Zero-emission technology for adopting oxidation heat twisting combination method for manufacturing straw pulp

A combination method and straw technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of limited application range, large amount of glue used, uneven cloth, etc., and achieve saving resources, improve stability, and overcome the effect of sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

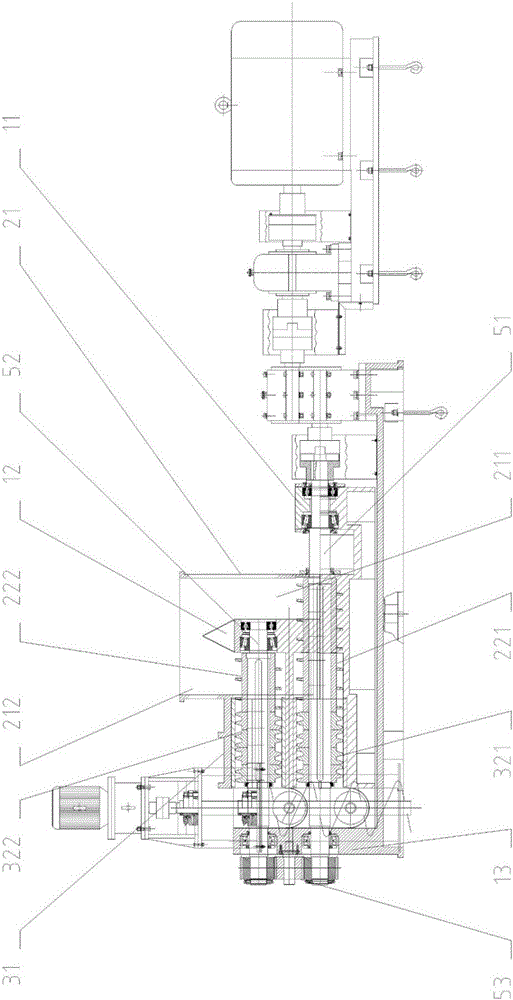

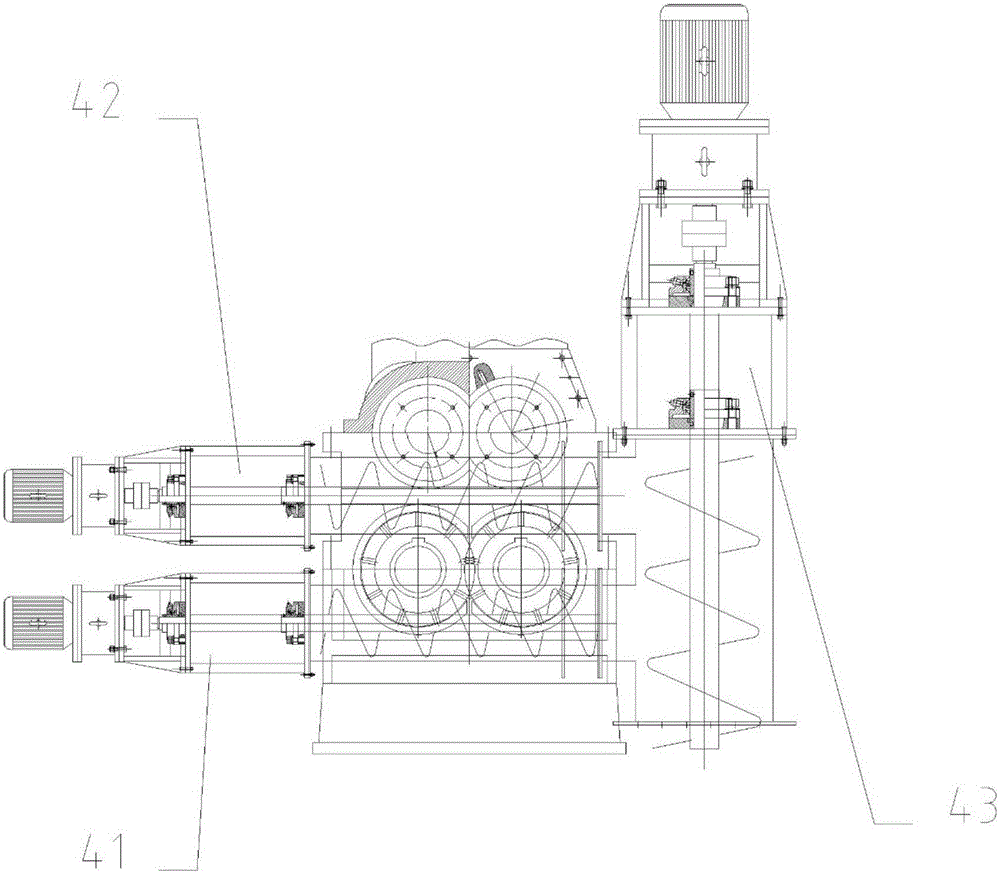

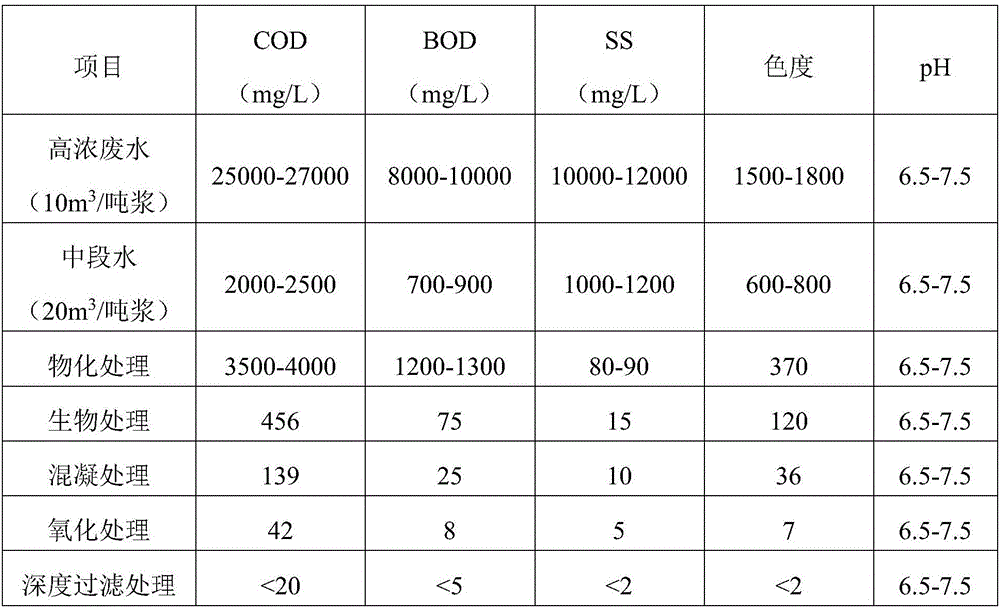

[0114] (1) Pump the ozone solution into the hydraulic pulper, the concentration of ozone is 60g / m 3; Then transport the cut and dedusted straw into the hydraulic pulper for stirring and oxidation, and process it for 25 minutes at a temperature of about 20°C. Pump the above-mentioned ozone-treated material into a dehydrator and concentrate it to a dryness of 25%. The material is quickly heated to 90°C with steam, and then the material is sent to the compound straw separator by a screw conveyor for the first stage of hot rubbing. At the same time, the material is heated to 80°C by steam in the screw conveyor.

[0115] (2) The material after the first stage of hot rubbing is transported into the continuous steamer, heated to 95°C with steam, and steamed continuously for 1 hour. Then send it to the single-type straw separator for the second stage of hot rubbing.

[0116] (3) Pump ozone solution in the submersible device, the concentration of ozone is 60g / m 3 ;Convey the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com