A fourdrinier multi-cylinder paper machine for producing high-filler paper

A paper machine, high filler technology, applied in the direction of paper machine, paper making, paper machine wet end, etc., can solve the problems of high retention rate of filler, failure to meet process requirements, poor water filtration performance, etc. , to achieve enhanced rapid and uniform forming, improved dehydration effect, and enhanced good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

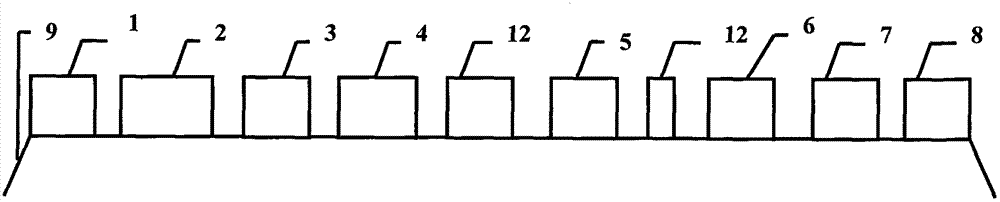

[0073] like figure 2 Shown, a kind of Fourdrinier multi-cylinder paper machine for producing high filler paper according to the present invention, it also has headbox 1, wire section 2, press section 3, front drying section 4, sizer 5, Post-drying section 6, calender 7, paper roll section 8, the above-mentioned parts are sequentially installed on the frame 9, and the connection and installation method is the same as that of the traditional paper machine. Among them, the headbox 1, the press section 3, the sizing machine 5. The form and structure of the calender 7 and the roll section 8 are the same as those of the traditional fourdrinier multi-cylinder paper machine with the same width and speed;

[0074] The difference from the structure of the traditional fourdrinier multi-cylinder paper machine with the same width and speed is:

[0075] 1. The structure of network part 2

[0076] like figure 1 , 3 , 5, the wire section 2 of a traditional paper machine has a forming wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com