Wear-resistant cold-resistant modified polyvinyl chloride (PVC)/thermoplastic polyurethane elastomer (TPU) composite lightweight conveyor belt and preparation method thereof

A lightweight conveyor belt, composite material technology, applied in conveyors, chemical instruments and methods, transportation and packaging, etc. problem, to achieve good compatibility, improve mechanical properties, improve wear resistance and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Present embodiment 2 is basically the same as embodiment 1, and its difference is:

[0040] In this embodiment 2, the composite cladding material includes the following components in parts by weight:

[0041] 100 parts of PVC powder;

[0042] 20 parts of TPU powder;

[0043] 60 parts of dioctyl phthalate;

[0044] 6 parts of epoxidized soybean oil;

[0045] 4 parts of calcium zinc composite heat stabilizer;

[0046] 10 parts of heavy calcium carbonate.

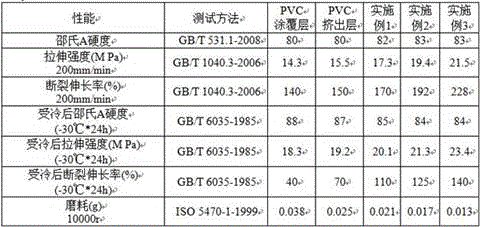

[0047] Performance testing was performed on the wear-resistant and cold-resistant modified PVC / TPU composite lightweight conveyor belt prepared in Example 2 above. The test results are shown in Table 1.

Embodiment 3

[0049] Present embodiment 3 is basically the same as embodiment 1, and its difference is:

[0050] In this embodiment 3, the composite cladding material includes the following components in parts by weight:

[0051] 100 parts of PVC powder;

[0052] 30 parts of TPU powder;

[0053] 60 parts of dioctyl phthalate;

[0054] 6 parts of epoxidized soybean oil;

[0055] 4 parts of calcium zinc composite heat stabilizer;

[0056] 10 parts of heavy calcium carbonate.

[0057] The wear-resistant and cold-resistant modified PVC / TPU composite lightweight conveyor belt prepared in Example 3 above was tested for performance, and the test results are shown in Table 1.

[0058] In order to detect the technical effect of the wear-resistant and cold-resistant modified PVC / TPU composite light conveyor belt prepared in the embodiment of the present invention, GB / T 531.1-2008, GB / T 1040.3-2006, GB / T 6035-1985, The method specified in ISO 5470-1-1999 was used for performance testing, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com