Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

282results about "Closed loop articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

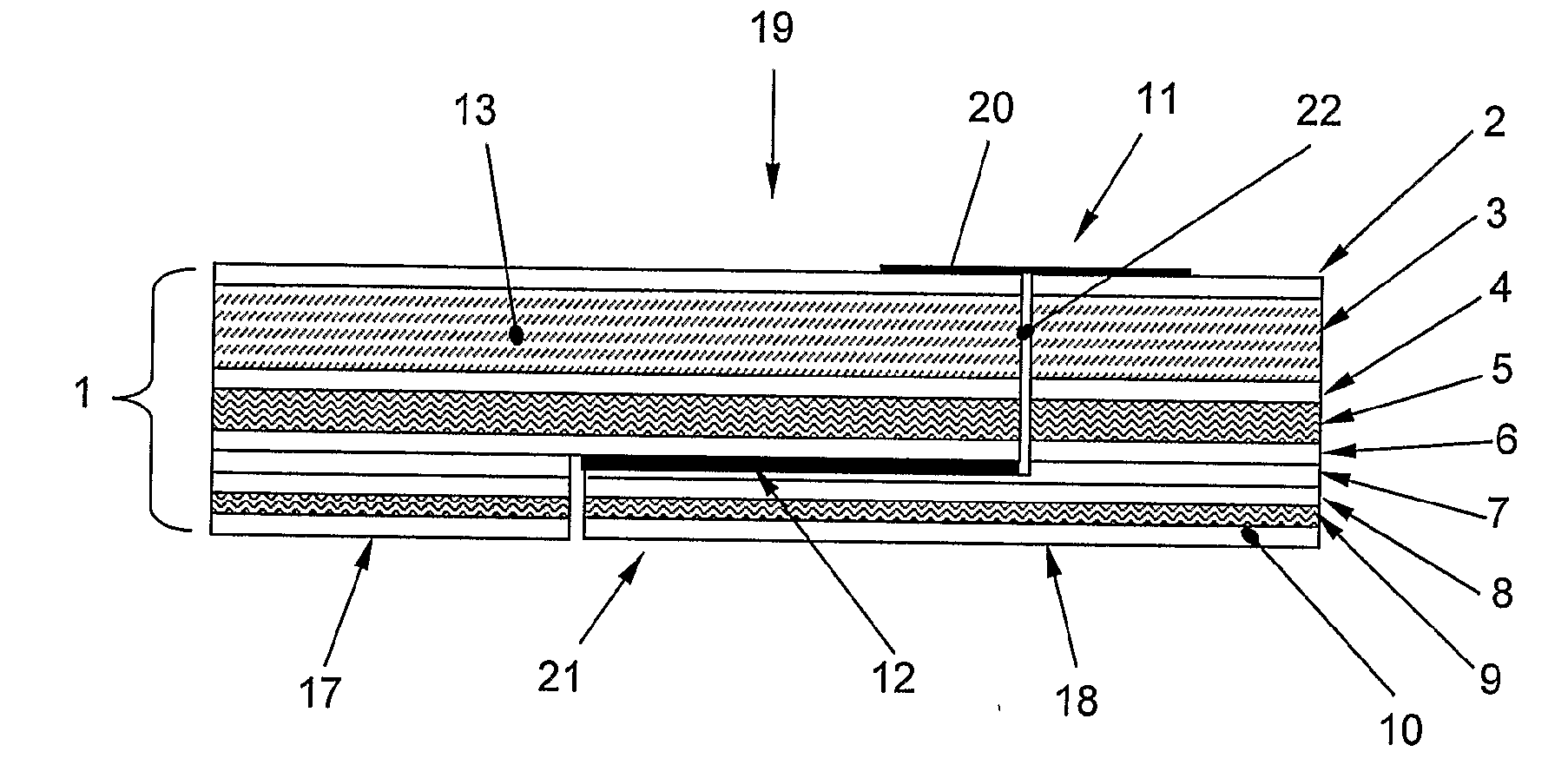

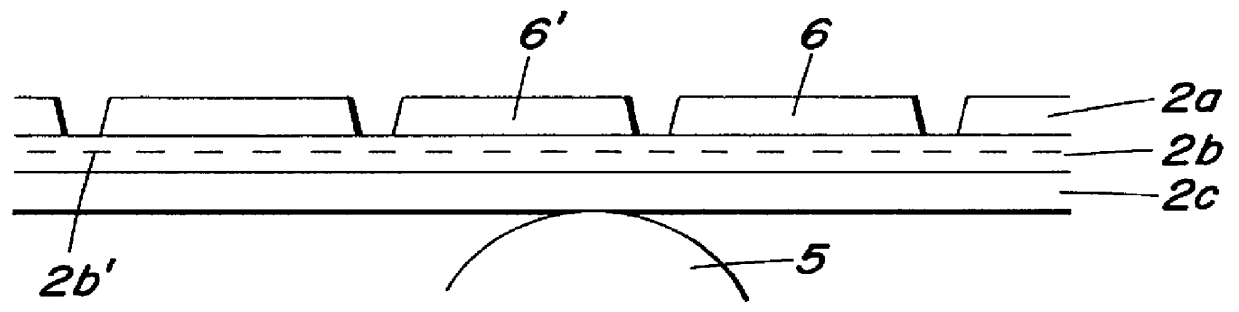

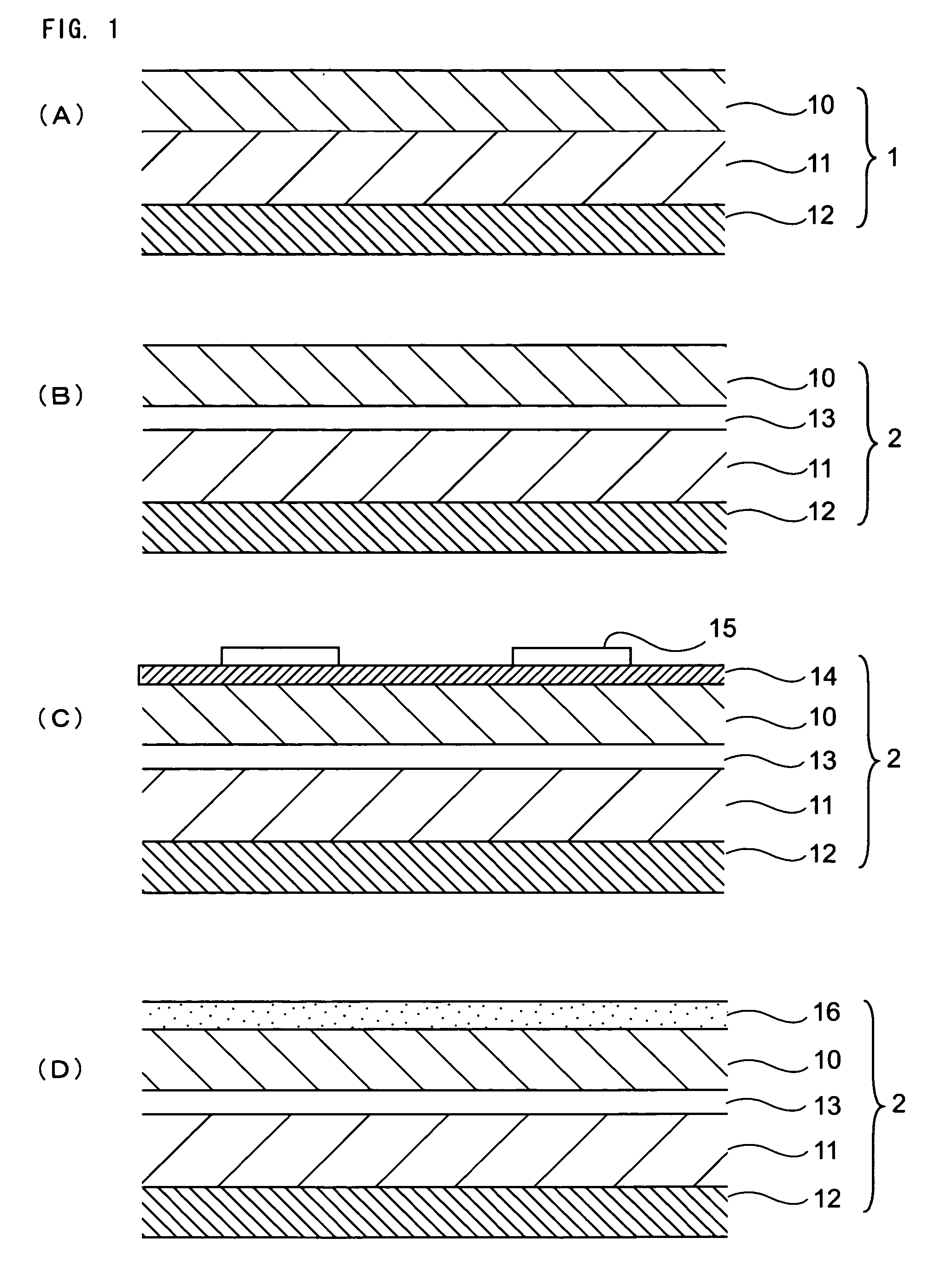

Multi-layered belt

InactiveUS20090098385A1Reliable and durable mechanical propertyReduce stress exertedConveyorsSynthetic resin layered productsEngineeringLeather belt

A multi-layered belt, in particular a continuous running and / or transport and / or processing belt, includes a traction layer and a functional layer that contains a gel. To reduce the stress placed on the transported goods, in particular persons, the gel is an unplasticized gel and the functional layer consist of a coating containing the interspersed gel. In addition, to a method for producing a belt of this type is provided, in which the gel is poured in a continuous method onto the traction layer and a mixer and delivery unit is guided back and forth in a reversible manner perpendicular to the displacement direction of the traction layer in such a way that a gel layer with a uniform thickness is applied to the traction layer. Furthermore, the use of said belt as a running belt for persons, in particular as a running belt for training and / or fitness equipment is described.

Owner:FORBO SIEGLING +1

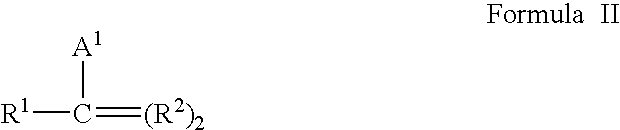

Multilayer structures

InactiveUS20050106965A1Domestic upholsteryPedestrian/occupant safety arrangementAlkeneOrganic chemistry

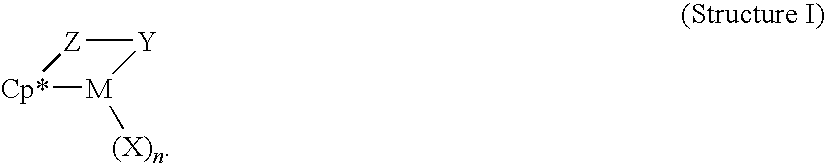

A multilayer structure comprising (A) a fabric and (B) a polymeric layer comprising a substantially random interpolymer comprising in polymerized form i) one or more α-olefin monomers and ii) one or more vinyl or vinylidene aromatic monomers and / or one or more sterically hindered aliphatic or cycloaliphatic vinyl or vinylidene monomers, and optionally iii) other polymerizable ethylenically unsaturated monomer(s); layer (B) being free from a substantial amount of tackifier. The multilayer structure has desirable haptics and surprisingly good drape properties. It is useful in many applications, for example as water-impermeable clothes, tablecloths, tents, water-impermeable covers, curtains, artificial leather or upholstery.

Owner:WEVERS RONALD +8

Non-curling reinforced composite membranes with differing opposed faces, methods for producing and their use in varied applications

InactiveUS20050170722A1Improve performanceConveyorsSynthetic resin layered productsGlass compositesIndependent function

A double-faced PTFE-silicone rubber reinforced composite with curling tendency controlled is achieved by coating one side of a balanced PTFE / glass composite with liquid silicone rubber. Each face of the composite can perform independent functions in a single application, thereby optimizing performance.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Non-curling reinforced composite membranes with differing opposed faces, methods for producing and their use in varied applications

InactiveUS6930063B2Improve performanceConveyorsSynthetic resin layered productsGlass compositesPolymer science

A double-faced PTFE-silicone rubber reinforced composite with curling tendency controlled is achieved by coating one side of a balanced PTFE / glass composite with liquid silicone rubber. Each face of the composite can perform independent functions in a single application, thereby optimizing performance.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

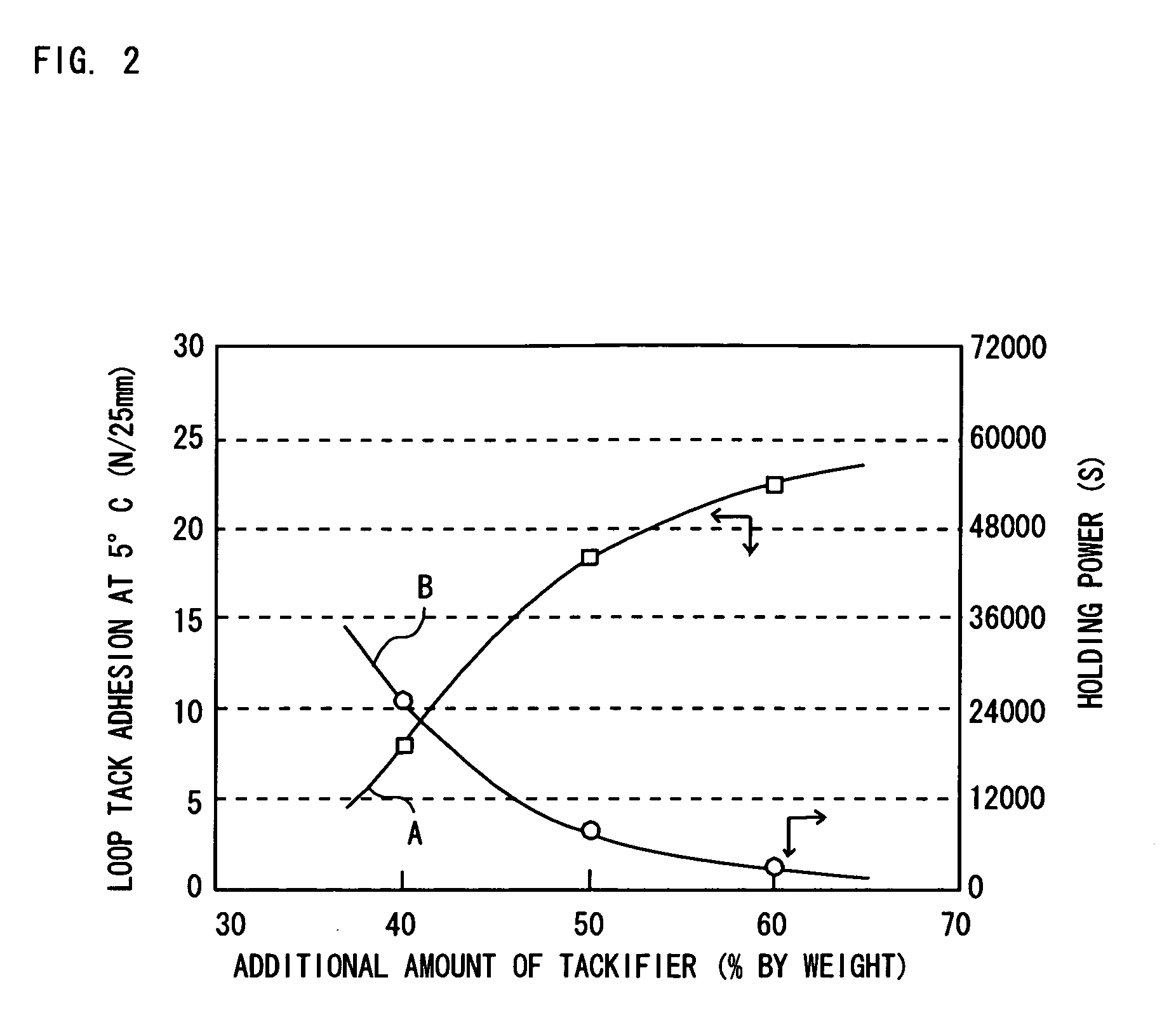

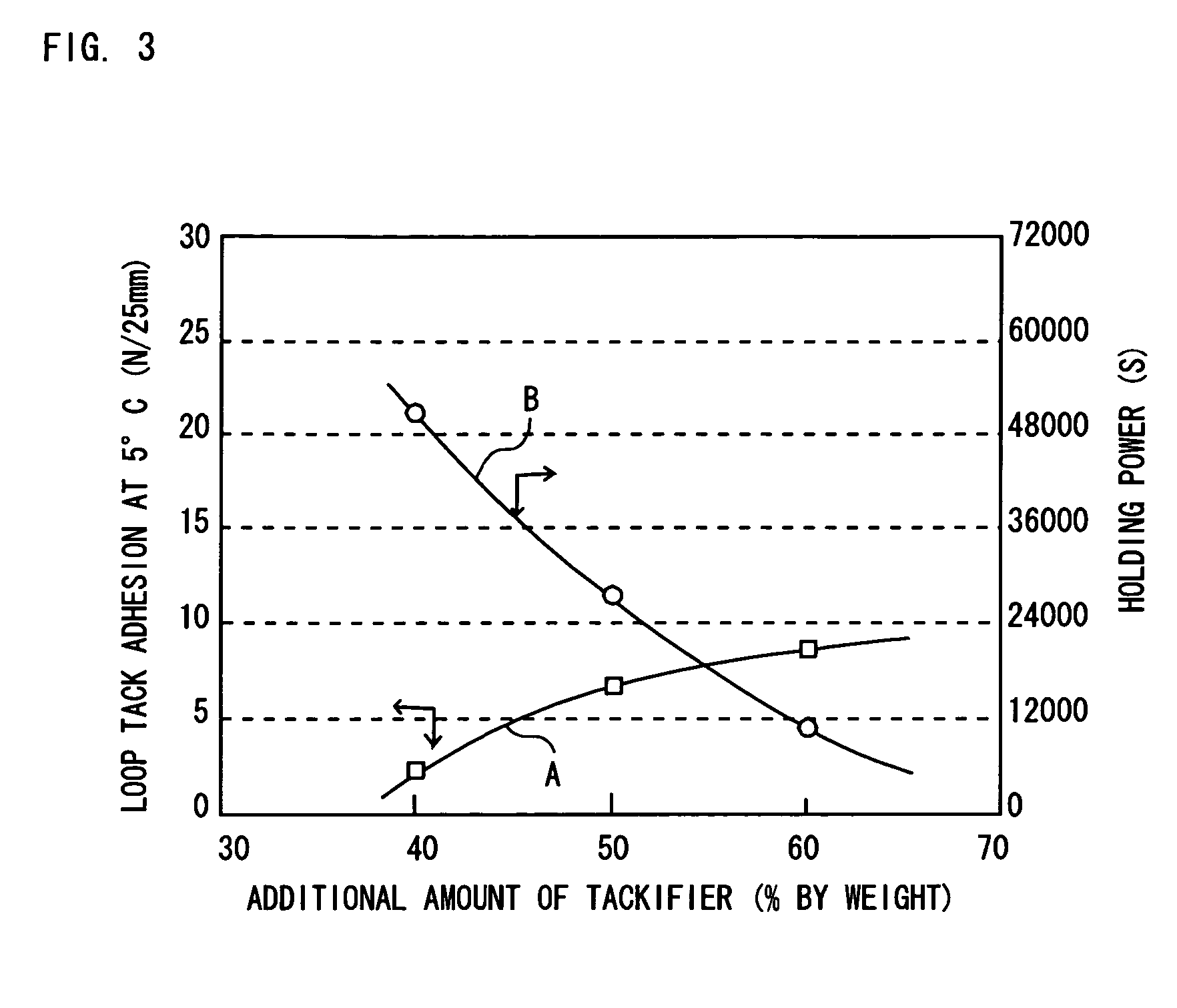

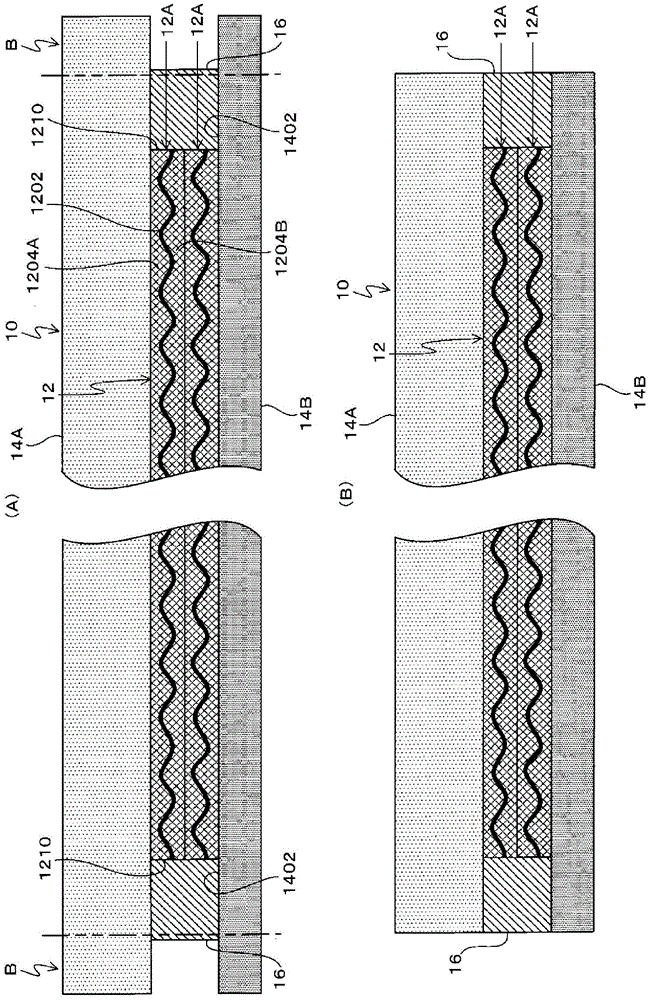

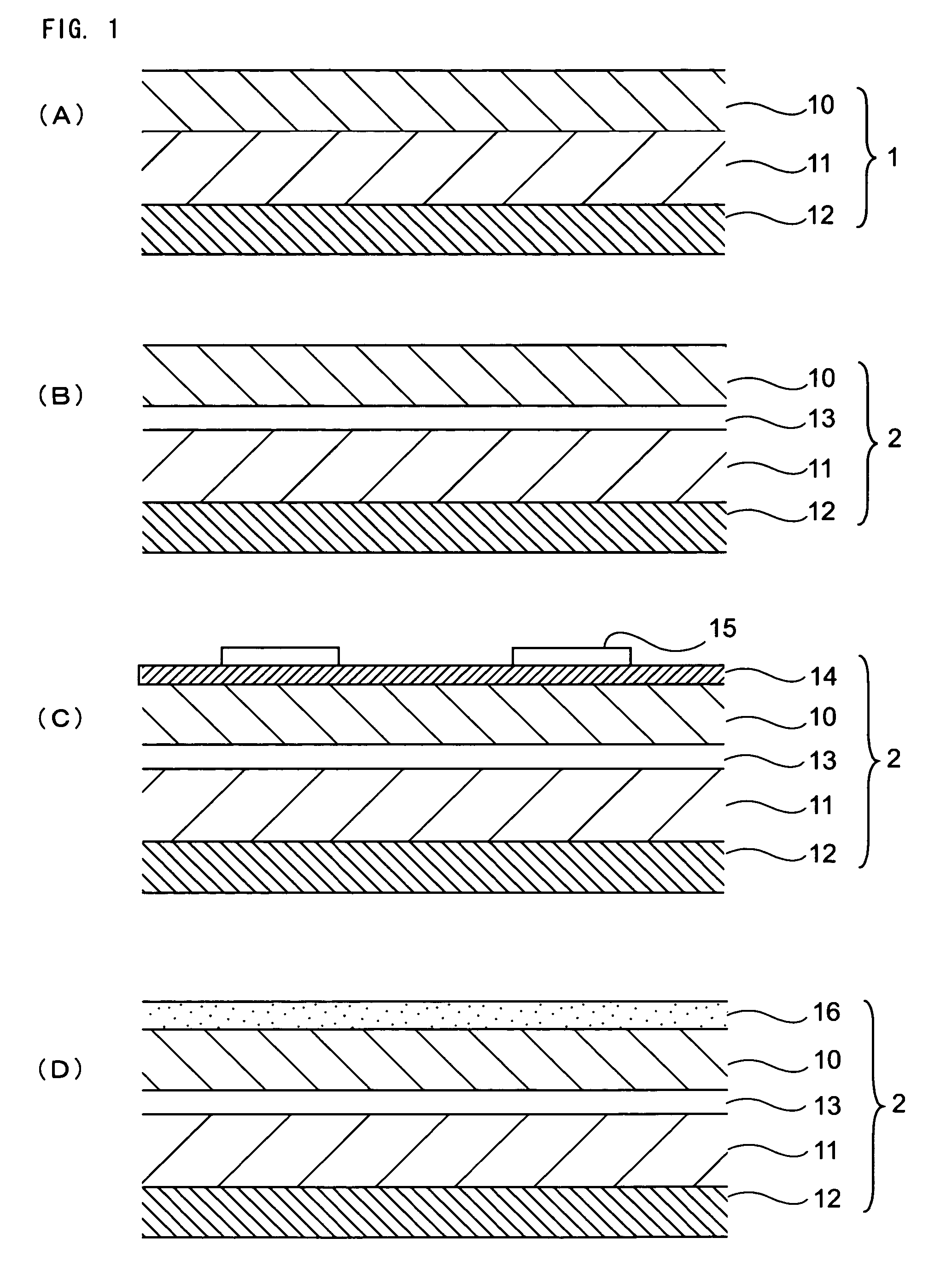

Laminate and pneumatic tires made by using the same

A laminate of an air permeation preventive layer an adhesive layer provided with an air permeation preventive layer comprising a thermoplastic elastomer composition containing a thermoplastic resin as a continuous phase and a rubber composition dispersed therein as a dispersed phase and arranged on one surface of the air permeation preventive layer, an adhesive composition layer having a thickness of 100 μm or less, a self tack of less than 5N and a tack to an unvulcanized diene-based rubber or 5N or more, containing 100 parts by weight of a thermoplastic elastomer containing 50 parts by weight or more of an epoxy-modified styrene-butadiene-based block copolymer so that a total of 30 to 200 parts by weight of a terpene resin and an aromatically modified terpene resin having a weight average molecular weight Mw of 1000 or less and a softening point of 60 to 120° C., 0.1 to 3 parts by weight of an internal mold release agent and 0.1 to 2 parts by weight of an organic peroxide.

Owner:YOKOHAMA RUBBER CO LTD

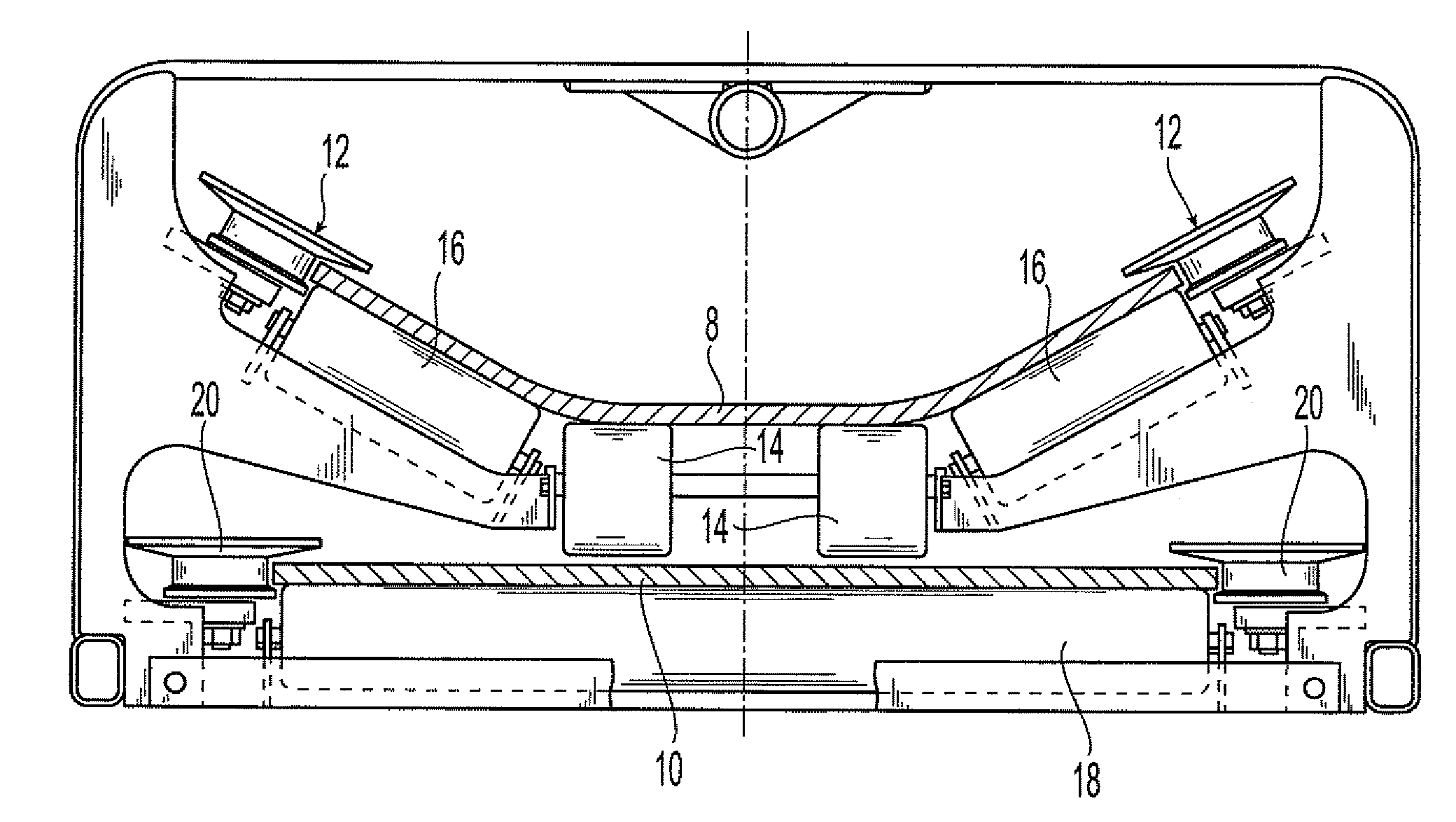

Conveyor belt construction

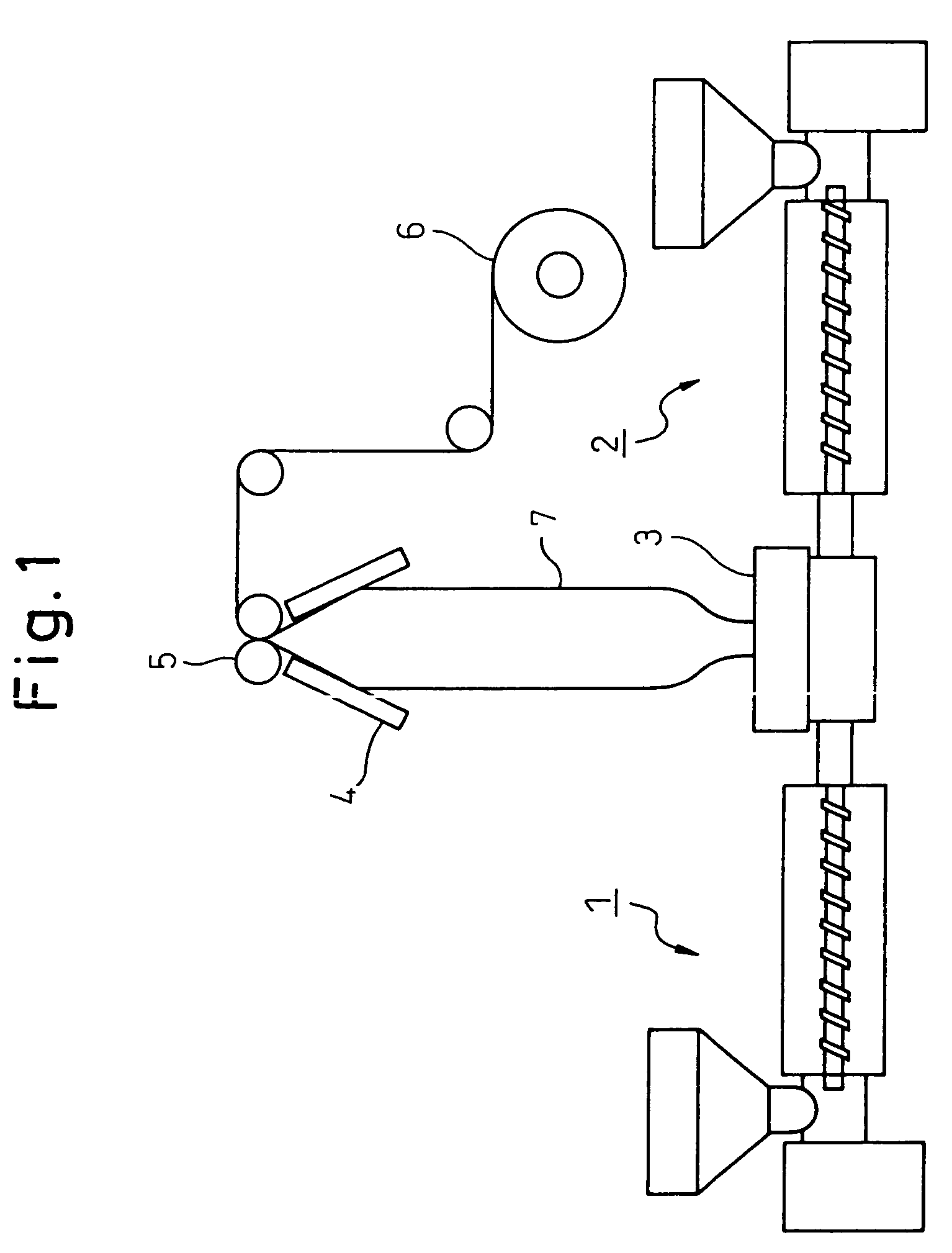

PCT No. PCT / SE96 / 01085 Sec. 371 Date Mar. 24, 1998 Sec. 102(e) Date Mar. 24, 1998 PCT Filed Sep. 2, 1996 PCT Pub. No. WO97 / 09252 PCT Pub. Date Mar. 13, 1997A conveyor belt intended for use as an endless conveyor path in a materials transporting system includes an upper ply, a load-absorbing intermediate ply, and a lower ply that provides wear protection against one or more belt supporting devices. The intermediate ply includes a load-absorbing fabric. The upper ply provides protection against wear by transported goods. The upper ply has at least one of sufficient softness and formfactor to take up shear forces acting in the belt, the shear forces being caused by a load exerted on the belt by the goods transported thereby upon retardation and acceleration of the belt and also by coaction of the belt with the belt supporting devices. The conveyor belt is an endless conveyor path for one or more paper rolls. The conveyor belt is positioned flush with a surrounding floor surface. The upper ply is in abutment with the paper roll and has at least one of elastic properties, hardness and thickness to be able to take-up acceleration and retardation forces acting between the belt and an outer layer of the paper roll without appreciable stretching of material in the upper ply. The upper ply includes an elastic layer covered with an outer, less elastic material.

Owner:WAHREN BERTIL

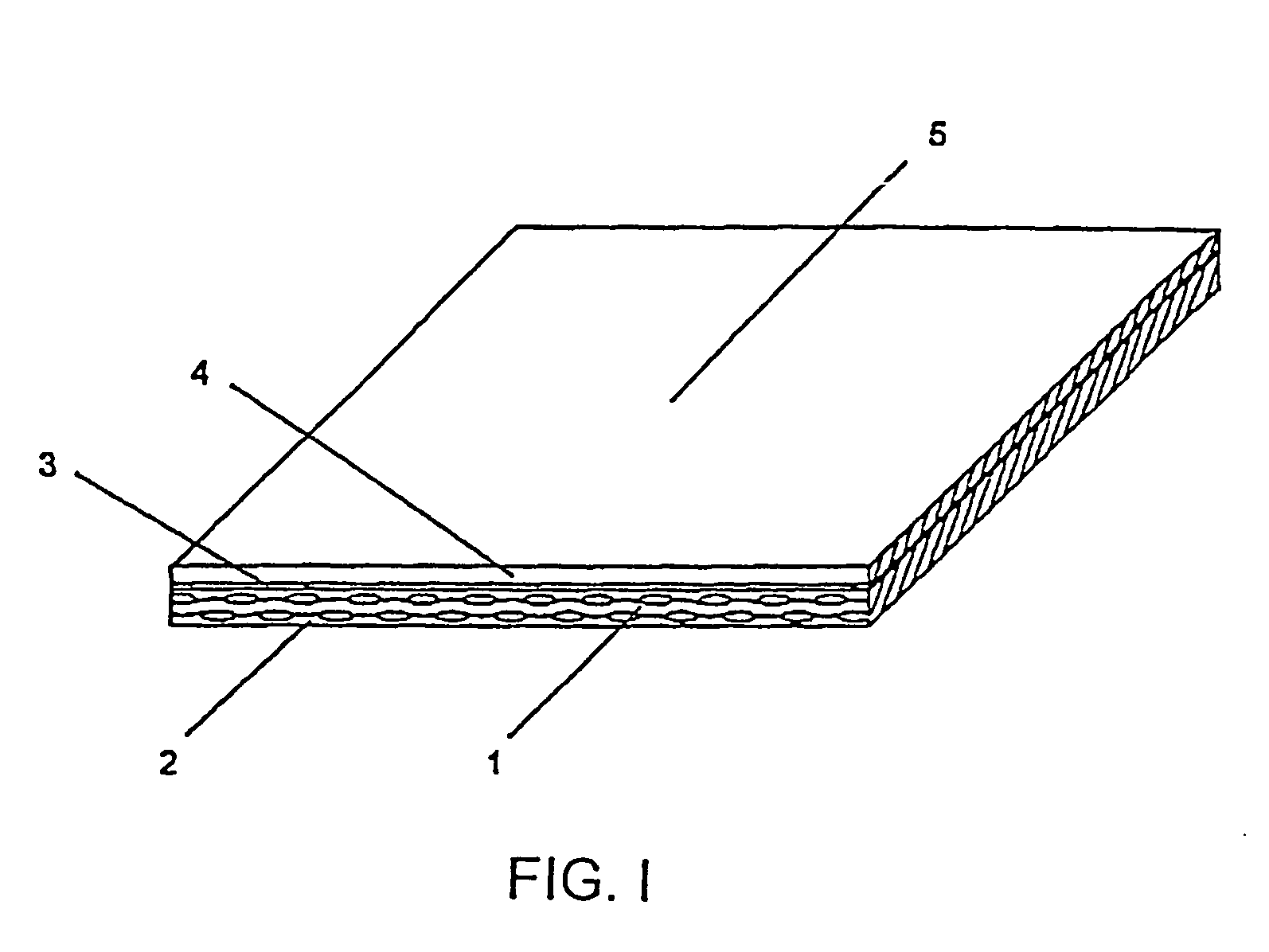

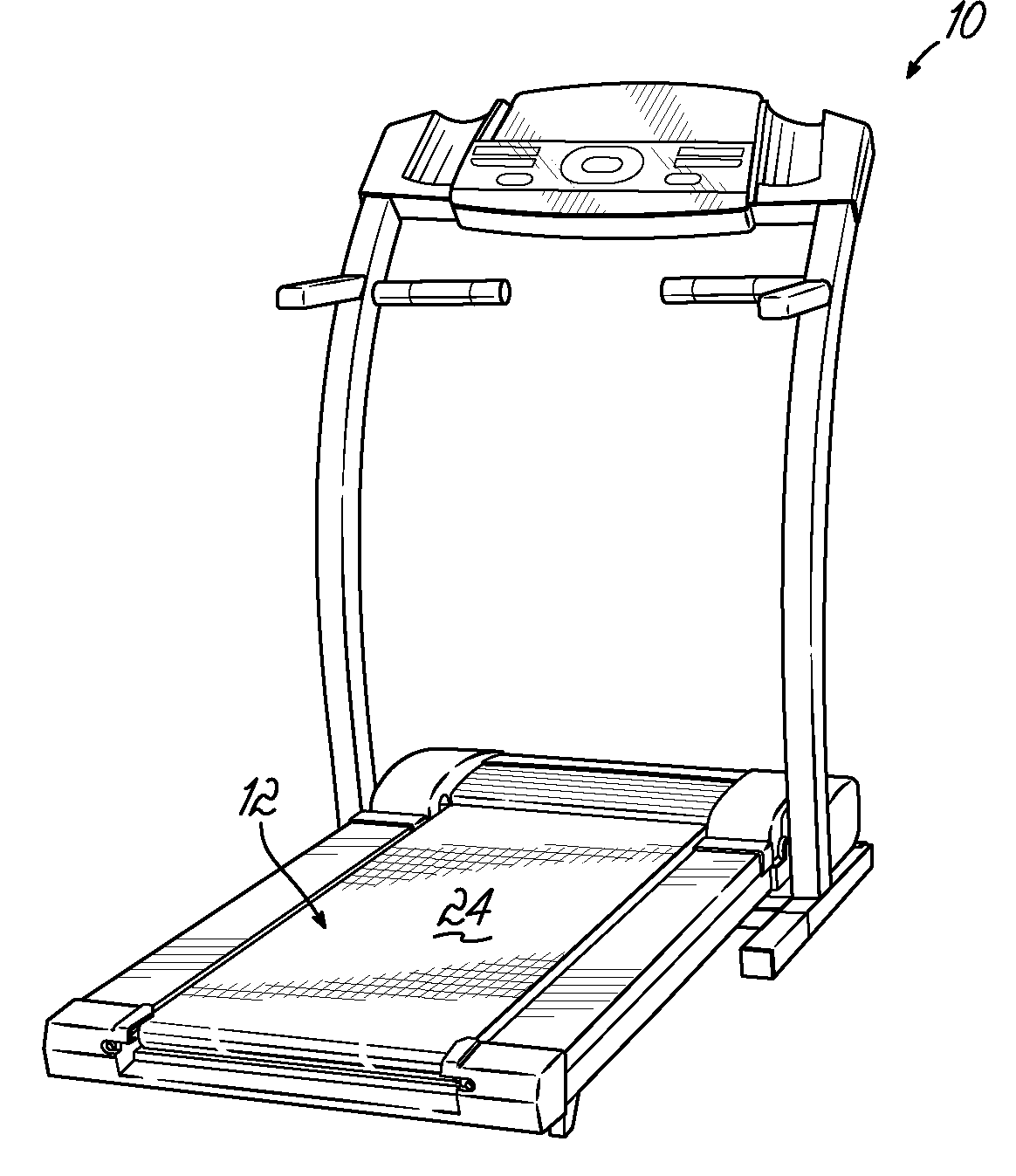

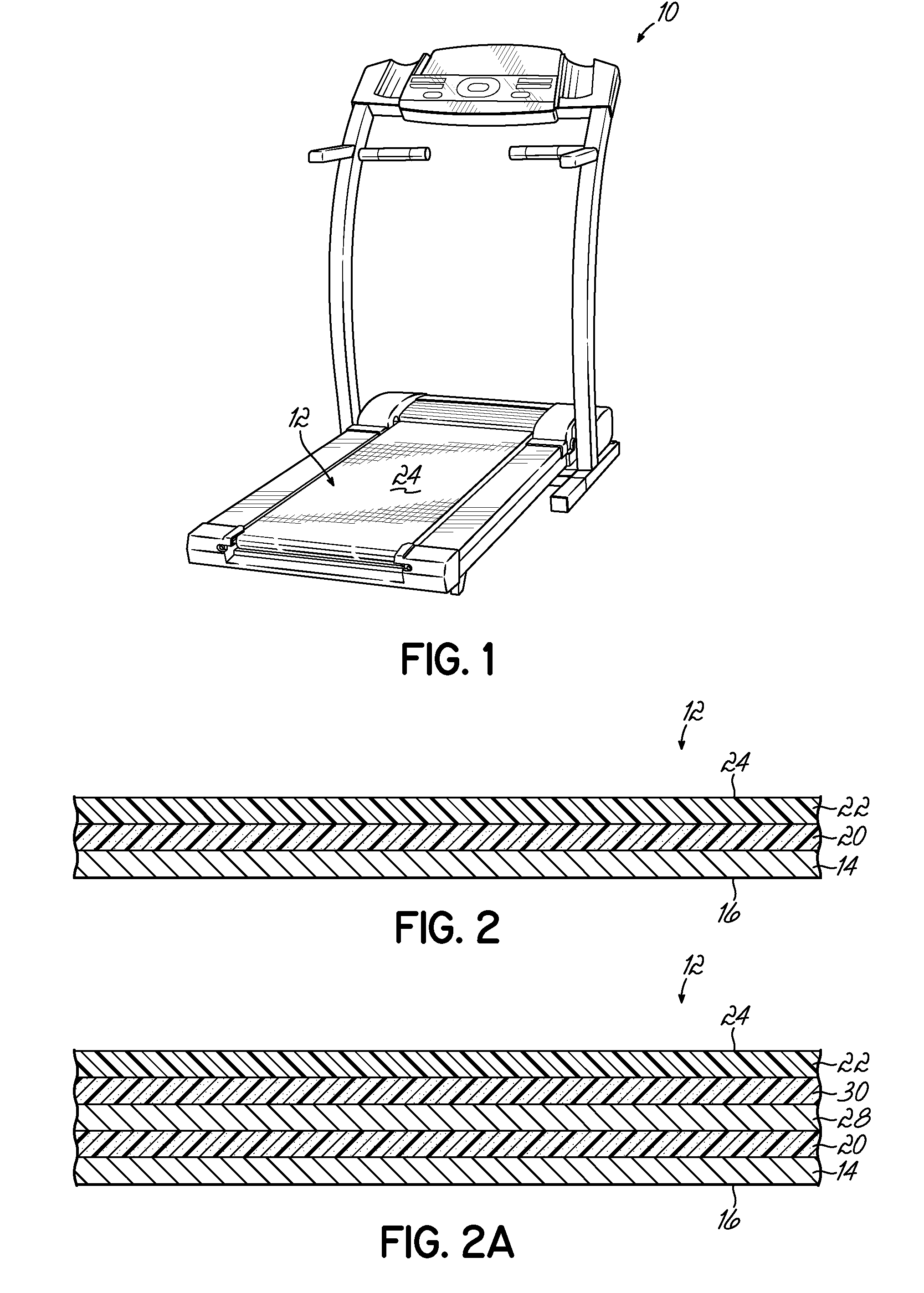

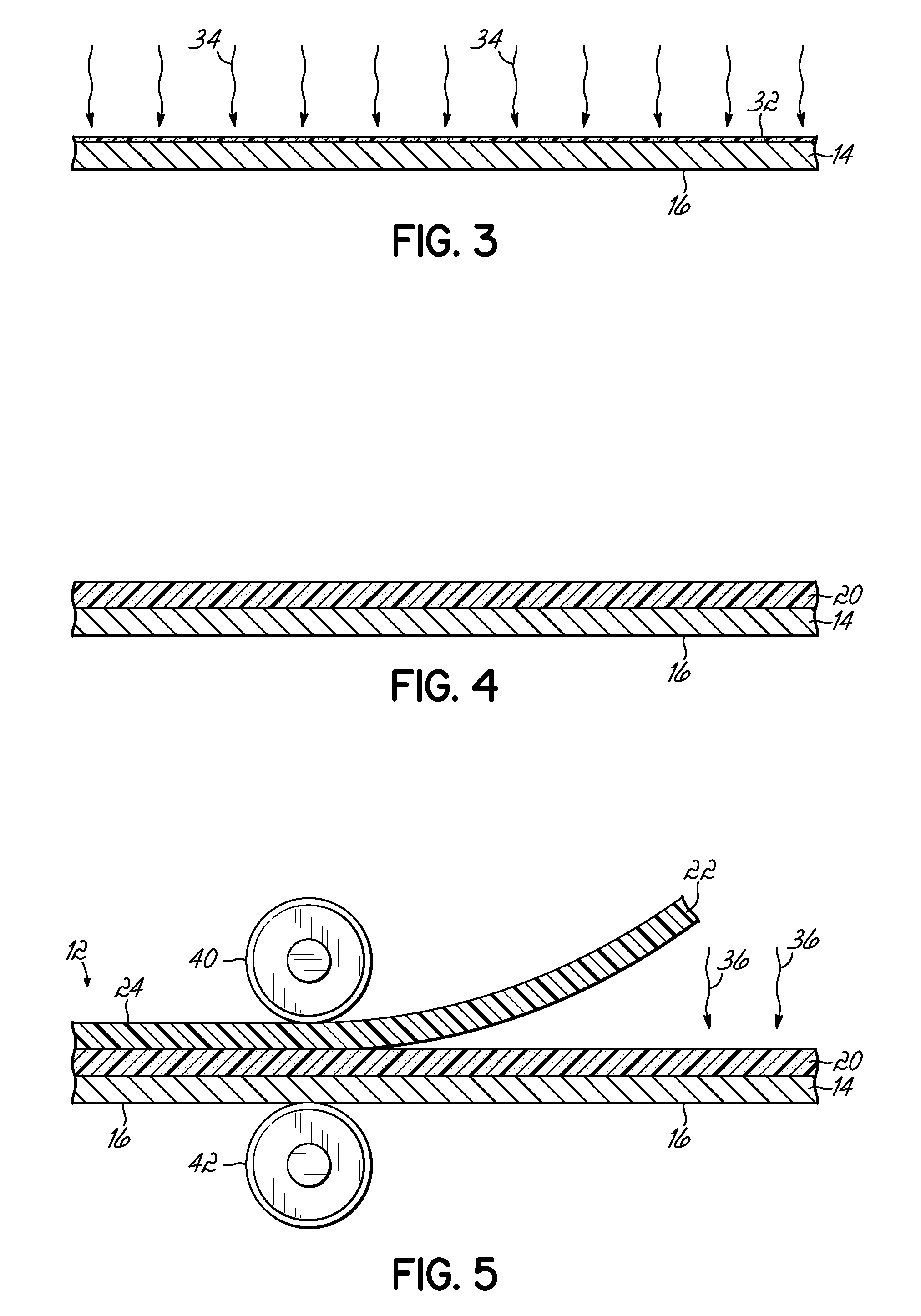

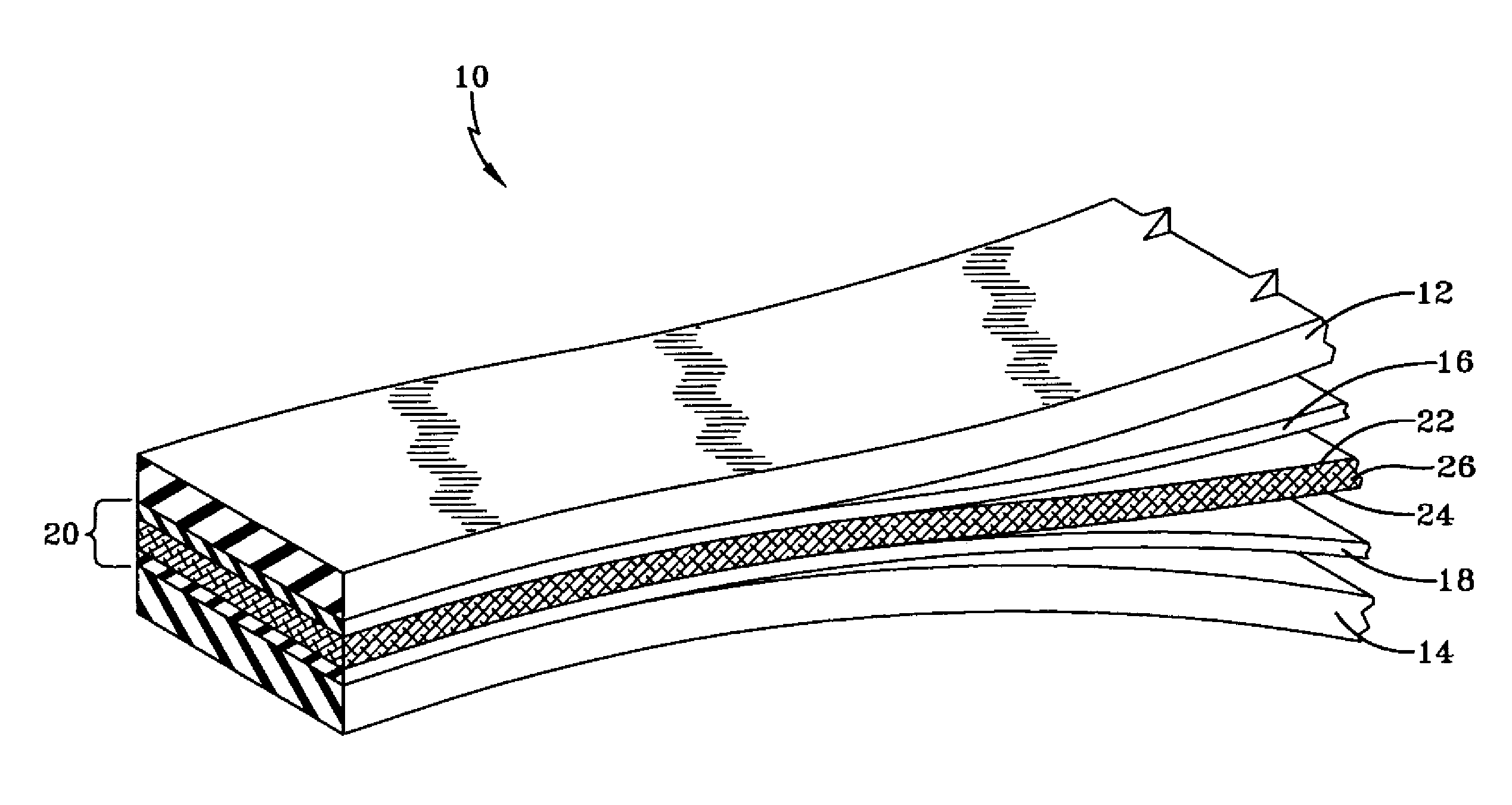

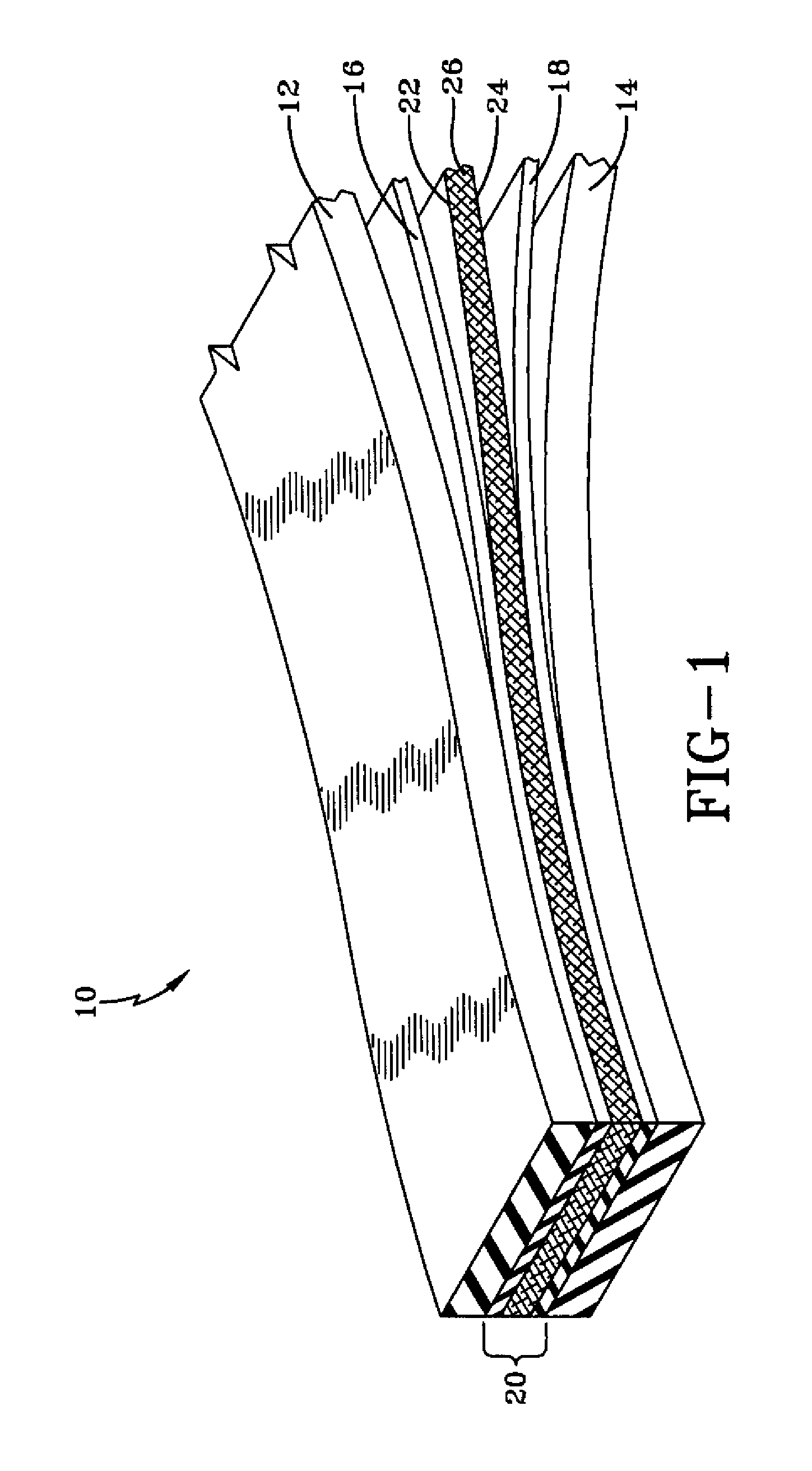

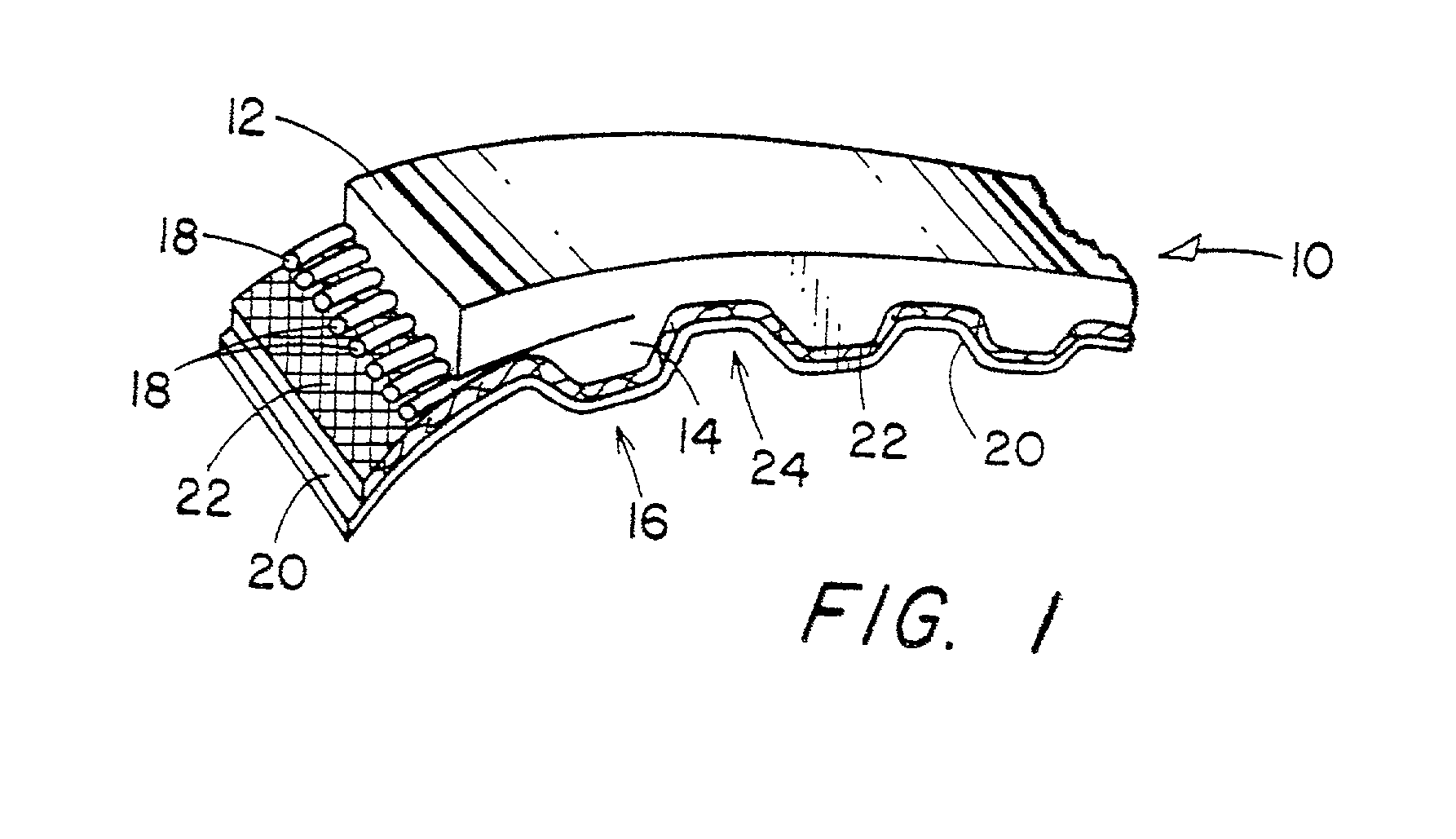

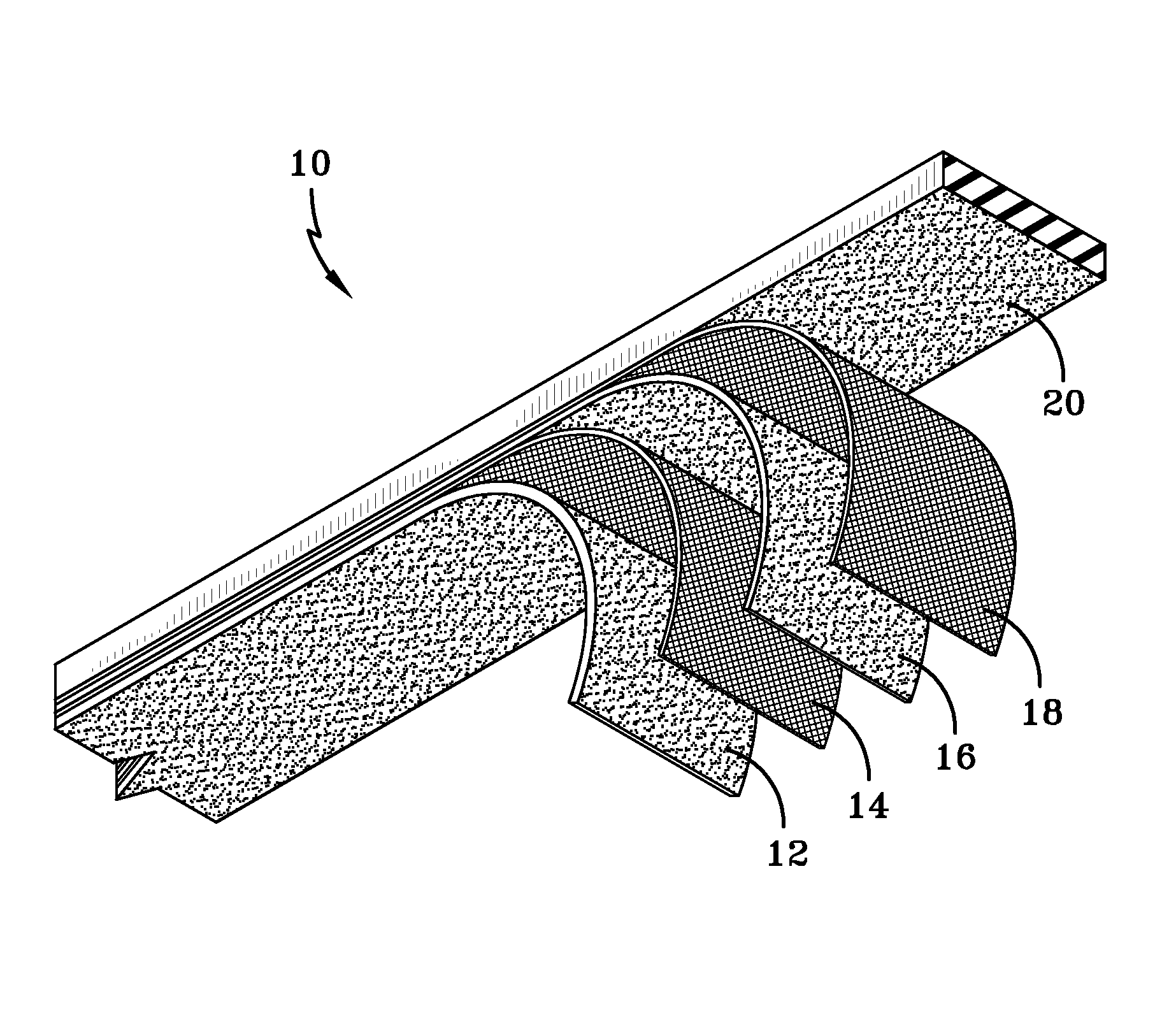

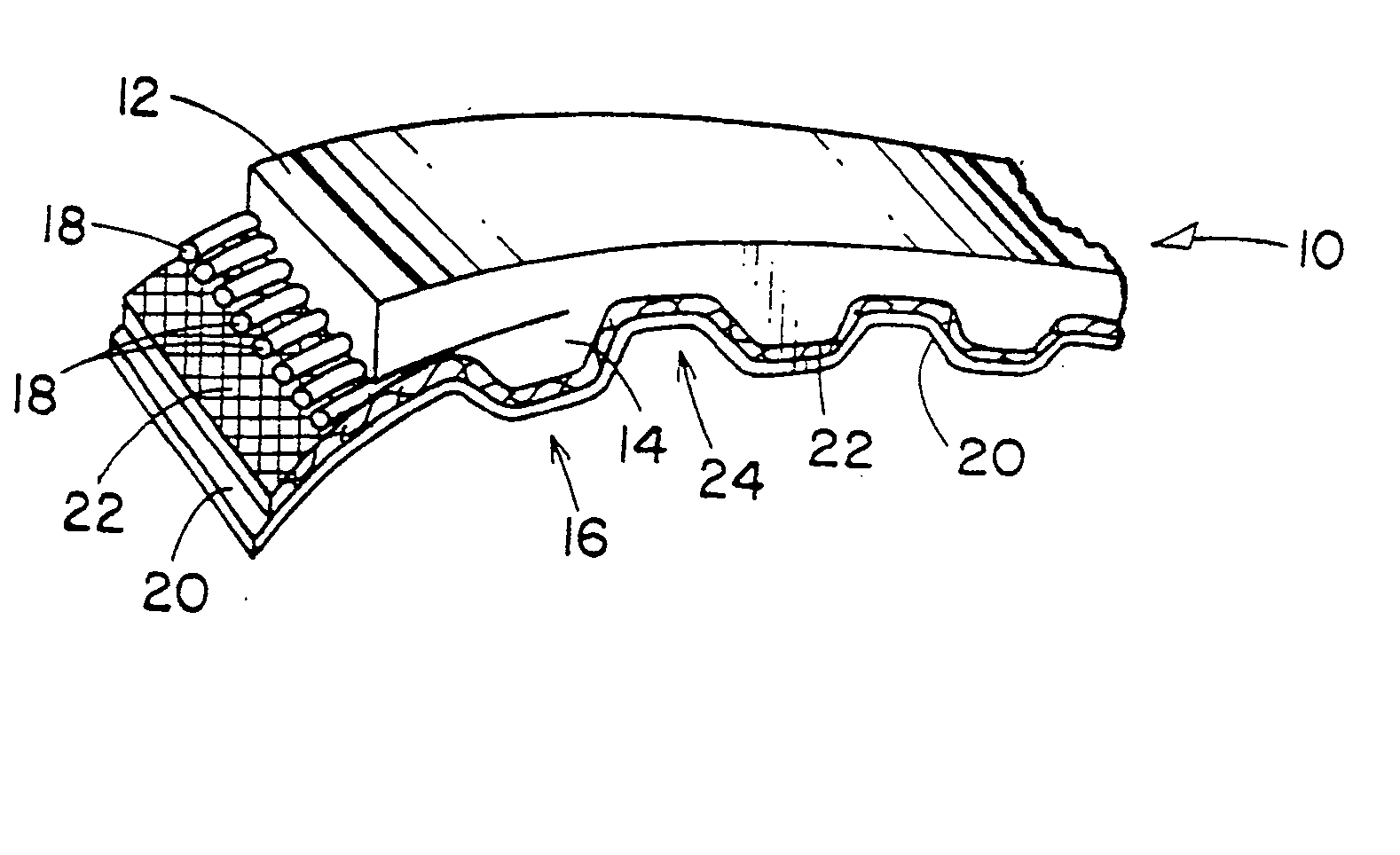

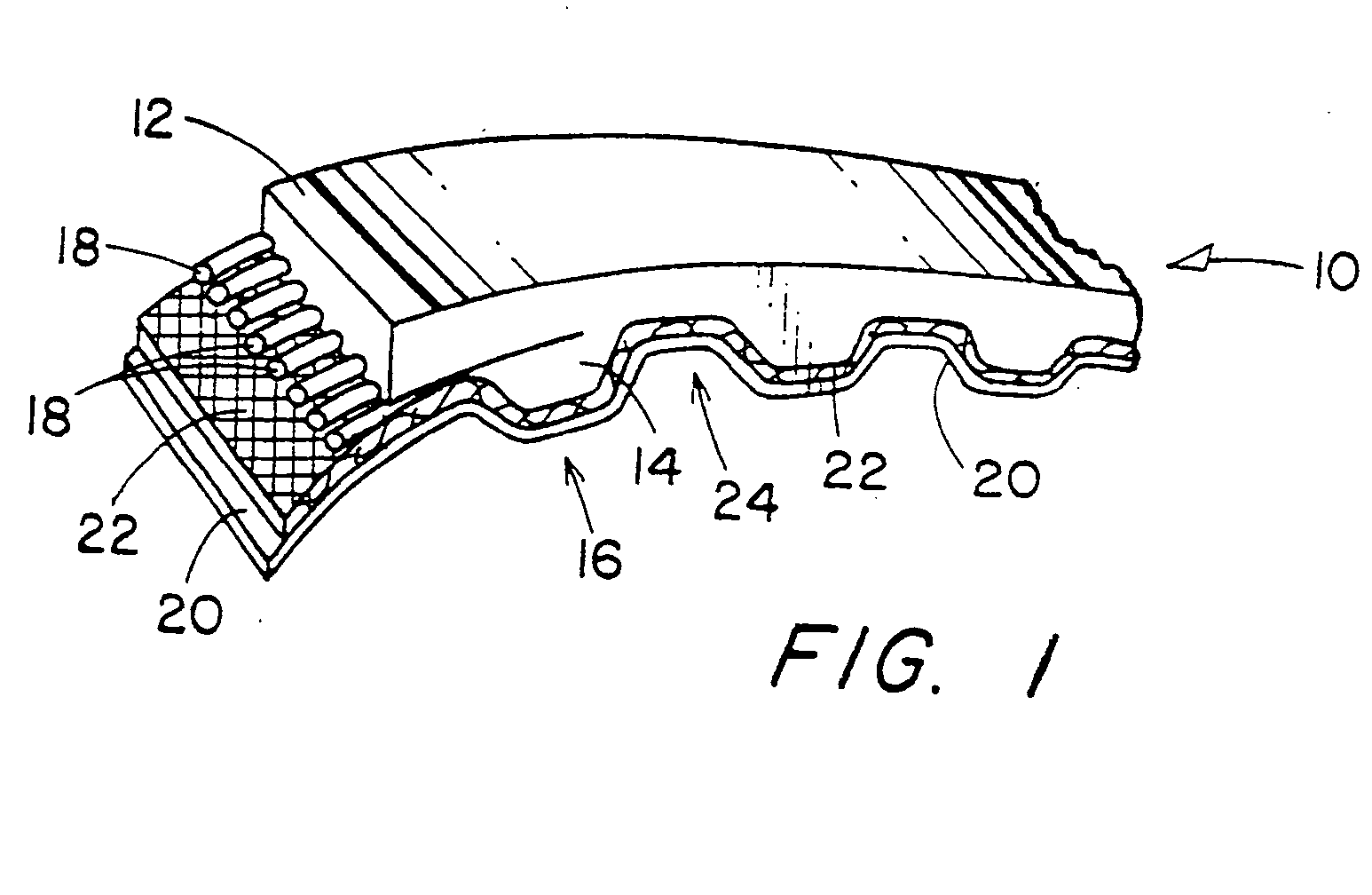

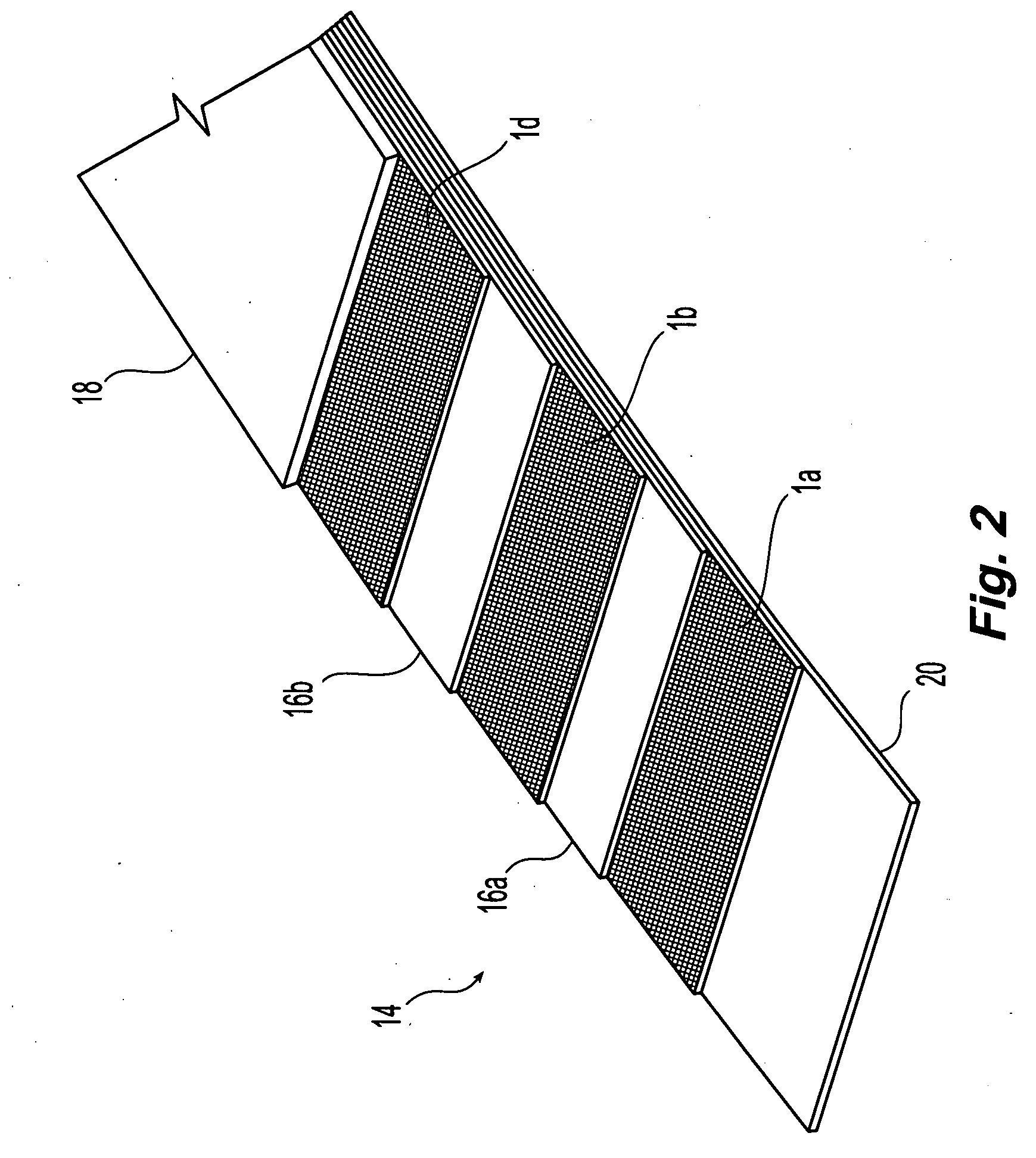

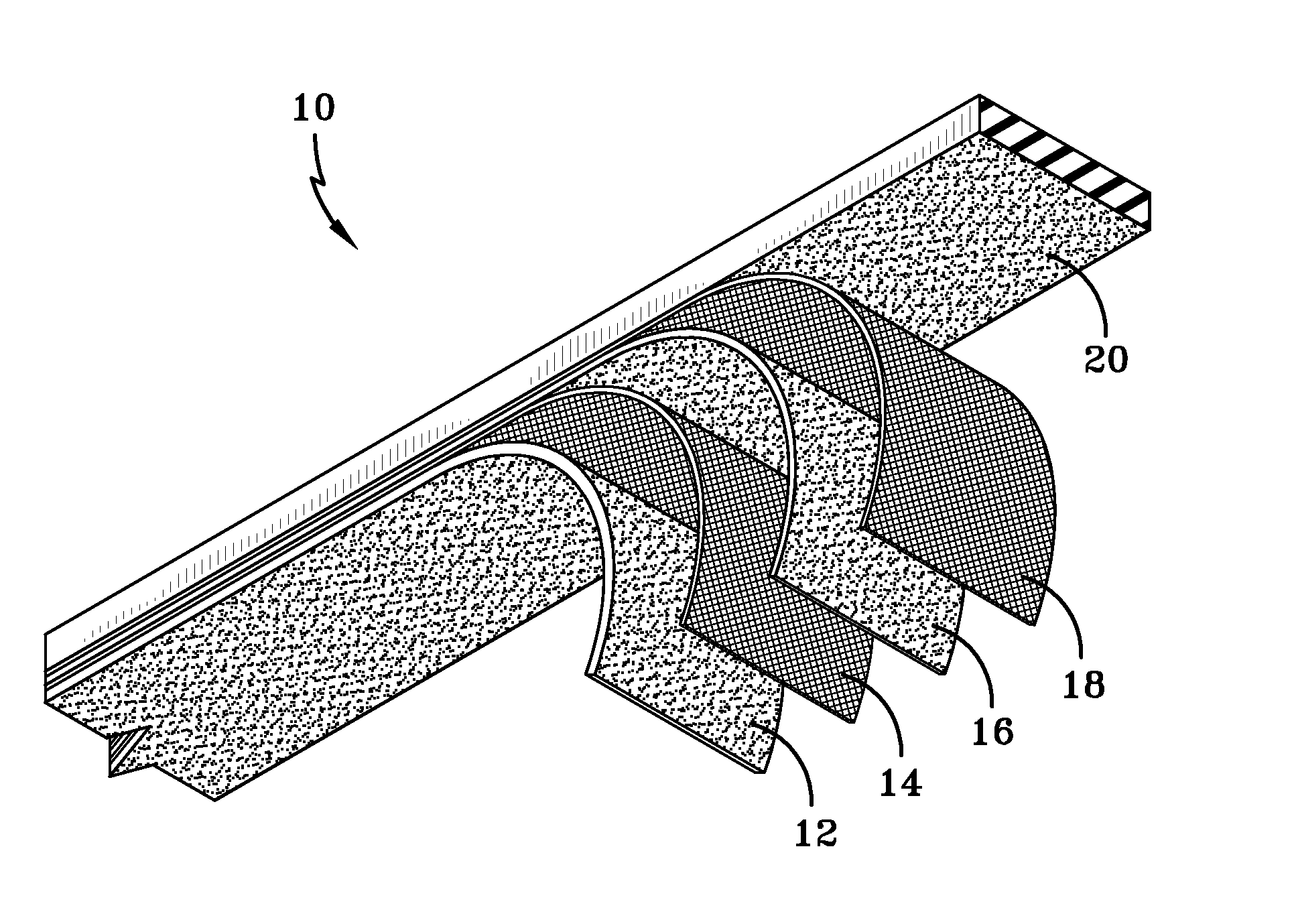

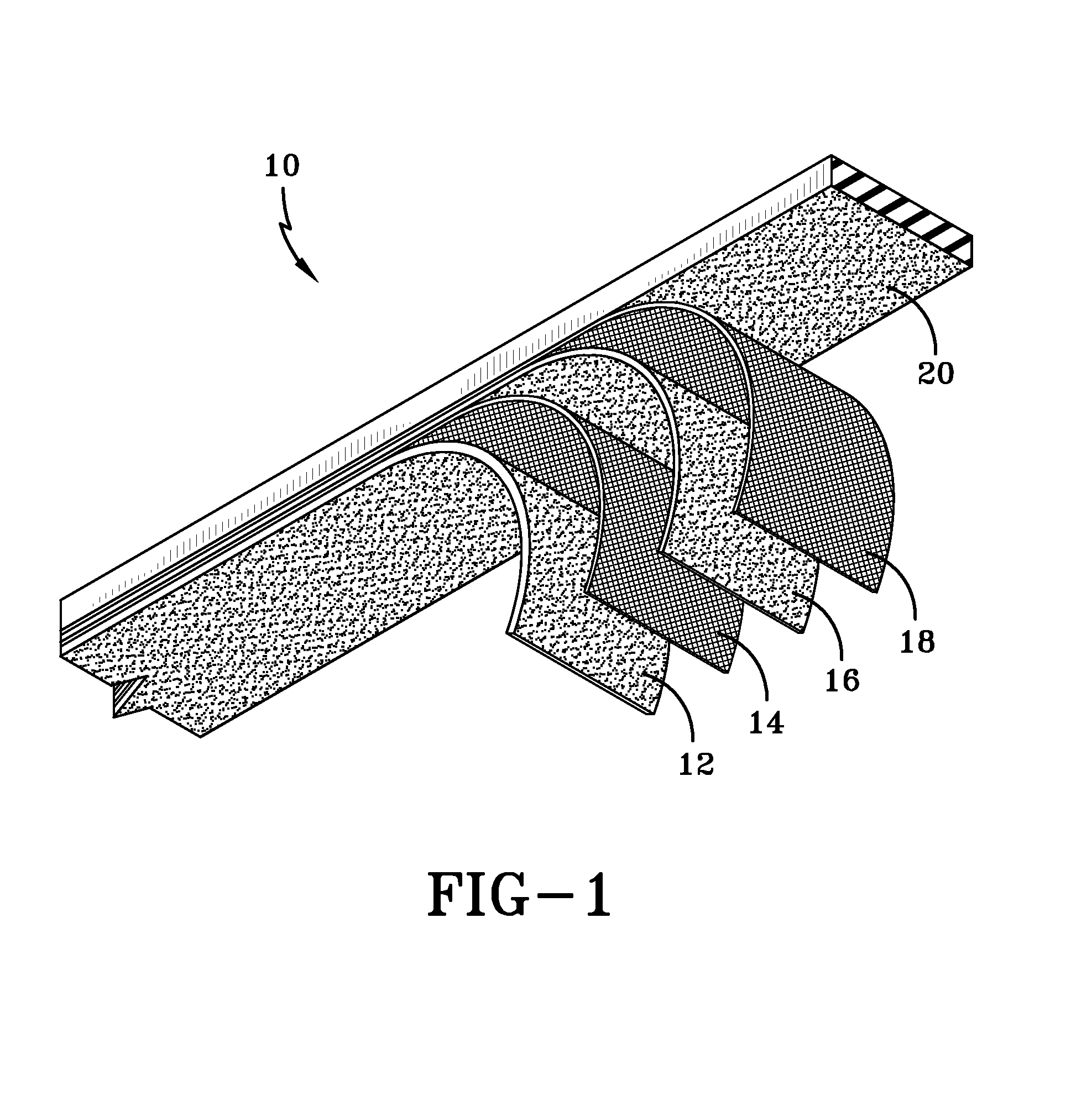

Treadmill belt with foamed cushion layer and method of making

ActiveUS20090176628A1Easy to manufactureAvoid injuryBeltsV-belt fasteningsFoaming agentPolyvinyl chloride

The present invention is directed to a treadmill belt with foamed cushion layer and method of making same. In one embodiment, the treadmill belt includes a fabric base layer and a foamed cushion layer foamed on and integral with the fabric base layer. The foamed cushion layer includes a thermoplastic composition and has a Shore A hardness of about 20 to about 80. In one example, the first foamed cushion layer is from about 0.05 inches to about 0.35 inches thick. The thermoplastic composition, prior to being foamed, includes about 1 part to about 5 parts of a foaming agent, e.g., a chemical foaming agent, based on 100 parts thermoplastic material, e.g., polyvinyl chloride. An outer wear layer is securely adhered on the foamed cushion layer to sandwich the foamed cushion layer between the fabric base layer and outer wear layer thereby defining the treadmill belt.

Owner:CONTITECH USA INC

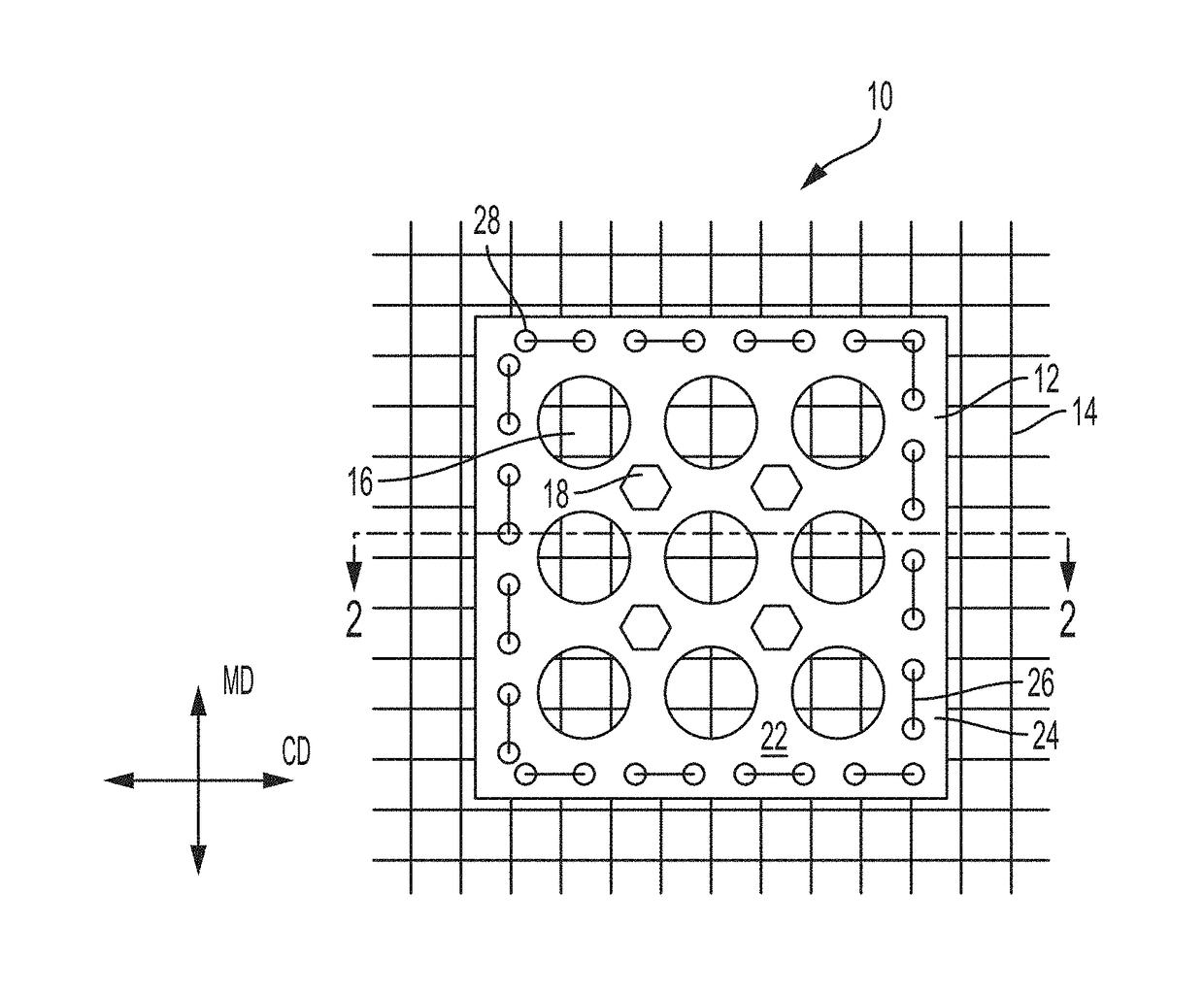

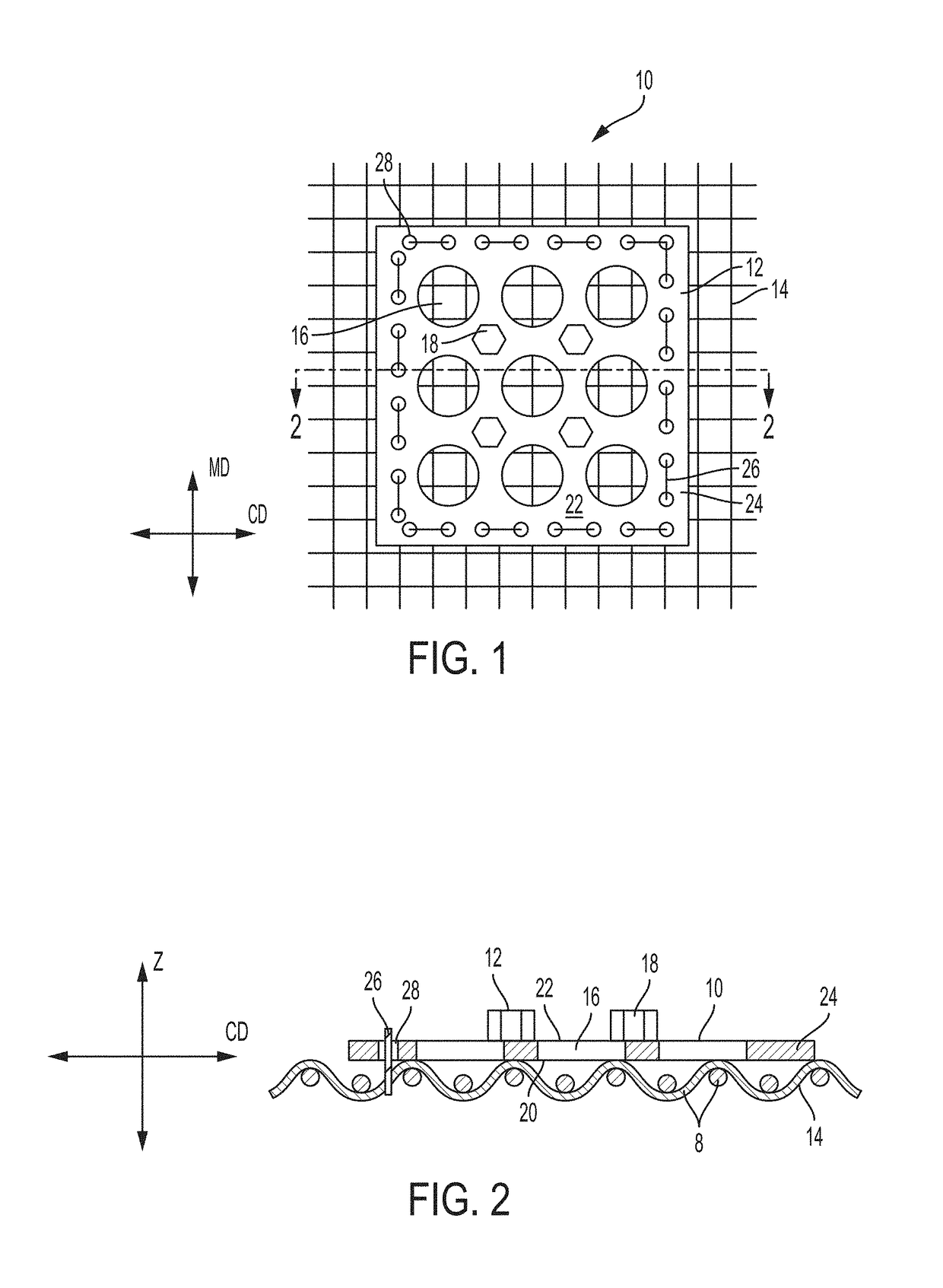

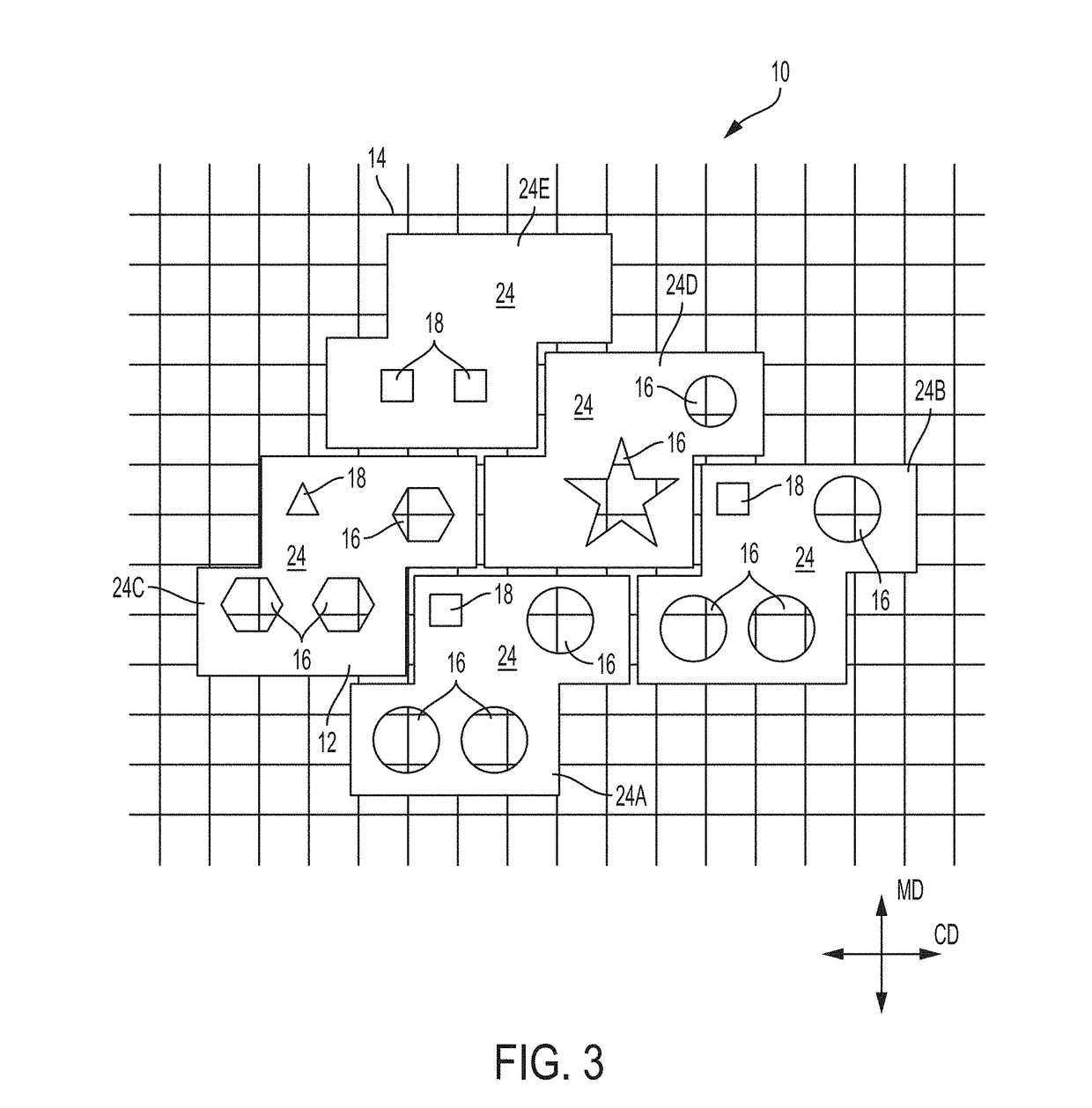

Deflecting Member for Making Fibrous Structures

Owner:THE PROCTER & GAMBLE COMPANY

Articles and methods of making the same

The invention provides an article comprising a first layer and a second layer, and wherein the first layer is formed from a first composition comprising an ethylene / α-olefin / diene interpolymer, an isoprene rubber (synthetic), a natural rubber, a butadiene rubber, a styrene butadiene rubber, a chloroprene rubber, a nitrile rubber, a hydrogenated nitrile rubber, a chlorinated polyethylene, a chlorosulfonated polyethylene, an ethylene / propylene rubber, an ethylene / diene copolymer, a fluoro rubber, a polyurethane, a silicone rubber, or a combination thereof; and wherein the second layer is formed from a second composition comprising a butyl rubber, a halobutyl rubber, polyvinylidene chloride, a brominated polymer derived from a copolymer of isobutylene and p-methyl styrene, a nitrile rubber, a chloroprene rubber, a chlorosulfonated polyethylene, a chlorinated polyethylene, a polyurethane, a fluoro rubber, or a combination thereof.

Owner:DOW GLOBAL TECH LLC

Laminate and pneumatic tires made by using the same

A laminate of an air permeation preventive layer an adhesive layer provided with an air permeation preventive layer comprising a thermoplastic elastomer composition containing a thermoplastic resin as a continuous phase and a rubber composition dispersed therein as a dispersed phase and arranged on one surface of the air permeation preventive layer, an adhesive composition layer having a thickness of 100 μm or less, a self tack of less than 5N and a tack to an unvulcanized diene-based rubber or 5N or more, containing 100 parts by weight of a thermoplastic elastomer containing 50 parts by weight or more of an epoxy-modified styrene-butadiene-based block copolymer so that a total of 30 to 200 parts by weight of a terpene resin and an aromatically modified terpene resin having a weight average molecular weight Mw of 1000 or less and a softening point of 60 to 120° C., 0.1 to 3 parts by weight of an internal mold release agent and 0.1 to 2 parts by weight of an organic peroxide.

Owner:THE YOKOHAMA RUBBER CO LTD

Non-halogenated rubber compounds for use in conveyor belts

ActiveUS20100044189A1Desirable workabilityConveyorsPlastic/resin/waxes insulatorsPolymer sciencePhosphate

A non-halogenated rubber compound is provided for use in conveyor belts, particularly those used in underground mining. The non-halogenated rubber compound is fire-resistant in accordance with MSHA standards and produces acceptable levels of toxicity and smoke upon burning. Such non-halogenated rubber compound includes a blend of rubbery polymers in combination with aluminum trihydrate, which is a fire retardant, and optionally a phosphate plasticizer, which can provide the rubber compound with a more desirable workability. The blend of rubbery polymers is composed of natural rubber and butadiene rubber, and optionally styrene-butadiene rubber, such blend being present in a total amount of 100 phr. In one embodiment, the aluminum trihydrate is present in an amount of about 30 phr to about 150 phr. In another embodiment, the phosphate plasticizer is present in an amount of about 10 phr to about 60 phr.

Owner:CONTITECH USA INC

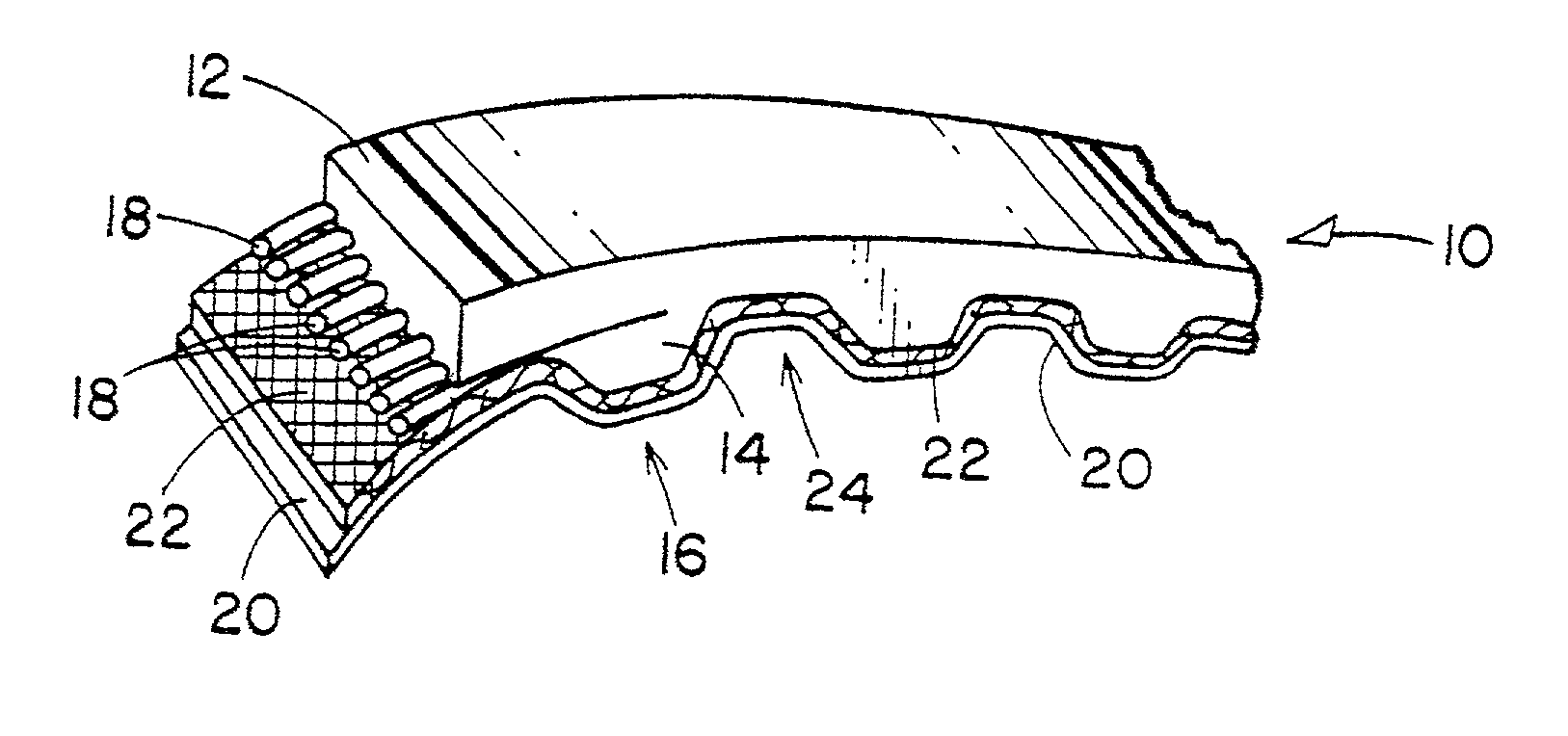

Wear resistant belts, and a process for their manufacture

Endless power transmission belts and processes for their manufacture, having power transmitting surfaces comprising a wear resistant composite, which belts exhibit improved abrasion- or wear resistance, reduced noise, reduced frictional heat generation, and improved dimensional stability compared to known belt constructions, as well as processes for manufacturing same. More particularly, an endless toothed belt having an abrasion- and noise resistant cover element, which comprises at least one friction-modifying constituent and at least one binder constituent.

Owner:THE GATES CORP

Friction drive belt and method for fabricating the same

InactiveUS20050143209A1Reduce coefficient of frictionIncrease the itineraryV-beltsRopes and cables for vehicles/pulleyTransmitted powerConveyor belt

A friction drive belt is used by being wrapped around a plurality of pulleys and transmits power by friction between its belt body and each of the pulleys. The working part of the belt body has a structure in which rubber layers and non-woven fabric layers are alternately stacked along the thickness of the belt.

Owner:BANDO CHEM IND LTD

Conveyor belt

ActiveUS8910780B2Low costReduce labor requirementsConveyorsLamination ancillary operationsEngineeringConveyor belt

The present invention reveals a method of manufacturing a fabric reinforcement having improved peel adhesion characteristics which is of particular value in reinforcing endless belts, wherein at least two layers of fabric material are embedded in the fabric reinforcement, said process comprising (1) impregnating a fabric material with a bonding agent in a plastisol to form coated fabric material, (2) applying a plastisol layer between two or more layers of coated fabric thereby creating a belt carcass, (3) continuously feeding the belt carcass into a double belt press which presses the impregnated fabric materials together with the plastisol layer(s) at a pressure of at least 5 psi to produce a preformed fabric carcass while (4) heating the preformed fabric carcass to a temperature which is within the range of 360° F. to 450° F. for a period of at least 6 minutes, and (5) continuously withdrawing the fabric carcass from the press.

Owner:CONTITECH USA INC

Wear resistant belts, and a process for their manufacture

InactiveUS20060174997A1Reduce noiseLow heat generationV-beltsDriving beltsWear resistantWear resistance

Owner:GIBSON DANIEL PATTIE +1

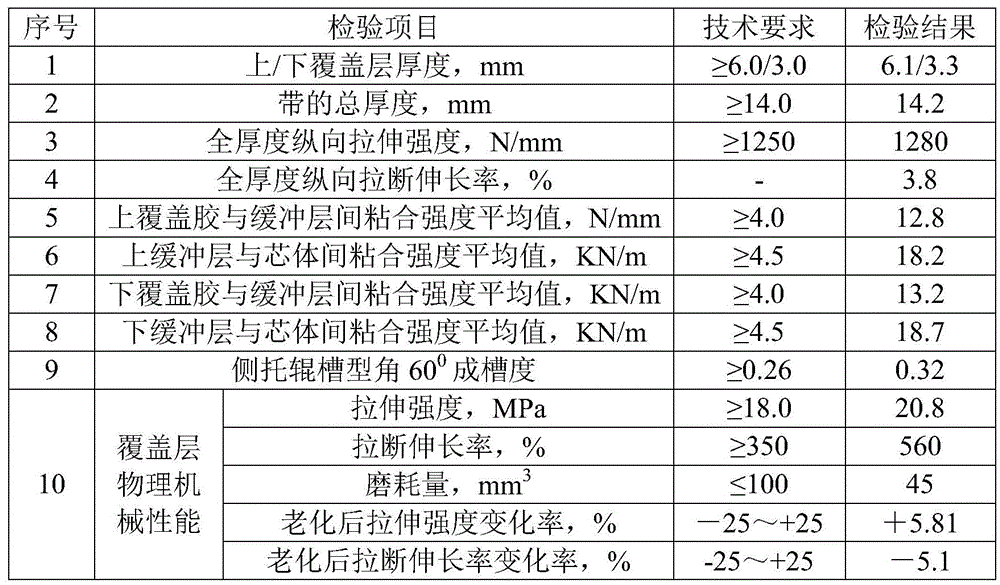

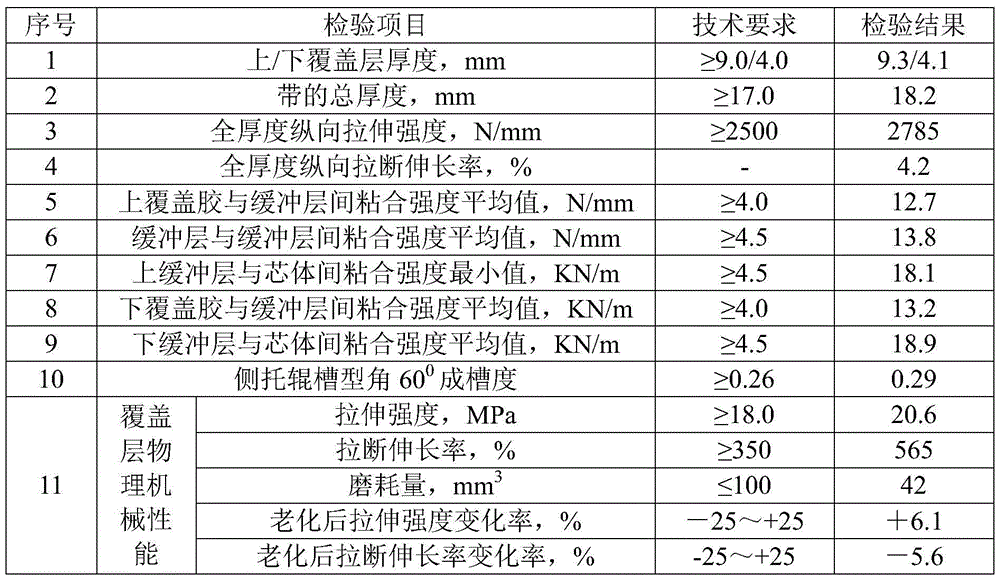

High-abrasion-resistance anti-impacting aramid fiber core conveying belt and production technology thereof

ActiveCN105600280AIncrease elasticityImprove impact performanceConveyorsSynthetic resin layered productsYarnNylon 66

The invention relates to a conveying belt, in particular to a high-abrasion-resistance anti-impacting aramid fiber core conveying belt and a production technology thereof. The conveying belt is formed by an aramid fiber canvas skeleton layer, anti-impacting and anti-tearing buffering layers, an upper covering rubber layer, a lower covering rubber layer and a side rubber layer; the anti-impacting and anti-tearing buffering layers are arranged at the upper side and the lower side of the aramid fiber canvas skeleton layer, and the aramid fiber canvas skeleton layer and the anti-impacting anti-tearing buffering layers, the adjacent anti-impacting anti-tearing buffering layers as well as the anti-impacting anti-tearing buffering layers, the upper and lower covering rubber layers and the side rubber layer are bonded through bonding glue and vulcanized into a whole; aramid fiber canvas is of a straight warp and straight weft structure, and warp-wise stress threads are composite thread ropes formed by doubling and twisting straight aramid fiber, nylon 66 composite thread ropes, aramid fiber plied yarn and nylon 66 plied yarn after twisting. A belt body of the high-abrasion-resistance anti-impacting aramid fiber core conveying belt has proper softness, and the anti-impacting capacity is enhanced. The anti-impacting anti-tearing buffering layers are additionally arranged, and the requirement for anti-impacting performance of an application environment with different impact types is met.

Owner:ANHUI OUNAI RUBBER & PLASTIC IND

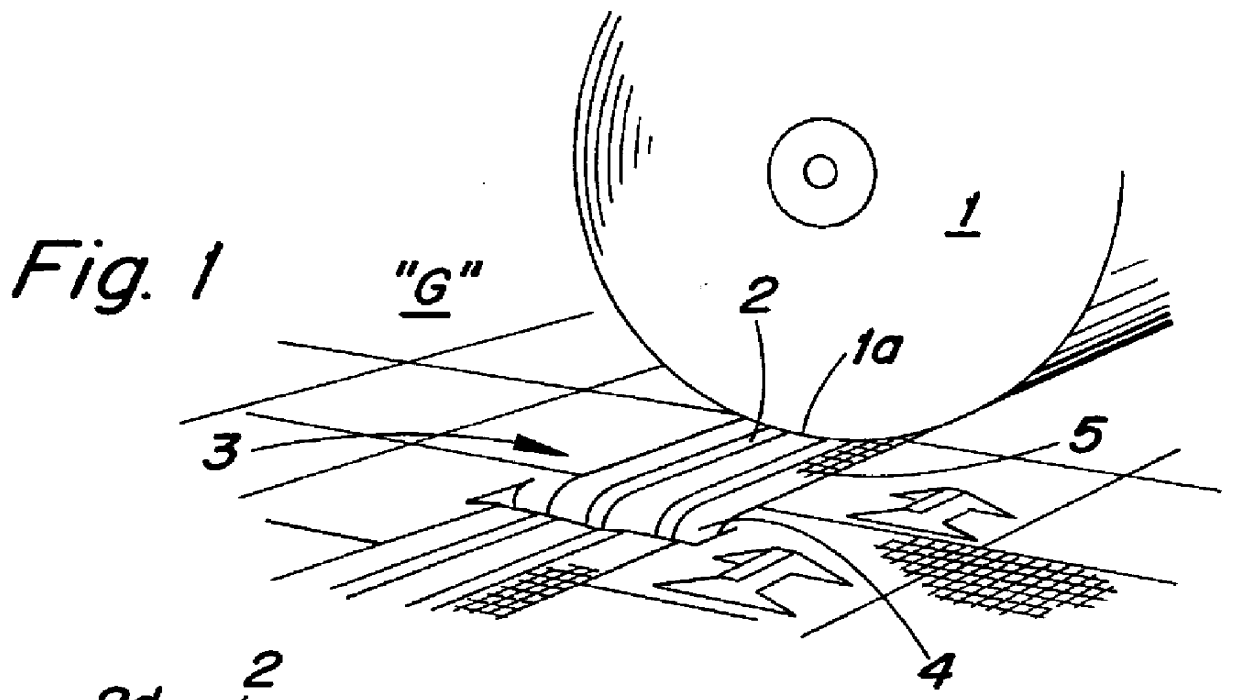

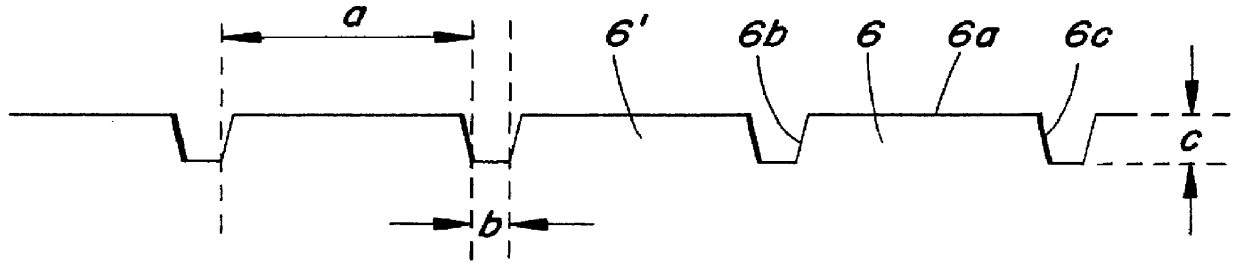

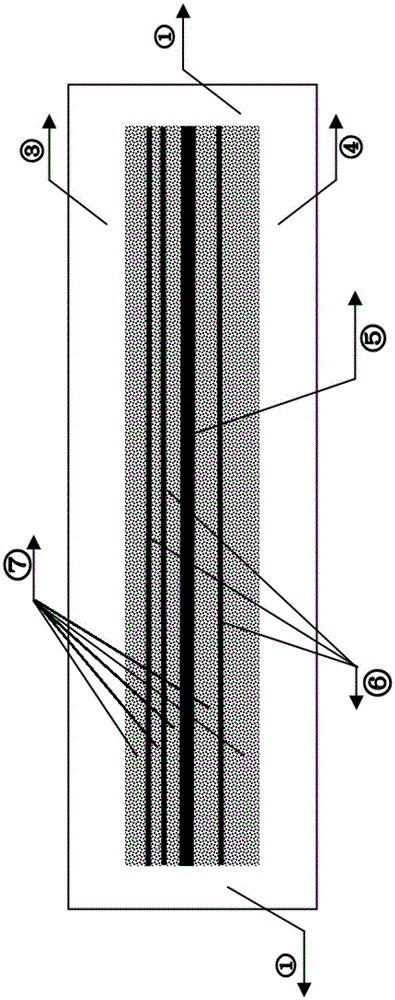

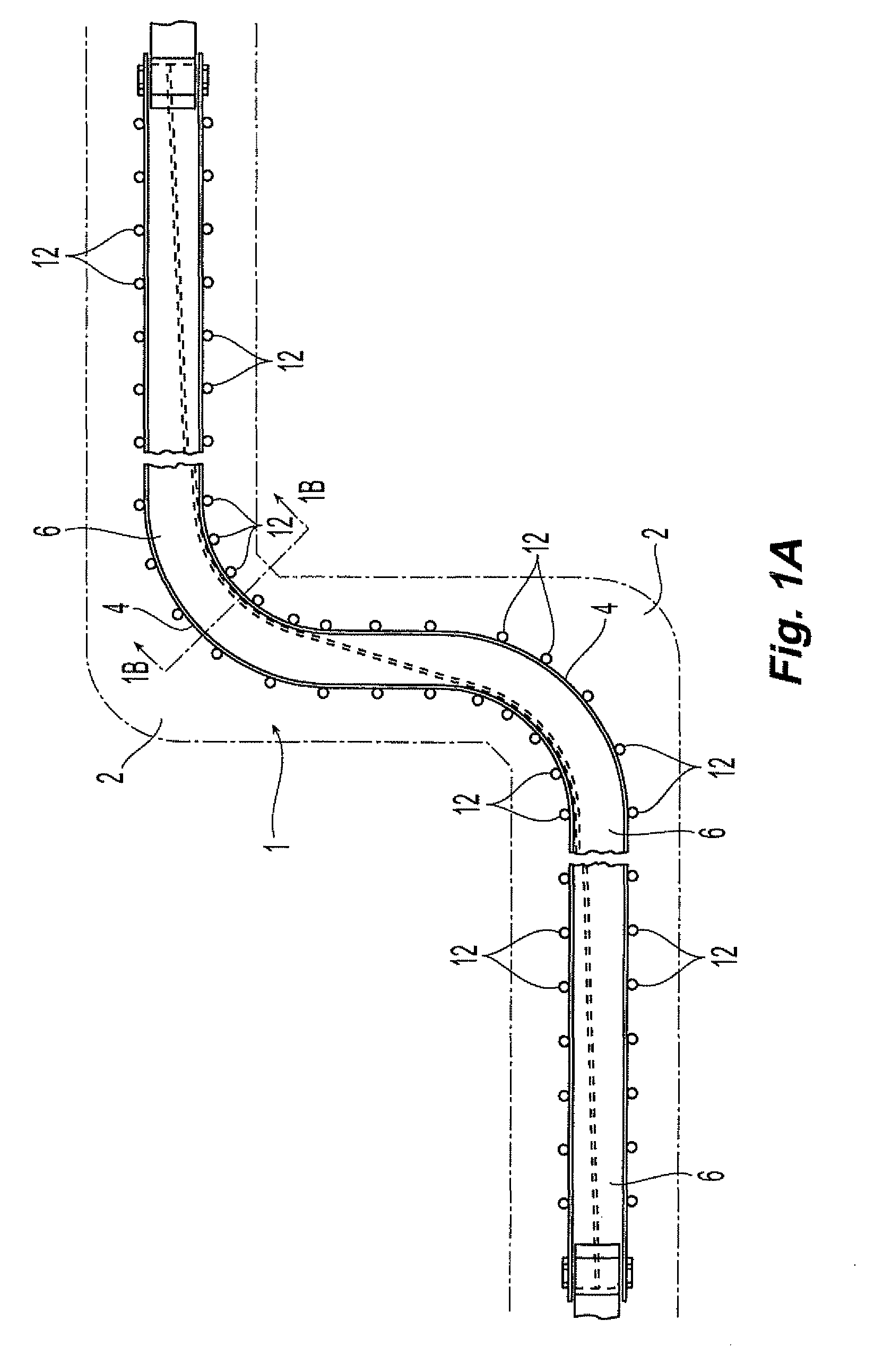

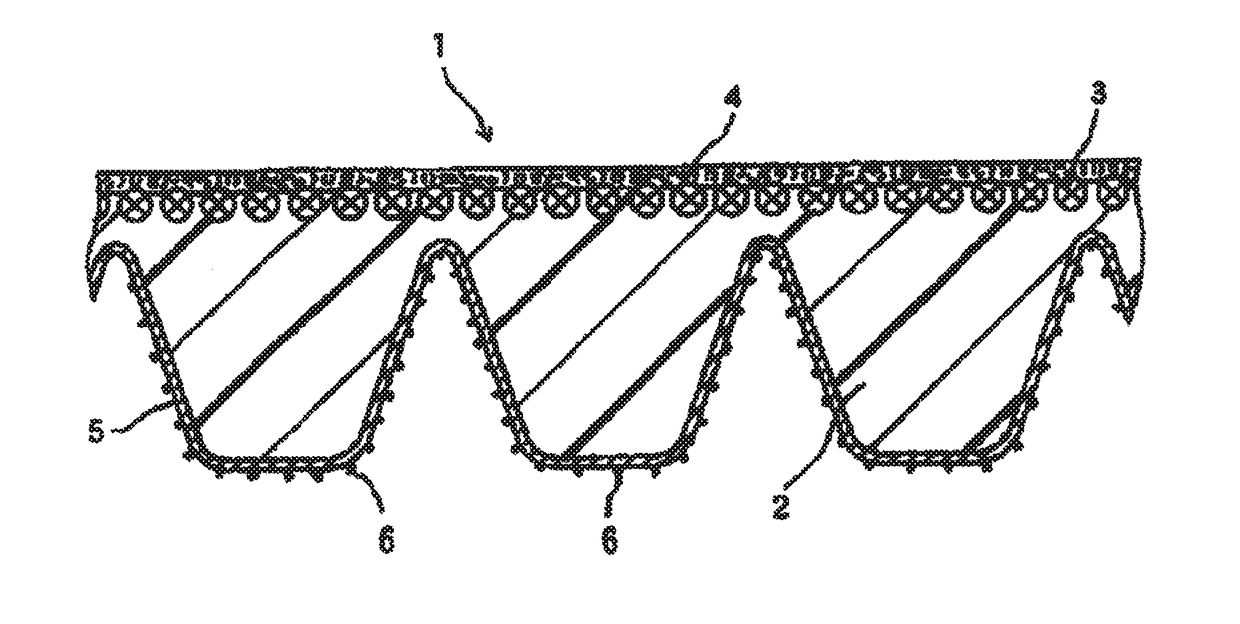

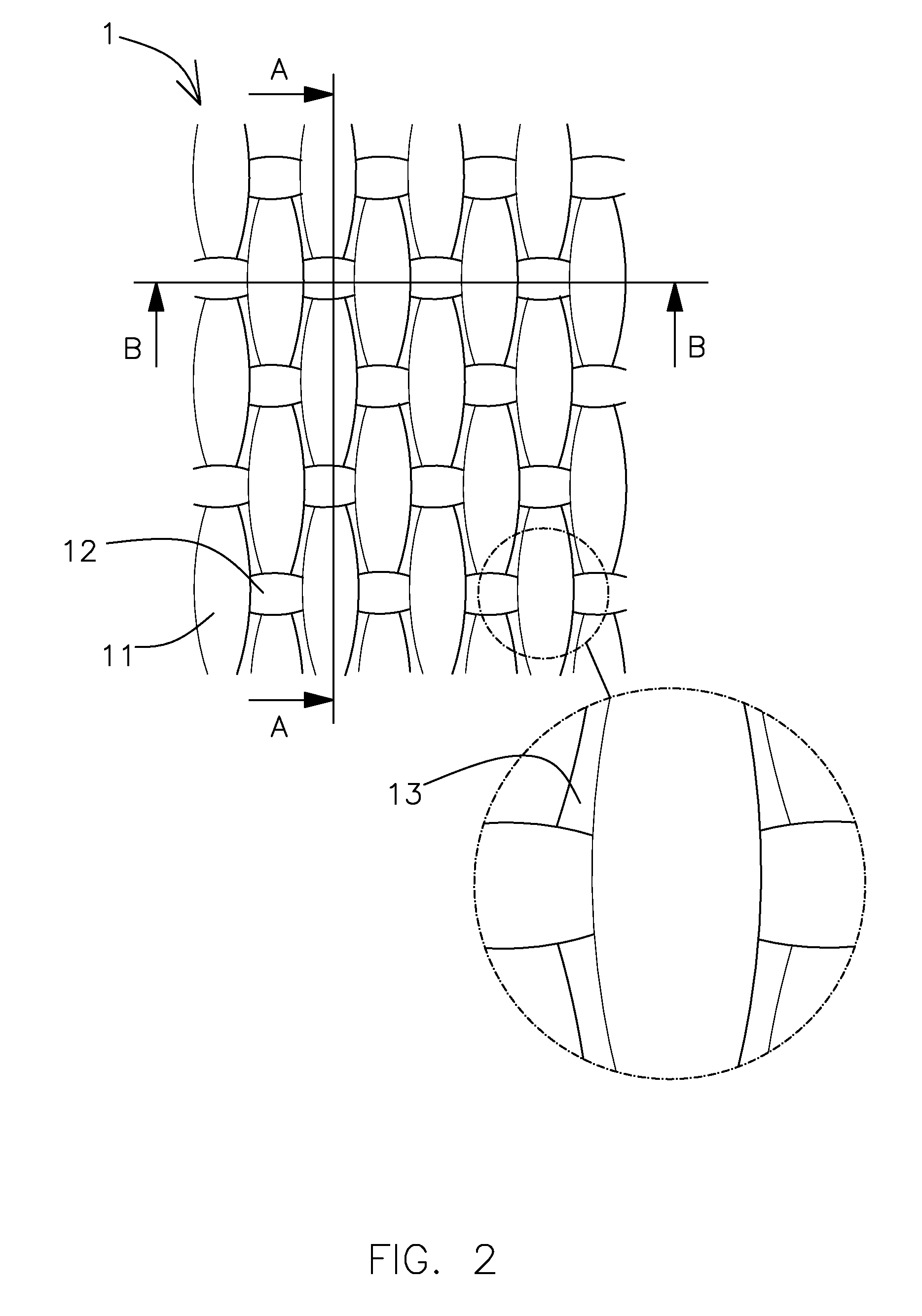

Laterally flexible reinforced structure

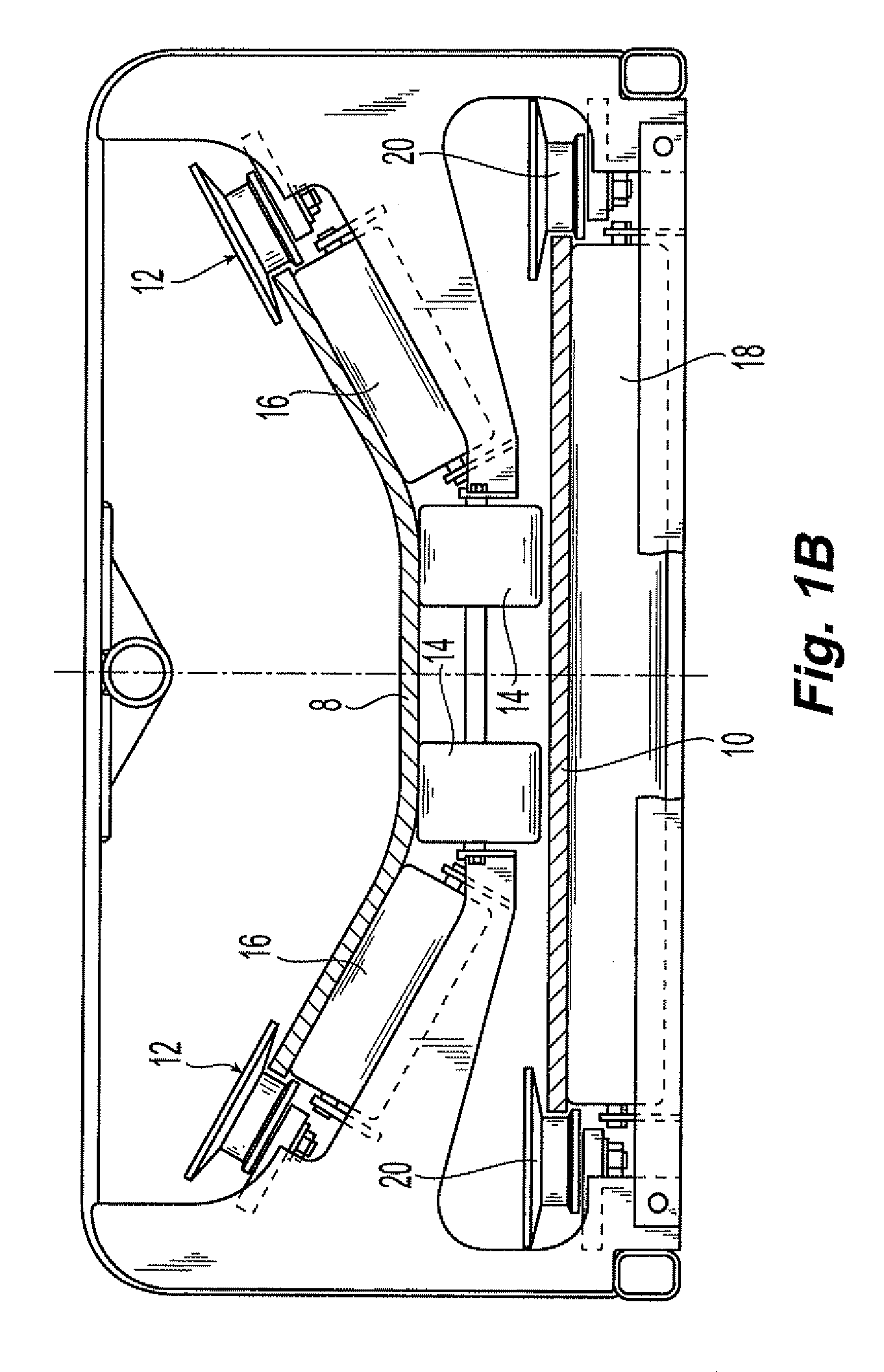

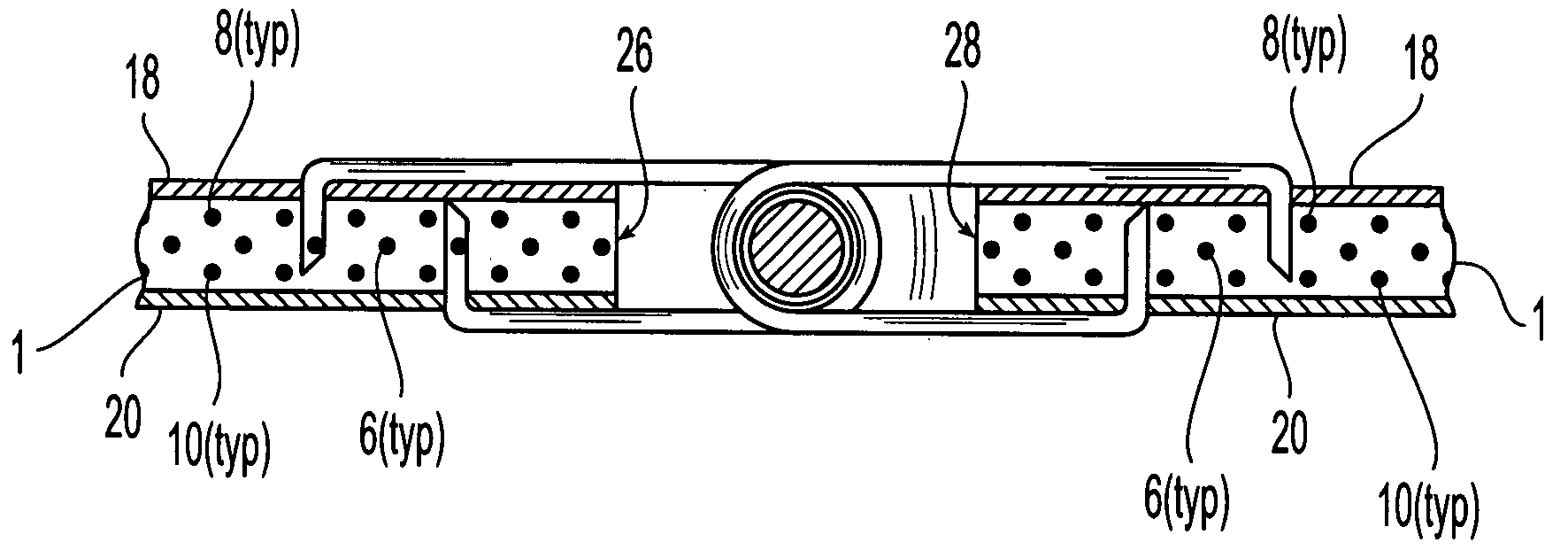

InactiveUS7815043B2Solution to short lifeOvercome disadvantagesConveyorsLamination ancillary operationsElastomerIn plane

In improved reinforced conveyor belt structure is disclosed having a segmented reinforcing structure for enabling enhanced in-plane expansion of the belt under conditions of extreme in-plane experienced during operation. The belt comprises at least one elastomer layer and at least one reinforcing layer. The reinforcing layer may comprise a continuous strip disposed along the longitudinal center line of the conveyor belt. A series of laterally-extending reinforcing strips are disposed on either side of the center strip, radiating outward toward respective edges of the belt. These laterally-extending strips are spaced apart from one another to form a series of flexibility enhancing gaps therebetween, thus enabling the belt to elongate at its edges without undue restraint from the reinforcing layer. The laterally-extending strips may be oriented perpendicular to the center strip, or they may be oriented at oblique angles with respect to the center strip. The reinforcing layer may comprise one or more plies. Additional light-weight layers of reinforcing material may be provided between the reinforcing layer and the elastomer layer in order to enhance the structural integrity of the belt. In one embodiment, these light-weight reinforcing layers are continuous sheets of non-segmented reinforcing material which extend across substantially the entire width of the belt. Additional layers of elastomer material may be disposed between the reinforcing layer and the light-weight layers.

Owner:FENNER DUNLOP AMERICAS

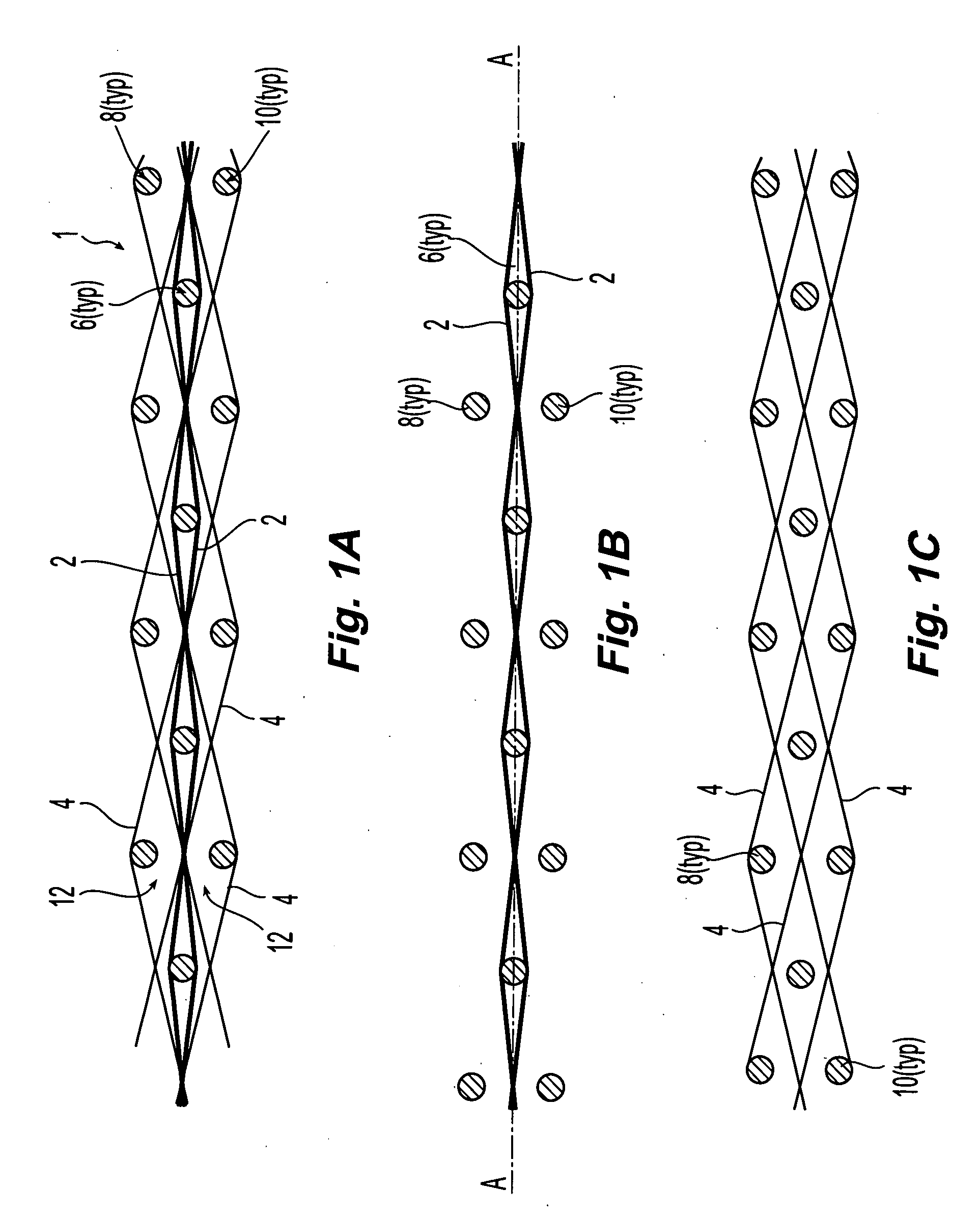

Dual crimped warp fabric for conveyor belt applications

ActiveUS20090014084A1Increase flexibilityHigh strengthConveyorsFibre treatmentEngineeringConveyor belt

A conveyor belt reinforcing fabric weave is disclosed, having a plurality of center tension warps crimped about a plurality of middle wefts. Upper and lower wefts lie above and below the middle wefts. The upper and lower wefts are in opposition to each other and in non-opposition with the center wefts. Binder warps are interlaced above and below the central tension warps in alternating sequence, with at least one of the binder warps interlacing upper and lower wefts other than those interlaced by an adjacent binder warp. Interlacing of the middle wefts by the central tension warps locks the wefts in place, providing enhanced resistance to faster pullout. The lack of straight tension warps provides a highly flexible fabric that can be used in multi-ply applications. A conveyor belt incorporating one or more plies of the inventive fabric is disclosed, as is a method for manufacturing the belt.

Owner:FENNER DUNLOP AMERICAS

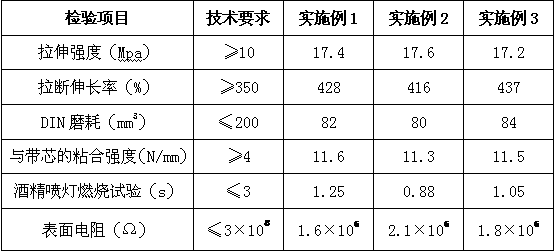

Fabric core anti-flaming conveyer belt with high abrasion resistance and manufacturing method thereof

InactiveCN107286498AImprove wear resistanceExtended service lifeConveyorsSynthetic resin layered productsVulcanizationPolyvinyl chloride

The invention discloses a fabric core anti-flaming conveyer belt with high abrasion resistance and a manufacturing method thereof. The fabric core anti-flaming conveyer belt is characterized in that a coating layer of the conveyer belt contains the following components in parts by weight: 30-40 parts of polyvinyl chloride, 30-40 parts of nitrile rubber powder, 25-35 parts of thermoplastic polyurethane elastomer, 3 parts of zinc oxide, 1.5 parts of stearic acid, 2 parts of paraffin oil, 1-1.5 parts of sulfur, 1-2 parts of accelerator, 1-2 parts of anti-aging agent, 10-15 parts of conductive carbon black, 10-15 parts of nanometer white carbon black, 8-10 parts of aramid fiber pulp, 10-20 parts of plasticizer, 10-20 parts of anti-flaming plasticizer, 10-20 parts of fire retardant, 1 part of lead stearate, 4 parts of lead dibasic titanate, 1-2 parts of silane coupling agent and 4-6 parts of antistatic agent. The conveyer belt disclosed by the invention has abrasion resistance and long service life; an extruder is adopted for veneering and forming and a dynamic vulcanization technology is adopted for producing; the technology is simple; the energy consumption is less; the production efficiency is high.

Owner:ANHUI ZHONGYI RUBBER BELTS

Conveyor belt

ActiveUS20140021021A1Low costReduce labor requirementsConveyorsLamination ancillary operationsBand patternEngineering

The present invention reveals a method of manufacturing a fabric reinforcement having improved peel adhesion characteristics which is of particular value in reinforcing endless belts, wherein at least two layers of fabric material are embedded in the fabric reinforcement, said process comprising (1) impregnating a fabric material with a bonding agent in a plastisol to form coated fabric material, (2) applying a plastisol layer between two or more layers of coated fabric thereby creating a belt carcass, (3) continuously feeding the belt carcass into a double belt press which presses the impregnated fabric materials together with the plastisol layer(s) at a pressure of at least 5 psi to produce a preformed fabric carcass while (4) heating the preformed fabric carcass to a temperature which is within the range of 360° F. to 450° F. for a period of at least 6 minutes, and (5) continuously withdrawing the fabric carcass from the press.

Owner:CONTITECH USA INC

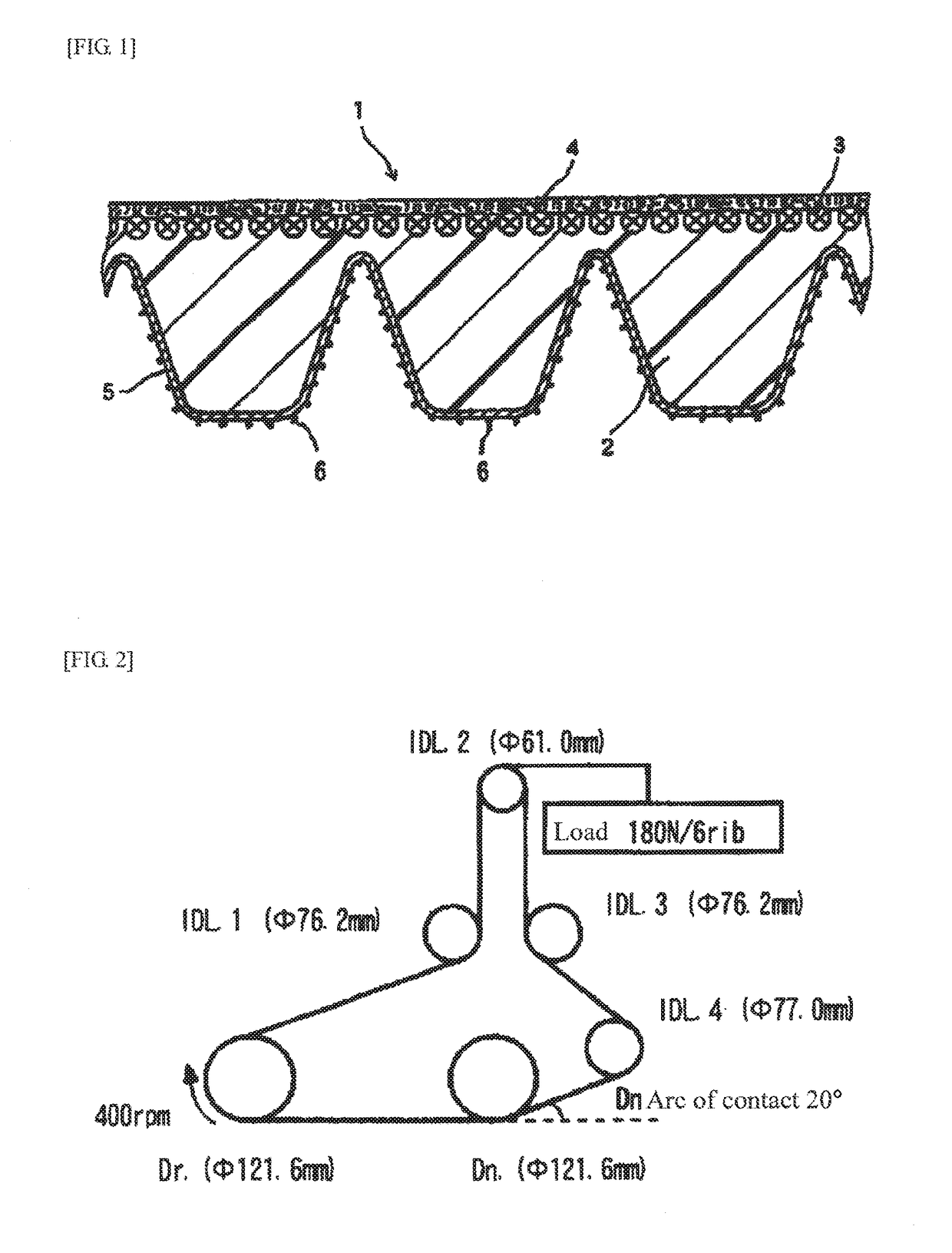

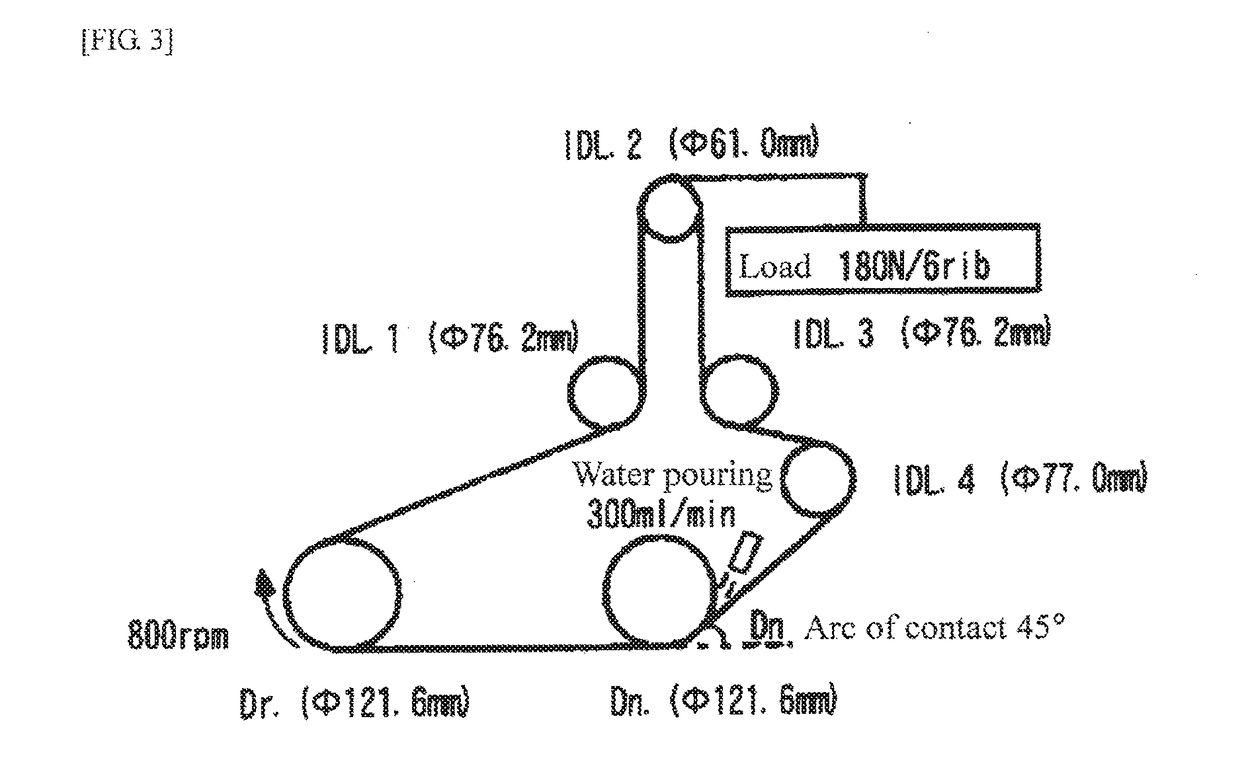

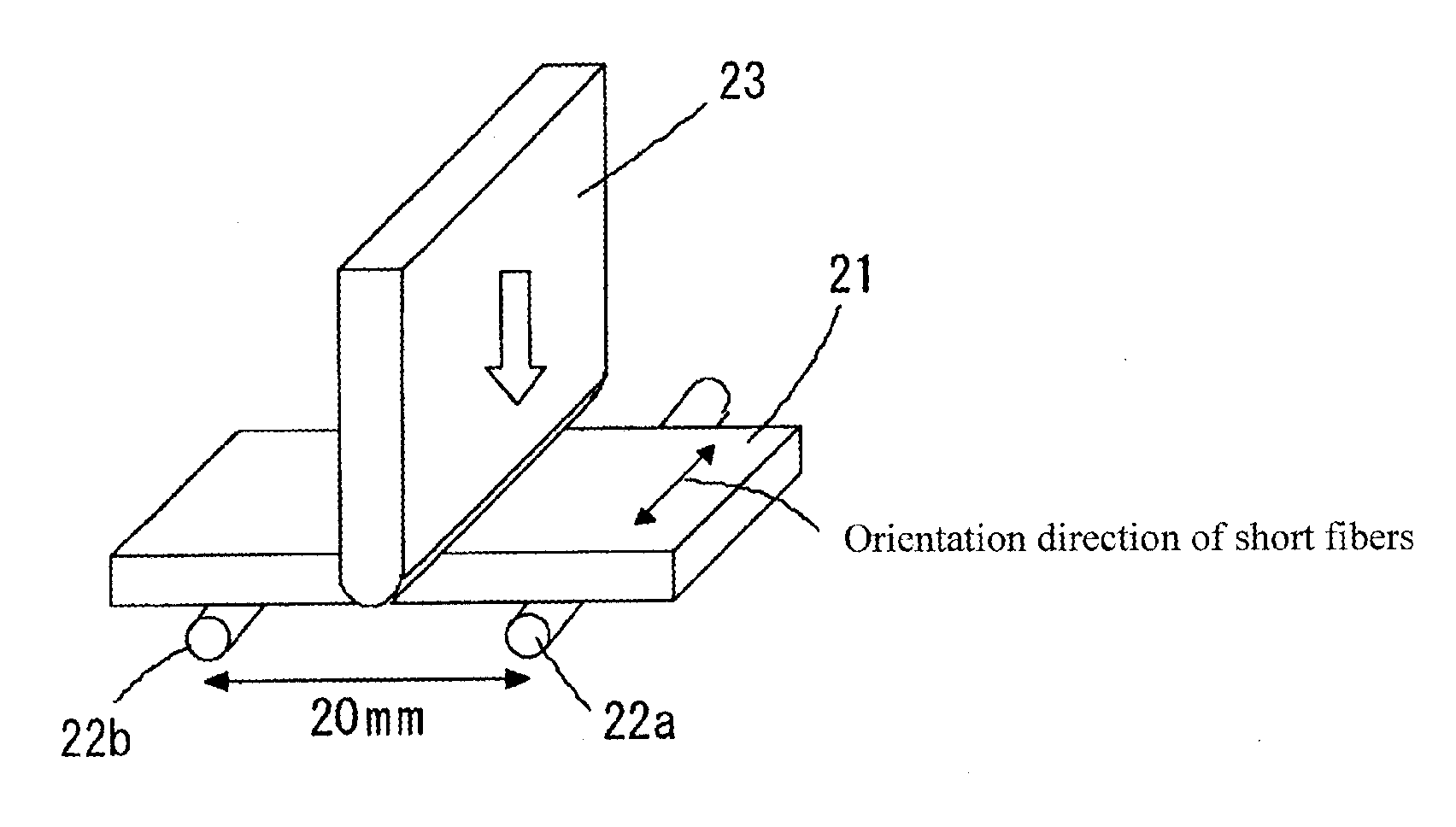

Power-Transmitting Friction Belt and Method for Manufacturing Same

ActiveUS20170284504A1Reduce exposureImprove power transmissionV-beltsDriving beltsFiberPower transmission

The present invention relates to a frictional power transmission belt (1) having a frictional power transmission surface in which the frictional power transmission surface is covered with a fibrous member (5) at least containing water absorptive fibers and an inorganic powder (6) exists in at least a surface of the fibrous member.

Owner:MITSUBOSHI BELTING LTD

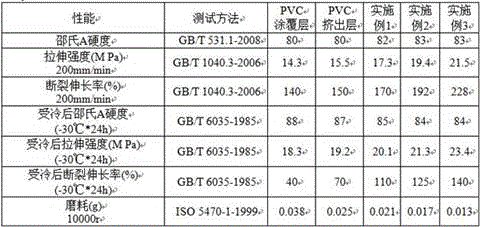

Wear-resistant cold-resistant modified polyvinyl chloride (PVC)/thermoplastic polyurethane elastomer (TPU) composite lightweight conveyor belt and preparation method thereof

InactiveCN106589674AImprove mechanical propertiesGood compatibilityConveyorsSynthetic resin layered productsPolyesterFiber

The invention discloses a wear-resistant cold-resistant modified polyvinyl chloride (PVC) / thermoplastic polyurethane elastomer (TPU) composite lightweight conveyor belt. The conveyor belt is formed by pressing a fiber fabric and a PVC / TPU composite clad material, the PVC / TPU composite clad material comprises the following components in parts by weight: 100 parts of PVC powder, 10-40 parts of TPU powder, 60-70 parts of dioctyl phthalate, 4-6 parts of epoxidized soybean oil, 2-4 parts of calcium-zinc composite heat stabilizer and 5-10 parts of ground calcium carbonate, so as to prepare the wear-resistant cold-resistant modified polyvinyl chloride (PVC) / thermoplastic polyurethane elastomer (TPU) composite lightweight conveyor belt. Because the compatibility of the polyester type TPU and the suspension type PVC of the composite clad material is good, the TPU can be uniformly dispersed in the PVC, the wear resistance and the low temperature resistance of the clad layer of the conveyor belt can be improved, the mechanical property of the material can be improved, the wear-resistant and low-temperature-resistant performance is superior to that of a traditional PVC coating clad layer, and the lightweight conveyor belt can be used for a long term in a low-temperature environment at the temperature of 30 DEG C, and the technical problems that the lightweight conveyor belt is prone to brittle cracking, easy to wear and the like in a low-temperature environment can be effectively solved.

Owner:AA IND BELTING (SHANGHAI) CO LTD

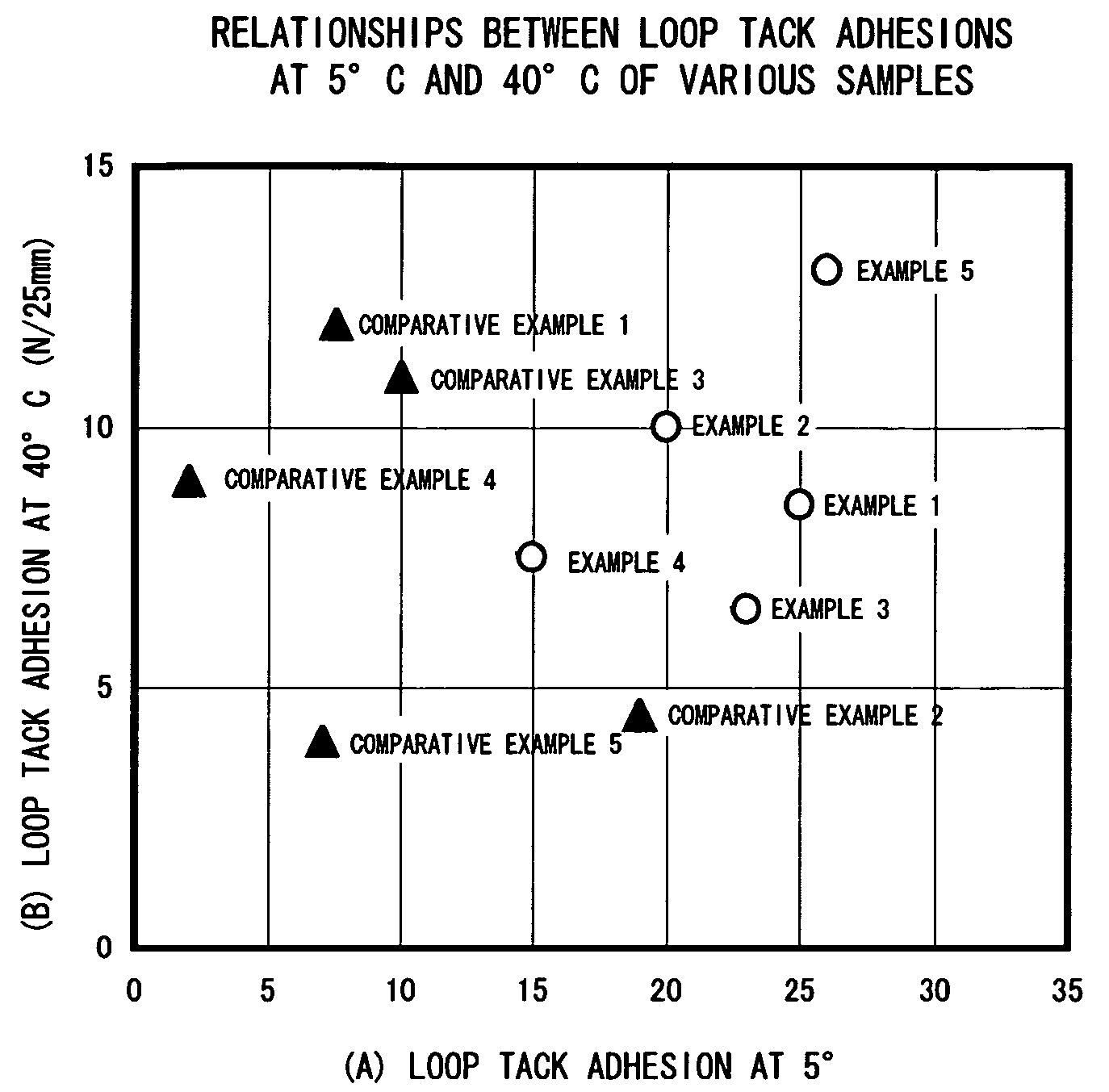

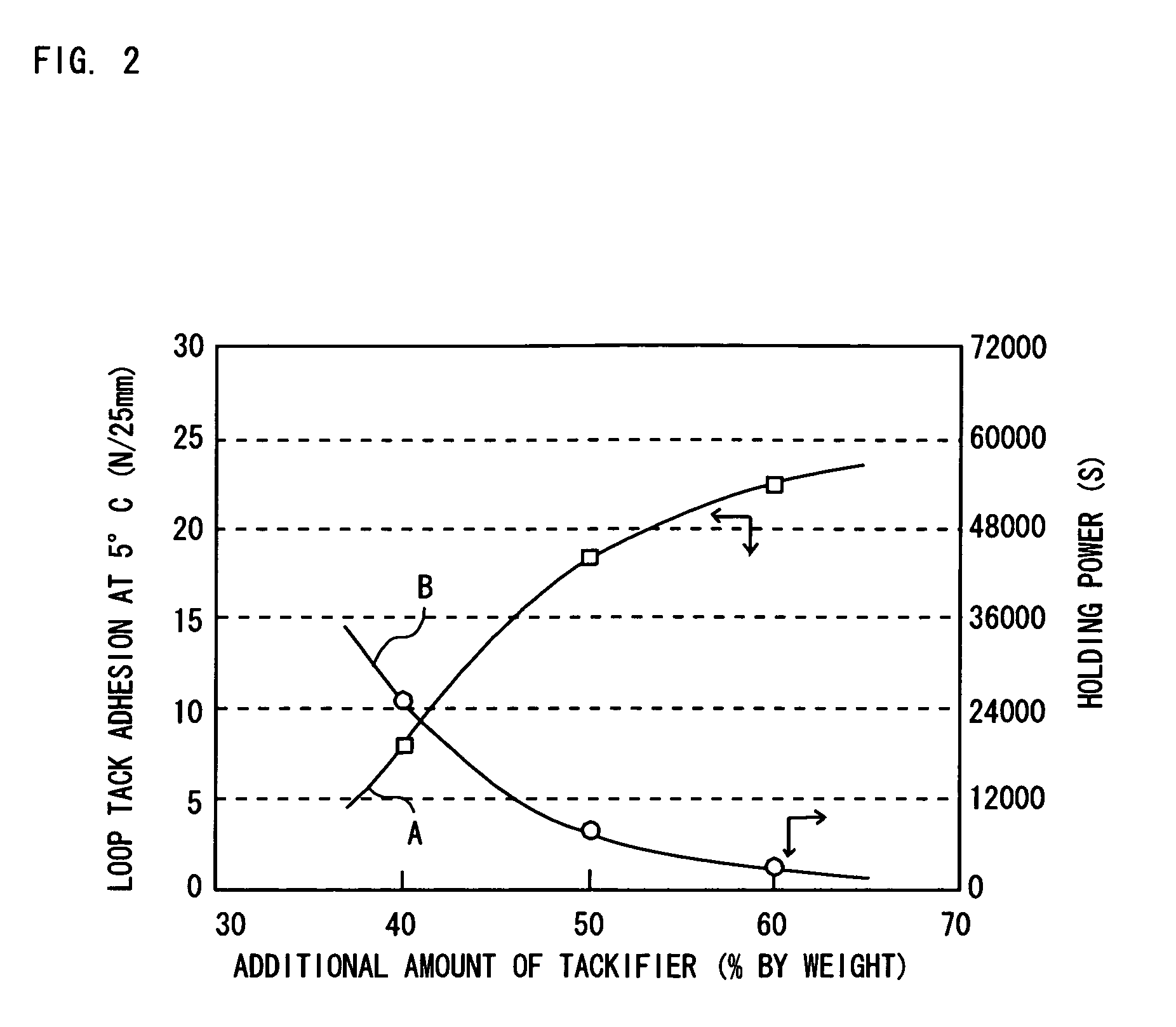

Pressure sensitive adhesive sheet for a tire and producing method for the same

ActiveUS20070054118A1Solve the lack of adhesionStrong adhesionFilm/foil adhesivesAdhesive articlesAdhesive cementPolymer science

A pressure-sensitive adhesive sheet for a tire that can be favorably attached to tires at low temperature and to tires such as studless tires is provided, as is a method for manufacturing the pressure-sensitive adhesive sheet for a tire. For the pressure-sensitive adhesive sheet for a tire and the method for manufacturing, the pressure-sensitive adhesive sheet for a tire includes a substrate and an adhesive layer, and the adhesive layer includes a hot melt-type adhesive composition and satisfies adhesive characteristics (A) and (B), where (A) loop tack adhesion at 5° C. is 14N / 25 mm or more, and (B) loop tack adhesion at 40° C. is 5N / 25 mm or more.

Owner:LINTEC CORP

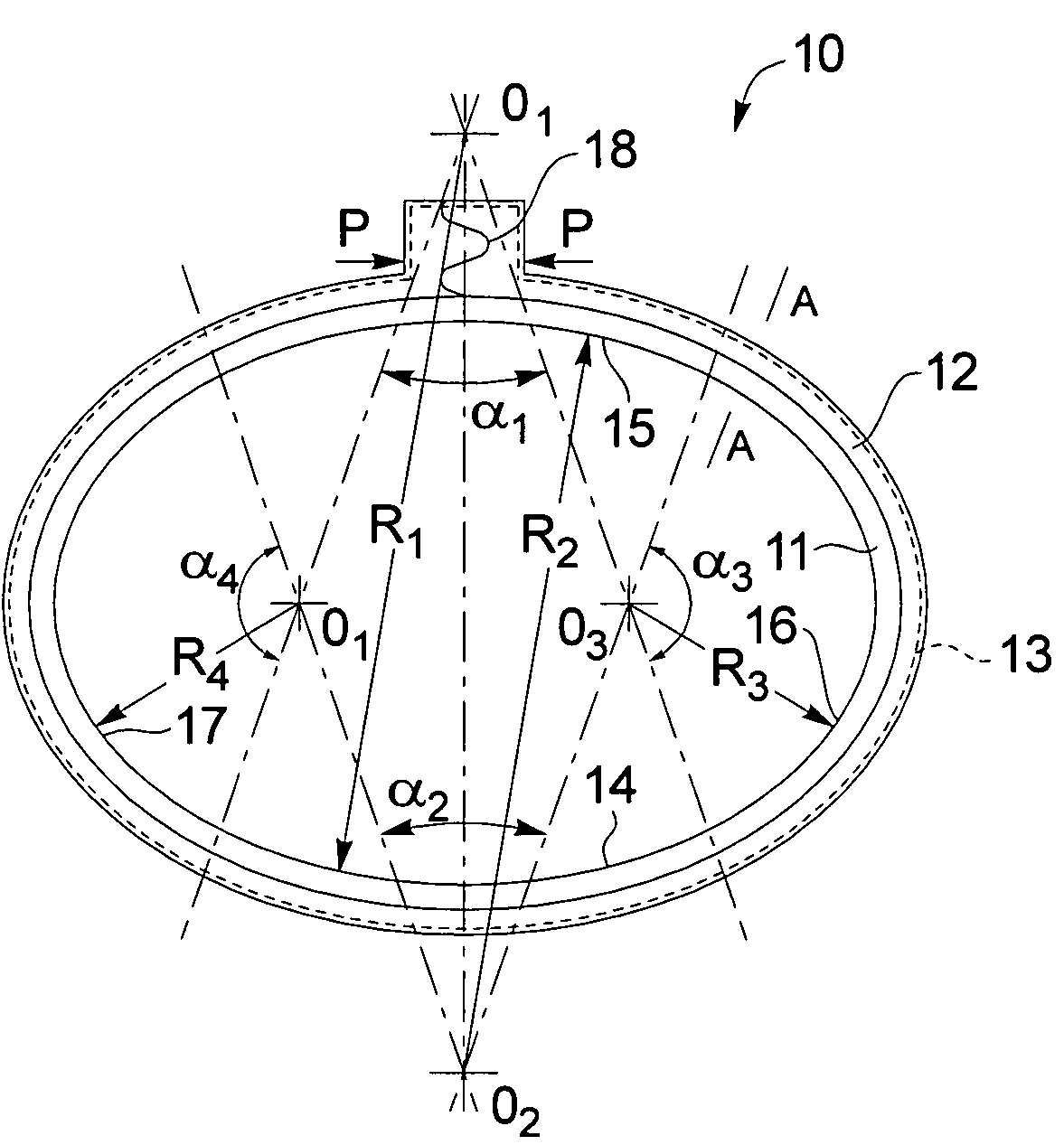

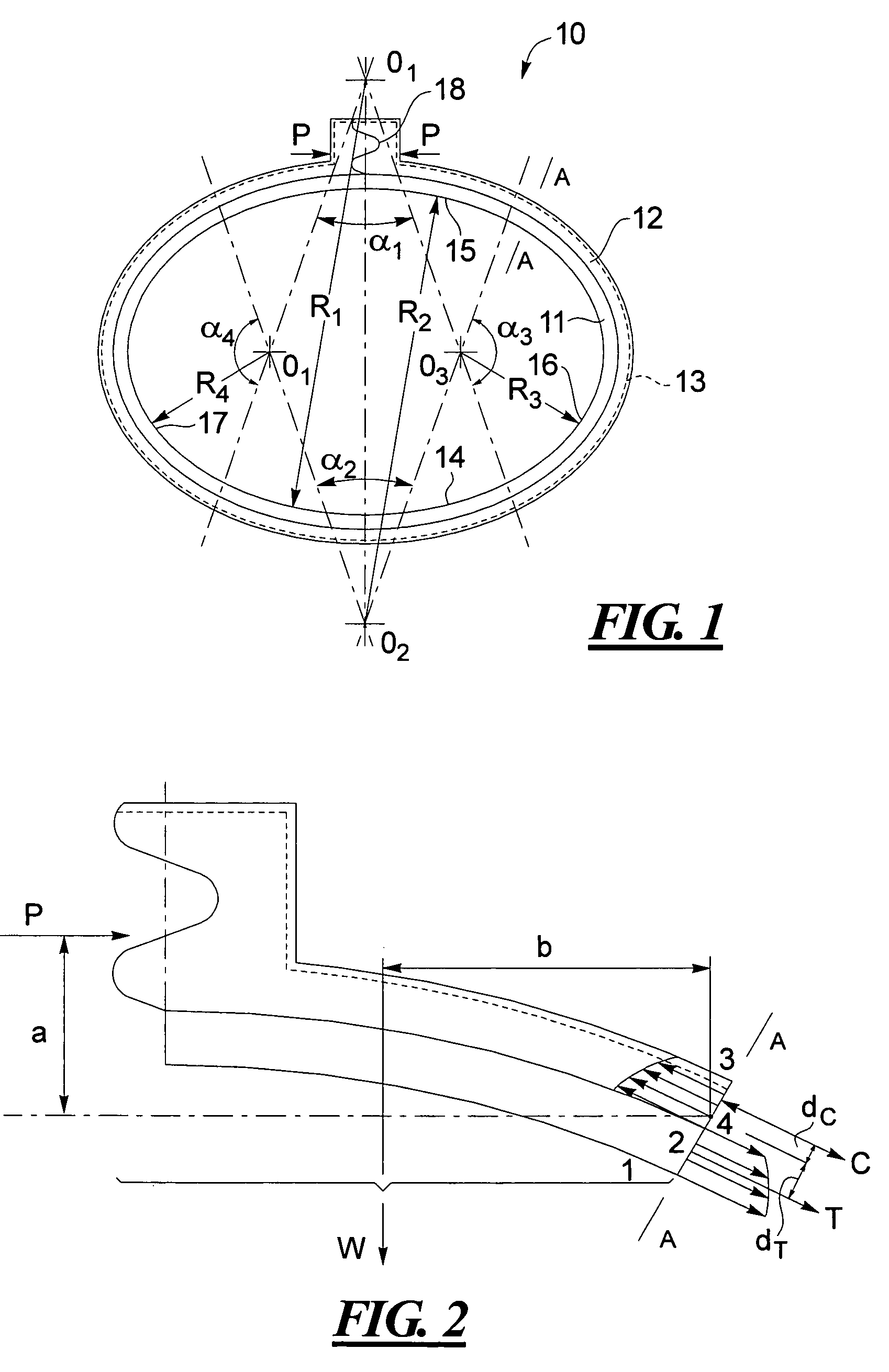

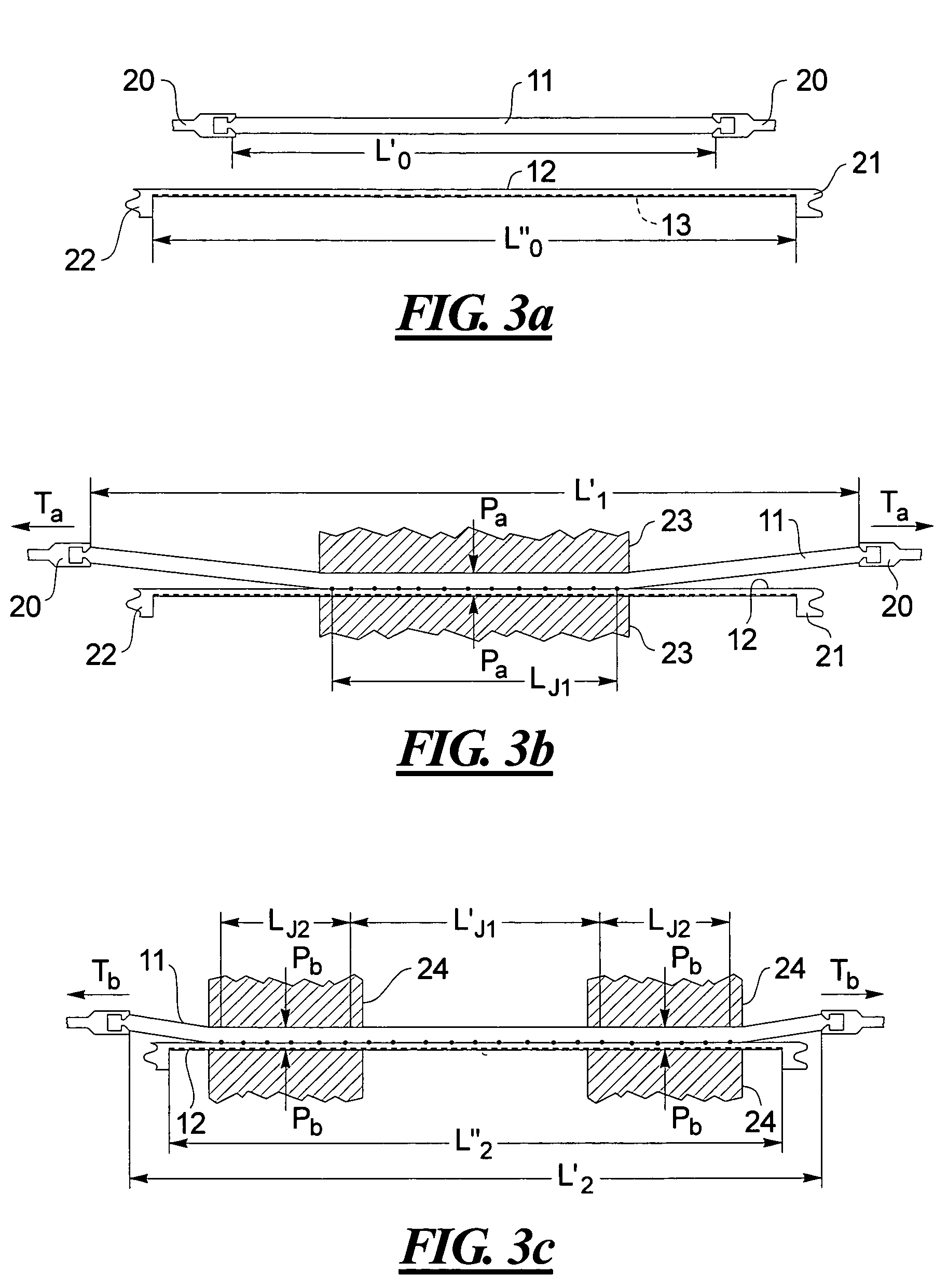

Prestressed tubular belt and method for making

A prestressed tubular belt has variable prestressing forces located along its width to provide control over the shape of the belt, while at the same time providing the proper forces in order to maintain the integrity of the belt shape. Various methods and systems are utilized in the manufacturing of such a tubular belt. One such method involves stretching and affixing one portion of a belt layer to a non-stretched layer in a stepwise manner. Another system and appertaining method involves utilizing anchor strips affixed to a layer of the belt and then stretching the belt in a stepwise manner using ribs on a tool that mate with the anchor strips to hold the layer in varying degrees of tension prior to affixing a second layer to it. Other mechanisms for applying variable prestressing forces are also considered.

Owner:ATBC

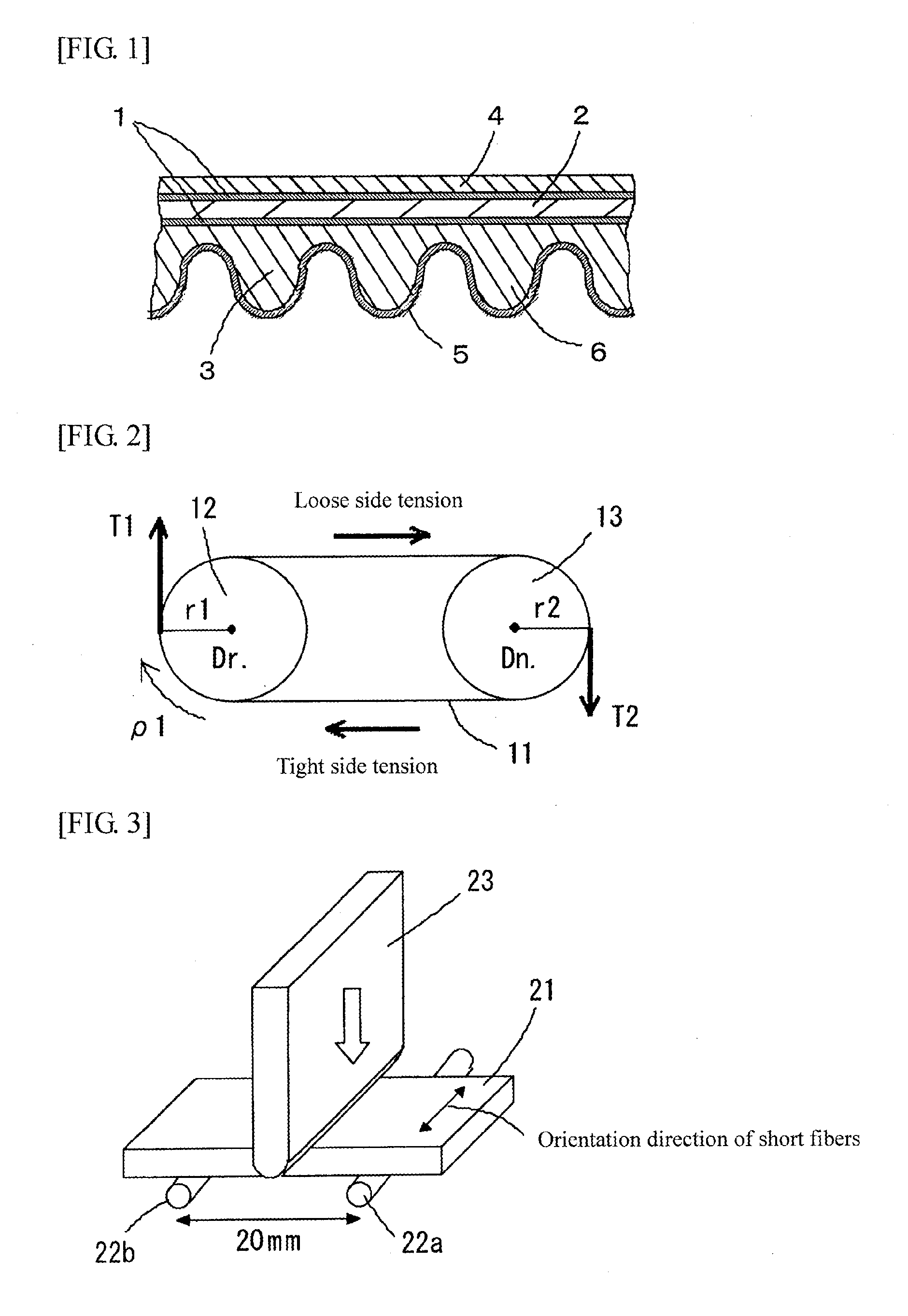

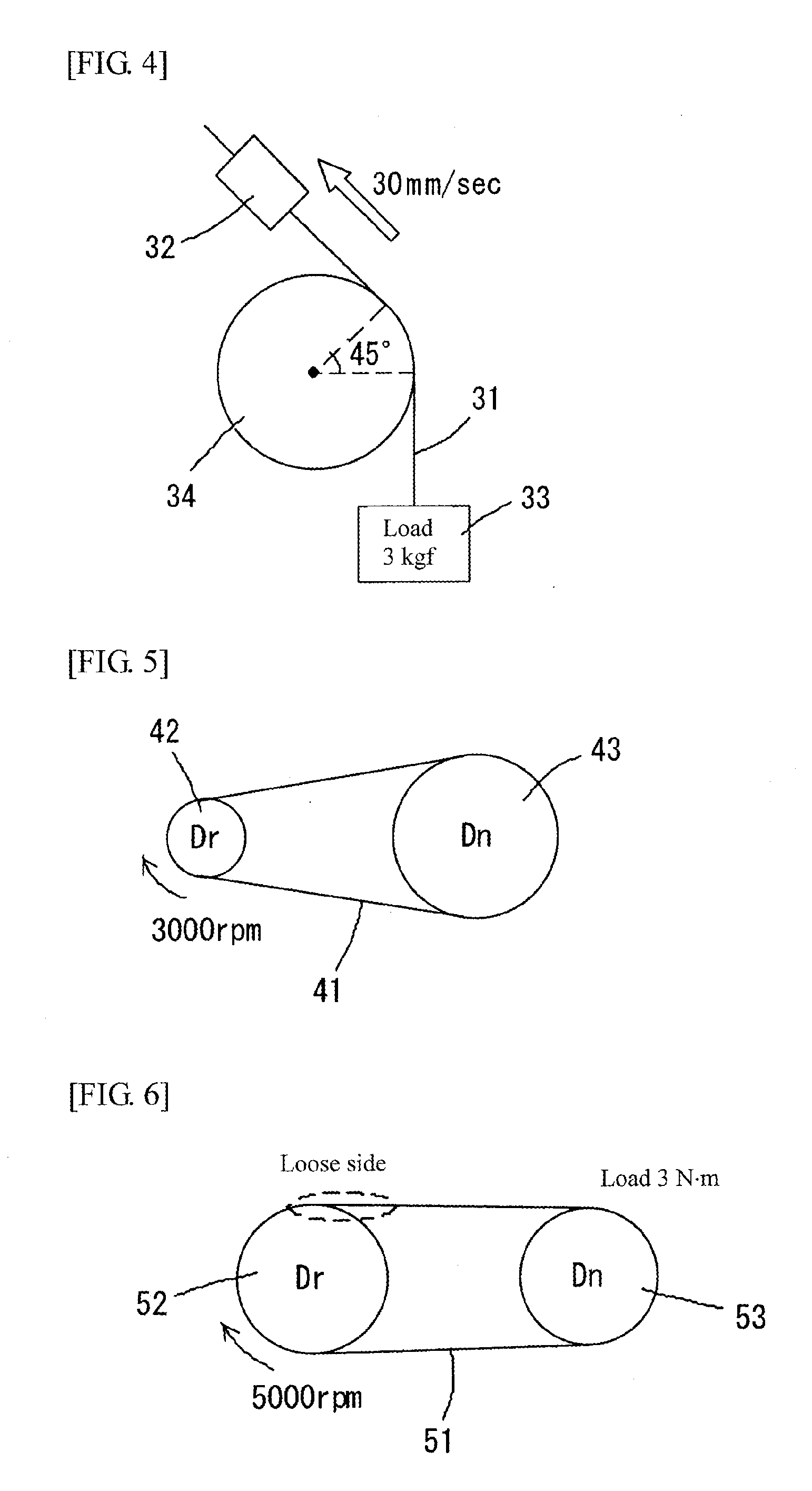

Transmission Belt

ActiveUS20160298725A1Maintain propertiesIncreased durabilityV-beltsSynthetic resin layered productsFiberPolyolefin

The present invention relates to a power transmission belt containing a tension member extending in a belt lengthwise direction, an adhesion rubber layer in contact with at least a part of the tension member, a compression rubber layer formed on one surface of the adhesion rubber layer, and a tension rubber layer formed on other surface of the adhesion rubber layer, in which the compression rubber layer is formed of a vulcanized rubber composition containing a rubber component, a polyolefin resin and a reinforcing material, the rubber component contains a chloroprene rubber, and the reinforcing material contains a short fiber.

Owner:MITSUBOSHI BELTING LTD

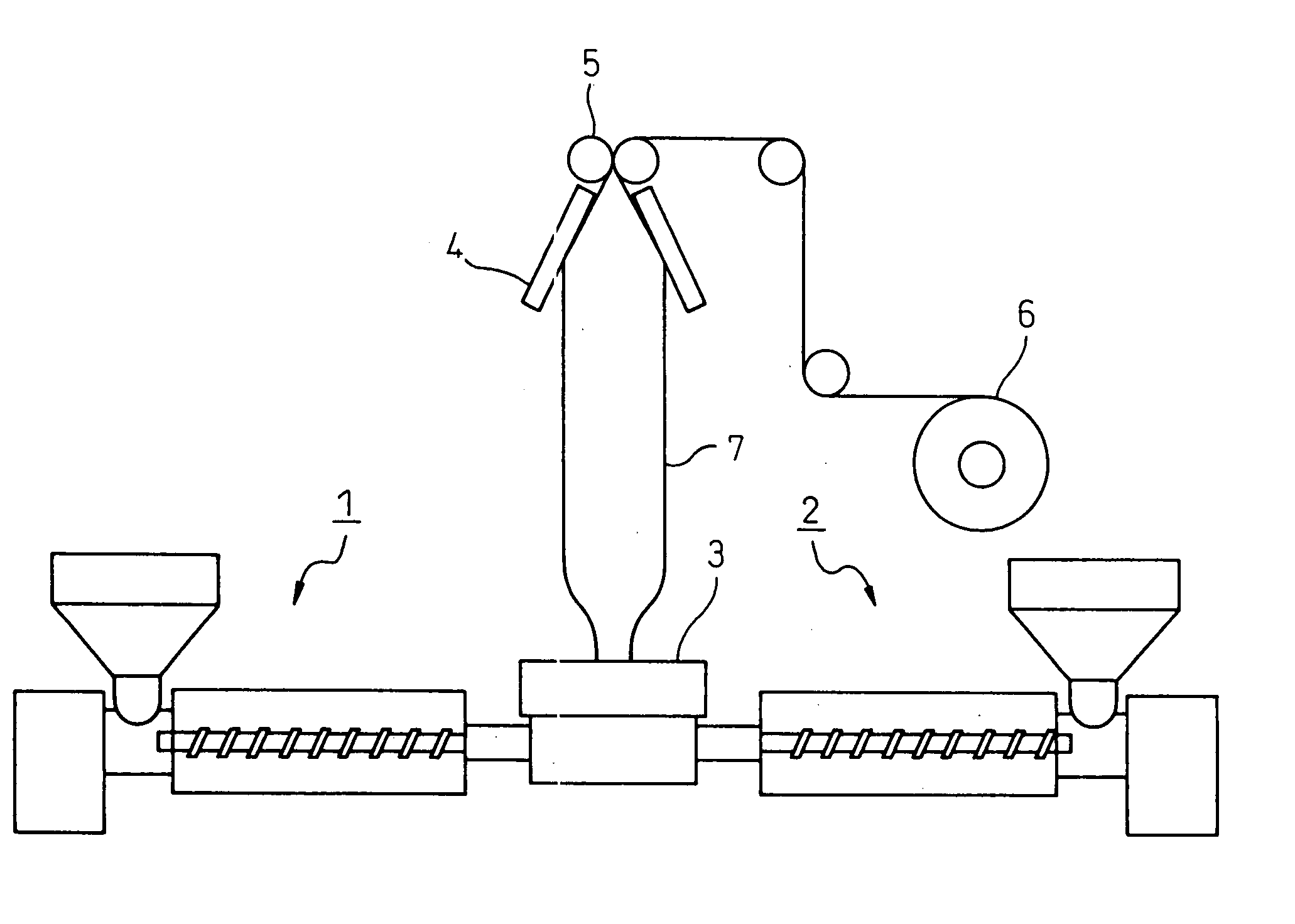

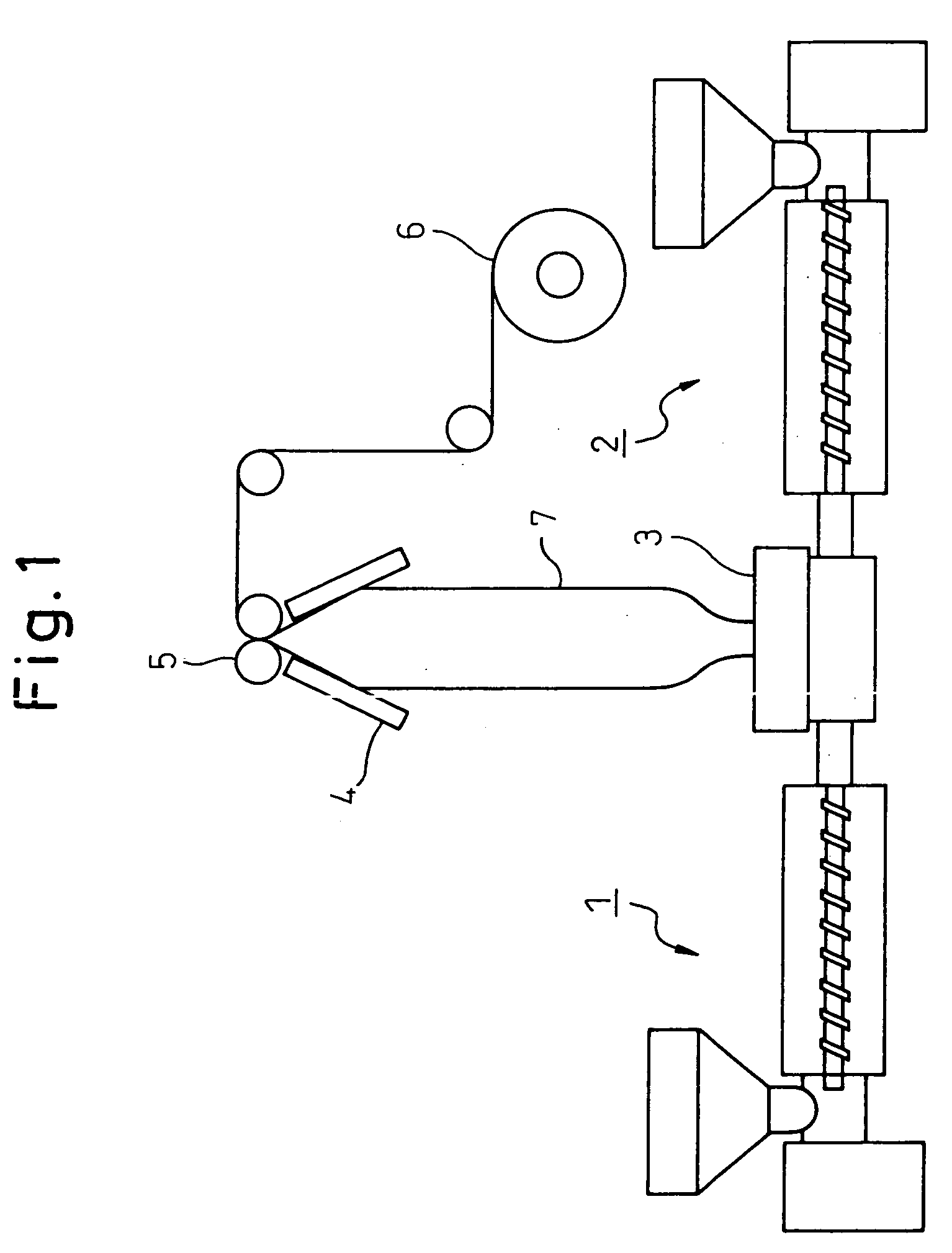

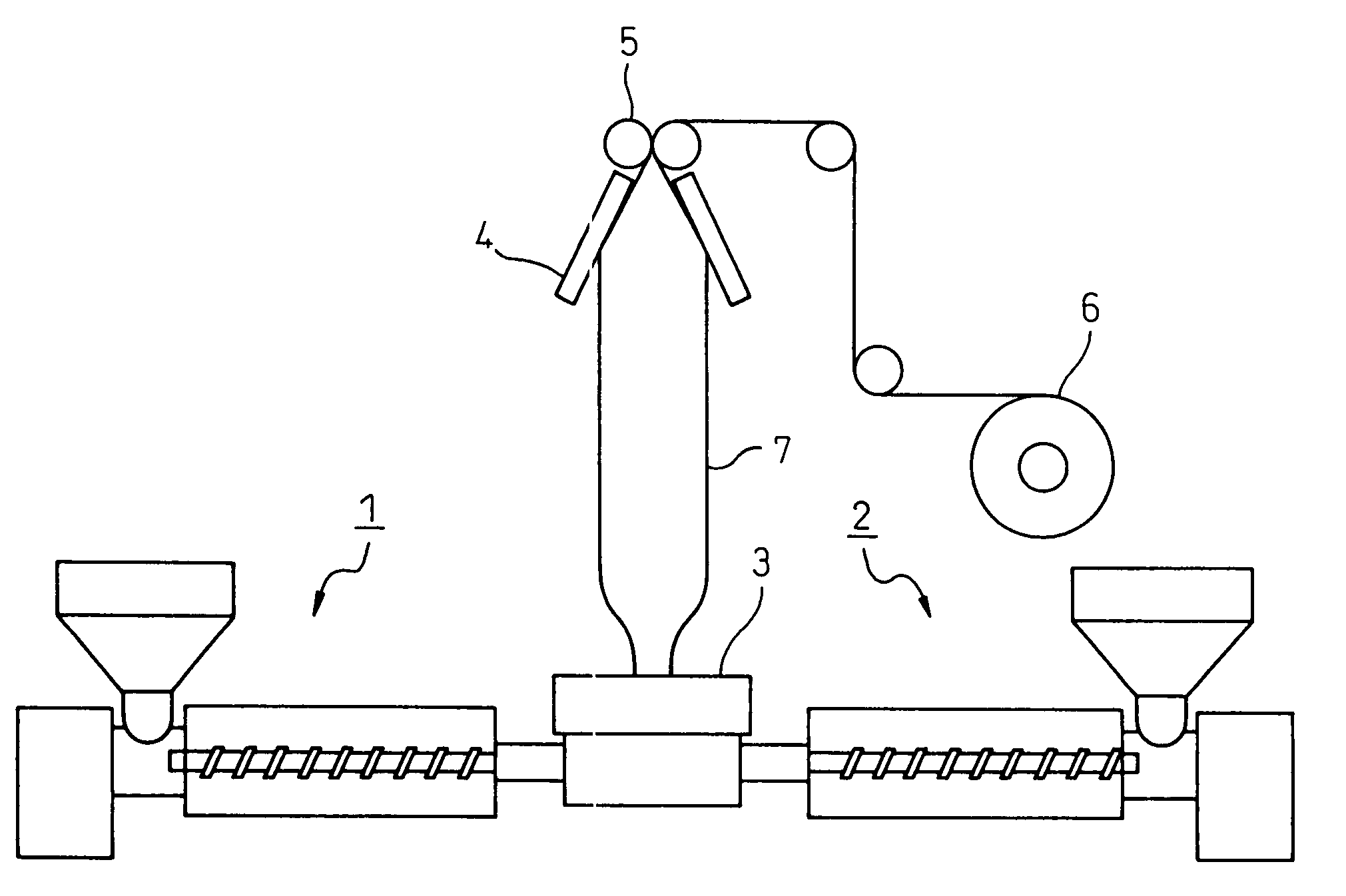

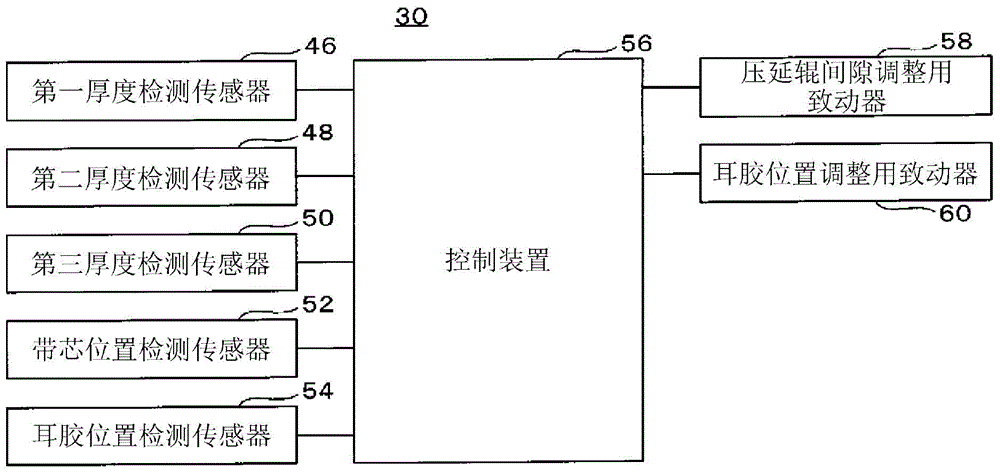

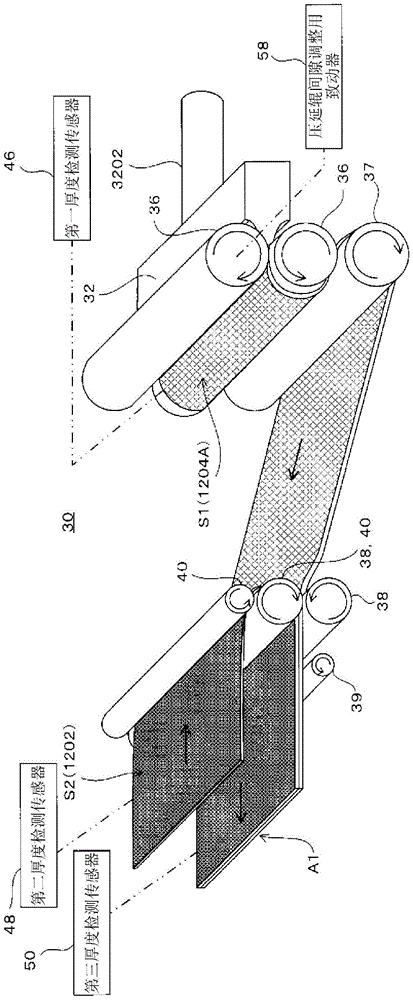

Method for producing laminate

In the present invention, when, while forming a first sheet-shaped member (S1) by rolling a rubber material extruded from a first rubber extruder (32) between a first pair of rollers (36, 36), continuously producing a laminate resulting from laminating the first sheet-shaped member (S1) and a second sheet-shaped member (S2) by overlapping the first sheet-shaped member (S1) and the second sheet-shaped member (S2) supplied from an original material and rolling between a second pair of rollers (38, 38), the gap between the first pair of rollers (36, 36) is controlled on the basis of the detection results of the thickness (d1) of the first sheet-shaped member (S1) rolled by the first pair of rollers (36, 36), the detection results of the thickness (d2) of the second sheet-shaped member (S2) supplied from the original material, and the detection results of the thickness (d3) of the laminate body.

Owner:YOKOHAMA RUBBER CO LTD

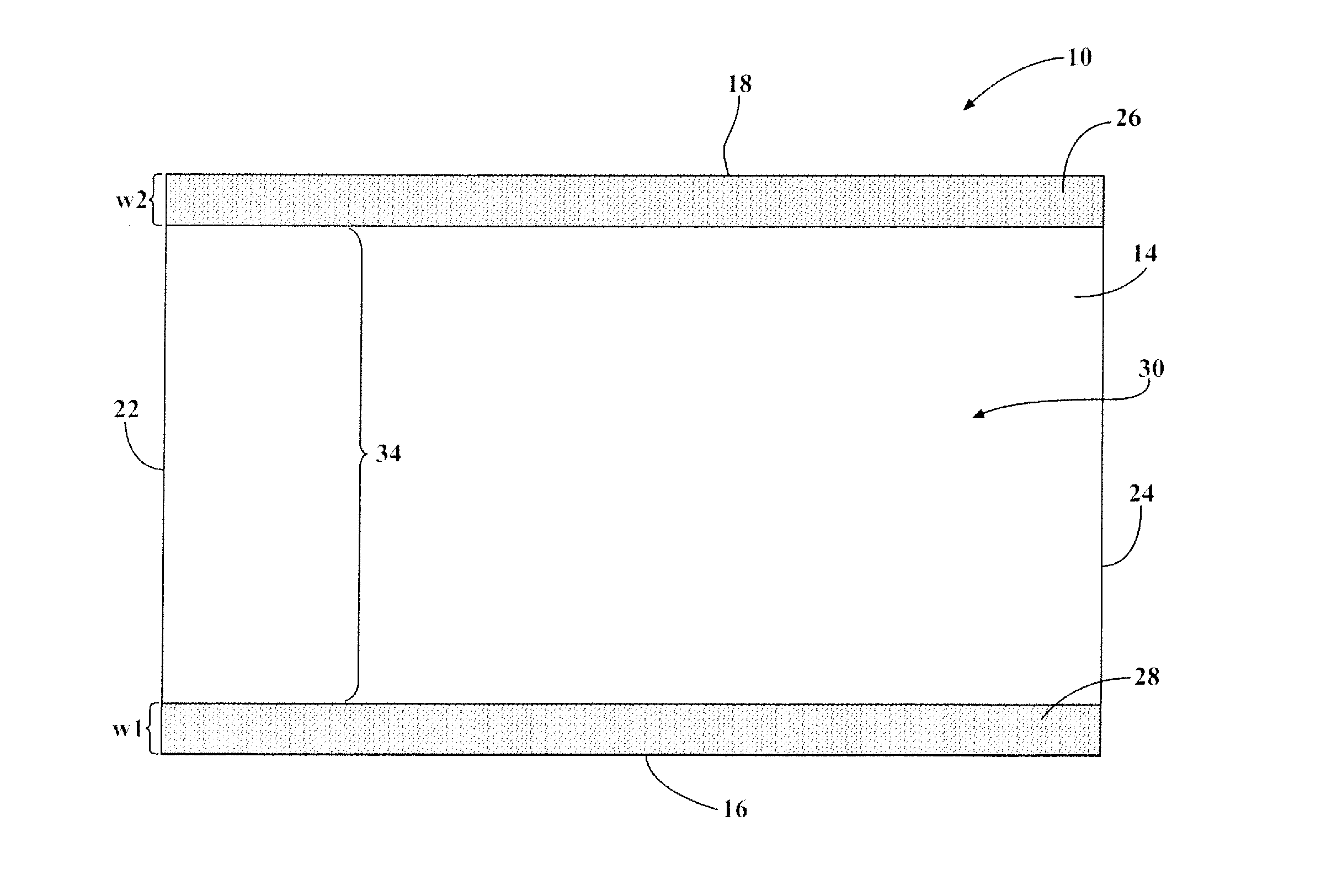

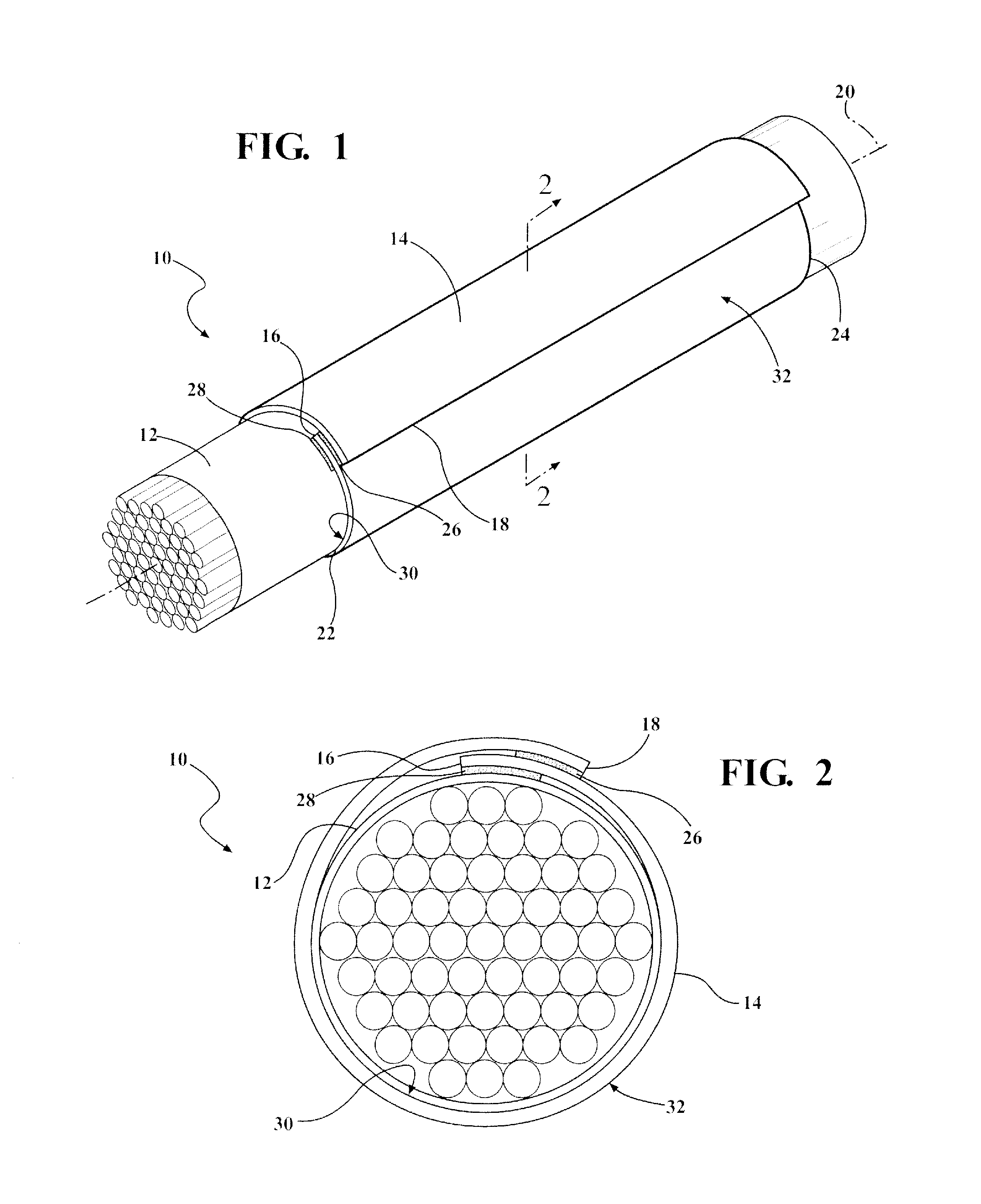

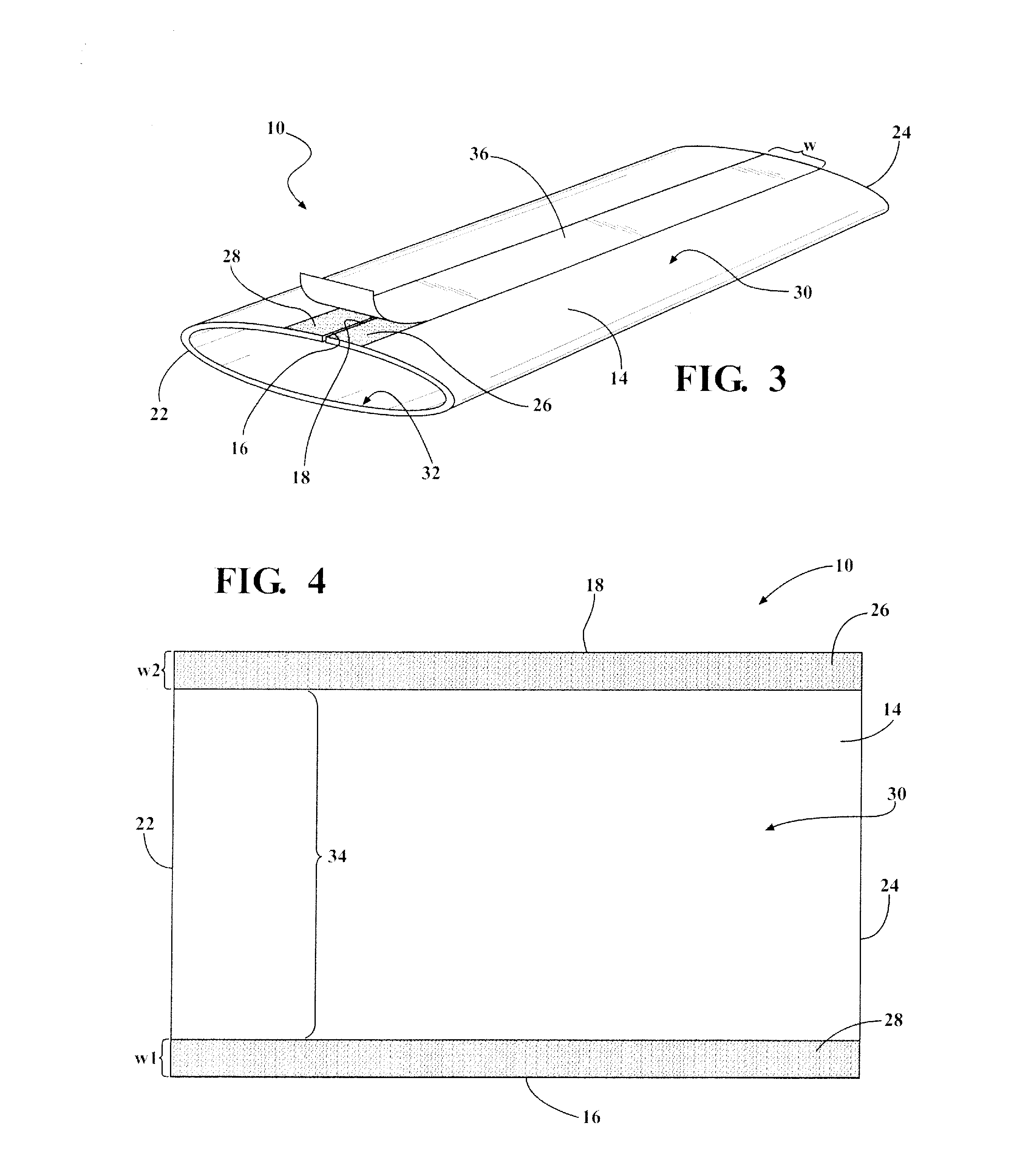

Wrappable Protective Sleeve With Closure And Locating Feature And Methods Of Construction And Use Thereof

ActiveUS20150027623A1Avoid excessive widthElectrical apparatusProtective equipmentEngineeringBuilding construction

A wrappable protective sleeve for providing protection to at least one elongate member contained therein and methods of construction and use thereof are provided. The sleeve includes a flexible textile wall having opposite inner and outer faces bounded by opposite edges and opposite ends. The opposite edges extend generally parallel to one another between the opposite ends. A pair of adhesive layers is bonded to the inner face, with each of the adhesive layers being spaced from one another. The adhesive layers extend between the opposite ends adjacent the opposite edges. Further, a release paper is releasably adhered to the pair of adhesive layers for subsequent removal and use of the sleeve.

Owner:FEDERAL MOGUL POWERTAIN LLC

Articles and methods of making the same

The invention provides an article comprising a first layer and a second layer, and wherein the first layer is formed from a first composition comprising an ethylene / α-olefin / diene interpolymer, an isoprene rubber (synthetic), a natural rubber, a butadiene rubber, a styrene butadiene rubber, a chloroprene rubber, a nitrile rubber, a hydrogenated nitrile rubber, a chlorinated polyethylene, a chlorosulfonated polyethylene, an ethylene / propylene rubber, an ethylene / diene copolymer, a fluoro rubber, a polyurethane, a silicone rubber, or a combination thereof; and wherein the second layer is formed from a second composition comprising a butyl rubber, a halobutyl rubber, polyvinylidene chloride, a brominated polymer derived from a copolymer of isobutylene and p-methyl styrene, a nitrile rubber, a chloroprene rubber, a chlorosulfonated polyethylene, a chlorinated polyethylene, a polyurethane, a fluoro rubber, or a combination thereof.

Owner:DOW GLOBAL TECH LLC

Pressure-sensitive adhesive sheet for tire and method for manufacturing the same

ActiveUS7618705B2Sufficient adhesionStrong adhesionFilm/foil adhesivesAdhesive articlesHot meltEngineering

A pressure-sensitive adhesive sheet for a tire that can be favorably attached to tires at low temperature and to tires such as studless tires is provided, as is a method for manufacturing the pressure-sensitive adhesive sheet for a tire. For the pressure-sensitive adhesive sheet for a tire and the method for manufacturing, the pressure-sensitive adhesive sheet for a tire includes a substrate and an adhesive layer, and the adhesive layer includes a hot melt-type adhesive composition and satisfies adhesive characteristics (A) and (B), where (A) loop tack adhesion at 5° C. is 14N / 25 mm or more, and (B) loop tack adhesion at 40° C. is 5N / 25 mm or more.

Owner:LINTEC CORP

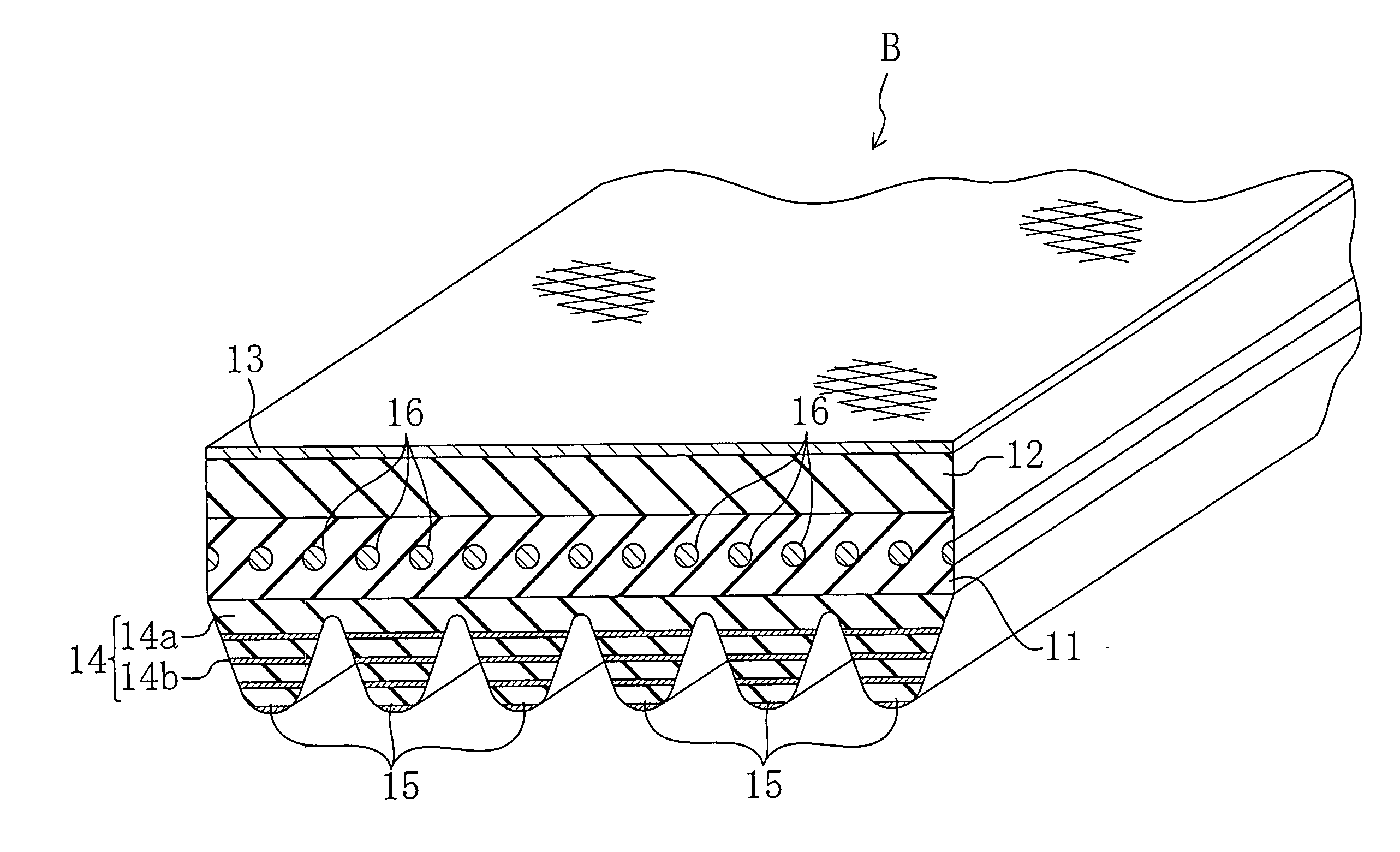

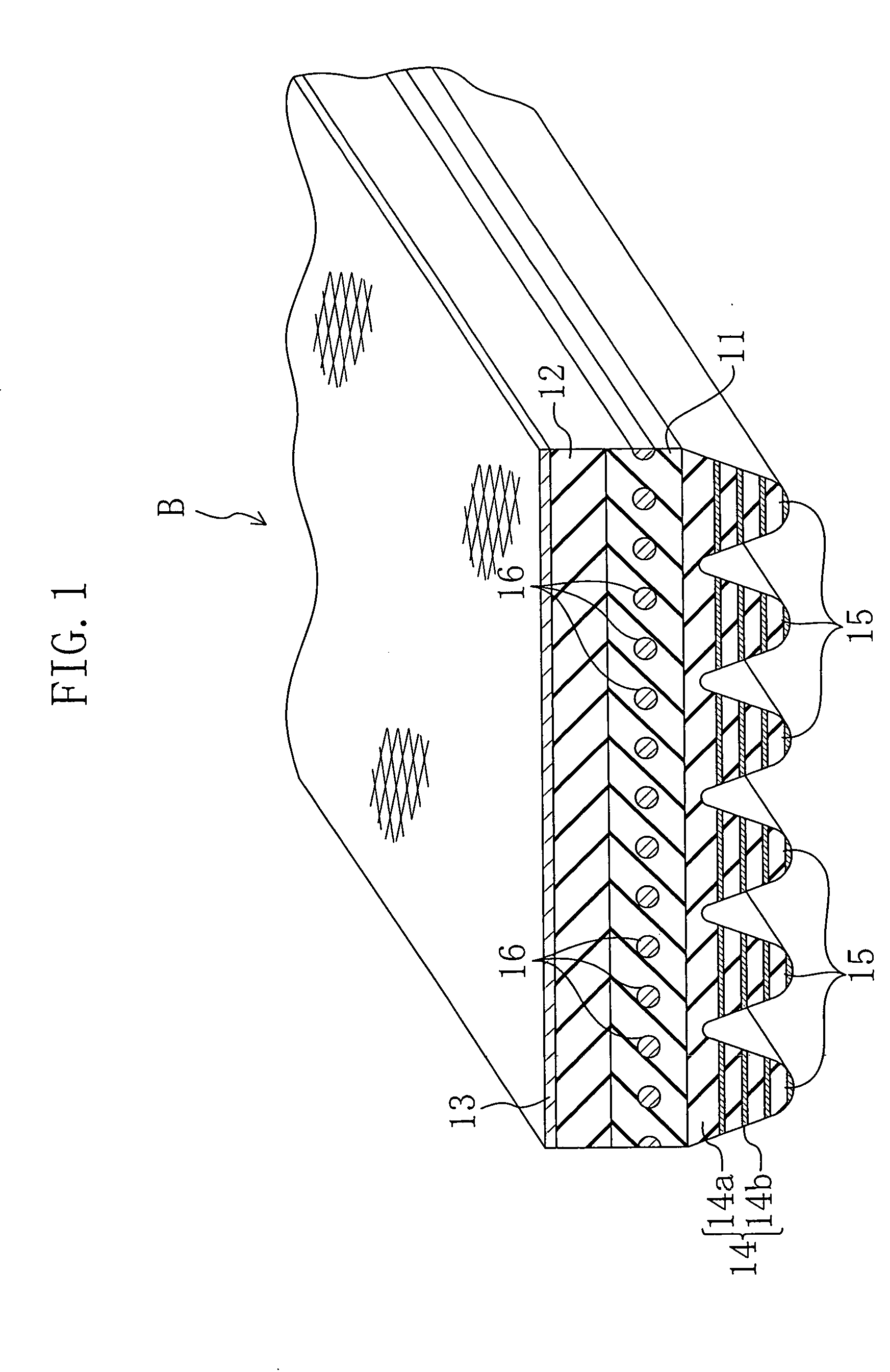

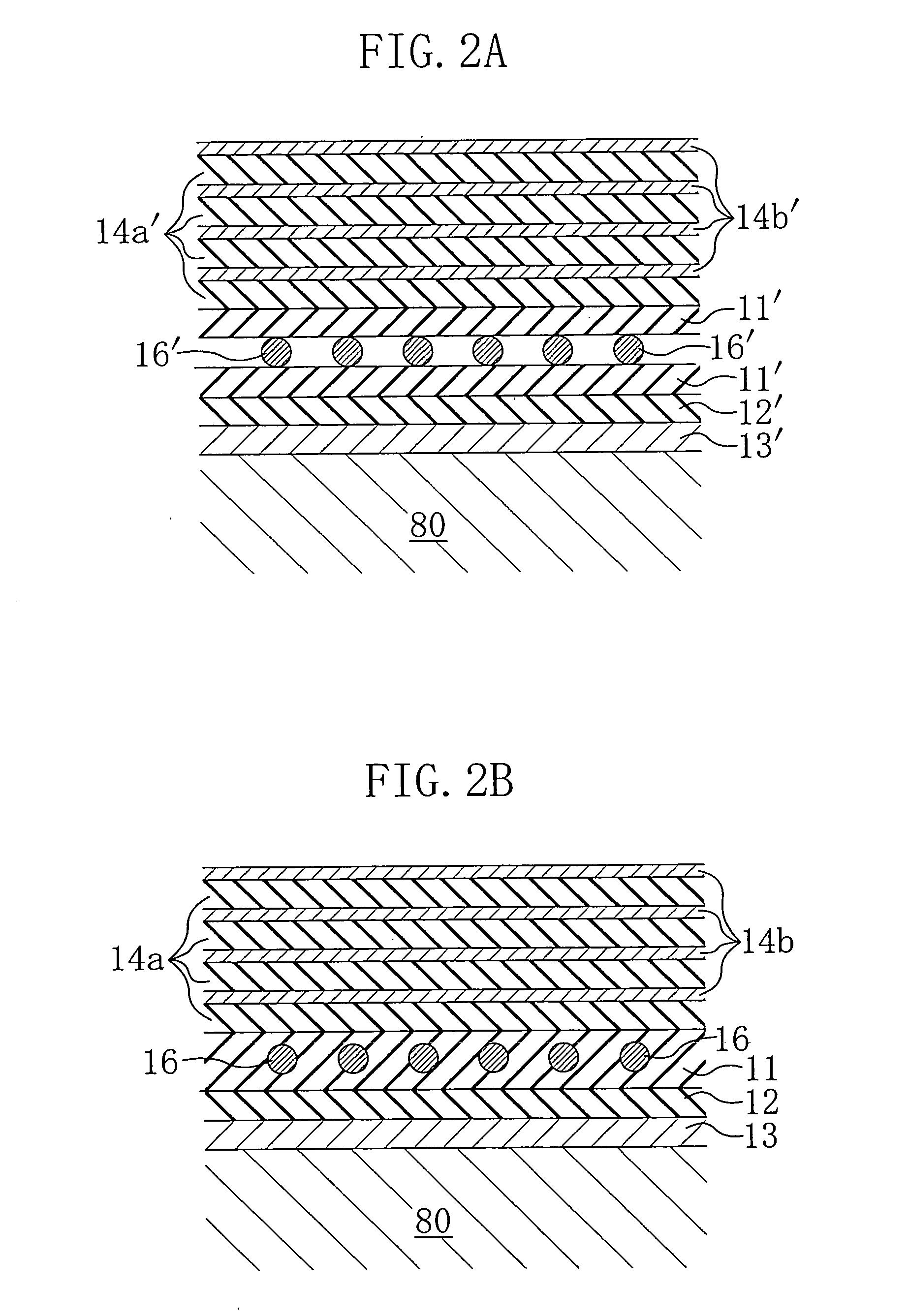

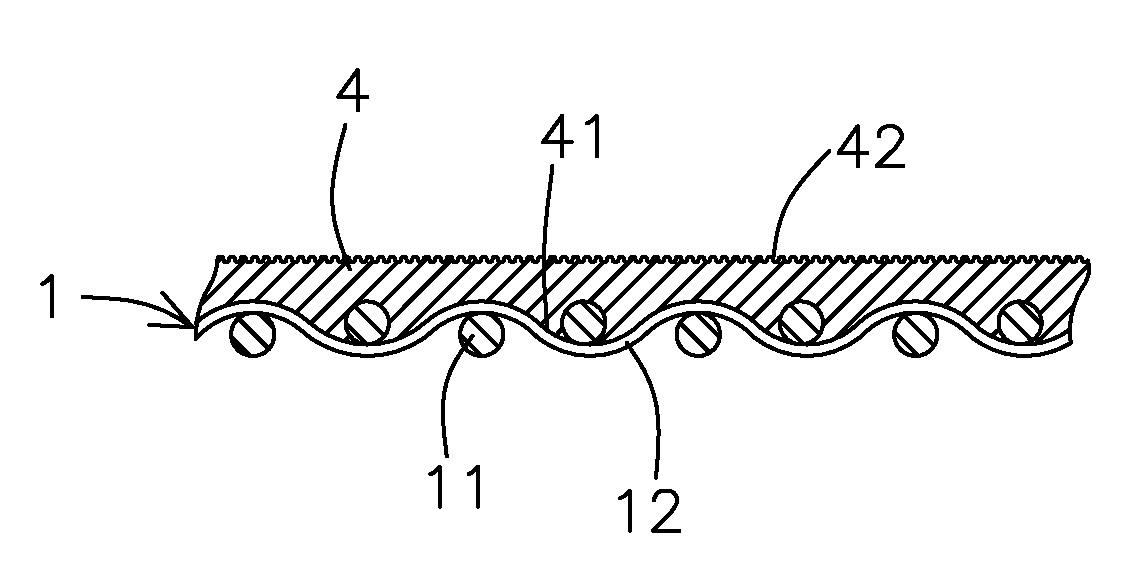

Conveyor belt or treadmill belt

InactiveUS20100304936A1Preferred stepping comfortnessSynthetic resin layered productsWoven fabricsEngineeringConveyor belt

A conveyor belt or treadmill belt comprises a cloth layer woven by at least one warp and woof and having an outer surface and an inner surface in response to each other, a clearance passing through the inner and the outer surfaces and being formed between the warp and the woof; a laminating layer serving as being stepped, the laminating layer being molded to a laminated film and melted to couple with an outer surface of the cloth layer, such that the laminating layer merges into the clearance between the warp and the woof of the cloth layer so that the laminating layer is integrally formed a rough connecting surface; a gel layer coated on an inner surface of the cloth layer so as to link with the connecting surface of the laminating layer, thus engaging the cloth layer between the gel layer and the laminating layer.

Owner:WANG SHUEI MU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com