Aging-resistant and wear-resistant light conveying belt and preparation method thereof

A light conveyor belt, anti-aging technology, applied in the field of conveyor belts, can solve the problems of poor aging resistance and wear resistance, large elongation of rubber conveyor belts, pollution of products and the environment, etc., to achieve excellent aging resistance and wear resistance , not easy to crack and fall off, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

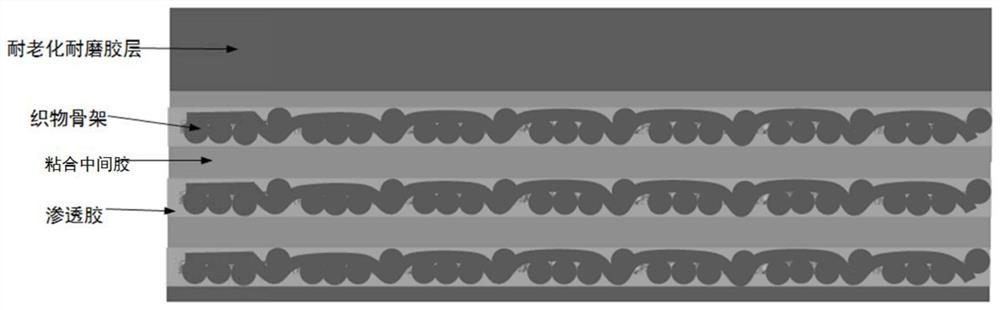

[0041] A light-duty conveyor belt resistant to aging and wear, which includes aging and wear-resistant glue, fabric skeleton, penetrating glue and bonding intermediate glue, wherein:

[0042] Such as figure 1 As shown, the fabric skeleton is woven from 1500D industrial polyester filament (warp yarn) and 2000D industrial polyester filament (weft yarn) by 1 / 3 plain weave method.

[0043] The aging-resistant and wear-resistant glue includes the following components in parts by weight: 100 parts of PVC resin, 35 parts of plasticizer, 25 parts of adipic acid polyester, 1.5 parts of silicone elastomer, 4 parts of heat stabilizer and 3 parts of color paste.

[0044] The penetration glue includes the following components in parts by weight: 100 parts of PVC resin, 12 parts of filler, 55 parts of plasticizer, 13 parts of polyisocyanurate and 4 parts of heat stabilizer.

[0045] The adhesive intermediate rubber comprises the following components by weight: 100 parts of PVC resin, 12 pa...

Embodiment 2

[0065] A light-duty conveyor belt resistant to aging and wear, which includes aging and wear-resistant glue, fabric skeleton, penetrating glue and bonding intermediate glue, wherein:

[0066] Fabric skeleton is with embodiment 1.

[0067] The aging-resistant and wear-resistant glue includes the following components in parts by weight: 100 parts of PVC resin, 30 parts of plasticizer, 30 parts of adipic acid polyester, 2 parts of silicone elastomer, 4 parts of heat stabilizer and 3 parts of color paste.

[0068] The penetration glue includes the following components in parts by weight: 100 parts of PVC resin, 15 parts of filler, 60 parts of plasticizer, 15 parts of polyisocyanurate and 4 parts of heat stabilizer.

[0069] The adhesive intermediate glue comprises the following components by weight: 100 parts of PVC resin, 15 parts of filler, 60 parts of plasticizer, 4 parts of heat stabilizer and 3 parts of color paste.

[0070] The preparation method of conveyor belt is the sam...

Embodiment 3

[0072] A light-duty conveyor belt resistant to aging and wear, which includes aging and wear-resistant glue, fabric skeleton, penetrating glue and bonding intermediate glue, wherein:

[0073] Fabric skeleton is with embodiment 1.

[0074] The aging-resistant and wear-resistant glue includes the following components in parts by weight: 100 parts of PVC resin, 40 parts of plasticizer, 20 parts of adipic acid polyester, 1 part of silicone elastomer, 4 parts of heat stabilizer and 3 parts of color paste.

[0075] The penetration glue comprises the following components in parts by weight: 100 parts of PVC resin, 10 parts of filler, 50 parts of plasticizer, 10 parts of polyisocyanurate and 4 parts of heat stabilizer.

[0076] The adhesive intermediate rubber comprises the following components in parts by weight: 100 parts of PVC resin, 10 parts of filler, 50 parts of plasticizer, 4 parts of heat stabilizer and 3 parts of color paste.

[0077] The preparation method of conveyor belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com