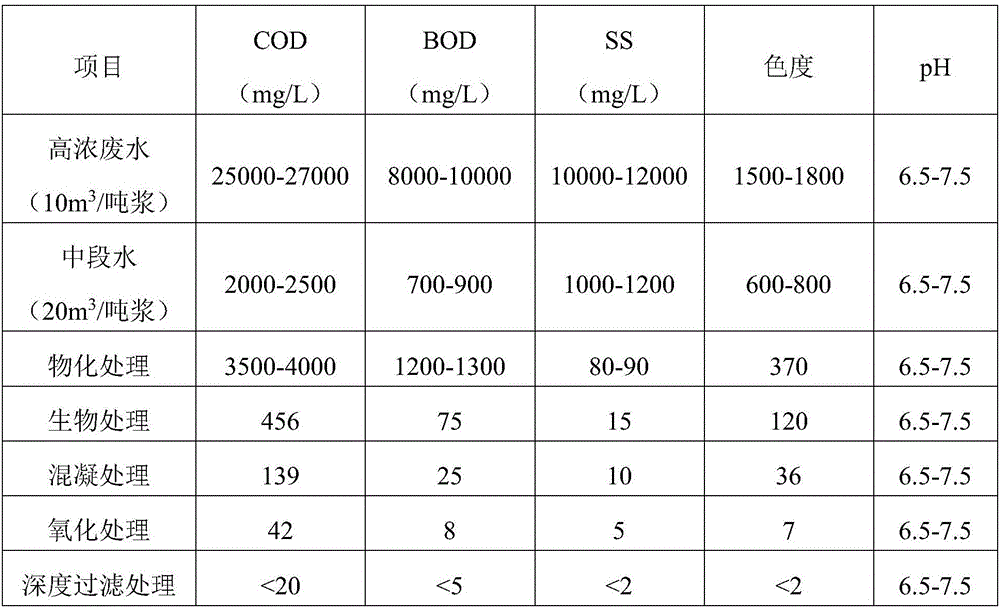

Zero-emission technology for adopting oxidation heat twisting combination method for manufacturing straw pulp

ActiveCN105780563ASave resourcesInhibition of bloomsPulp liquor regenerationTreatment involving filtrationWastewaterHemicellulose

The invention discloses a technology adopting an oxidation heat twisting combination method for manufacturing straw mechanical pulp. The technology comprises the steps that straw is cut off and subjected to ozone treatment; a material subjected to ozone treatment is concentrated; the concentrated material is fed into a compound straw separator to be subjected to first-stage heat twisting; the material subjected to first-stage heat twisting is conveyed into a continuous steamer to be subjected to continuous steaming; the material subjected to continuous steaming is fed into a single straw separator to be subjected to second-stage heat twisting; the material subjected to second-stage heat twisting is conveyed into a latency device to be subjected to ozone oxidation; the material treated through the latency device is conveyed into a disc type separator to be subjected to wire separation and brooming; the material subjected to wire separation and brooming is screened in a low-concentration mode to obtain the straw mechanical pulp. According to the technology for adopting the oxidation heat twisting combination method for manufacturing the straw mechanical pulp, cellulose and hemicellulose are preserved to the greatest extent, and the pulp obtaining rate reaches 80% or above. The technology for manufacturing the straw mechanical pulp further comprises a technological waste water treatment technology, technological water is purified and recycled, and zero emission is achieved.

Owner:朱迅

A kind of diaphragm paper for mercury-free alkaline zinc-manganese battery and preparation method thereof

ActiveCN104631198BImprove densification performanceHigh strengthWater-repelling agents additionPaper coatingManganeseZinc

The invention discloses diaphragm paper for a mercury-free alkaline zinc-manganese dioxide cell, and a preparation method of the diaphragm paper, and belongs to the technical field of fiber-containing paper and a preparation method thereof. A sizing agent comprises the following raw materials in parts by weight: 40-55 parts of superfine nylon fibers, 25-35 parts of tencel fibers and 20-30 parts of pulp fibers; the sizing agent is prepared by dispersing a dispersing agent by adopting a papermaking machine wet-process papermaking technology. The three types of fibers are mixed to prepare an alkaline zinc-manganese dioxide cell diaphragm, so that not only can the physical strength performance of the diaphragm paper be improved and the relatively good alkaline absorption performance can be guaranteed; due to the improvement of the strength of the diaphragm paper, the usage amount of the sizing agent can be properly reduced, so that the quantitation and the thickness fluctuation of the diaphragm paper can be favorably stabilized, and thus guarantee for meeting the use of the mercury-free alkaline zinc-manganese dioxide cell can be provided.

Owner:浙江鹏辰造纸研究所有限公司

New material for road base layer

InactiveCN1440945AHigh compressive strengthIncrease elasticityRoadwaysSolid waste managementFirming agentWater resistant

The present invention relates to road building material and is especially a kind of new material for road base layer. The material consists of flyash 65-95 wt%, lime 4-30 wt% and cure agent 0.5-5 wt%; and the cure agent consists of carbonate, chlorate, NaAlO3, MgFSi and Na3SiO3.XH2O. It meets the requirement of protecting environment, has high strength and low cost, and is water resistant and acid and alkali resistant.

Owner:中国民用航空学院

Reflector plate with different viscosity on double faces

InactiveCN106556950ARemovable stickersImprove wrinkle resistanceMountingsNon-linear opticsWrinkle skinCooling effect

The invention provides a reflector plate with different viscosity on double faces. The reflector plate comprises a base material, a silver coating is arranged at one side of the base material, and a graphite layer is arranged at the other side of the base material; the silver coating is coated with a thin adhesive layer, and the graphite layer is coated with a thick adhesive layer. The reflector plate with different viscosity on double faces can be applied to the lower part of a display screen, and has excellent characteristics that the reflector plate can be torn and pasted repeatedly, and is good in wrinkle resistance, low in ratio of expansion and contraction, and good in reflection effect and cooling effect, and is insulated and the like.

Owner:SHANGHAI YAOJIA INFORMATION TECH

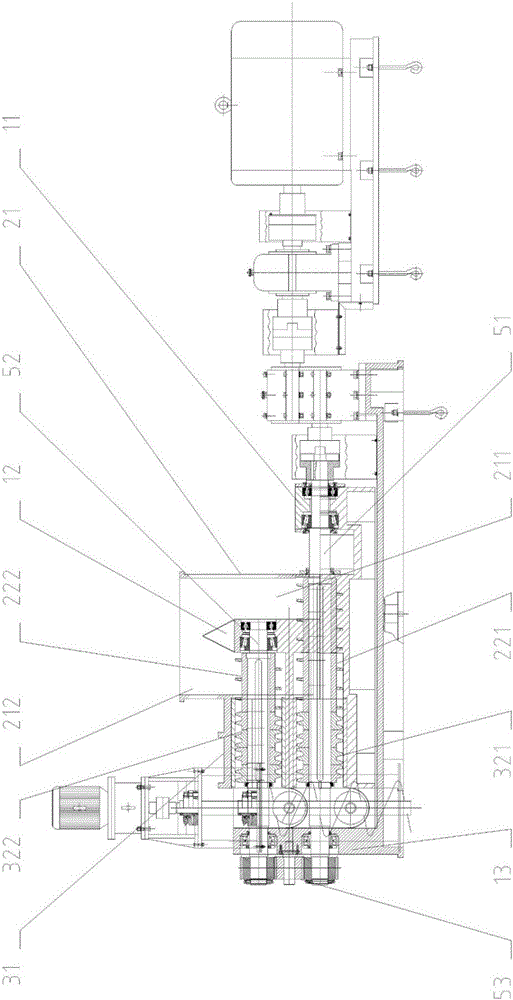

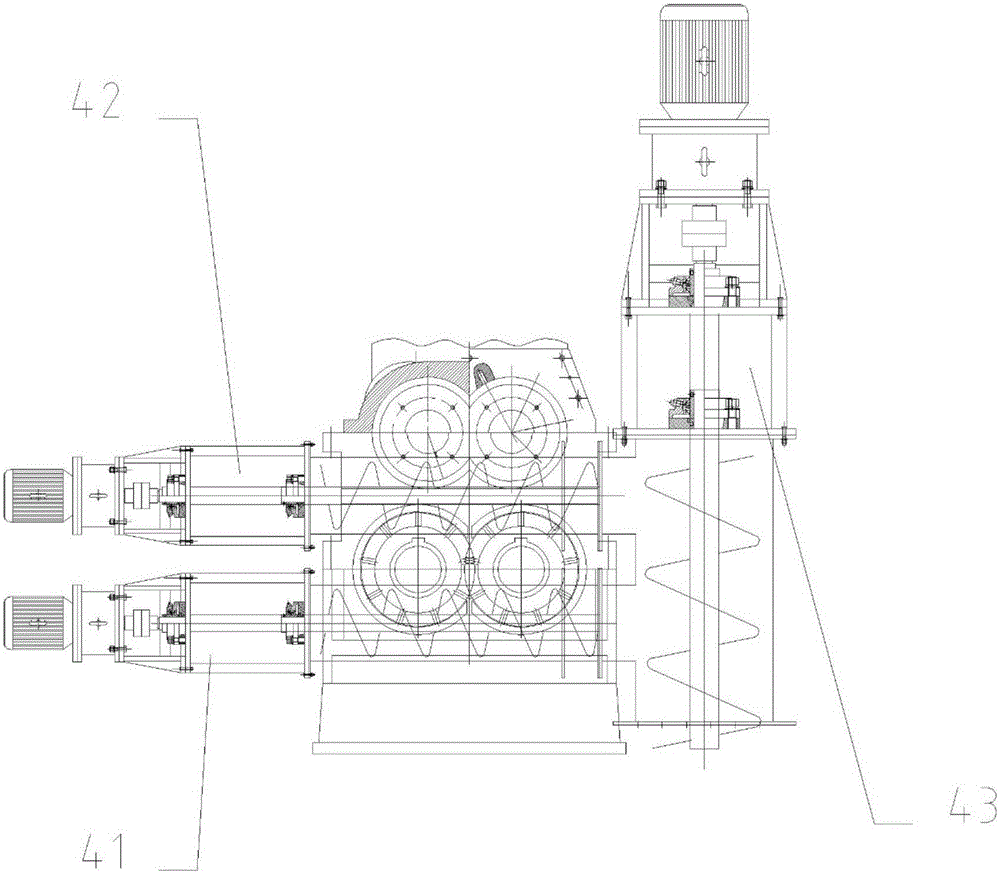

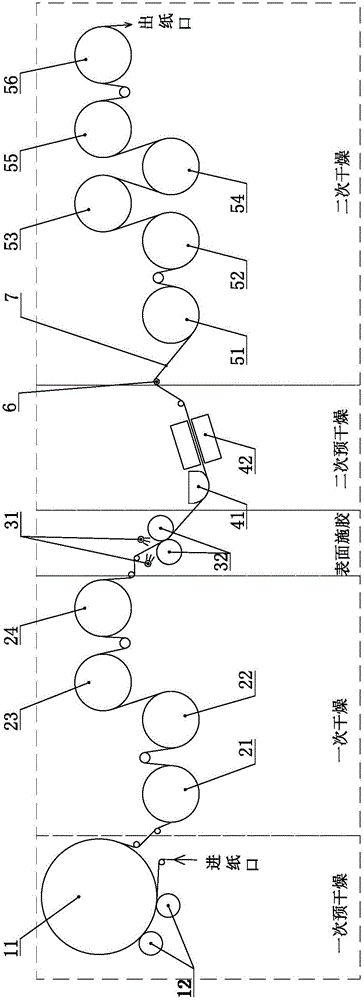

Drying equipment and drying process applied to thermal dye sublimation body paper

The invention discloses drying equipment and a drying process applied to thermal dye sublimation body paper. The drying equipment sequentially comprises a primary pre-drying unit, a primary drying unit, a surface gluing unit, a secondary pre-drying unit and a secondary drying unit along the advancing method of paper, the primary pre-drying unit comprises a big dryer and a plurality of supporting rollers arranged on the outer side of the big dryer, the primary drying unit comprises a plurality of first small dryers, the secondary pre-drying unit comprises a drying box, and the secondary drying unit comprises a plurality of second small dryers and a cooler which are arranged sequentially along the advancing direction of the paper. Primary pre-drying and secondary pre-drying are added before primary drying and secondary drying respectively, and the big dryer is adopted for primary pre-drying, so that through strong drying of the big dryer, expanding and contracting ratio of the paper is lowered effectively, and influence on smoothness of the paper due to scrapings caused by the fact that undried glue is bonded to a drying net and the dryers is avoided.

Owner:SHANDONG TIANYANG PAPER

Surface moisture resisting agent for base paper, production method of surface moisture resisting agent and application of surface moisture resisting agent in papermaking

InactiveCN109826050AImprove bindingHigh compressive strengthWater-repelling agents additionPaper coatingPapermakingSizing

The invention relates to a surface moisture resisting agent for base paper, a production method of the surface moisture resisting agent and application of the surface moisture resisting agent in papermaking, and relates to the technical field of papermaking surface sizing. The solid content of the moisture resisting agent is 9-11%, and the moisture resisting agent is prepared from, by mass, 20-25%of a cationic polyacrylamide starch polymer and 5-15% of a styrene-acrylic or AKD surface sizing agent. The moisture resisting agent is obtained through the following steps that 1, hydroxyacrylamidemonomer, third monomer and hydrolyzed starch are polymerized, and a cationic polyacrylamide starch polymer is obtained; 2, the polyacrylamide starch polymer is mixed with the styrene-acrylic or AKD surface sizing agent, and a final product moisture resisting agent for the base paper is obtained. The moisture resisting agent for the base paper not only has the advantages of improving the ring crushstrength of the base paper and resisting damping, but also has the advantages of enhancing high temperature, high humidity and high cold resistance of the base paper. Zero emission of the chlorine content is achieved, the surface moisture resisting agent is environmentally friendly, the production method is easy to implement, the cost is low, and the surface moisture resisting agent is especiallysuitable for industrial production.

Owner:湖北中之天科技股份有限公司 +1

Manufacturing technology of polyvinyl-polyester hook wire

InactiveCN105155078AHigh breaking strengthSmall stretch rateJacquardsFibre typesPolyesterBreaking strength

The invention provides manufacturing technology of a polyvinyl-polyester hook wire. The manufacturing technology comprises the follow steps : 1) performing wire merging; 2) performing first twisting; 3) performing second twisting; 4) winding the twisted compound wire, the twist degree of which is 180-270, into a stranded wire with a yarn reeler; 5) performing slurry mixing in a slurry pool; 6) putting the stranded wire into the adjusted slurry; 7) removing 60-70% of slurry from the sized polyvinyl / polyester compound wire with a dehydrator; and 8) performing drawing setting of the sized compound wire through a wire waxing machine for 15-25 min, when the dryness of the obtained polyvinyl / polyester harness wire reaches 70-80%, performing manual waxing for 2-3 min, and performing air-drying after the wire passes through the wire waxing machine till the humidity is less than 3% to prepare the polyvinyl-polyester hook wire. The prepared polyvinyl-polyester hook wire is obviously enhanced in breaking strength, and reduced in expansion and contraction, and the friction coefficient is raised by 30-60%.

Owner:安徽创星实业有限公司

The process of processing floors with annual ring patterns

ActiveCN103978535BIncrease profitAvoid crackingNatural patternsWood compressionSolid woodState of art

The invention discloses a technology for processing a floor with special patterns. The technology belongs to the field of processing or storing technology of woods or other similar materials. Particularly, the invention relates to a technology for processing the floor with special patterns, in particular to a processing technology for a floor with annual rings. The invention aims at solving the problem and making up the shortcomings of the prior art and provides the technology for processing the floor with special patterns. The technology has the advantages of being high in utilization rate of wood, good in compression resistance and not easy to crack. The technology method includes that step 1, a board with special patterns is selected; step 2, the board with special patterns is fabricated; step 3, splint wood is fabricated; step 4, a solid wood floor or a solid wood composite floor is fabricated.

Owner:辽宁卓艺木业有限公司

Sheet material with three-layer structure and clothes comprising sheet material

ActiveCN106903947AStrong abrasion resistanceImprove radiation protection performanceSynthetic resin layered productsClothingsSurface layerPolymer coatings

The invention provides a sheet material with a three-layer structure and clothes. The sheet material comprises a first surface layer, a middle layer and a second surface layer which are sequentially arranged, the first surface layer is a macromolecule fiber layer plated with first metal, the middle layer is a macromolecule fiber layer plated with second metal, and the second surface layer is a water-tolerance macromolecule polymer coating. The sheet material is a light soft material, particularly applicable to military fields such as military operation command tents, anti-electromagnetic shielding clothes and electromagnetic shielding rooms and the fields such as aviation, aerospace and offshore wild rescue and used for military electronic countermeasures, military false targets and has electromagnetic shielding effects on 90db or more.

Owner:青岛天银纺织科技有限公司

A fourdrinier multi-cylinder paper machine for producing high-filler paper

InactiveCN103669097BEnhanced effect of low vacuum dehydrationIncrease the number ofDryer sectionMachine wet endPaper sheetDehydration

The invention discloses a multi-cylinder long mesh paper machine used for producing high-filler paper. Compared with a traditional multi-cylinder long mesh paper machine with the same width and the same speed, the whole multi-cylinder long mesh paper machine is 8-25 meters longer, the mesh portion is 4-6 meters longer, the front drying system portion is 5-15 meters longer, and the rear drying system portion is 1-1.5 meters longer. Accordingly, corresponding structures are changed, the problem that the traditional paper machine can not manufacture cultural paper which meets the standards through high-filler paper pulp is solved, and the multi-cylinder long mesh paper machine has the advantages of being long in dehydration time, high in dehydration efficiency, good in dehydration quality, low in investment, good in drying effect and high in paper product quality.

Owner:GUONENG PAPER IND +1

A kind of polymer packing belt material and preparation method thereof

The invention belongs to the field of the packing materials and relates to a polymer packing belt material. The polymer packing belt material is composed of the following components in parts by weight: 3-10 parts of 4-methyl-1-amylene, 4-9 parts of 2-hexene-1-alcohol, 9-17 parts of polystyrene, 7-12 parts of polyethylene, 4-7 parts of polyester fiber, 2-6 parts of pentaerythritol and 5-8 parts of stearic acid. The preparation method comprises the steps of mixing, squeezing, molding, winding and the like. As the components of the packing belt material are reasonably optimized and the 4-methyl-1-amylene and the 2-hexene-1-alcohol are added, the tensile strength of the packing belt material is effectively and remarkably improved to the range from 213MPa to 245MPa, and the elongation at break is relatively low; the polymer packing belt material is only 65% to 74%, and thus has relatively low deformation and small shrinkage ratio under external pressure.

Owner:CHONGQING KNVAN ELECTRONICS

Paper with nano structural surface possessing characters of super hydrophobicity and self-cleaning

InactiveCN1182297CAchieve the purpose of self-cleaningSmall stretch rateWater-repelling agents additionImpressionabilityEthyl ester

An ultrahydrophobic self-cleaning paper with nano surface structure is made up by using silica gel (703,704, or 705), ethyl acetate, n-butyl acetate and banana oil to prepare an ultrahydrophobic self-cleaning nano layer on the surface of ordinary paper. Its advantages are high impressionability and writability, high water-proof and self-cleaning function.

Owner:HUAZHONG NORMAL UNIV

Manufacturing method of high-strength abrasion-resisting vinylon harness cords

InactiveCN105019087AHigh breaking strengthImprove wear resistanceFibre typesYarnBreaking strengthFrictional coefficient

A manufacturing method of high-strength abrasion-resisting vinylon harness cords comprises the following steps of 1 doubling, 2 primary twisting, 3 secondary twisting, 4 stranding, 5 pulp mixing and dyeing in a pulp chest, 6 dehydration, 7 first-time drafting and setting and air drying and 8 second-time drafting and setting, wherein the humidity is lower than 3% through first-time drafting and setting and air drying. The breaking strength of the vinylon harness cords manufactured by means of the manufacturing method is remarkably improved, the abrasion resistance is improved, the ratio of expansion and contraction is reduced, and a frictional coefficient is improved by 30% to 60%.

Owner:安徽创星实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com