Easy-to-use ink-jet heat sublimation transfer paper

一种转印纸、热升华的技术,应用在特种纸、造纸、印刷等方向,能够解决提高干燥速度的能力受限、托墨能力差、涂布的量多等问题,达到干燥速度快、提高转印率、伸缩率低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

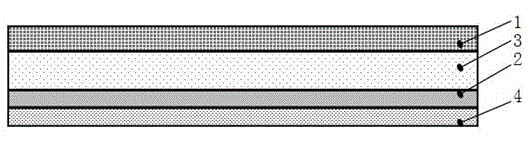

[0039] like figure 1 As shown, an easy-to-use inkjet sublimation transfer paper includes an ink carrier layer 1, a paper fiber bonding layer 2, a base paper layer 3 and a back coating layer 4, and the transfer paper is back from bottom to top. Coating layer 4, base paper layer 3, paper fiber bonding layer 2 and ink carrier layer 1.

[0040] The basis weight of the base paper layer 3 is 30g / m 2 , water absorption value is 80g / m 2 , The pulp is 50% hardwood pulp and 50% softwood pulp.

[0041] The ink layer is selected from polyanionic cellulose, and the degree of substitution is greater than 0.9. The solid weight ratio of anionic cellulose and hydrophobic starch is 40%: 60%. The mixing process is to first disperse and dissolve polyanionic cellulose with warm water, and then add hydrophobic starch dispersed in cold water. mix. The ink-carrying layer coating is coated with a doctor blade, one layer of coating, and the total dry weight of the ink-carrying layer coating is 3g / ...

Embodiment 2

[0046] like figure 2 As shown, an easy-to-use inkjet sublimation transfer paper includes an ink carrier layer 1, a paper fiber bonding layer 2, a base paper layer 3 and a back coating layer 4, and the transfer paper is back from bottom to top. Coating layer 4, paper fiber bonding layer 2, base paper layer 3 and ink carrier layer 1.

[0047] The basis weight of the base paper layer 3 is 30g / m 2 , water absorption value is 80g / m 2 , The pulp is 50% hardwood pulp and 50% softwood pulp.

[0048] The ink carrier layer 1 is selected from polyanionic cellulose, and the degree of substitution is greater than 0.9. The solid weight ratio of anionic cellulose and hydrophobic starch is 40%: 60%. The mixing process is to first disperse and dissolve polyanionic cellulose with warm water, and then add hydrophobic starch dispersed in cold water. mix. The coating of the ink-carrying layer 1 is coated with a doctor blade, one layer of coating, and the total dry weight of the ink-carrying ...

Embodiment 3

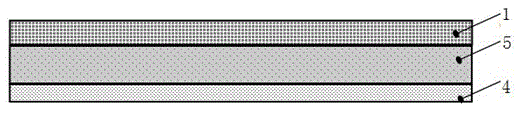

[0053] like image 3 Shown, a kind of easy-to-use ink-jet heat-sublimation transfer paper, comprises ink support layer 1, paper fiber binder and base paper layer mixed layer 5 and back coating 4, and described transfer paper is successively from bottom to top Back coat layer 4, paper fiber binder and base paper layer mixed layer 5 and ink carrier layer 1.

[0054] The adhesive of the paper fiber adhesive layer 2 can also penetrate into the base paper layer 3 to form a mixed layer 5 of the paper fiber adhesive and the base paper layer.

[0055] The quantitative of paper fiber binder and base paper layer mixed layer 5 is 45g / m 2 , water absorption value is 50g / m 2 , The pulp is 85% hardwood pulp and 15% softwood pulp. In the papermaking process, pour 10% solid content of polyamide urea resin aqueous solution into the sizing machine inside the machine, and apply it by soaking. The dry coating amount is about 1.5g / m on both sides. 2 , become the mixed layer 5 of paper fiber bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com